How to Measure Duct Airflow?

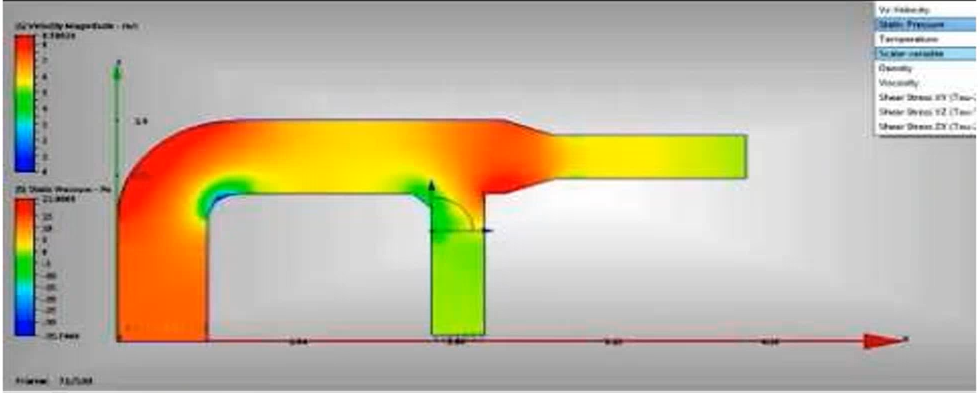

- Understand the Airflow Pattern in Duct Directly measuring the airflow at the supply air outlet is more accurate but...

- Prepare the Airflow Measurement Holes It is inaccurate to measure airflow with just a single point. Instead, we need...

- Measure the Airflow at Each Point

How do you measure air flow?

- Rotating Vane Anemometer (Measurement, mid airflow range)

- Pressure drop across the dry evaporator coil (estimate)

- Total external static pressure method (estimate)

- Pitot tube and digital manometer (Measurement, full range airflow measurement, however low range requires special instrumentation.)

How fast does the air flow in the duct?

Typical Air Velocity Guidelines Low Velocity Duct Systems typical 400 - 2000 ft/min (2 - 10 m/s) Medium Velocity Duct Systems typical 2000 - 2500 ft/min (10 - 12.5 m/s) High Velocity Duct Systems typical 2500 - 3000 ft/min (12.5 - 15 m/s)

How to test air flow?

- Set the multimeter to 20 volts.

- Disconnect the connector of the MAF sensor.

- Connect the black lead of the multimeter to the signal ground terminal of the MAF sensor and connect the red lead to the battery positive source or the positive wire ...

- Turn the ignition of the car on.

- If you get 5 to 12 volts, then it is working correctly.

How to measure cfm air flow?

- Measure the room’s width and length. …

- Multiply the three measurements from step 1 to determine the cubic footage of the room. …

- Multiply the cubic volume of the room by the number of times you want the air to turn over or exchange in an hour.

What is the most common way to measure airflow?

The most common and easiest way to measure or with some methods estimate and set airflow is to use one of the following methods: Rotating Vane Anemometer (Measurement, mid airflow range) Pressure drop across the dry evaporator coil (estimate) Total external static pressure method (estimate)

How is CFM airflow measured?

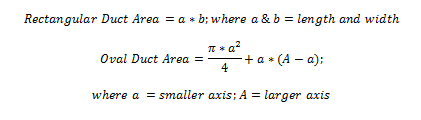

To calculate Air Flow in Cubic Feet per Minute (CFM), determine the Flow Velocity in feet per minute, then multiply this figure by the Duct Cross Sectional Area.

How do you measure duct CFM?

0:0111:57Airflow CFM Measured with a Hot Wire Anemometer! - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd we're gonna be taking this probe and putting it into the duct on. The tool right now you see itMoreAnd we're gonna be taking this probe and putting it into the duct on. The tool right now you see it says feet per minute and then here it says temperature. Now you can go down. And you see CFM's.

How many CFM do I need for 1000 square feet?

50 CFMHeat and energy recovery ventilatorsTotal area of home (square feet)Continuous ventilation rate1,000 square feet50 CFM2,000 square feet100 CFM3,000 square feet150 CFM

How many CFM is a 3 ton?

1200 CFMA 3-ton heat pump has approximately 1200 CFM of air flow.

How many CFM do I need for 500 square feet?

133 CFMThat's why we need to divide the total volume by 60; hence 4,800/60 = 80 CFM. Answer: You need an 80 CFM airflow (for 300 sq ft standard room and 2 ACH)....CFM Chart For Common Room Sizes.Room Size:CFM (At 2 ACH)How many CFM for a 400 sq ft room?107 CFMHow many CFM for a 500 sq ft room?133 CFM12 more rows

Does an anemometer measure CFM?

Nearly all anemometers measure air speed in feet per minute (FPM), but they don't always measure air flow specifically. Although you can technically convert FPM to cubic feet per minute (CFM), it's much easier to use an anemometer that will do this for you.

How is fan airflow measured?

0:152:47How to Measure HVAC Fan Airflow Video 3 of 5 - YouTubeYouTubeStart of suggested clipEnd of suggested clipUsing plastic tubing a digital manometer is a fast accurate way to measure the static. Pressure nowMoreUsing plastic tubing a digital manometer is a fast accurate way to measure the static. Pressure now james has already connected the tubing to the static pressure probe and the manometer.

How to measure airflow accuracy?

For maximum airflow accuracy, take several readings across a traverse plane, convert them to velocity, and then average them. The illustration in Figure 1 shows the points along the traverse plane where you should take the measurements, in either rectangular or circular ducts.

How many measurements are required for a circular duct?

However, circular ducts require measuring across 3 diameters (see air flow guide ), with a minimum of 6 measurements per diameter. Multiply the number of points you'll measure with the figure in the second half of table 1 to determine the measuring position relative to the inner wall of the duct. Notes:

How many straight duct diameters are there in a pitot tube?

When we talk about positioning the pitot tube 10 straight duct diameters upstream and 3 straight duct diameters downstream of the tranverse plane, we need to first convert rectangular duct measurements into their equivalent circular diameters.

How far apart should duct traverses be?

If the duct side is less than 18", then any readings you take should be taken from the center of equal areas that are no more than 6" apart, with a minimum of two points per side of the duct. The preferred location of the traverse in a supply duct should be in a straight section of duct with 10 straight equivalent duct diameters upstream, ...

How to conduct a duct traverse?

Conducting a duct traverse 1 For duct sides shorter than 30", five traversal points must be taken (5 on each side, 5*5=25). 2 For duct sides of 30 through 36", six points must be taken. 3 For duct sides longer than 36", seven points must be taken. 4 If the duct side is less than 18", then any readings you take should be taken from the center of equal areas that are no more than 6" apart, with a minimum of two points per side of the duct.

What is a duct traverse?

Many circumstances warrant measuring air velocities or air flow, and a duct traverse is the most precise method of obtaining that information. A duct traverse consists of a number of regularly spaced air velocity and pressure measurements throughout a cross sectional area of straight duct (for a diagram, reference this airflow guide ).

How many traversal points are needed for ducts?

For duct sides shorter than 30", five traversal points must be taken (5 on each side, 5*5=25).

How is air flow measured in HVAC?

Actual measurements of airflow in an HVAC system or at air supply registers are expressed in cubic feet per minute and are most often made in the field using a hand held flow meter through which air moves. The flow meter is calibrated based on the its input area and the resistance offered by its own fan blades.

How to measure air flow rate?

Air flow rate is measured by calculating an average velocity for the conduit of interest, and then, multiplying this velocity by the cross sectional area of the duct at the measurement location.

What is a FLST airflow?

Above: the Dwyer Instruments FLST airflow rate monitoring device intended for monitoring air flow rates in an HVAC duct system .#N#The Dwyer Instruments FLST (illustrated here) is indeed an air duct flow rate sensing system (used in connection with additional instrumentation) described by the manufacturer as:#N#The SERIES FLST Airflow Measurement Station utilizes an airflow averaging element generating a velocity pressure signal similar to the orifice, venturi, and other primary elements. Single or multiple airflow elements are factory mounted and pre-piped in a casing designed for flanged connection to the ductwork.

What is the most common air flow measurement device used in HVAC systems?

The most common air flow measurement device used in HVAC systems is a hand-held vane anemometer or a hand-held hot-wire an emometer. The vane anemometer is in essence a small fan driven by the movement of air across the fan blades.

How are pressure transducers used?

How Pressure Transducers are used for air flow measurements. Pressure transducers: also measure pressure from a flowing gas or air and permit conversion to CFM measurements in the same manner as a pitot tube - knowing the cross sectional area of the duct or opening.

How many inches is a cubic foot of airflow?

If I held up a one-foot square sensor in front of an air source (say an air supply register) and the sensor measured air velocity at 12 inches per minute, I'd be measuring 1 CFM of airflow. (One cubic foot = 12 x 12 x 12 inches).

What is the flow rate of an HVAC system?

The Air flow rate for an HVAC system is defined as the volume of air being delivered at some speed or "rate", typically cubic feet per minute (CFM) or m/sec (meters per second), ft/sec (feet per second), or ft/min (feet per minute).

Why measure exhaust airflow?

The primary reason to measure airflow is for you to discover ventilation issues that your customers have been suffering with for years. Measuring exhaust airflow brings opportunity for your customers to receive improved ventilation and comfort.

How many lengths of straight exhaust ducts are needed for an airflow traverse?

An airflow traverse requires at least 5 lengths of straight exhaust duct. Two or more 3/8-in. test holes are then drilled into the duct. An anemometer, a test instrument that measures air velocity is used to determine the average air speed in the duct.

What is static pressure test?

A duct static pressure test consists of two one-minute measurements. You compare each pressure reading to a maximum allowable duct pressure and immediately reveal the duct system's resistance to airflow. Static pressure tests also assess duct installation conditions. Email me for a free test procedure ( ncilink.com/ContactMe ). Customers easily understand these test results, too.

Where are exhaust fans located?

Although in-line exhaust fans exist, most exhaust fans are found at either the start of a duct or at the end of a duct. This is a defining characteristic of some exhaust fans that affects the way we may determine fan airflow as compared to a forced air system where fans are located between the supply and return ducts. The Dangerous Assumption.

Do you measure RPM on a fan?

Smaller fans are often constant or single-speed. With these fans, you are not required to measure fan RPM. Larger fans require that you measure the fan RPM. This is normally done using a non-contact tachometer that reads RPM from reflective tape affixed to the fan. Exhaust fan performance chart.

Can airflow be measured with a balancing hood?

When airflow cannot be measured directly with a balancing hood, airflow can be measured in the exhaust duct by performing an airflow traverse. 2.

Do service companies sell duct systems?

Your first thought may be, "Service companies don't sell duct systems! Only new construction companies deal with them." If so, think again. Service companies that renovate existing duct systems along with equipment replacement have found an additional source of highly profitable work with little competition.

How to measure air flow?

Turn on the anemometer and set it to measure air flow. If you just recently purchased your anemometer, insert batteries or plug it in to power it up. Once it’s on, change the measurement settings to CFM so you can measure air flow. A typical anemometer will have a button that reads “Unit” or “Units.”.

How to read air flow on a hood?

1. Set the balancing hood to read in exhaust mode. Your air balance hood will likely have several different modes that it can be set to. Follow the manufacturer’s instructions to make sure your hood is set to exhaust mode in order to ensure an accurate air flow measurement.

What is the CFM of a fan?

CFM stands for “cubic feet per minute,” which is how airflow is measured. Most exhaust fans should have an airflow reading of somewhere between 40 and 60 cfm to operate efficiently.

What does FPM mean in an anemometer?

Nearly all anemometers measure air speed in feet per minute (FPM), but they don’t always measure air flow specifically. Although you can technically convert FPM to cubic feet per minute (CFM), it’s much easier to use an anemometer that will do this for you.

How to pause anemometer reading?

Press “Hold” to pause the anemometer on a particular reading. The readings on your anemometer will constantly fluctuate as air flows past the vane wheel reader. Pressing “Hold” will allow you to freeze the meter on one specific airflow reading and record it.

What does the button on an anemometer mean?

A typical anemometer will have a button that reads “Unit” or “Units.” Toggle this button to switch the measurement settings of your anemometer.

Can you record your readings on an anemometer?

Some anemometers will also allow you to digitally save and record your reading to the device when you hit “Hold.”