What are O-rings made of?

O-rings are made from various types of elastomers with the more typical ones being PTFE, Nitrile (Buna), Neoprene, EPDM Rubber, Fluorocarbon (Viton), and Silicone with silicone being used for high temperature applications. The chart below is a short list of a few O-ring materials and their properties.

What is the difference between O-rings and square rings?

The physical sealing performance of square rings in static applications is superior to that of O-rings, however in dynamic applications it is inferior to that of O-rings. Square rings are usually used only in dynamic applications as energizers in cap seal assemblies. Square rings can also be more difficult to install than O-rings.

What is an O ring used for?

In the electronics industry, O-rings are used for electromagnetic interference (EMI) shielding using elastomers produced to resist a range of ohms from 7 cm to 0.002 cm. These specially designed O-rings are used by telecommunications, the military, and for consumer and industrial electronics.

What is the difference between soft O rings and hard o-rings?

The orange lines are hard surfaces, which apply high pressure. The fluid in the seams has lower pressure. The soft O-ring bridges the pressure over the seams. O-rings are available in various metric and inch standard sizes. Sizes are specified by the inside diameter and the cross section diameter (thickness).

What are O-rings made out of?

Due to many applications, there is also a wide variety of O-ring material choices available. Nitrile (Buna), Neoprene, Ethylene Propylene (EPDM Rubber), Silicone, Fluorocarbon (Viton), and PTFE (Teflon) are among the most commonly used compounds for O-rings and seals.

Are O-rings made of metal?

The O-ring consists of stainless steel or other alloys and can be electroplated with silver, cooper, nickel, gold, lead or other metals or can be coated with Teflon*). The flowing of the coating material improves the sealing especially under high pressure and / or vacuum.

How are rubber seals made?

Background information: Extruded rubber seals are made by forcing the uncured rubber through a die while it is under heat and pressure. This uncured rubber is then vulcanized, i.e. heated, to cause a chemical reaction which cures the rubber.

How do you make O-ring seals?

0:127:29O-Rings? O-Yeah! How to Select, Design, and Install O-Ring SealsYouTubeStart of suggested clipEnd of suggested clipAn o-ring forms a seal when it's squeezed between two adjacent surfaces as the ring is squeezed aMoreAn o-ring forms a seal when it's squeezed between two adjacent surfaces as the ring is squeezed a contact stress between the o-ring. And the surfaces emerge.

What is the difference between O-ring and seal?

While o-rings are typically round and vary in thickness, gaskets are flat seals that sit between two flat surfaces. Gaskets are often circular, however they can be cut into virtually any shape, including square, triangle, rectangle or any other complex form.

Why are O-rings different colors?

Black o rings were primarily the only coloured o rings around prior to 1987; however, as new materials come onto the market, different colours were required to identify the different materials in use, marking out their visibility and allowing businesses to check their suitability for specific and different applications ...

Why is it called an O-ring?

A mechanical O-ring is made of elastic polymer in the shape of a letter 'O'. It provides a mechanical seal to contain liquids or gases. It typically sits in a groove, compressed between a piston and a cylinder.

What are purple O-rings used for?

Purple, Heat-Resistant, Silicone Sealing Rings for your break box. Comes in a set of 4. Durable, environmentally friendly, non-toxic, and odorless, with great elasticity, these O-rings will help keep your favorite break box leak-free. Easy to clean, dishwasher safe, and heat-resistant.

Are O-rings injection molded?

#4) Injection Molding Injection molding is a manufacturing process that's used to create O-rings. It involves injecting raw material into a mold cavity. The raw material typically comes in the form of pellets. The pellets are heated, after which the newly liquified material is injected into a mold cavity.

Can you use petroleum jelly on O-rings?

1:082:41Can I Use Vaseline On My O-Rings? - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe petroleum jelly just eats away at the rubber. And it caused them to deteriorate quicker and failMoreThe petroleum jelly just eats away at the rubber. And it caused them to deteriorate quicker and fail. So you want to use something silicone or Teflon base to lubricate the o-rings keep them soft.

Why do O-rings leak?

O-ring leaks can usually be traced back to three common causes. The main cause is the incorrect dimensioning of the O-ring combined with the groove dimensions. You can use our O-ring calculator to help you do this. The second cause of leaks from seals is the excessive stretching or compression of the O-ring.

How much pressure can an O-ring hold?

1,500 psiMost o-rings are designed to operate at pressures up to 1,500 psi. At higher pressures, the material must have enough strength to resist extruding into the clearance gap. The chart shows the recommended combined limits of clearance, gap, material hardness and system pressure differential.

What type of rubber is used for seals?

Nitrile rubberNitrile rubber—also known as Buna-N or NBR—is the most commonly used elastomeric material for gaskets and seals. It exhibits excellent resistance to acids, alkalis, gasoline, hydraulic fluids, and petroleum-based compounds.

Why are gaskets made of rubber?

Rubber and Plastic Gaskets Due to its elastomeric properties, rubber is a popular material for gasket production. Since they can undergo a high degree of deformation without permanent damage or loss of attributes, rubber gaskets can form very tight seals within a wide range of applications.

What is a rubber seal?

Rubber seals are used in numerous industries to prevent the unwanted leakage of liquids and gases in various components such as pumps, valves, pipe fittings, and vacuum seals, to name only a few.

What are car door seals made of?

Rubber door seals are manufactured from either a durable EPDM rubber or PVC with a metal infill and a rubber or foam sealing face....PEXT1611*Length (mtrs):1.409Material:EPDM

Silicone Rubber

Silicone rubber is a common material used in the construction of O-rings. Silicone rubber O-rings are resistant to both cold and hot temperatures, and they also have a longer lifespan than O-rings made of other materials. Furthermore, food and beverage companies often use them because silicone is considered safe and nontoxic.

Neoprene

Some O-rings are made of neoprene. Also known as polychloroprene, neoprene is a type of synthetic, manmade rubber. When compared to natural rubber, neoprene offers greater protection against degradation. This means neoprene O-rings can create longer-lasting seals while requiring less-frequent replacing.

Aflas

You may come across O-rings made of Aflas. What is Aflas exactly? It’s a polymer of tetrafluoroethylene (TFE) and propylene. Jargon aside, Aflas is recognized for its superior performance when exposed to oils and other chemicals. While harsh oils and chemicals may eat away at other materials, Aflas will resist them.

Polyurethane

Polyurethane is another common material used in the construction of O-rings. By definition, polyurethane is an organic material that’s jointed via carbamate, urethane links. Polyurethane has many properties that make it an effective choice of material for O-rings. It’s durable, elastic and resistant to moisture.

In Conclusion

While all O-rings feature the same shape, they are available in different materials. Some of them are made of silicone rubber, whereas others are made of Aflas or polyurethane. These are just a few materials used in the construction of O-rings. Others include polytetrafluoroethylene, Buna, Viton and more.

Manufacturing

O-rings can be produced by extrusion, injection molding, pressure molding or transfer molding.

History

The first patent for the O-ring is dated May 12, 1896, as a Swedish patent. J. O. Lundberg, the inventor of the O-ring, received the patent. The US patent for the O-ring was filed in 1937 by a then 72-year-old Danish -born machinist, Niels Christensen.

Theory and design

O-ring mounting for an ultra-high vacuum application. Pressure distribution within the cross-section of the O-ring. The orange lines are hard surfaces, which apply high pressure. The fluid in the seams has lower pressure. The soft O-ring bridges the pressure over the seams.

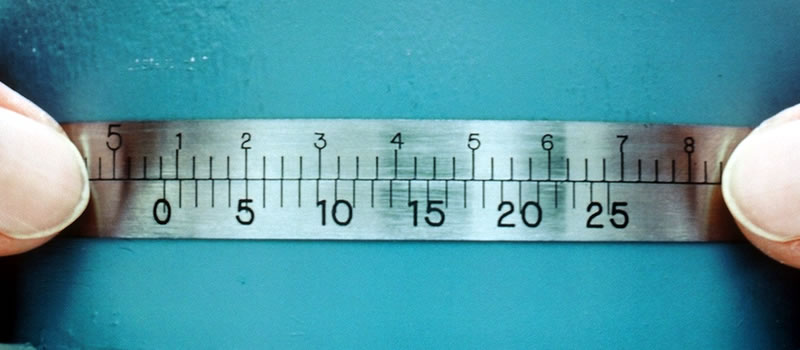

Sizes

O-rings come in a variety of sizes. Society of Automotive Engineers (SAE) Aerospace Standard 568 (AS568) specifies the inside diameters, cross-sections, tolerances, and size identification codes (dash numbers) for O-rings used in sealing applications and for straight thread tube fitting boss gaskets.

Material

O-ring selection is based on chemical compatibility, application temperature, sealing pressure, lubrication requirements, durometer, size and cost.

Other seals

Although the O-ring was originally so named because of its circular cross section, there are now variations in cross-section design. The shape can have different profiles, such as an x-shaped profile, commonly called the X-ring, Q-ring, or by the trademarked name Quad Ring.

Failure modes

O-ring materials may be subjected to high or low temperatures, chemical attack, vibration, abrasion, and movement. Elastomers are selected according to the situation.

History of the O-Ring

The O-ring is the brainchild of J. O. Lundberg. In 1896, the Lundberg filed a patent for the circular-looped gasket. Although it was invented in Sweden, the O-ring slowly made its way across the Atlantic Ocean. In 1937, the first patent for an O-ring in the United States was filed by professional machinist Niels Christensen.

Materials Used to Make O-Rings

O-rings are available in many different materials, each of which has different properties. Some of the most common materials used to make O-rings include the following:

Sealing Pressure

When choosing O-rings, it’s important to consider the maximum amount of pressure the o-ring can seal. O-rings are designed to naturally compress when installed between two working surfaces, which prevents air or liquid from leaking. If too much pressure is placed on an O-ring, though, it may fail.

Step 1: Materials

The primary material is Silicone adhesive that comes in tubes for caulking guns. 1. THERE IS A DIFFERENCE AMONG SILICONE TYPES. DO NOT USE "Silicone II", it is not pure Silicone, and will not behave as predictably as "Silicone I" , (or 100% silicone). The black Silicone is from ACE and is my favorite. Clear GE Silicone 1 is great too. 2.

Step 2: Inject the Silicone Into the Vinyl Tubing

Using the caulking gun to force the Silicone into the Vinyl tubing, squeeze away! You will notice that as the Vinyl tubing fills up with silicone, it will get harder and harder to fill, due to the high viscosity of the Silicone. It will take considerable pressure to hold the Vinyl tubing onto the tip of the caulking tube.

Step 3: Optional : Make Hollow Tubing Instead of Solid Silicone

At this point the Vinyl tubing is filled with uncured Silicone, and you can keep it solid, or make tubing out of the silicone itself! All that needs to be done is apply compressed air back into the Vinyl tubing, which will force the uncured Silicone to flow back out, while leaving enough of it stuck to the inside of the Vinyl, so that when it cures, it will be tubing! If you use compressed air to do this, use the bare minimum amount of pressure.

Step 4: Waiting for the Silicone to Cure

Now comes the waiting... a little extra information while we wait for the cure: The interesting thing about this method, is that the Vinyl tubing material, though waterproof and highly resilient, will not prevent the Silicone within from curing. The Vinyl does not make a good "vapor barrier" and therefore permits curing.

Step 5: De-molding the Silicone From the Vynil

Now comes the really really fun part! - Removing the cured Silicone from the Vinyl tubing! There are two methods for doing this. The compressed air method works only on solid Silicone.

Step 6: Cutting the O-rings to Size

From the Silicone that has emerged from the Vinyl, you now have material for your O-rings! 1.Cut the Silicone rubber "cord" to the desired size (circumference) 2.

Step 7: Join the Ends to Make the Final O-ring

Basically, you're going to use the same Silicone adhesive that you made the O-rings with, to glue the ends together. 1. Using masking tape, wrap both ends of the cord. Doing this prevents the Silicone you use for the fusion, from getting onto the smooth surface of the O-ring. 2.

About us

O-Rings, Inc. is a proud American business since 1958. We are the world’s leading supplier of quality O-Rings to our most valued customers. We serve global iconic customers in more than 125 markets. O-Rings, Inc. is value-based with proven performance in quality, innovation, and customer service.

Popular O-Ring Materials

We’re proud to offer the on demand inventory of readily-available o-rings. Explore some of the most common materials we offer here.

Mil-Spec O-Rings

We proudly supply a full range of MADE IN THE USA military specification O-Rings. We offer economy through high volume and one-per-packaging of MIL-P-4861B military standard and we meet the quality assurance to MIL-I-45208A.

Overview

An O-ring, also known as a packing or a toric joint, is a mechanical gasket in the shape of a torus; it is a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly between two or more parts, forming a seal at the interface.

The O-ring may be used in static applications or in dynamic applications wher…

Manufacturing

O-rings can be produced by extrusion, injection molding, pressure molding or transfer molding.

History

The first patent for the O-ring is dated May 12, 1896, as a Swedish patent. J. O. Lundberg, the inventor of the O-ring, received the patent. The US patent for the O-ring was filed in 1937 by a then 72-year-old Danish-born machinist, Niels Christensen. In his previously filed application in 1933, resulting in Patent 2115383, he opens by saying, "This invention relates to new and useful improvements in hydraulic brakes and more particularly to an improved seal for the pistons of p…

Theory and design

O-rings are available in various metric and inch standard sizes. Sizes are specified by the inside diameter and the cross section diameter (thickness). In the US the most common standard inch sizes are per SAE AS568C specification (e.g. AS568-214). ISO 3601-1:2012 contains the most commonly used standard sizes, both inch and metric, worldwide. The UK also has standards sizes know…

Sizes

O-rings come in a variety of sizes. Society of Automotive Engineers (SAE) Aerospace Standard 568 (AS568) specifies the inside diameters, cross-sections, tolerances, and size identification codes (dash numbers) for O-rings used in sealing applications and for straight thread tube fitting boss gaskets. British Standard (BS) which are imperial sizes or metric sizes. Typical dimensions of an O-ring are internal dimension (id), outer dimension (od) and thickness / cross section (cs)

Material

O-ring selection is based on chemical compatibility, application temperature, sealing pressure, lubrication requirements, durometer, size and cost.

Synthetic rubbers - Thermosets:

• Butadiene rubber (BR)

• Butyl rubber (IIR)

Other seals

Although the O-ring was originally so named because of its circular cross section, there are now variations in cross-section design. The shape can have different profiles, such as an x-shaped profile, commonly called the X-ring, Q-ring, or by the trademarked name Quad Ring. When squeezed upon installation, they seal with 4 contact surfaces—2 small contact surfaces on the top and bot…

Failure modes

O-ring materials may be subjected to high or low temperatures, chemical attack, vibration, abrasion, and movement. Elastomers are selected according to the situation.

There are O-ring materials which can tolerate temperatures as low as −328.0 °F (−200 °C) or as high as 482 °F (250 °C). At the low end, nearly all engineering materials become rigid and fail to seal; at the high end, the materials often burn or decompose. Chemical attack can degrade the …