How to calculate standard deviation?

Overview of how to calculate standard deviation

- Find the mean.

- For each data point, find the square of its distance to the mean.

- Sum the values from Step 2.

- Divide by the number of data points.

- Take the square root. The formula above is for finding the standard deviation of a population. ...

How do you calculate standard deviation percentage?

Calculate the percent deviation. The formula for the percent deviation is 100 times the difference between your data and the standard and then divided by the standard. 100 * (|data – standard|) / (standard) For the acceleration experiment, the formula is written: 100 * (9.8 – 9.5)/(9.8) = 100 * (0.3)/9.8 = 3.06%

What does standard deviation tell us?

Standard deviation tells us about the variability of values in a data set. It is a measure of dispersion, showing how spread out the data points are around the mean. Together with the mean, standard deviation can also indicate percentiles for a normally distributed population.

What is the equation for standard deviation?

Standard Deviation, σ = ∑ i = 1 n ( x i − x ¯) 2 n. In the above variance and standard ...

How many standard deviations are there in Six Sigma?

six standard deviationsThe Six Sigma program strives to achieve six standard deviations between the mean and the closest specification limit on a short term study.

Is Six Sigma 3 standard deviations from the mean?

First and foremost, it's important to understand that a standard deviation is also known as sigma (or σ). And Six Sigma is a methodology in which the goal is to limit defects to six “sigmas,” three above the mean and three below the mean.

How many standard deviations is the mean?

The empirical rule, or the 68-95-99.7 rule, tells you where most of the values lie in a normal distribution: Around 68% of values are within 1 standard deviation of the mean. Around 95% of values are within 2 standard deviations of the mean. Around 99.7% of values are within 3 standard deviations of the mean.

Is standard deviation 1 sigma?

One standard deviation, or one sigma, plotted above or below the average value on that normal distribution curve, would define a region that includes 68 percent of all the data points. Two sigmas above or below would include about 95 percent of the data, and three sigmas would include 99.7 percent.

Is Six Sigma +/- 3 sigma or +/- 6 Sigma?

What is Six Sigma? Six Sigma is the highest level of Sigma, which dictates that the margin of error can be up to six standard deviations from the mean. This results in a 99.999997% rate of accuracy, maximizing efficiency and reducing defects more than the lower Sigma levels.

What is 3 standard deviations from the mean?

In statistics, the empirical rule states that 99.7% of data occurs within three standard deviations of the mean within a normal distribution. To this end, 68% of the observed data will occur within the first standard deviation, 95% will take place in the second deviation, and 97.5% within the third standard deviation.

What is 2 standard deviations from the mean?

Standard deviation tells you how spread out the data is. It is a measure of how far each observed value is from the mean. In any distribution, about 95% of values will be within 2 standard deviations of the mean.

What is 1 standard deviation from the mean?

What does 1 SD (one standard deviation) mean. On a bell curve or normal distribution of data. 1 SD = 1 Standard deviation = 68% of the scores or data values is roughly filling the area of a bell curve from a 13 of the way down the y axis.

What does 2 standard deviations below the mean mean?

The standard deviation is (σ) . When z is negative it means that X is below the mean. For this example, z = (70 - 80)/5 = -2. As stated, only 2.3% of the population scores below a score two standard deviations below the mean.

What is 4 standard deviations from the mean?

What Percentage Is 4 Standard Deviations From The Mean? For a data set that follows a normal distribution, approximately 99.99% (9999 out of 10000) of values will be within 4 standard deviations from the mean. So, for every 10000 data points in the set, 9999 will fall within the interval (S – 4E, S + 4E).

What percentage is 6 sigma?

99.99966%Six Sigma quality – Six Sigma performance produces a defect-free product 99.99966% of the time; allowing only 3.4 errors per one million opportunities.

How is Six Sigma calculated?

Defects per million opportunities (DPMO) Six Sigma is determined by evaluating the DPMO, Multiply the DPO by one million. Process Sigma Once you have determined the DPMO, you can now use a Six Sigma table to find the process sigma. You will look for the number closest to 33,333 under defects per 1,000,000.

How do you find standard deviation with 3 Sigma?

An Example of Calculating Three-Sigma LimitFirst, calculate the mean of the observed data. ... Second, calculate the variance of the set. ... Third, calculate the standard deviation, which is simply the square root of the variance. ... Fourth, calculate three-sigma, which is three standard deviations above the mean.

What does 6 sigma mean in statistics?

Six Sigma is a process that makes use of statistics and data analysis to analyze and reduce errors or defects. In this process, the purpose is to improve cycle times while reducing manufacturing defects to no more than 3.4 defects per million units or events.

What percentage is 6 standard deviations from the mean?

Two standard deviations in either direction (4σ) covers 95.4% of the data. Three standard deviations in either direction (6σ) covers roughly 99.7% of the data. The goal here is to achieve what is commonly known as “Six Sigma Quality” or defect rates that fall outside the 6σ range.

Is mean difference the same as standard deviation?

Key Differences between Standard Deviation vs Mean In fiancé standard deviation is used for calculation of an annual rate of return, whereas mean is calculated for the use of calculating the average with the help of historical data.

What is standard deviation in statistics?

Standard deviation is used to measure the amount of variation in a process. This is one of the most common measures of variability in a data set or population. There are 2 types of equations: Sample and Population.

What is uniform distribution?

A uniform distribution is a continuous probability distribution. It describes the condition where all possible outcomes of a random experiment are equally likely to occur. For the uniform distribution, the probability density function f (x) is constant over the possible values of x.

Do you need to use the sample SD?

If all you have is a sample, but you wish to make a statement about the population standard deviation from which the sample is drawn, you need to use the sample SD.

What happens to defects as a sigma level increases?

In the above table, you will observe that as the Sigma level increase the Defects decrease. For example, for a 2σ process the Defects are as high as 308,537 in one million opportunities. Similarly, for a 6σ process the Defects is as low as 3.4 in one million opportunities. The 2σ performance level will have more defects than a system in 6σ performance level as the standard deviation for a 2σ process is much larger than the standard deviation for a 6σ process.

What is the meaning of sigma?

What is Sigma and Why is it Six Sigma? Mean is the arithmetic average of a process data set. Central tendency is the tendency of data to be around this mean. Standard Deviation (also known as Sigma or σ) determines the spread around this mean/central tendency. The more number of standard deviations between process average ...

What does DPMO mean in a financial statement?

Time indicates the total time it takes to correct those misspellings. DPMO indicates the total Defects in One Million Opportunities.

Is 6 Sigma process better than 7?

Obviously 7 or more σ processes are even better than a 6σ (Six Sigma) process, and yet throughout the evaluation and history of Six Sigma process, the practitioners gained the belief that a 6σ process is good enough to be reliable in almost all major situations except some systems whose defects can cause unrepairable consequences.

Can pharmaceutical companies work at Sigma?

The answer is yes. Pharmaceutical Companies, Airline Manufacturing Organizations, Automobile Manufacturers, among others are bound to work at a sigma level which is either 6σ or more than that. If they are not able to perform at this efficiency, the organization cannot exist. Think about it, you are in the air, 5000 feet above the ground, flying in a Boeing 777 Aircraft and suddenly a nut-bolt in the wing of the plane loosens (probably due to manufacturing defect) making it difficult for the pilot to steer the flight! This is the only reason why defects are not welcome and organizations try to achieve higher Sigma levels.

Does Sigma decrease DPMO?

We can clearly observe that as the Sigma Level increase, the defects (misspellings) decrease, the indebtedness reduce and the time for rework also reduces, thus it reduces the DPMO-Defects per Million Opportunities.

How Does Standard Deviation Relate to Six Sigma?

And Six Sigma is a methodology in which the goal is to limit defects to six “sigmas,” three above the mean and three below the mean. Anything beyond those limits requires improvements. Because three standard deviations contains 99.8% of the data in a set, Six Sigma requires continuous refinement to consider improvements that fall within that 0.2% of data in the set.

How to find standard deviation?

The steps to calculating the standard deviation are: 1 Calculate the mean of the data set ( x-bar or 1. μ) 2 Subtract the mean from each value in the data set. 3 Square the differences found in step 2 4 Add up the squared differences found in step 3 5 Divide the total from step 4 by either N (for population data) or (n – 1) for sample data (Note: At this point, you have the variance of the data) 6 Take the square root of the result from step 5 to get the standard deviation.

What are the standard deviations for donut holes?

If we want to serve 95% of customers interested in donut holes, we should offer sizes two standard deviations away from the mean, on both sides of the mean. So, sizes of 10 (20-5-5), 15 (20-5), 20 (the average), 25 (20+5) and 30 (20+5+5).

What is the assumption that follows a normal curve?

The assumption we can make about the data that follows a normal curve is that the area under the curve is relative to how many standard deviations we are away from the mean. The area between plus and minus one standard deviation from the mean contains 68% of the data. Two standard deviations contains 95% of the data and three standard deviations contains 99.8% of data.

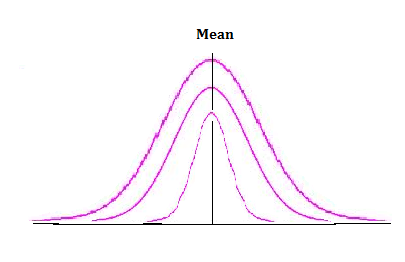

What is the difference between standard deviation and mean?

The mean of a normal curve is the middle of the curve (or the peak of the bell) with equal amount of data on both sides , while the standard deviation quantifies the variability of the curve (in other words, how wide or narrow the curve is).

Why is standard deviation important?

Standard deviation is important because it measures the dispersion of data – or, in practical terms, volatility. It indicates how far from the average the data spreads. This helps you determine the limitations and risks inherent in decisions based on that data.

How to determine risk in stock?

Real-life example: When considering investing in a stock, you can use standard deviation to determine risk. A stock with an average price of $50 and a standard deviation of $10 can be assumed to close 95% of the time (two standard deviations) between $30 ($50-$10-$10) and $70 ($50+$10+$10). It’s safe to assume that 5% of the time, it will plummet or soar outside of this range. If you were to compare this to a stock that has an average price of $50 but a standard deviation of $1, then it can be assumed with 95% certainty that the stock will close between $48 and $52. The second stock is less risky, more stable. The higher the standard deviation in relation to the mean, the higher the risk. Blue-chip stocks, for example, would have a fairly low standard deviation in relation to the mean.

What is standard deviation in statistics?

The standard deviation (Sigma, σ for the population, or S for a sample within the population) of a data series is a measure related to the distribution of the numbers in that series. It is a value that tells you how much on average you deviate from the mean. The smaller the standard deviation (and thus the spread), the better it is. Within six sigma there are two different types of standard deviation. Overall standard deviation (described in Minitab as StdDev (Overall) ) and standard deviation within, which takes subgroups of data into account. This is described as StdDev (within) in Minitab.

Why are Xbar-S charts more accurate than I charts?

This is why in terms of control charts (chapter 10) Xbar-S charts are more accurate than the simple I-charts, because common variation is taken out of the dataset by capturing them into subgroups.

Can you do a standard deviation calculation in Excel?

You can, of course, also perform the calculation in Microsoft Excel, Minitab, JMP or SPSS, for example. Figure 97 shows the results of part of the graphical summary of the above example in Minitab. On the right side, we see the values mean and the StdDev (standard deviation) that correspond to the by us calculated values 7 and 3,399.

How many standard deviations are there in a Six Sigma process?

A Six Sigma process has a specification limit which is 6 times its sigma (standard deviation) away from its mean. Therefore, a process data point can be 6 standard deviations from the mean and still be acceptable. (See Figure 1.)

What is Six Sigma process?

Six Sigma is a data-driven approach to quality, aimed at reducing variation and the associated defects, wastes and risks in any process . This article explores the basics of Six Sigma process quality – definition and measurement.

What does deviation mean in a process?

In a process, deviations from the target or mean are accepted to a certain value defined by the specification limits (SL) around the mean. Any value beyond the specification limit indicates a defect or unacceptable result. The farther the specification limits are from the mean, the lower the chance of defects.

What is 1.5 sigma?

The 1.5-sigma shift makes defects approach 0 on the opposite side of the shift even at lower sigma levels. The one-sided defect rate is applicable to any capable process with 1-sided or 2-sided SLs, even at a 3- sigma level.

What is the difference between process sigma and process sigma?

Sometimes the term process sigma is used instead of the process sigma level, which may cause confusion. Process sigma indicates the process variation (i.e., standard deviation) and is measured in terms of data units (such as seconds or millimeters), while process sigma count Z, or process sigma level, is a count with no unit of measure.

How many values are there for Z?

Referring back to the short- and long-term behavior of the process mean, there are 2 values for Z, short-term Z, or Z st, and long-term Z, or Z lt.

Is the Golden Six Sigma process a 3 sigma?

Therefore, the process is at a 3-sigma quality level. In order to bring the process to the golden Six Sigma quality level, the process sigma would have to be reduced to 1.

How many standard deviations are there in Six Sigma?

This is where Six Sigma comes in, ensuring that 99.99966% of the yield works as intended; six standard deviations outward from the mean. This reduces parts per million (PPM) defects to 3.4, a more acceptable number (and one of the best we can hope for).

Why is Six Sigma important?

Six Sigma is therefore necessary for modern society to function, as some of our most important achievements and technologies can only function with a minimum of Six Sigma certainty. As a result things like manufacturing, computing, banking, telecommunications, and any sub-industries of those hold themselves to a Six Sigma or higher standard.

What is 99.73% probability?

Common probability dictates that 99.73% of all outcomes will fall within 3 standard deviations of the mean (above or below); this is Three Sigma. For most purposes, this is a fine system. There are very few scenarios in daily life or most professions where 99.73% certainty or accuracy is not acceptable. But…manufacturing is one of those exceptions, as are computers.

How many standard deviations does a 6 Sigma process have?

If Sigma is the measure from the mean, then a 6 sigma process actually has 12 standard deviations from the lower limits to the upper limits? (sigma as a measurement from the mean, so 6 on each side). Sigma cant be a measurement from the mean or we have a general terminology problem.

What is Six Sigma?

By todays thinking your are correct, Six Sigma refers to the method rather than a numeric goal. The idea today is to improve the product/process until it is no longer cost effective to make further improvements. The goal is the bottom line.

What is the difference between sigma and std?

Std Deviation in essence is the average distance of the data from the mean. Sigma is the number of std. deviations between the mean and spec. limit.

What is a sigma measurement?

The sigma measurement (or Z value) is the number of standard deviations (units) that exist between the mean of the data and the nearest specification.

How many units are in a six sigma?

Six Sigma = 3.4 per million unitsIn formulae for control limits and process capabilities, sigma is the symbol for Standard Deviation, calculated from the squares of the deviations of measured samples from the mean value (or sometimes by other methods using ‘magic’ numbers). For a normally distributed output, 99.7% would be expected to fall between +/- (3 x sigma) levels.Posted By: Tom

What is the Greek letter for sigma?

The Greek letter s (sigma) refers to the standard deviation of a population. Sigma, or standard deviation, is used as a scaling factor to convert upper and lower specification limits to Z. Therefore, a process with three standard deviations between its mean and a spec limit would have a Z value of 3 and commonly would be referred to as a 3 sigma process.Posted By:

What is the failure rate of 6 sigma?

However, originally the six sigma goal was to obtain a failure rate <= 6 sigma around a mean and within the customer specification. That failure rate was deemed to be 3.4 dpm (with the bogus 1.5 sigma shift). An actual 6 sigma failure rate is 2 ppb.

Why do we take large samples from the process to account for variation?

Because there is not a lot of historical data we take large samples from the process to account for variation. Process Performance generally uses sample sigma in its calculation. In theory Cpk will always be greater than or equal to Ppk.

Is there less variation in the long term?

It is not real, there can never be less variation in the long term since the long term is using all of the data not just two pieces of data from every subgroup. Evaluating process capability with Cp & Cpk mirror what is done (and why it is done) when following the Pp & Ppk approach.