Since the feddrate for turning is expressed in distance per one full s [spindlerotation, the linear speed in the feed direction is the product of the feedrate and the spindle rotation speed: V f = n × F n Hence the cutting time is the length divided by the linear speed:

What determines turning feed rate?

Turning feed rate is determined by the type of cutting tools, surface finish desired for milling parts, power available at the spindle, rigidity of the machine and tool setup, characteristics of the material to be cut, workpiece strength, cut width, etc. The Importance of Turning Speed and Feed Calculations

Is there a free feed rate calculator for milling?

You’ve found our simple free online Feeds and Speeds Calculator that uses the classic formulas taught in shop class. With a calculator, you don’t need to worry about how to calculate feed rate for milling, or the speed (rpms) either.

What is the difference between feed rate and speed?

Speed, Feed, and Depth of Cut 1 Cutting speed is defined as the speed (usually in feet per minute) of a tool when it is cutting the work. 2 Feed rate is defined as tool’s distance travelled during one spindle revolution. 3 Feed rate and cutting speed determine the rate of material removal, power requirements, and surface finish. More items...

How do you calculate adjusted feed rate from cutter diameter?

You must take (Major Diameter – Cutter Diameter) / Major Diameter and then multiply the results by the Intended Feed Rate, to get your adjusted feed rate. Most people seem to be taking (MD-CD) and dividing by (MD*Intended Feed Rate).

How is lathe feed calculated?

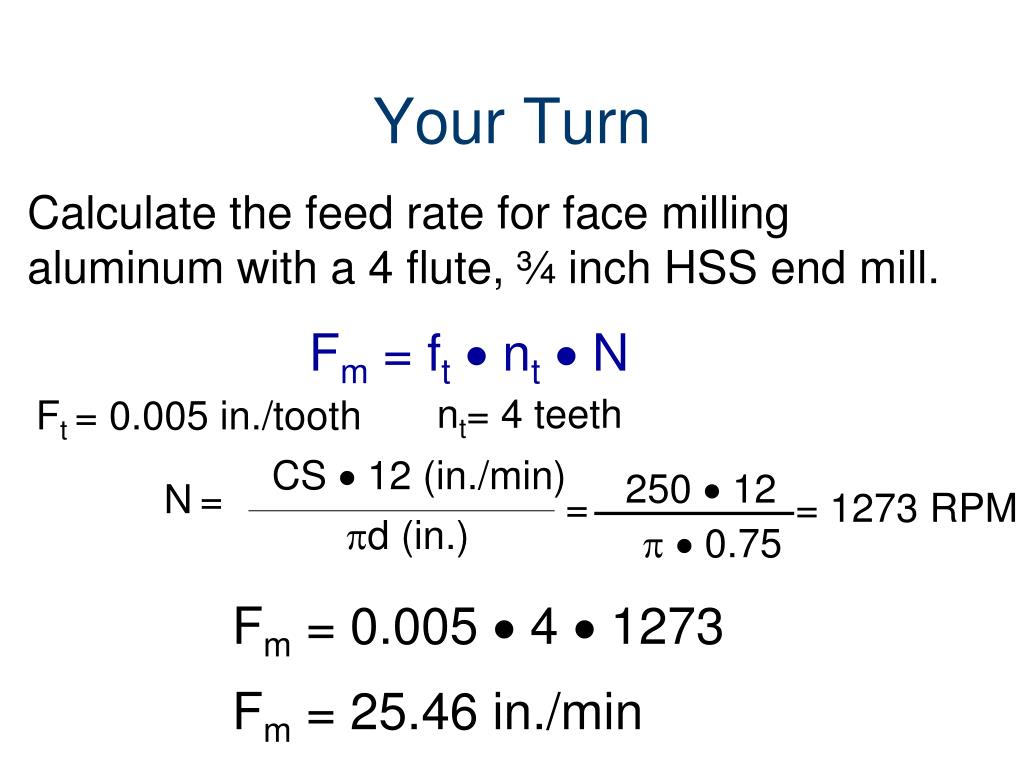

Using the equation, rpm = sfm ÷ diameter × 3.82 = 350 ÷ 1.0 × 3.82 = 1,337, the feed rate = rpm × no. of flutes × chip load = 1,337 × 4 × 0.005 = 26.74 ipm.

What is feed rate in turning?

Feed rate. Feed rate is the velocity at which the cutter is fed, that is, advanced against the workpiece. It is expressed in units of distance per revolution for turning and boring (typically inches per revolution [ipr] or millimeters per revolution).

How do you calculate revolution feed per turn?

CNC Milling Machining Time CalculationLength of Cut (mm) = Tool Approach + Job Length + Tool Over Travel + Compulsory Distance.Feed (mm per revolution) = Feed Per Tooth x Number of Teeth.Revolutions Per Minute = 1,000 x Cutting Speed / π x Diameter of Rod (mm)

How do you calculate lathe feed and speed?

0:061:35Machinist Calc Pro Feed and Speed How To Calculate - YouTubeYouTubeStart of suggested clipEnd of suggested clipNow let me show you how to do feed and speed solutions on the machinist calc pro it'll give youMoreNow let me show you how to do feed and speed solutions on the machinist calc pro it'll give you quick and accurate solutions. Great for playing what-if extending your tool life and just really trying

How do you calculate feed rate and spindle speed?

How do I calculate feed rate?Multiply the number of teeth with the feed length per tooth.Multiply that product by the spindle speed.

What is feed per minute?

It is expressed in units of distance along the workpiece surface per unit of time, typically surface feet per minute (sfm) or meters per minute(m/min). Feed rate (IPR) IPR - Also called, feedrate, or called simply feed) is the relative velocity at which the cutter is advanced along the workpiece.

How do you calculate rpm and feed on a drill?

S.F.M. = 0.2618 x Drill Diameter x R.P.M. Machine Time (seconds) = (60 x Feed minus Stroke) / I.P.M....Feeds and Speeds - Formulas.R.P.M. = Revolutions Per MinuteI.P.R. = Inches Per RevolutionS.F.M. = Surface Feet Per MinuteFeed Stroke = Drill Depth + 1/31 more row

How do you calculate feed on a mill?

Milling FormulasSpeed (RPM) = (SFM x 3.82) / D.Feed (IPM) = RPM x FPT x Z.SFM (Surface Feet per Minute) = (RPM x D) / 3.82.IPT (Inches per Tooth) = (IPM / RPM) / Z.MRR (Cubic Inches per Minute) = IPM * WOC * DOC.AFPT (@ less than 1/2 dia. WOC) = IPM x sqroot of (D / WOC)HP (Horsepower Consumption) = MRR x mf.

What is feed in CNC?

Feed Rate is one of the most important factors to consider when implementing any CNC strategy. Simply put, feed rate is the speed at which the cutter engages the part and is typically measured in units/minute.

How do you calculate feed and tap speed?

Feed per revolution = f Example: the machine feed rate (Vf) of a single start M12 X 1.75 thread ran at 186 revolutions per minute (RPM) is calculated as follows; Vf = 186 RPM X 1.75mm Thread Pitch = 325.5mm per minute feed rate millimeters per minute (mmpm). 325.5 ÷ 1,000 = . 325 feed rate in Meters Per Minute (MPM).

How do you calculate speed and feed in metric?

4:3714:39How To Calculate Speeds and Feeds (Metric Version) - YouTubeYouTubeStart of suggested clipEnd of suggested clipThem RP M equals cutting speed times 1000 all divided by our diameter. Times pi n is our rpmMoreThem RP M equals cutting speed times 1000 all divided by our diameter. Times pi n is our rpm revolutions per minute that's the S code in our program what we're trying to solve.

What is feed and depth of cut?

Cutting feed focuses on how far the cutting spindle travels across the metal part during one full rotation of the tool. As the cutting tool moves into the metal part, the distance that it moves is the depth of cut. These three parameters ensure accuracy of the finished workpiece and the surface finish.

What is the feed rate in CNC?

Feed Rate is one of the most important factors to consider when implementing any CNC strategy. Simply put, feed rate is the speed at which the cutter engages the part and is typically measured in units/minute.

What is spindle speed and feed rate?

Feed rate is the distance which the cutting tool during one spindle revolution. It is also defined as the velocity at which the cutter is advanced against the workpiece. It is measured in either inch per revolution or millimeters per revolution (ipr or mpr) for turning and boring processes.

What does higher feed rate mean?

Higher feed rate indicates higher material removal rate (MRR) as MRR is directly proportional to the feed rate. So productivity can be enhanced by using higher feed rate. However, higher feed rate results in poor surface finish. The scallop marks and thus the surface roughness value will be higher.

What is the difference between feed rate and cutting speed?

Cutting speed is considered the speed of a tool that cuts the workpiece. In comparison, the feed rate is the distance traveled by the tool in one revolution of the spindle. Therefore, the feed rate is considered as the velocity at which the cutter is fed.

What determines the feed rate of a lathe?

4. Feed rate and cutting speed are mostly determined by the material that’s being cut. In addition, the deepness of the cut, size and condition of the lathe, and rigidity of the lathe should still be considered.

What is the difference between feed rate and cutting speed?

2. Feed rate is defined as tool’s distance travelled during one spindle revolution. 3. Feed rate and cutting speed determine the rate of material removal, power requirements, and surface finish. 4.

How to change speed on a lathe?

The lathes are designed to operate at various spindle speeds for machining of different materials. There speeds are measured in RPM (revolutions per minute) and are changed by the cone pulleys or gear levels. One a belt-driven lathe, various speeds are obtained by changing the flat belt and the back gear drive. One the geared-head lathe speeds are changed by moving the speed levers into proper positions according to the RPM chart fastened to the lathe machine (mostly on headstock). While shifting the lever positions, place one hand on the faceplate or chuck, and form the face plate slowly by hand. This will enable the levers for engage the gear teeth without clashing. Never change speeds when the lathe is running on lathers equipped with variable speed drivers, the speed is changed by turning a dial of handle while he machine is running.

What is the feedrate of aluminum?

5. Roughing cuts (0.01 in. to 0.03 in. depth of cut) for most aluminum alloys run at a feedrate of .005 inches per minute (IPM) to 0.02 IPM while finishing cuts (0.002 in. to 0.012 in. depth of cut) run at 0.002 IPM to 0.004 IPM.

What is the recommended feed for cutting?

For general purpose machining a .005 – .020 inch feed for roughing and a .012 to .004 inch feed for finishing is recommended.

How to determine the RPM of a lathe?

The RPM at which the lathe should be set for cutting metals is as follows: To determine the RPM of the lathe while performing procedures on it: Formula: RPM = (CuttingSpeed x 4) / Diameter. We first must find what the recommended cutting speed is for the material we are going to machine.

How to control feed on engine lathe?

We can control the feed on an engine lathe by using the change gears in the quick-change gearbox. Our textbook recommends whenever possible, only two cuts should be taken to bring a diameter to size: a roughing cut and a finishing cut.