What kinds of Pullers are available for bearings?

So, we found out what kinds of pullers are available for bearings. The most common types are universal solutions of mechanical type. They can be used to extract any bearings and pulleys. A puller is a very useful thing in the household. Especially if you own a car.

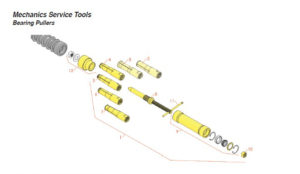

What are the parts of a puller?

Each puller has a cage around the jaws that keeps them in place for a quick job of gripping bearings and pulleys. Grip bearings, gears, and wheels from the outside edge to pull them off a shaft.

What is the 3 jaw bearing bearings?

【Strong 3 Jaw Bearing Puller】 The internal bearing puller has a sturdy structure, high-strength torque and high toughness. As long as the small wrench is turned slightly, it will generate a large pulling force, which can be slip-resistant and firmly grasped, saving time and saving when using (claw length 80 mm)

What are the dimensions of the puller of internal bearings?

As for dimensions, the puller of internal bearings may have a different diameter. On the average - from 28 to 200 millimeters. The height of the foot is from 35 to 60 millimeters. The size of the bolt head is from 9 to 22 millimeters. Slip Puller

What is an internal bearing puller?

Internal bearing puller. Internal bearing puller. Internal bearing pullers are made up to extract bearing set. These are generally favorable in condition of small dent puller. They have a slide hammer with shaft to act thrust upward &shock to the bearing.

What is the safest type of bearing puller?

1. Bearing split ter plates. Bearing splitter plates are safest types of bearing pullers to use. From technically point of view they are actually not puller as they uses the mechanism of pushers, they tends to push and pop ( meet or fixed) with the shaft. Bearing splitter plates.

What are the main components of a puller?

Main components of puller. Some main parts of the pullers assembly are listed below: Hexagonal head on bearing puller – hexagonal head is attached to the forcing screw. It is fixed with socket wrench for rotation with ease.

What is a bearing splitter plate?

Bearing splitters plates mainly consist of two plates held together with respective to their large diameter, heavy nut with good duty screwed with the help of nut on the all 4 ends.

What is a bearing puller cross arms?

Bearing pullers cross arms – the cross arms attaches the legs to forcing screw. Reversible claw legs on a bearing pullers – legs allows internal & external pulls.

What is a puller?

Types of Puller :- A puller is a tool used to remove sets from the rotating machine shaft. The most common application of puller is removing a caped set of ball or tapered bearing from a rotating shaft. For example In car transmission pullers are made up of steel of tool grade. While tool grade is harder than the parts they are used on.

What is a bar type with side rod threaded into bearing separator?

Bar type with side rod threaded into bearing separator provides knife edge to get behind components or when there is not good gripping edge at all.

Looking for the best Bearing Pullers?

Discover now our comparison of the best Bearing Pullers. It is never easy to choose from the wide range of offers. On the market, you will find an incalculable number of models, all at different prices.

What is the purpose of a comparison site?

When you search for a product on the Internet, you can compare all the offers that are available from the sellers.

What are the components of a puller?

Common components to remove include bearings, gears, wheels, pins, bushings, sleeves, couplers, sprockets, and pulleys.

How many tons are in a puller?

Pullers are available with a wide range of capacities. The majority of models available range somewhere between 2 and 64 imperial tons. However, specialist 2 and 3 jaw 100-ton puller units are available from Enerpac. These large and heavy products are mounted on a cart with an on-board lift and hydraulic pump.

What is synchronous lock grip puller?

The synchronous feature of Enerpac lock grip pullers allows all jaws to move simultaneously. Benefits of this feature are that the spindle stays centered on the shaft, misalignment is prevented, set up requires fewer people, and takes and less time.

How do hydraulic pullers work?

Mechanical and Hydraulic Pullers. Mechanical pullers work by rotating a crossbar which moves the centre bolt/force screw towards the shaft. Hydraulic pullers include an integral hydraulic cylinder that is powered by a pump to apply the required force.

What is the locking mechanism on a puller?

The locking mechanism helps prevent jaws from slipping off the application during the pulling process. Turning the puller handle locks the jaws onto the application – allowing the shaft mounted component be pulled free when the spindle is turned.

What is included in a master puller set?

A typical set will include the puller, a pump, a hose, and pressure gauge. Master puller sets include not just one puller type but also, cross bearing puller, a bearing separator, and a bearing cup puller. See Different Types of Enerpac Puller.

What is an internal puller?

An internal puller is used with an attached slide hammer which allows a high-impact force to be applied.

What is a pilot bearing puller?

Also known as pilot bearing pullers, use these pullers to grip the interior edge of press-fit bearings, oil seals, and bushings.

How much force can a puller set have?

Move the immovable— this puller set includes a hydraulic hand pump so you can create up to 17 1/2 tons of pulling force.

How to make old puller work like new?

Make your old puller work like new by replacing worn forcing screws.

What is a puller cage?

These pullers have a cage around the jaws that keeps them aligned so you can secure bearings and pulleys quickly .