How many expansion joints are in concrete? Usually, expansion joints should be no farther apart than 2 to 3 times (in feet) the total width of the concrete (in inches). So for a 4 inch thick concrete slab, expansion joints should be no more than 8 to 12 feet apart.

Why do we need an expansion joint in slab?

This is why expansion joints are used. Expansion joints are filled with a flexible material that runs along and inside the joint or gap in slabs and other concrete structures. An expansion joint is designed to absorb the expansion and contraction of concrete that naturally occurs due to change in temperatures.

Why to replace concrete expansion joints?

Concrete expansion joints are designed to prevent moisture from seeping under the pads. When this happen, the level of the concrete can sink or cracking on the surface can result. The expansion joints allow for expansion and contraction during extremes of heat and cold, dryness and humidity. When these joints wear out, the concrete becomes more ...

Why your concrete floor needs an expansion joint?

- Hairline cracks developing into larger caverns

- Pieces of expansion joint material beginning to loosen and dislodge

- Discoloration and water retention during regular cleanups

What is the necessity of providing joints in concrete?

Why construction joints are necessary?

- Joints are very essential to prevent the cracks due to strain produced. ...

- Joints prevent unnecessary cracks. ...

- Joints ease in the massive construction work.

- Joints sometimes prevent the entire failure of the structure. ...

- Joint helps to prevent unnecessary deformation as well.

How many expansion joints are in concrete?

Usually, expansion joints should be no farther apart than 2 to 3 times (in feet) the total width of the concrete (in inches). So for a 4 inch thick concrete slab, expansion joints should be no more than 8 to 12 feet apart.

Where should I put expansion joints in concrete?

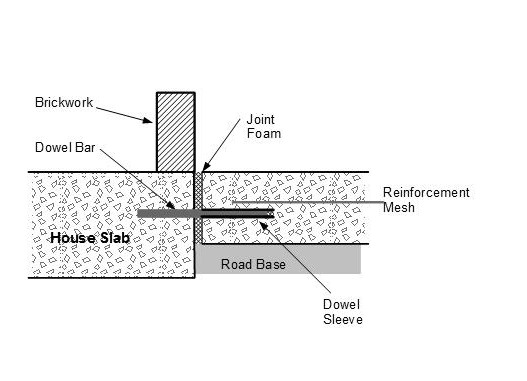

Expansion joints are put in place before the concrete is poured. Expansion joints are used to allow the slab to move and not put stress on whatever it abuts. These joint are placed where a slab meets a building, where a slab meets another slab, and where a pool deck meets the coping.

Do concrete slabs need expansion joints?

Expansion joints are virtually never needed with interior slabs, because the concrete doesn't expand that much—it never gets that hot. Expansion joints in concrete pavement are also seldom needed, since the contraction joints open enough (from drying shrinkage) to account for temperature expansion.

How big of a slab can you pour without expansion joints?

Rule #2 – In order to prevent intermediate cracking, space joints (in feet) no more than 2 – 3 times the slab thickness (in inches).

What happens if you don't put expansion joints in concrete?

Concrete expansion joints give the slabs just enough room to move which helps prevent cracks & buckling. Without these joints, even a little movement creates pressure and stress on the concrete. Eventually weak spots can crack or buckle. Expansion joints are used to relieve this pressure.

Should you fill concrete expansion joints?

After a joint is established, it needs time to activate as the slab cures. Ideally after 90 days, the joint should be filled or sealed. Joint filling is done the full depth of the joint while sealing is only done over the surface level with a flexible material over a rod to help keep the proper shape of the joint.

How far apart should concrete joints be?

Joints are commonly spaced at distances equal to 24 to 30 times the slab thickness. Joint spacing that is greater than 15 feet require the use of load transfer devices (dowels or diamond plates).

How deep should expansion joints be?

Tips for placing concrete expansion joints Make sure joints are cut deep enough: they need to be at least a quarter of the thickness of the slab. For a 100mm slab, cut the joints at least 25mm deep. If you're cutting joints after the concrete has been poured, don't leave it too long.

How deep should expansion joints be cut in concrete?

A good rule of thumb is to make your cut ¼ the thickness of your concrete. If ¼ of your slab's thickness, doesn't reach 1” make sure you still cut at least a 1” depth.

How long after pouring concrete should you cut it?

6 to 18 hoursJoints should be sawed as soon as the concrete can withstand the energy of sawing without raveling or dislodging aggregate particles. For most concrete work, cutting should take place within the first 6 to 18 hours and never beyond 24 hours.

What happens if you don't cut concrete?

Late sawing can result in random concrete cracks. Shallow cracks aren't sufficient to prevent uncontrolled cracking while deep cuts are excessively labor intensive and undermine the aggregate interlock in the concrete.

Does a concrete slab need rebar?

Rebar is not necessary for every concrete project. The general rule of thumb is that if you are pouring concrete that is more than 5 inches in depth, you are probably going to want to add in some rebar to help reinforce the entire structure.

How deep should expansion joints be cut in concrete?

A good rule of thumb is to make your cut ¼ the thickness of your concrete. If ¼ of your slab's thickness, doesn't reach 1” make sure you still cut at least a 1” depth.

When Should expansion joints be cut in concrete?

Joints should be sawed as soon as the concrete will withstand the energy of sawing without raveling or dislodging aggregate particles. For most concrete mixtures, this means sawing should be completed within the first six to 18 hours and never delayed more than 24 hours.

Do you need expansion joints in a garage floor?

Many people understand that wood shrinks and expands as temperature and humidity ebb and flow through the year. But the same thing happens with concrete. That's why it is necessary to include expansion joints along the edges of the concrete garage floor as well as around posts or other protrusions in the slab.

What do you put between House and concrete?

The best way to fill a gap between a concrete slab and a wall is by first measuring the size of the gap. If it is ¼-inch (6 mm) or smaller, it can be filled with urethane caulk. If the gap is larger than 0.25 inches, press a foam backer rod into the gap, then fill the gap with urethane caulk.

What are Expansion Joints?

Similarly, as concrete experiences different temperature changes, it expands and contracts – sometimes more in some parts of the slab compared to others. Expansion joints are full-width cuts installed in professional concrete floors and walls that allow the concrete to expand and contract without cracking randomly. They isolate different parts of the slab so that the whole slab can move without straining certain parts more than others.

How far apart should expansion joints be?

Usually, expansion joints should be no farther apart than 2 to 3 times (in feet) the total width of the concrete (in inches). So for a 4 inch thick concrete slab, expansion joints should be no more than 8 to 12 feet apart.

What happens to concrete when it dries?

As concrete dries, it shrinks and forms to the topography of the ground it was poured on. Some parts of the concrete can shrink more than others, pulling and stressing other parts of the slab. Similarly, as concrete experiences different temperature changes, it expands and contracts – sometimes more in some parts of the slab compared to others. ...

Is concrete floor expensive?

At Kaloutas, we know that interior and exterior concrete flooring is expensive. For that reason, you need to protect your investment from the most common form of damage in concrete – cracking. The most popular way to protect against random cracking is the installation of expansion joints. In this post, we’ll talk more about expansion joints and answer the question of how often you need them in your slab of concrete.

Can expansion joints be cut with saws?

In cooler weather, expansion joints can be cut with saws after the concrete has hardened a little. Expansion joints cut through the entire width of the slab and are then filled with some sort of filler.

How to use expansion joints?

Laying a concrete driveway is a typical project often requiring the use of expansions joints, depending on the size of the area to be covered.

Why are expansion joints important?

They are also installed to absorb vibration, hold parts together or allow those parts to move as the ground settles or if there is an earthquake. Thankfully, there are few earthquakes in the UK, however, expansion joints are an important element in construction using concrete for all the other reasons.

What causes cracks in concrete?

However, this also means tensile pressure is put through the concrete as it shrinks, which can cause cracks.

What type of joint is used to fill concrete?

An expansion joint that can add flexibility and buffer the movement in the concrete is therefore the best solution. There are two types of expansion joint filler, foam and fibreboard. When working with concrete you should use fibreboard, which offers flexibility across the surface of concrete, allowing movement that will prevent cracking.

Can cracks in a house cause structural problems?

Remember, any cracking can cause structural problems in your build. However, more likely, it will look particularly unsightly. This obvious appearance of cracks could compromise the end finish of your build.

Does concrete shrink in heat?

As with wood, concrete can expand and shrink in heat. There is also shrinkage after the concrete has hardened. By placing expansion joints in a grid form across an expanse of concrete pouring, in positions where cracks can be expected to occur, cracks, if they occur, are held below the surface, remaining superficial and mostly invisible.

When is an expansion joint made?

When the site is prepared for the concrete pouring and the provisioning of the expansion joints in slabs are made prior to the placing of concrete. An individual expansion joint is created by the insertion of a flexible material that runs along the joint length.

What are the characteristics of expansion joints?

Characteristics of Expansion Joints 1 Expansion joints permits thermal contraction and expansion without inducing stresses into the elements. 2 An expansion joint is designed to absorb safely the expansion and contraction of several construction materials, absorb vibrations, and permit soil movements due to earthquakes or ground settlement. 3 The expansion joints are normally located between sections of bridges, paving slabs, railway tracks, and piping systems. 4 The expansion joints are incorporated to endure the stresses. 5 An expansion joint is simply a disconnection between segments of the same materials. 6 In the concrete block construction, the expansion joints are expressed as control joints.

Why does concrete expand?

Concrete undergoes expansion due to high temperature when in a confined boundary which leads to cracks. Expansion joints are provided in slabs, pavements, buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

What is bridge expansion?

Bridge expansion joints are designed to allow for continuous traffic between structures while accommodating movement, shrinkage, and temperature variations on reinforced and prestressed concrete , composite, and steel structures.

Why are pipe expansion joints needed?

Pipe expansion joints are necessary in systems that convey high temperature substances such as steam or exhaust gases, or to absorb movement and vibration. Based on the type of material used in making of joint, expansion joints are further classified into following types,

Why are expansion joints incorporated?

The expansion joints are incorporated to endure the stresses.

How deep is an expansion joint?

The depth of an expansion joint is usually one fourth of the slab thickness, or more if necessary. The expansion joint gap depends on the type of slab, like floating slab floor, vehicle pavement, sidewalk, or monolithic slab foundation.

Where are expansion joints placed?

These joint are placed where a slab meets a building, where a slab meets another slab, and where a pool deck meets the coping.

What material is used to make expansion joints?

A pliable material is used (asphalt coated, cork, plastic) to construct these types of joints. The material should extend the depth of the slab and extend the full width of the slab. Ideally, for expansion joints on the exterior of a structure, sealing these joint is preferable.

What is the purpose of concrete control joints?

Placement of concrete control joints and expansion joints are crucial when designing and pouring concrete slabs and sidewalks. Both of these types of joints, while very different, help take stress off of the concrete slab.

How long does caulk last on concrete?

Some of the better caulk/sealants are rated up to 50 years. With a little planning prior to pouring, utilizing control joints and expansion joints will help minimize cracking and extend the life of the concrete. If your existing concrete driveway, sidewalk, or patio happens to crack over time, there are several things you can do to prolong ...

How many times should a contraction joint be spaced?

Joints are commonly spaced at distances equal to 24 to 30 times the slab thickness.

How deep should a concrete slab be for cracking?

Contraction/control joints must be established to a depth of ¼ the slab thickness (Figure 2). Proper joint spacing and depth are essential to effective control of random cracking.

How long does it take to saw concrete?

For most concrete mixtures, this means sawing should be completed within the first six to 18 hours and never delayed more than 24 hours.

What is concrete mixture?

A fresh concrete mixture is a fluid, plastic mass that can be molded into virtually any shape, but as the material hardens there is a reduction in volume or shrinkage . When shrinkage is restrained by contact with supporting soils, granular fill, adjoining structures, or reinforcement within the concrete, tensile stresses develop within ...

Is concrete a compressive or tensile material?

While concrete is very strong in compression the tensile strength is only 8 to 12 percent of the compressive strength. In effect, tensile stresses act against the weakest property of the concrete material. The result is cracking of the concrete.

Is concrete cracked or uncracked?

The concrete has still cracked which is normal behavior, but the absence of random cracks at the concrete surface gives the appearance of an un-cracked section. Concrete slabs-on-ground have consistently performed very well when the following considerations are addressed.

Can steel reinforcement be used on concrete?

It is important to recognize that using steel reinforcement in a concrete slab actually increases the potential for the occurrence of random hair line cracks in the exposed surface of the concrete. The most widely used method to control random cracking in concrete slabs is to place contraction/control joints in the concrete surface ...

What is expansion joint?

Expansion joints are installed in a concrete slab where expansion and contraction caused by temperature cycles and moisture are likely to occur. Expansion joints can also alleviate the pressures caused by frost heave, foundation settlement, and the curing process. The function of the joints is to relieve stress concentrations ...

How thick should a concrete board be for expansion joints?

The most common method creates a space for the joint as part of the formwork. A board 1-inch thick will leave sufficient space for the insertion of the expansion joint. The board should be coated with a form-release compound or even ordinary motor oil so that it is easily removed when the concrete has set.

Where to install expansion joints in basement?

The expansion joint is installed along the edge of the slab where it meets the foundation wall. A thin layer of sand placed between the slab and the top of the footing allows for some additional expansion. Joints can be installed in the interior of the slab with maximum spacings of 25 feet.

How deep should a saw joint be?

A saw joint is made by sawing to a maximum depth equal to ¼ the thickness of the slab with a concrete saw. The width of the cut should be no greater than 1/8-inch. The saw cut is then filled with a sealant or with a pre-molded metal strip that is finished flush with the surface of the slab.

Do you need expansion joints for a slab?

Larger slabs, in particular, require expansion joints at regular intervals. Expansion joints provide an added advantage when a slab is too large to finish in one pouring: the individual sections created by the expansion joints can be poured one at a time.

Why Does Concrete Expand or Contract?

Cement is the key ingredient because it causes concrete to change size and shape. When it reacts with water, it causes the concrete to expand. When exposed to cold weather conditions like freezing temperatures or heavy rain, concrete will also shrink.

How Can You Keep Your Structure Safe From Expansion and Contraction?

The amount of water, the type of aggregate, the consistency of the mix, and the climate play a part in this process. There are also other factors that can affect how much concrete expands and contracts at any given time. In many cases, it’s not fully known why or how this happens.

Does Concrete Expand When It Wet?

Yes, concrete expands when it dries. That’s what causes cracks in the surface of a slab and walls to pop out. There are many factors that contribute to this phenomenon:

What is the difference between expansion and control joints?

Control joints are meant to control cracking, while expansion joints are meant to allow for movement. Expansion joints, or isolation joints, are used between two different concrete pours, or where concrete meets with another material or even a structure.

WHAT ARE CONTROL JOINTS?

Control joints are planned cracks which allow for movements caused by temperature changes and drying shrinkage. In other words, if the concrete does crack-you want to have an active role in deciding where it will crack and that it will crack in a straight line instead of randomly.

How long after finishing concrete can you cut?

Make sure you are cutting joints soon enough. In hot weather, concrete might crack if joints are not cut within 6-12 hours after finishing concrete. In this condition, if you don't want to use a grooving tool to cut joints, there are early-entry dry-cut lightweight saws that can be used almost immediately after finishing.

What tools do you use to cut concrete?

Groover tools cut joints in fresh concrete. Saw cutting cuts joints as soon as the concrete is hard enough that the edges abutting the cut don't chip from the saw blade. Under walls they won't be seen. Under carpet areas the joints won't have a chance to telegraph through vinyl areas.

Do concrete plans have joint spacing?

And, most plans don't have joint spacing marked on them. So don't leave this important part of concrete construction to chance. Find local concrete contractors to help with your project.

Can you stamp concrete with a diamond pattern?

When arranging joints, skilled contractors will often use them to create an attractive diamond pattern. If your concrete will be stamped, ask about the best ways to avoid interrupting the pattern with control joints. Watch this video for a good solution: Pouring Concrete with Zip Strips.