Weight varies depending on design; a two-blade propeller weighs between 10 and 14 pounds and a three-blade propeller weighs between 11 and 15 pounds. The difference in weight (from using a wood-core prop instead of a metal prop) will provide a noticeable savings in fuel alone.” Unfortunately, you cannot put just any prop on any engine.

How much does a 3-blade propeller weigh?

Weight of metal three-blade propeller/spinner on Cirrus SR20: 80.7 lbs. Weight of Hartzell three-blade Raptor composite prop on same plane: 51.2 lbs.

What does the number of blades on a propeller mean?

This means the propeller will “feel” smoother as it grabs water or loads the blades. The number of blades does many other things to the performance and control of a vessel.

What is a propeller and how does it work?

At the heart of it, a propeller is a rotating airfoil required to operate at widely varying airspeeds along its length. Its job is to convert the potential horsepower of the engine into effective thrust in the most efficient manner possible.

Why do pilots calculate the weight of the aircraft?

The weight of the aircraft is needed to be calculated by the pilot for every flight to ensure the aircraft remains within weight limitations set by the manufacturer. These limitations are to ensure the aircraft is able to perform and recover from all flight maneuvers and withstand structural loading.

What do Cessna propellers weigh?

Weight of Propeller = 134.7 lbs.

How big is a plane propeller?

Looking at aircraft of a similar size and performance, the propeller diameter is generally in the region of 1.4 – 1.8 m (4.6 ft to 6.0 ft).

HOW FAST DO plane props spin?

An airplane׳s engines often run faster than its propellers. For example, on one airplane, the most efficient engine speed is 3,000 RPM, while the most efficient propeller speed is about 1,500 RPM.

Can a plane fly without a propeller?

Instead of propellers or turbines, the light aircraft is powered by an “ionic wind” — a silent but mighty flow of ions that is produced aboard the plane, and that generates enough thrust to propel the plane over a sustained, steady flight.

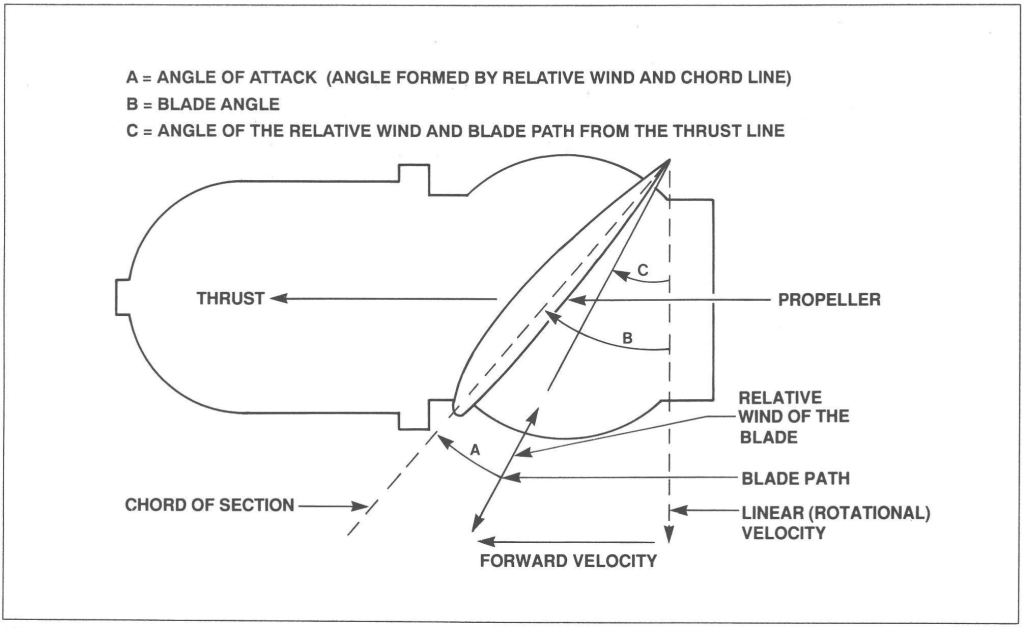

Why are airplane propellers twisted?

Propeller Design There is a twist along the length of a propeller blade because the blade speed is much higher at the tip than it is at the root. The twist is necessary to maintain a more or less constant angle of attack along the length of the blade.

What are airplane propellers made of?

Today propellers are made from wood, aluminum, or composites. The leading edge may also be reinforced with nickel for durability. The purpose of the propeller's design is to convert the energy generated by the airplane's engine into thrust that propels the aircraft forward.

How much does a propeller plane cost?

The price range for planes is vast: A new general aviation jet will cost you at least $1 million, but some used single-engine propeller planes go for under $40,000.

How high can a propeller plane fly?

With the normal propellers, you can take off up to 2500 m (8200 ft) AMSL. For flying higher, you need the high-altitude propellers, which allow taking off at altitudes up to 4800 m (15.700 ft) AMSL and flying at altitudes up to 5000 m (16400 ft) AMSL.

Why do airplane propellers turn clockwise?

In a counter-rotating installation, the propellers on the right wing turn counter-clockwise while those on the left wing turn clockwise. The principle advantage of counter-rotation is to balance propeller torque effects thus eliminating any problems associated with a Critical Engine.

What happens if a plane loses its tail?

If the plane loses just a small part of of the fin, it might be ok, but if it loses the fin completely two major things happen: The plane becomes unstable in yaw. If the plane needed such a big surface behind its center of gravity (CG) to be stable there is almost no chance of flying without it.

Can a plane fly if both engines fail?

Can a plane fly if all its engines have failed? A passenger aircraft will glide perfectly well even if all its engines have failed, it won't simply fall out the sky. Infact it can fly for around 60 miles if it loses its engines at a typical cruise altitude of 36,000ft.

Can you land a plane without fuel?

Fortunately, it rarely happens, but when it does, pilots are trained properly on how to handle a particular aircraft without any engine work. You may remember one of the most famous emergency landings when Captain managed to land his Airbus A320 over the New York's Hudson River.

How long is a Cessna propeller?

DM7652 Cessna 172 McCauley Two Blade Fixed Pitch Propeller (Length: 74-3/4")

How do you size a propeller?

Propeller Sizes are given in a set of numbers, e.g. 13x17 or 19x23 usually labeled on the propeller. The first number is the Diameter (width of the circle of the blades) and the second is the Pitch (theoretical travel distance of the angled blades in one revolution). Two other design features include Rake and Cup.

What are the 6 types of aircraft propellers?

We will look at some of the most common types of aircraft propellers and see how they are different from one another.Fixed-Pitch. ... Ground-Adjustable Propeller. ... Controllable-Pitch Propellers. ... Constant-Speed Propellers. ... Feathering Propellers. ... Reverse-Pitch Propellers.

How do you measure an airplane propeller?

Measuring Pitch Most propellers are labeled with their pitch and diameter, but it is possible to determine both given an umarked prop. The diameter is straightforward to measure of course. Measurements needed to determine the pitch of a propeller should be taken 3/4 of the way from the hub to the tip.

What Do Aircraft Weight Names Mean?

You may have been looking at the table above and thinking the numbers don’t work out because if you took the Aircraft Empty Weight and added the Maximum Fuel Weight and Maximum Cargo it could carry, it could be well over the aircraft’s Maximum Gross Weight.

Why is there a weight limit on airplanes?

Many aircraft accidents have been caused by an aircraft being overweight and the pilot/s have not had enough power or maneuverability to prevent the accident.

How much does a 737 weigh?

The Boeing 737 can weigh from 132,000lbs/60,000kg to 187,000lbs/85,000kg at takeoff depending on the model, compared to a small Cessna 172 weighing ...

Why is weight needed for every flight?

The weight of the aircraft is needed to be calculated by the pilot for every flight to ensure the aircraft remains within weight limitations set by the manufacturer. These limitations are to ensure the aircraft is able to perform and recover from all flight maneuvers and withstand structural loading.

What does OEW mean in aviation?

This is sometimes referred to as OEW – Operating Empty Weight and it is the weight of the aircraft with all its equipment on board but no fuel, no passengers or no cargo.

How many blades does a propeller have?

Performance type hulls tend to show the greatest response from adding and subtracting blades. Propellers typically come with 2 to 6 blades. -BBlades [2] Regardless of the number, you generally want an odd number of blades.

How does the top of a propeller get set?

Your typical is propeller should always be fully submerged. So the top of the propeller gets set by the lightest draft waterline. On passenger vessels, we see very little variation. But for cargo vessels, there may be significant variation in the waterline between fully loaded and light loaded.

Why are propellers so fast?

The reason for its great speed would be the lack of blade drag caused by metal in the water . As blades are added to propeller hubs, the drag is increased. However, the ability to grab more water and decrease the time frame between load and unload is shortened. This means the propeller will “feel” smoother as it grabs water or loads the blades. The number of blades does many other things to the performance and control of a vessel. Performance type hulls tend to show the greatest response from adding and subtracting blades. Propellers typically come with 2 to 6 blades.

What happens when you convince a propeller blade to pack in more lift?

Generally, when you convince a propeller blade to pack in more lift, the penalty is extra drag. That leads to greater torque on the propeller and lower efficiency.

What is the vertical clearance between propeller tip and hull?

Recommendation from naval vessels: vertical clearance between propeller tip and hull should be 25% of propeller diameter .

Why do propeller blades have larger areas?

We also favor larger blade areas to avoid problems with cavitation. This should be the first check when considering smaller blade areas. When we try to squeeze extra lift out of a propeller blade, we increase the pressure drop on the blade face. That quickly leads to cavitation.

Why do ships have a propeller on the bottom?

The bottom of the propeller generally aligns with the bottom of the ship. The intent is that the ship hull should protect the propeller . This also makes it easier when the ship needs to get drydocked. It helps all around if the propeller is never below the lowest point on the ship.

How much does a 3 blade propeller weigh?

Weight varies depending on design; a two-blade propeller weighs between 10 and 14 pounds and a three-blade propeller weighs between 11 and 15 pounds.

What is the job of propellers?

Its job is to convert the potential horsepower of the engine into effective thrust in the most efficient manner possible.

Where are Sensenich props made?

It operates in two separate but co-managed locations, the original headquarters near Lancaster, Pennsylvania, and a facility in Plant City, Florida, where wood and composite propellers are made.

What is the lightest propeller?

The lightest propeller is a simple fixed-pitch one, with wood or wood-core composite construction weighing less than aluminum. Constant-speed propellers add considerable weight, often where it isn’t wanted from a center of gravity standpoint, in trade for flexible performance options and reduced workload.

What is the lightest three blade propeller?

DUC’s SWIRLBLACK-3 Hydraulic is termed the world’s lightest three-blade constant-speed hydraulic propeller, along with the FLASHBLACK Hydraulic, which comes as a two- or three-blade configuration with an Inconel leading edge. The company also offers 100% electric variable-pitch propeller systems with carbon/titanium blades, available in two-, three-, four- or five-blade models.

What is a fixed pitch propeller?

A fixed-pitch propeller is, as the name implies, an unchangeable concession between climb performance and cruise speed. A ground-adjustable prop has its blades fitted into a hub that allows rotation to change pitch through a range of options.

What is the difference between wood and composite propellers?

Wood props, on the other hand, have a natural ability to absorb vibration and they’re cheaper. Composite construction offers extended life and some ability to flex into a different pitch under load .

What are metal propellers?

The metal propellers installed were hand-me-down types off of wrecked or canabalized aircraft, or, at best, were "serviceable" used propellers. It is true that some of them had gone through authorized prop shops and were properly reconditioned. A good number of them, however, were cut down to salvage a bent prop.

Why are metal propellers so popular?

I guess one reason for the popularity of the metal propeller is, believe it or not, because it is much heavier than a wood prop. Most homebuilt designs are prone to be tail heavy and a metal prop often helps to balance things up. Wood props are nevertheless gaining in popularity again.

What does it mean when a prop is cut down?

What it means is that they have a damaged prop which was probably cut down and refinished. It can no longer be used legally on a store bought aircraft so why not sell it to the homebuilders . . . they will use anything. Well, from some of the propeller accident reports I've read about, it may be true.

What is the static rpm of a fixed pitch propeller?

Lycoming advises that, when using a fixed pitch propeller, the static rpm should be 2300 plus or minus 50 rpm when the engine is rated at 2700 rpm.

Can a tail dragger make a wheel landing?

There is a beautiful sleek all-wood tail dragger job I know of that could never make a wheel landing safely because it has little, if any, propeller ground clearance. Anyhow, by all means do consider the requirement for safe ground clearance in selecting your propeller diameter. WEIGHT AND BALANCE IS A FACTOR.

Does Joe know what aircraft he came from?

Joe doesn't know what aircraft it came from but he realizes he won't need one himself for a couple of years, so he will let you have it pretty cheap. The offer is tempting for you have just found out what the prices are for new metal props. The money you have set aside may not be enough for a new propeller.

Does Joe down the street have a propeller?

By Tony Bingelis (originally published in EAA Sport Aviation, February 1973) YOUR AIRPLANE IS just about finished and you do not yet have a propeller for it. Joe down the street has a good metal prop but the tips are curled from a taxiing accident. Joe doesn't know what aircraft it came from but he realizes he won't need one himself for a couple ...

What is MT propeller made of?

Another way to think of MT Propellers products is as a wooden blade mounted in a metal base and covered with composite material for protection and durability. The companys composite blades start life as a wooden blank, made from layers of both beech and spruce; the latter is used predominantly in the blade root. Once the woodworking is complete, the wooden core is reinforced by layers of epoxy fiberglass, Kevlar or carbon fiber and sealed by several

What are composite props made of?

For example, Sensenichs composite blades use a pre-impregnated material consisting of glass fabric and unidirectional carbon fiber. Layers of this material are computer-cut to size and shape, then theyre laid up and heat/pressure is applied for curing. The resulting blade actually is hollow in places, but the layers are cut and laid to create an internal structure.

Why do airplanes use composites?

Performance is another reason to go composite, according to both MT and Hartzell. In addition to the weight savings and how it will impact your airplanes useful load, reduced weight for the engine to spin can translate into less of the available power being wasted by turning the prop. More power is available to put into thrust. Reduced vibration also should result from changing an all-metal prop to composite, since composite materials tend to dampen various harmonics the engine produces, according to MT, rather than support and amplify them as all-metal props can. Not only is reduced vibration good for the prop itself, anything working to dampen

Why change an all metal prop to composite?

Reduced vibration also should result from changing an all-metal prop to composite, since composite materials tend to dampen various harmonics the engine produces, according to MT, rather than support and amplify them as all-metal props can.

Is composite material good for aviation?

Composite materials are not news in general aviation applications. Their traditional advantages-less weight, often-greater strength and relative ease in forming complex shapes-are well-known. Those characteristics, coupled with reduced need for skilled labor to, say, build a wing or fuselage when compared to traditional manufacturing methods make them ideal for aviation applications. And, thanks to Cirrus, Diamond and Lancair/Columbia, along with hordes of experimental designers and LSA manufacturers, its the exception these days

Is MT prop a composite?

If your airplane is FAA-certified and requires a fixed-pitch prop, the only composite choice of which were aware is something from MT Propellers. But thats not a bad thing: Their products have racked up an enviable track record overseas and here in North America, especially when mounted on fixed-pitch Diamond DA20s and LSAs.

Is it better to swap a metal prop for composite?

that energy before its transmitted to the engine and airframe can be beneficial. Many owners report smoother operation after exchanging a metal prop for composite.

Does a -7 work?

In a -7, it works out just fine. Also, the kick in the pants on takeoff is tremendous!

Does Hartzell have weight specs?

I find it odd that Hartzell will post all the specs on the full line of props but only a few have the weight listed. I would think this is a pretty important number not to be left out of the specs. I've searched lots of Hartzell catalogs and found very little weight data. I guess a call or email to Hartzell would get you the data you need.

Why is it important to know the maximum weight that an aircraft can carry?

A more massive load requires more engine power. For that reason, more fuel is needed to power the plane. That is why it is important to know the maximum weight that the aircraft can carry to still function at an optimal rate.

What does it mean when an airplane is in the climb phase?

It means that a lot of fuel will be used during this phase. The consumption gradually decreases as the airplane approaches the climb phase. Fuel consumption becomes even lower during the cruise phase. The second thing to consider is the size of the aircraft’s engine or the number of engines. The more engines present, the more fuel needed.

What is the first phase of a flight?

First is the phase of flight . The phase of flight means the period within a flight. The primary flight phases are take-off, climb, cruise, descent, and final approach. The amount of fuel needed for an aircraft to function varies depending on the phase.

Do you need to worry about your aircraft consuming more fuel?

With Knisley Exhaust, you do not need to worry about your aircraft consuming more fuel than it normally does.