The two ends of each wire (one wire for each pole) are soldered onto a terminal, and then each of the three terminals is wired to one plate of the commutator. The final piece of any DC electric motor is the field magnet. The field magnet in this motor is formed by the can itself plus two curved permanent magnets.

Full Answer

What are the 3 wires on an electric motor?

For a standard 3-wire motor, the lead wire colors are typically white, red, and black. Black is always connected to neutral (N). Both white and black are connected to the 2 terminals of the dedicated capacitor.

How are DC motors wired?

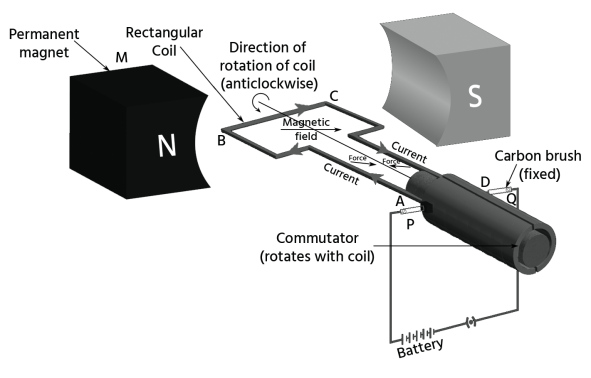

A simple DC motor uses a stationary set of magnets in the stator, and a coil of wire with a current running through it to generate an electromagnetic field aligned with the centre of the coil. One or more windings of insulated wire are wrapped around the core of the motor to concentrate the magnetic field.

Are motors wired in series or parallel?

A stepper motor may be wired in either series or parallel, depending on the needs of the application. A series-wired motor will deliver more stall torque, but torque drops quickly as velocity increases. A parallel-wired motor typically maintains its (lower-than-series) torque to a higher velocity.

How does an electric motor work step by step?

Electric motors work by converting electrical energy to mechanical energy in order to create motion. Force is generated within the motor through the interaction between a magnetic field and winding alternating (AC) or direct (DC) current.

Why do DC motors have 3 wires?

The three wires give the brushless motors more pulling power. Understanding this helps understand stepper motors below. The two wires of the brushed dc motor can be thought of as forward and reverse. The three wires of brushless can be thought of as 1, 2 and 3.

Why do DC motors have 4 wires?

The motor has 4 leads, it says to turn clockways, hook two leads to + voltage and two to common ground. To turn counterclockways, swap one pair, such as take one wire from + and hook to ground, and vice versa. The motor works when I connect leads direct to power and ground.

Why does a motor have 12 wires?

Of all types of three-phase motors, the twelve-wire motor provides the most options for connecting based on voltage and system configuration (wye or delta).

How are motor windings connected?

The windings can also be connected in series or parallel, Y or YY for instance. If the rating plate on a squirrel cage motor indicates voltages or both the star and delta connection, it is possible to use the motor for both 230 V, and 400 V as an example.

How do you know if a motor is Delta or Wye?

If leads are numbered 1-6, the winding can usually be connected wye or delta. On machines rated for two voltages, the wye connection is for the high voltage; the delta connection is for the low voltage. For a single voltage rating, most 6-lead machines are capable of wye-delta starting (and will run in delta).

How long can an electric motor run continuously?

How long can a DC motor run continuously? If you can replenish the lubricants, there is no limit implied by the operating principles. Mike Azeka has pointed out that the Brushes are wear parts,so call it one to five years.

What are the 6 parts of an electric motor?

Six Key Components That Make Up Your Industrial Electric Motor1) The Rotor. The rotor is the moving part of your electric motor. ... 3) The Bearings. ... 4) The Windings. ... 5) The Air Gap. ... 6) The Commutator. ... What Do All of These Components Have in Common?

Which is faster Star or Delta?

There is no change in speed for both star and delta connection for induction motor Speed N = 120F/P i.e. Speed depends upon only supply frequency and No of pole in motor speed can not change due to voltage variation for Ac induction motor – star delta connection used for Ac induction motor.

What does A1 A2 S1 S2 mean on DC motor?

DC motor terminal leads are labeled for easy identification in the motor's terminal box. For example, leads labeled "A1" and "A2" are connected to the armature through the motor's brushes; leads labeled "S1" and "S2" are the ends of the series field; and leads labeled "F1" and "F2" are the ends of the shunt field.

How many wires are there in a DC motor?

Servos have three wires to them, unlike most DC and gearhead motors, which have two. The first two in a servo are power and ground, and the third is a digital control line.

How does a DC motor work step by step?

In a DC motor, the stator provides a rotating magnetic field that drives the armature to rotate. A simple DC motor uses a stationary set of magnets in the stator, and a coil of wire with a current running through it to generate an electromagnetic field aligned with the centre of the coil.

What is DC motor connections?

There are three types of electrical connections between the stator and rotor possible for DC electric motors: series, shunt/parallel and compound (various blends of series and shunt/parallel) and each has unique speed/torque characteristics appropriate for different loading torque profiles/signatures.

Motor circuit diagrams

Diagrams indicate the voltage-free or current-free status of the electrical installation. A distinction is drawn between:

Motor wiring diagrams

Wiring diagrams show the conductive connections between electrical apparatus. They show the internal and/or external connections but, in general, do not give any information on the mode of operation. Instead of wiring diagrams, wiring tables can also be used.

Premium Membership

Get access to premium HV/MV/LV technical articles, advanced electrical engineering guides, papers, and much more! It will help you to shape up your technical skills in your everyday life as an electrical engineer.

What is PWM drive?

The PWM Drive (pulse-width modulated drive) to motor power conductors are typically the most intense noise source in a system. Proper implementation of shielding, grounding, splicing, and treatment of excess cable is essential to reducing noise in your system.

Why do you splice a power cable?

The most common reason for splicing is to incorporate high-flex cable for continuous flexing applications.

How to reduce noise in a drive?

A ferrite sleeve around the three power conductors as they leave the drive will help to reduce common-mode noise current. Take all three conductors two or three times through the core. If it runs hot reduce the number of turns.

What connector is used for splicing?

If necessary, the preferred method of splicing is to use a fully shielded bulkhead connector!

What causes ground currents to flow?

Stray capacitance at A & C cause ground currents to flow creating a magnetic noise field that couples inductively with adjacent wiring.

What is the effect of shielding on electric field?

The shield strongly attenuates the electric field (E field) noise.

Can shield drain wire be grounded?

Shield drain wire must be spliced only to mating shield dra in wires and not grounded at the junction box.

How much current does a spinning motor use?

For the spinning motor, the current is right around 40 mA compared to almost 105 mA when my fingers stopped the spinning shaft. Oh, maybe you would like to see this as a video. Here you go.

Why do electric motors burn out?

Really, this is also how motors can burn out. If you hold the shaft too long, there will be a higher current in the coil of wire.

How does a coil of wire work?

Basically, it is a coil of wire with some magnets. The current runs through the wire interacts with the permanent magnets to make the coil of wire turn. Then, there must be some means of reversing the current in the coil of wire to keep the coil spinning.

What happens if you don't let that coil of wire spin?

Now, what happens if you don't let that coil of wire spin? In that case, you just have a coil of wire hooked up to a battery. Pretty boring - but as a circuit diagram it would look like this:

Why are electric fields curly?

Curly Electric Fields: These are electric fields produced by a changing magnetic field. Why curly? Why not Mo or Larry? They are curly since they don't look like they are coming from a charge. Instead, they look like they would make complete loops. These are not your dad's electric fields. Here is another image from a vpython program.

Why does magnetic flux change?

Magnetic flux is just like that - except instead of rain, you have a magnetic field. In the rotating coil, the magnetic flux changes because the orientation changes.

What does the green arrow on a magnet mean?

This program shows a magnet moving towards a coil. The green arrows represent the magnetic field and the purple-ish arrow shows the direction the magnetic field is changing. If the magnet was stationary, the magnetic field would not be changing and there would be no curly electric field.

Where to find wiring diagram for motor?

The type of connectors will depend on the manufacturer and size of the motor. Locate the wiring diagram for your motor on the faceplate or inside of the cover you have removed. Typically, you will have two distinct diagrams. One will be for low voltage and another for high voltage connections.

How many volts should a motor be?

The first step is to figure out the voltage of your phases. In the United States, for low voltage motors (below 600v), you can expect either 230v or 460v. That being said, there is a wide range of different motors and what you have on hand can be completely different. Make sure that the voltage you will be supplying to your motor matches the specifications on the faceplate.

Why do motor windings have different offsets?

In simple terms, the current is being alternated during a different time. As the motor windings receive current, they create a magnetic field which propels them toward the next stator winding.

What is 3 phase wiring?

Three phase systems are extremely common in industrial and commercial settings. They can also be found in large residential complexes and appliances requiring a large amount of power. Although these systems may seem intimidating at first, a walkthrough on 3 phase wiring for dummies will help clarify the whole situation.

What is the purpose of 3 phase power?

The most common use of three-phase power is for motors. It provides a unique feature which is a rotating field in order to rotate the motor without the need of a starter circuit. This is accomplished due to the fact that each one of the three phases has a different offset.

What is a three phase system?

A three-phase system is simply a system which will have three conductors which will carry current and have a certain voltage. Depending on the source, this system may also have a neutral wire for returning current back to the transformer.

What is AC in power?

The electrical term AC simply means that the current will alternate the direction of the flow.

What is the information on a motor?

Typical information found on most motors include (but not limited to): Manufacturer's Name — the name of the company the made the motor. Model and Serial Number — information that identifies your particular motor. RPM — the number of revolutions the rotor makes in one minute. Horsepower — how much work it can perform.

How to test a motor when power is off?

Set a Digital Volt Ohm Meter (DVOM) to the ohm setting and test the motor while the power is shut off. On average, most motors will have little resistance.

How to check if a motor is a centrifugal?

Check the rear bell housing of the motor. Some motors have centrifugal switches used to switch the start / run capacitor (or other windings) "in" and "out" of the circuit at a specific RPM. Check the switch contacts are not welded closed or are contaminated with dirt and grease that could prevent a good connection. Use a screwdriver to see if the switch mechanism and any spring can be operated freely.

How to check bearings on a motor?

To perform a cursory check of the bearings, place the motor on a solid surface and place one hand on the top of the motor, spin the shaft/rotor with the other hand. Closely watch, feel, and listen for any indication of rubbing, scraping, or unevenness of the spinning rotor.

What does high resistance mean in motors?

Expect to see a very low value of resistance in ohms. Low, single digit resistance values are expected. Make sure your hands are not touching the metal probe tips, as doing so will cause the reading to be inaccurate. Values greater than this indicate a potential problem and values significantly greater than this indicate the winding has failed opened. A motor with high resistance will not run - or not run with speed control (as is the case when a 3-phase motor winding opens while running).

How to check if a motor is drip proof?

Check that drip-proof motors are exposed to directed water spray or moisture, and that open motors aren't exposed to any water or moisture at all.

What is RPM in motor?

RPM — the number of revolutions the rotor makes in one minute

What is winding in motor?

In a motor, windings provide a path to current flow, which as a result, creates a magnetic field that rotates the gears. Besides, they play a significant role in motor function; you need to inspect them regularly.

How to inspect a motor?

General Inspections; See the basic wiring of the motor. Rotate the shaft and fan with your hand to see if they are running smoothly or not. This way, you will inspect that the basic components are good for the run.

What to Test on A Motor?

For electric motor testing, you need to know what parts or factors to check periodically to minimize the potential delay.

What are the problems with motors?

Some of the common issues motors face are rotor and winding failure. To lessen these problems, you can test the motor from a variety of proven methods. Common approaches are

What temperature should a motor be inspected for resistance?

According to IEEE 43 standard, this test needs a temperature rectification of 40C.

How to check if a motor is running smoothly?

General Inspections; See the appearance of the motor and look for any burnt or damaged area. Rotate the shaft and fan with your hand to see if they are running smoothly or not. After that, test it with amps test and access the value compared to the values proved on the motor manual.

How many classes of motor testing are there?

For a good maintenance program, you need to plan out the technique you choose from several methods. Typically, there are two classes of motor testing;