A cross-cut sled can be any size you want. Just keep in mind the bigger it is, the harder it is to handle. So for me, the ideal size was approximately the dimensions of my tablesaw top. Plywood base: 34″ Wide x 30 ” Deep (1/2″ Baltic Birch Ply) Fences: 4 1/4″ Wide x 30″ Long. Runners: 30″ Long x 3/4″ Wide x 3/8″ Thick.

What size should I make my cross-cut sled?

A cross-cut sled can be any size you want. Just keep in mind the bigger it is, the harder it is to handle.

How thick should my crosscut sled be?

Just be sure the front fence is at least 1 in. thick and the rear fence at least 11⁄2 in. thick. With the partially assembled sled on the saw, place the head of a combination square against the sawblade and use the rule to mark a line square to the blade where you will position the rear fence.

How tall should a crosscut sled fence be?

The main fence should be 1 1/2" to 2 1/2 wide and 2" to 3 1/2" tall. The fence height may need to be higher in the area where the blade cuts through it. Any of the basic sled designs outlined here can benefit from a few useful accessories.

How do I make sure my cross-cut sled is square?

0:414:382 Easy Ways to Square a Cross Cut Sled's Fence - YouTubeYouTubeStart of suggested clipEnd of suggested clipNow take a framing square one that you know actually is square and place it against both fencesMoreNow take a framing square one that you know actually is square and place it against both fences adjust the sleds fence until it looks square. Then clamp it down without moving the sleds fence.

Is a crosscut sled worth it?

2:074:16Four Reasons to Use a Table Saw Crosscut Sled | Rockler Skill BuildersYouTubeStart of suggested clipEnd of suggested clipAnd finally there's angle cuts and that's the fourth big advantage to a crosscut sled. We all wantMoreAnd finally there's angle cuts and that's the fourth big advantage to a crosscut sled. We all want to be able to cut accurate miters for picture frames.

What is the best wood to use for a table saw sled?

1/2 " MDF is an excellent and recommended choice for the sled. Base the size of your sled on the size of your table saw and your woodworking requirements but not so large that it is difficult to control.

Do fence corners have to be 90 degrees?

A corner post should be used on a 90 degree corner to join two lines of fence. Corner posts can be used for odd angles where the angle is closer is between 45 and 90 degrees. An angle of 45 degrees may require a corner post, depending the tension of the cable.

Does a crosscut sled prevent kickback?

0:0014:06Simple ZERO-KICKBACK, Repeatable-Cut Crosscut Sled ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipI think i've actually figured out a solution to all of that. And so far it works pretty darn. Good.MoreI think i've actually figured out a solution to all of that. And so far it works pretty darn. Good. Now this is my old small part sled i've run dados through it i've used it on both sides.

Is it better to be taller or shorter in fencing?

A common question from parents in regards to fencing is whether the size of their child matters. This is one question with a quick answer: It doesn't. It does not matter if a child, or even an adult, fencer is much shorter or much taller than their opponent.

Can you use a miter gauge as a crosscut sled?

Crosscut capacity. With most miter gauges you can safely crosscut stock about 12" wide; wider than that and the gauge's head can catch on the table edge during the cut.

How do you make the perfect cross cut?

0:191:31How to Make a Cross Cut in Less Than 1 Minute - PRO TIP - YouTubeYouTubeStart of suggested clipEnd of suggested clipYour board. We just need to take a couple inches off of this one. For our custom build. In. Once youMoreYour board. We just need to take a couple inches off of this one. For our custom build. In. Once you've done that use your rafter square. To make a line that you're going to be able to see.

What runners should I use for crosscut sleds?

0:5610:54Easy! Make Runners for Table Saw Sleds! - YouTubeYouTubeStart of suggested clipEnd of suggested clipOne option is UHMW plastic UHMW stands for ultra high molecular weight. If you care it doesn'tMoreOne option is UHMW plastic UHMW stands for ultra high molecular weight. If you care it doesn't really shrink or expand at all it is flexible though you can buy it in sheets.

How much weight should a sled be loaded?

Load the sled with a moderate-to-heavy load — 70% of your maximum load is a good place to start. If you don't know this, go with a weight that is 70% of your body weight.

What runners should I use for crosscut sleds?

0:5610:54Easy! Make Runners for Table Saw Sleds! - YouTubeYouTubeStart of suggested clipEnd of suggested clipOne option is UHMW plastic UHMW stands for ultra high molecular weight. If you care it doesn'tMoreOne option is UHMW plastic UHMW stands for ultra high molecular weight. If you care it doesn't really shrink or expand at all it is flexible though you can buy it in sheets.

How many teeth per inch does a crosscut have?

Crosscut saws have 8 to 15 pointed teeth per inch.

Does a crosscut sled prevent kickback?

0:0014:06Simple ZERO-KICKBACK, Repeatable-Cut Crosscut Sled ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipI think i've actually figured out a solution to all of that. And so far it works pretty darn. Good.MoreI think i've actually figured out a solution to all of that. And so far it works pretty darn. Good. Now this is my old small part sled i've run dados through it i've used it on both sides.

What is a large sled?

A large sled is bulky to use with smaller pieces of wood.

What determines how wide a material you could cut?

Length would determine has wide a material you could cut.

How long is a spherical cylinder?

It's an inch or so wider than the miter slots are apart, and about 12" long.

How many feet of depth does a woodworking cover hold?

They recommended two, a longer narrow one to support cross-cuts, and a wider one to help break down sheet goods that will hold two feet of depth.

Can you make a sled any size?

You can make the sled whatever size you desire.

How many screws do I need to put on a sled?

I then screwed the back fence of the sled into place with four screws. The back fence doesnt need to be square, it just needs to be fastened over the kerf in the sled, as its primary function is helping to hold the sled together once you complete the kerf cut.

Do screws need to sit flush?

Once my holes were drilled, I flipped the base over and countersink the holes. The screws need to sit flush or slightly below the surface so they don’t interfere with or mark up your work pieces.

Can you make a cross cut sled with plywood?

There really isn’t much plywood material needed for this project. I made mine using scraps I already had. You need enough material to make the front fence (nearest you) the back fence and the sled base. You can make your cross cut sled as wide and deep as you wish to accommodate your needs.

Can a miter saw handle a cross cut?

Hi Clyde! Miter Saws are a great alternative but there are some limitations when it comes to how wide your stock can be. Most miter saws can handle 8-12 inch crosscuts. My cross cut sled can handle 20 inch panels. Also, miter saws are notoriously inaccurate when it comes to setting and maintaining square cuts. A well made cross cut sled will be accurate for its use life. And finally some folks might not have a chop saw but only a table saw. Hope that explanation helps!

What kind of saw should I use for cutting boards?

I think a decent circular saw combined with a quality blade and a LONGGGGGGG straightedge work fine for cutting wide/long awkward boards. Using a cross cutting sled works ok for smaller boards.

How wide is UHMW plastic?

For runners, I bought UHMW plastic from McMaster-Carr. It's reasonably-priced, it's exactly 1/2 wide (and available in other sizes as well). It slides perfectly!

Is a cutline parrallel perpendicular to the edge?

You get a cutline parrallel to the rip fence, not perpendicular to the edge.

Is a straight edge better than a table saw?

See I like simple elegant answers like that. a straight edge will work just as nice as a table saw and much nicer than a table saw with a sled.. Sleds are too darn awkward for long boards and take up too much space for their use.. straight edges on the other hand can be stored with the rest of the lumber or some much smaller space..

Does size matter on a sled?

Size does matter, IMHO. The wider the sled is (perpendicular to blade) the easier it is so set a stop b/c you just clamp a scrap block to the fence. For longer stuff i'll clamp an arm to the back side of the fence with a block attached at the end. Also having it 48" wide gives me ample registration space for jigs (up to 24" in fact) I used some 1 and 1/8" straight grained red oak screwed and glued to the far and near eadges for the fence.

How to make a sled for a sled?

First, cut the sled base as square as possible, making the length slightly longer than your final dimension (approx. 1/2" or so). Second, after determining how much of the sled you want on each side of the blade, cut it in two.

How thick should a sled fence be?

The fences should be at least 3" high and 1 3/4" thick. The length of the front and the rear fences can vary depending on the preference of the user. Since the purpose of the front fence is to simply help hold the sled together, I opted for a shorter fence. This also reduced the total weight of the sled.

How to attach fence to sled?

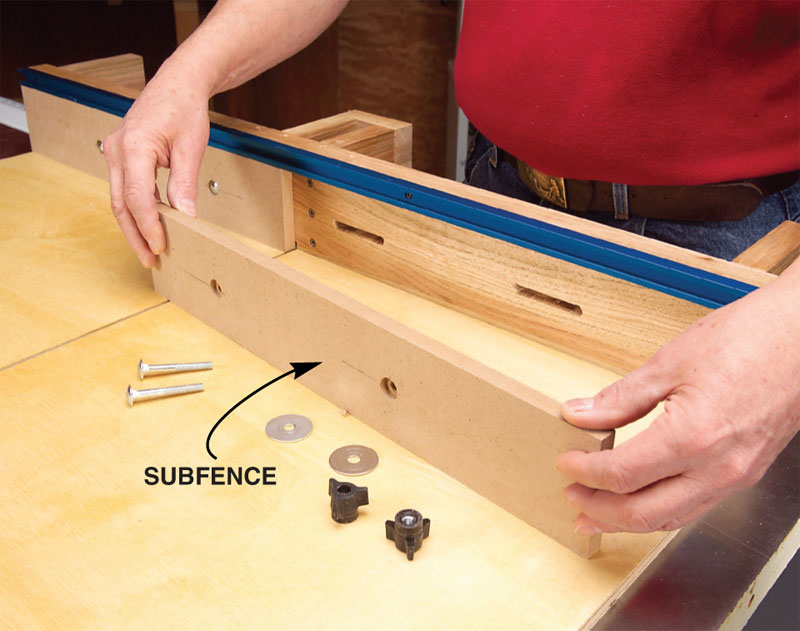

1) Drill countersunk holes through the sled base to attach the fences to the sled (later in this step). 2) Photo #1: Put the sled halves in position on the table saw and lightly clamp them together so the runners are pressing against the blade side of each miter gauge slot.

What are the disadvantages of wood sled runners?

The disadvantage of wood runners is that the wood can swell with changes in humidity making smooth travel through the miter slots difficult or impossible. Tip #1: Since most wood movement is with the grain, mill the sled runners with the grain running vertically as shown in the photo.

What are sled runners made of?

They are most often made from hardwood such as maple or white oak, however, steel, aluminium or plastic runners are also options. Wood runners are more commonly suggested, most likely, because of the moderate cost.

What is a Kentm sled?

More About KentM ». A cross-cut sled for the table saw is a must have jig for any serious woodworker. More accurate than a miter gauge, it also makes cross-cutting any board easy and safe. However, in order to provide the proper results it must be built with care.

How to get an accurate cut?

The only way to get an accurate cut is to have the rear fence perfectly square (at a 90 degree angle) to the saw blade. Most often a single square is set against the blade and the fence to determine the proper fence position.

What is the rear fence on a sled?

The rear fence is used to help hold the sled together.

How to stop a saw blade from cutting through a sled?

The saw block has to be at the bottom of the sled. Carriage bolts attach stop blocks to the table saw bed. Add wood glue onto the surface and put the plywood piece on top .

How to build a crosscut led?

Amongst the materials are the base, runners, and two supports at the sled ends. The plywood should have smooth surfaces. Cut the strips of plywood that you are using for the stiffener, blade cover, and front fence. They have to be ¼ inch wide and 12 inches longer than the finished size. That leaves room for trimming edges .

How to square plywood?

Use the table saw fence to square the material. You square the saw fence with the blade. Raise the saw blade and press the square against it. Adjust the squares if they are not perfect. Put some weight on top of the plywood and leave the material for an hour .

How to measure table saw blade?

When you want to measure your table saw, you make use of the tape measure. Measure the distance from the fence to the close edge of the saw blade tooth. You choose the saw blade tooth from the left or the right side.

What type of wood is used for a sled?

If you have a wood sled, you need to run tests to choose the wood for your sled. The types of wood are softwood and hardwood. The names are self-explanatory. High-quality sleds are stable and durable, and that makes them appropriate for hardwood. Longer runners are not difficult to run on high-quality sleds.

What does the distance on a saw blade mean?

The distance represents the bigger piece of wood pressing between the saw blade and the throat.