How do they cut rifling?

Cut Rifling The cut-rifling method removes metal from the surface of the bore to create the grooves using a single-bladed, hook-type cutter of groove width that is pulled through the cold barrel. It is sometimes called "hook rifling" after the fishhook-shaped cutter used.

How is rifling machined in a barrel?

The bore of the barrel is lubricated first, before the button is pulled through it. As the hard button passes through the softer steel of the barrel, it engraves the rifling grooves on to the inside of the barrel. The whole process takes only a minute or less.

How are rifled barrels manufactured?

The rifling process is a key part of barrel manufacturing, resulting in lands (bore) and grooves that create a spiral down the length of the barrel. This process is done after there's a hole in the barrel blank. Rifling can be achieved as either a metal cutting, or cold forming process.

What are three methods that firearms manufacturers manufacture rifling?

There are three basic machining processes that modern firearms manufacturers use to form the rifling in barrels. Rifling can be cut into the inner surface of a barrel using a broach, the rifling can be formed using a hardened steel button, or the rifling will be formed through a process called hammer forging.

Can you do rifling on a lathe?

No. You don't rifle on a lathe. Rifling can be done very easily by hand as shown in several you tube videos, but it is not done on a lathe.

Does rifling cut into the bullet?

Rifling refers to the spiral grooves that are cut into the internal surface of a gun barrel. Rifling helps impart a spinning motion to a bullet when it's fired. A spinning bullet is much more stable in its trajectory, and is therefore more accurate than a bullet that doesn't spin.

How do they cut rifling in gun barrels?

Cut Rifling The cut-rifling method removes metal from the surface of the bore to create the grooves using a single-bladed, hook-type cutter of groove width that is pulled through the cold barrel. It is sometimes called "hook rifling" after the fishhook-shaped cutter used.

What machine is used to make rifle barrels?

Button Rifling is the most common method of manufacturing rifled barrels in the United States today. Precihole Button Rifling machines incorporate the latest features to form precision grooves in small caliber weapon systems.

Are rifle barrels hardened?

A tradeoff is made between tensile strength and impact strength and therefore, the barrels are hardened to between 25 and 32 on the Rockwell C hardness scale.

Can rifling be restored?

Yes, the rifling can be restored at a slightly larger diameter of both lands and grooves. When you look down the barrel, you will see that there are "pits" in both the bottoms of the grooves and lands. To restore, the grooves must be cut deeper (larger diameter) and the lands bored to a larger diameter.

Is polygonal rifling better?

Pistols with polygonal rifling have smaller bore diameters than pistols with traditional rifling. This gives the polygonal barrels a tighter gas seal on the projectile. That gas seal gives polygonal guns an advantage in generating muzzle velocity.

How is rifling invented?

Gaspard Kollner, a 15th century gunmaker in Vienna, is thought by many to have invented rifling. Others think it was Augustus Kotter of Nuremberg who invented rifling in about 1520. At about that same time some crossbows fired a bolt (short heavy arrow) through a tube with spiral grooving.

What are the typical methods for rifling a gun barrel?

The four basic methods of making rifling in a barrel are single-point, broach, button, and hammer-forged.

What machine is used to rifle a barrel?

Button Rifling is the most common method of manufacturing rifled barrels in the United States today. Precihole Button Rifling machines incorporate the latest features to form precision grooves in small caliber weapon systems. The rifling button is pulled and rotated precisely through the barrel.

Which rifling method involves cutting the metal of the barrel with a series of concentric steel rings?

The broach cutting method involves a series of concentric steel rings (known as a “broach”), with the size of the ring increasing slightly down the line. The broach simultaneously cuts all of the grooves into the barrel at the required depth as it passes through the barrel.

How are barrels forged?

The forging process involves threading a short and thick steel rod onto a mandrel and then beating the mass of steel into the final shape of a barrel. The process work-hardens all the steel in contact with the mandrel, which creates the bore.

What was the purpose of the rifling machine?

This rifling machine (1853) was used to cut pistol barrels. The machine was ahead of others in its automatic movements. Watch how this machine works.

Who invented the rifling machine?

In the South, Major Hagner at the Frankford Armory designed a machine that carved spiraling grooves in the inside of the gun barrels. His invention had a rod that had several “cutting heads” or pieces that engraved into the metal to make the grooves. Those heads cut the bore in one motion, instead of the single cutting head on the rod that took repeated actions to rifle the barrel (such as the one on rifling machine in the video). His machine was manufactured and running in 1856 and within a year, it could cut 39 to 42 barrels in 8.5 hours.8 Although his invention was innovative and faster than Buckland’s machine, it was too costly to produce, and, therefore, it was not widely manufactured for private companies.9 Although rifling machines were innovative, advancements had price tags that not everyone could afford.

Why was a reliable rifling machine important in the Civil War?

A reliable rifling machine was extremely important in carbine manufacturing during the Civil War. That machine tool changed the manufacturing process of arms , allowing the widespread conversion of muskets to rifles and the creation of a multitude of rifled arms --including the famous carbines of the Civil War--to be feasible.

When were rifling machines invented?

By 1831 , the rifling machines had been so perfected that there was little changes to them in the following years.

Who invented the four barrel machine?

Yet, in the 1840s, Frederick Howe did create a machine that could bore four barrels at once, and it became popular.1 By rifling four barrels instead of just one at a time, his tool demonstrated manufacturers’ push to increase production output, while decreasing production time. .

What is the name of the arm maker in the Connecticut Valley?

2 Deyrup, Arms Makers of the Connecticut Valley, 155.

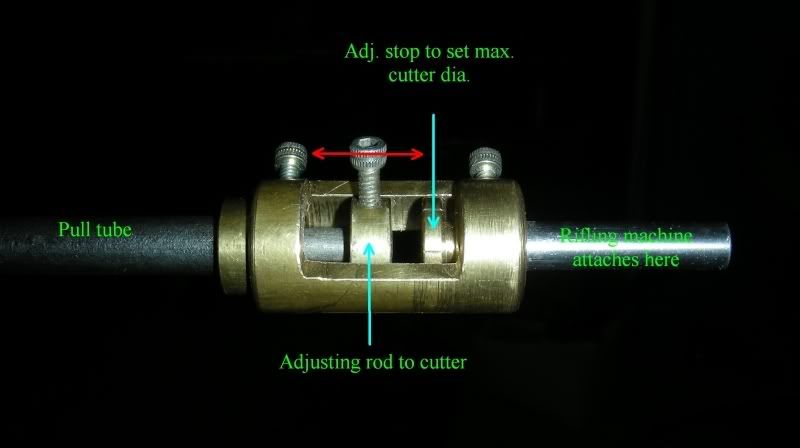

How does a rifling cutter work?

The other end of the cutter box is attached to a hollow steel tube through which coolant fluid is pumped to keep the cutting head cool. As the cutter box is pulled through the barrel, it is also rotated about its axis at a set rate to give the rifling a spiral shaped groove.

When was rifling invented?

Cut Rifling, also known as Single Point Cut Rifling, is one of the oldest methods of rifling and dates back to the time that rifling was first invented in Nuremberg, Germany in 1520. Cut Rifling consists of removing steel from the inside of a barrel using a cutting tool with a hard point. The cutting tool used is called a “hook cutter”.

How to describe a rifling?

Rifling is often described by its twist rate, which indicates the distance the rifling takes to complete one full revolution, such as “1 turn in 10 inches” (1:10 inches), or “1 turn in 254 mm” (1:254 mm). A shorter distance indicates a “faster” twist, meaning that for a given velocity the projectile will be rotating at a higher spin rate.

What is rifling in metal?

Rifling can be achieved as either a metal cutting, or cold forming process. The 4 most common types of rifling in modern manufacturing are, in no particular order - button rifling, single point cut rifling, broach rifling, and hammer forging.

How Does Barrel Rifling Work?

This process is done after there's a hole in the barrel blank. Rifling can be achieved as either a metal cutting, or cold forming process. The 4 most common types of rifling in modern manufacturing are, in no particular order - button rifling, single point cut rifling, broach rifling, and hammer forging. Although other methods may still be used, these types are typical for the majority of barrels that are on the market, because of their repeatability and manufacturing process efficiency for most barrel applications.

Why is button rifling not a chip control?

Because no metal is cut, manufacturers and operators do not have to manage chip control. Button rifling is also a highly controlled process that is repeatable across an entire production lot. Progressive twist is possible with the button rifling process.

What are the pros and cons of button rifling?

Cons of Button Rifling - With button rifling, an additional stress relieve step is required adding cost and time - the stress relieving operation is used to relieve stress introduced in the bore of the barrel because of the cold forming process. Also, pre-machining of pistol barrel features is not possible, as a uniform outside diameter is necessary due to the swaging performed when button rifling. A unique tool is needed for every twist, as the helix is ground into the carbide button.

What is button rifling?

Button rifling is a cold forming process that swages rifling in the barrel with a carbide tool that has grooves in a specific dimension and twist rate. Button rifling is a single pass operation, where the button is pushed or pulled at a controlled rate through the bore of a barrel blank, resulting in the desired lands and grooves.

Why is button rifling so popular?

Popularity - Because of the simplicity, consistency, and short cycle time that button rifling offers , this is by far the most commonly used process in rifle barrel manufacturing by volume. Typical Applications - Hunting rifles, MSR style rifles as well as some precision rifles and some pistols.

Why use a single tool for rifling?

Because the tools are not specific to a twist rate, manufacturers are able to use a single tool for a range of rifling configurations. Advancements in modern machine design and the use of servo technology allows operators to easily program a gain twist with the same tool, while modern CNC technology enables a simpler, more repeatable operation.