Square Steel Tubing Specifications

- Nominal Size. The Steel Tube Institute of North America specifies the measurement of square tubing by its outside width.

- Wall Thickness. Square steel tubing wall thickness ranges from 1/8 inch, also known as 11 gauge, to 5/8-inch thick. ...

- Weight Per Foot. ...

- Engineering Specifications. ...

What is the standard size of square tubing?

The Steel Tube Institute of North America specifies the measurement of square tubing by its outside width. For example, a tube with 2-inch wide sides calls out as 2 by 2 inches. Sizes range from 1-1/4 by 1-1/4 inch to 32 by 32 inch.

How is pipe size measured and handled?

The following is an overview of how tube and pipe size is measured and handled. Tubing is measured by the OUTSIDE DIAMETER (O.D.), specified in inches (e.g., 1.250) or fraction of an inch (eg. 1-1/4″). Pipe is usually measured by NOMINAL PIPE SIZE (NPS). Although it is related to the outside diameter, it is significantly different.

What is the difference between pipe size and tubing size?

Tubing is measured by the OUTSIDE DIAMETER (O.D.), specified in inches (e.g., 1.250) or fraction of an inch (eg. 1-1/4″). Pipe is usually measured by NOMINAL PIPE SIZE (NPS). Although it is related to the outside diameter, it is significantly different. For example, a 1-1/2″ pipe size actually has an outside diameter of 1.9″ NOT 1.5″.

What are the uses of square steel tubing?

Many projects take advantage of square steel tubing, including all types of buildings, highway guardrails and signage, support columns, trusses, bridges, heavy equipment, storage systems, and exercise equipment. The Steel Tube Institute of North America specifies the measurement of square tubing by its outside width.

Is square tubing measured OD or ID?

Tubing is measured by the OUTSIDE DIAMETER (O.D.), specified in inches (e.g., 1.250) or fraction of an inch (eg. 1-1/4″). Pipe is usually measured by NOMINAL PIPE SIZE (NPS). Although it is related to the outside diameter, it is significantly different.

How is square tubing sized?

Square steel tubing is available in cross-sectional dimensions ranging from ½ inches per side to 24 inches per side, available in several thicknesses and several lengths.

How do you measure square metal tubing?

0:112:32Basic Home Improvements : How to Measure Tubing - YouTubeYouTubeStart of suggested clipEnd of suggested clipWhat we can do is you take a tape measure. And as long as you know that there is an inside diameter.MoreWhat we can do is you take a tape measure. And as long as you know that there is an inside diameter. And outside diameter. Then you can line up the edge of the inside with the one inch mark.

What is the ID of 1/4 square tubing?

Speedy Metals 1-1/4" SQ x 1.010" ID x . 120" Wall Other Steel Square Tube.

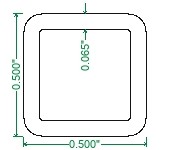

What is the ID of 3/4 square tubing?

3/4" SQ {A} x 0.620" ID {B} x . 065" Wall {C} Square Steel Tubing.

How thick is 2x2 square tubing?

0.1875 inchesA 2-inch x 2-inch piece of square steel tube with a wall thickness of 0.1875 inches can carry 4.32 lbs per foot of length.

How is tubing length measured?

0:091:44How to Measure Pipes & Tubes - YouTubeYouTubeStart of suggested clipEnd of suggested clipMark the point where the string touches. Together. Use a ruler or measuring tape to find theMoreMark the point where the string touches. Together. Use a ruler or measuring tape to find the circumference or the length between the tip of the string.

What gauge is 2x2 square tubing?

Steel Square Tube 2" x 2" x 16 Gauge (Grade A500)

How thick is 14ga tubing?

6" OD with . 083" wall thickness.

What is the outside radius on square tubing?

11.6 Corner Radius—For square and rectangular structural tubing, the radius of each outside corner of the section shall not exceed three times the specified wall thickness. by the specification.

How much is 1x1 square tubing?

Material SpecificationsQuantityPrice1$13.92 each2 - 9$8.29 each10 - 24$5.01 each25 - 99$3.89 each

What gauge is 2x2 square tubing?

Steel Square Tube 2" x 2" x 16 Gauge (Grade A500)

How thick is 14ga steel tubing?

15 U.S. Code § 206 - Standard gauge for sheet and plate iron and steelNumber of gaugeApproximate thickness in fractions of an inchWeight per square meter in pounds avoirdupois145/6433.64159/12830.27161/1626.91179/16024.2241 more rows

How much is 1x1 square tubing?

Material SpecificationsQuantityPrice1$13.92 each2 - 9$8.29 each10 - 24$5.01 each25 - 99$3.89 each

What Is Square Tubing?

Square steel tubing is tubing that is manufactured using welding. This kind of tubing is of structural grade. It comes in either type A513 or A500 Grade B. The different kinds of steel tube are determined by the size and how thick the tube’s wall is. Regardless of the grade, steel tubing is used for a variety of purposes.

How to determine how strong a square tubing is?

In steel tubing, the strength rating of the tube is measure by weight per foot . This standard measurement is useful if you need to compare different manufacturers or products. The standard measure also lets you know ...

How much weight can a 16 inch square tube hold?

So, a 16-inch x 16-inch square tube with a wall of 0.5 inches can carry 103.3 lbs per foot. Square steel tubing is plenty strong enough for many construction and manufacturing uses. It is also strong enough for significant weight-bearing uses in vehicles and much more.

How much weight can a piece of square steel carry?

Let’s look at a couple of standard sizes of square steel tubing to see how strong it is. A 2-inch x 2-inch piece of square steel tube with a wall thickness of 0.1875 inches can carry 4.32 lbs per foot of length.

What is the wall thickness of a 16 inch steel tubing?

At 16-inches x 16-inches, which is one the largest square steel tubing sizes available, the wall thickness is either 0.3125, 0.375, or 0.5 inches.

What is square steel used for?

Regardless of the grade, steel tubing is used for a variety of purposes. Typical uses of square steel tubing include construction and structural uses. It is also used for a wide variety of manufacturing and fabrication applications. You can find square steel tubes in vehicles, trailers, agricultural and transport equipment, and much more.

Why is round steel better than square steel?

This increased weight-bearing capacity is because a circle is a stronger shape than a square. Because there are no corners, there are fewer pressure points to give way when excess load is applied.

How is tubing measured?

Tubing is measured by the OUTSIDE DIAMETER (O.D.), specified in inches (e.g., 1.250) or fraction of an inch (eg. 1-1/4″). Pipe is usually measured by NOMINAL PIPE SIZE (NPS). Although it is related to the outside diameter, it is significantly different.

What is the thickness of a 12 gauge tubing?

You can see by the chart at the right, not all 12 Gauge allows a thickness between 0.101 to 0.111. The typical value, which is not half way between, is used for calculation of section properties.

What is the minimum wall thickness for pipe?

This means that a minimum wall of 0.875 times the nominal wall could apply for regular mill rolled steel.

How thick is a STD?

STD and SCH 40 are the same in sizes through 10-inch; in sizes above 10-inch, STD has a wall of 3/8-inch. XS has a wall thickness of 1/2-inch. XXS has no corresponding schedule number, but in sizes through 6-inch, XXS has a wall thickness twice as thick as XS. Stainless steel schedules 40S and 80S are identical with carbon steel designations Std and XS, respectively, through 12-inch.

Why is tubing measured by OD?

Tubing is generally measured by the OD Outside Diameter because it is used with push-to-connect fittings.

What is a softer tube?

Softer tubes that use barbed fittings or compression fittings are measured by ID Inside Diameter. PVC tubing is a prime example of a softer tube that would use barbed fittings or two piece compression fittings to make the connection.

Round Tube Calculator

This is a useful form to get the stress in a tube and the safety factor with a given load (see definitions below). Compare material geometry (OD and wall) by comparing the STRESS. Compare materials (steel vs aluminum, etc) by comparing the SAFETY FACTOR.

Rectangular Tube Calculator

This is a useful form to get the stress in a tube and the safety factor with a given load (see definitions below). This assumes no self-weight of loaded members (this matters a lot on very heavy/dense beams, and contributes very little to stress in smaller beams, like frame rails!).

WARNING

We created this tool to help with comparing materials for use in various projects. This tool is NOT a substitute for professional engineering or consulting service. Many people call us with questions about steel or aluminum beams, building design, supporting loads over humans, maximum spans for tubing, etc.

Definitions

This is the material strength divided by the load. Higher values are safer. If the material can take 50,000 PSI of stress and the load puts 25,000 PSI of stress on the material, the safety factor is 2 (the material is 2 times as strong as the stress from the load).

What You Should Use This Calculator For

You should use this calculator to compare materials, diameters, and wall thicknesses to find out how to make your designs safer. For example, lets say your local metal distributor has 1.75x.095 tube and 1.25 solid bar on sale from some huge bulk purchase that fell through with another customer.

Comparison to an Actual Rollover

In a real rollover, the weight of your vehicle will not be a static load on just one tube. Your vehicle will be moving, with many tubes in the roll cage supporting constantly changing loads during the roll. The laod will spread out over more than one tube when 2 or more tubes are in contact with the ground/rocks/etc.

Material Weight Per Foot

Use the color coded table below to quickly see how much each material and tube size will weigh per foot (all materials are round tube).