Pasteurization is the process of heating and cooling food to kill bacteria.... Pasteurization does not add any chemicals or other additives to milk, nor does it remove the nutrients found in milk. It is simply a process of heating and cooling to kill harmful pathogens. It does not alter milk otherwise. What is chemical pasteurization?

What are the steps in pasteurization?

What are the steps involved in the pasteurization of milk?

- Step. 1: Needed Stuffs. for this you will need.

- Step. 2: Preparations. Boil empty milk bottles submerged in water for 10 minutes to disinfect them.

- Step. 3: More Preparations. Pour raw milk into the top of a double boiler and fill the bottom section with water.

- Step. 4: The Pasteurization.

- Step. 5: Cooling and Storing the Milk. Click to see full answer. ...

What are steps in pasteurizing?

Pasteurizing raw juice kills harmful bacteria so it can't make you sick. Pasteurizing is a fairly simple process. You simply heat up the juice to just below boiling. Be sure to pour it into a clean container, as you'll just recontaminate if you don't. To increase the time you have to drink it, pour it into sterilized jars.

What is the difference between pasteurization and fermentation?

pasteurization is the process of heating the object what ever it is for example milk it is heated then the harm full things are killed and made safe.. .. fermentation is the chemical breakdown of a substance by bacteria, yeasts, or other microorganisms, typically involving effervescence and the giving off of heat.

What are the advantages of pasteurization?

pasteurization is the process of heating a fluid to a specific temperature for a definite period of time without allowing recontamination during the heat treatment process and then cooling it immediately. Two (2) major benefits are: 1. Destroy disease causing microorganisms (pathogens) that may be present in milk thereby increasing in food safety. 2.

What is pasteurization in food?

Why is pasteurization important?

What is the term for the application of beta rays to food to increase storage time?

How long does it take to pasteurize milk?

How long can you keep milk in a sterile container?

See 2 more

About this website

What type of process is pasteurization?

Pasteurization or pasteurisation is a process in which packaged and non-packaged foods (such as milk and fruit juices) are treated with mild heat, usually to less than 100 °C (212 °F), to eliminate pathogens and extend shelf life.

What is chemical pasteurization?

Pasteurization is the process of applying low heat to kill pathogens and inactivate spoilage enzymes. It does not kill bacterial spores, so pasteurization does not truly sterilize products. Pasteurization is named for Louis Pasteur, who developed a method to kill microbes in 1864.

What chemicals are used in pasteurization?

Table 1.Target ChemicalAbbreviationChemical ClassChlorpyrifosCLPOrganophosphate insecticidePermethrinPERPyrethroid insecticideMonoethylphthalateMEPPhthalate plasticizerMono-2-ethylhexylphthalateMEHPPhthalate plasticizer21 more rows•Mar 30, 2018

Why is pasteurization a physical change?

Solution : Pasteurization of milk does not involve any considerable physical or chemical change. During this process, harmful bacteria are killed and a negligible % of constituents of milk undergo change.

What are the 3 types of pasteurization?

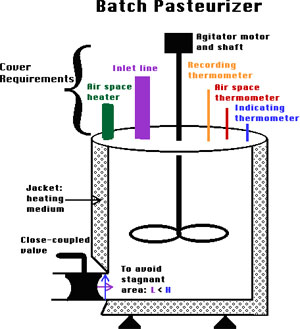

Different Types of Thermal Processing MethodsThermization: Heat the milk to between 57°C to 68°C and hold for 15 minutes. ... Batch pasteurization: Also known as low-temperature long time (LTLT) pasteurization. ... Flash pasteurization: Also known as high-temperature short time (HTST) pasteurization.More items...•

Is pasteurization a type of sterilization?

Pasteurization is not a sterilization process; its purpose is to destroy all pathogenic microorganisms with the exception of bacterial spores.

What are the two methods of pasteurization?

When it comes to pasteurizing dairy products such as milk and cream, two of the most common types are vat pasteurization and HTST pasteurization.

What is difference between sterilization and pasteurization?

Its main difference lies in the fact that sterilization seeks to eliminate all microorganisms and spores, while in pasteurization, the most resistant forms and some spores remain present.

What is the process of pasteurization of milk?

Pasteurisation makes sure milk is safe to drink (by killing any harmful bacteria) and also helps to prolong its shelf-life. The process of pasteurisation involves heating milk to 71.7°C for at least 15 seconds (and no more than 25 seconds).

Is pasteurization a physical process?

Pasteurization is a physical process based on the heat treatment of liquid and solid foods to substantially reduce their microbiological load by controlling temperature and time. This technique allows the elimination of microorganisms that cause food spoilage or are a problem for food safety.

Is heating milk a physical or chemical change?

No worries! We've got your back. Try BYJU'S free classes today!

Is milk a biological chemical?

Milk contains many natural enzymes, and other enzymes are produced in milk as a result of bacterial growth. Enzymes are biological catalysts capable of producing chemical changes in organic substances.

What are the two methods of pasteurization?

When it comes to pasteurizing dairy products such as milk and cream, two of the most common types are vat pasteurization and HTST pasteurization.

Is vat pasteurized milk safe?

Ultra-pasteurization employs temperatures high enough to kill all pathogens in two seconds or less. Vat pasteurized milk flips the ratio, favoring a lower temperature and a longer heating time. The two methods result in the total elimination of harmful pathogens.

How many types of pasteurization are there?

Organic Valley mainly uses two kinds of pasteurization: High Temperature Short Time (HTST, or simply “pasteurized”) Ultra-High Temperature (UHT, or ultra-pasteurized)

What is pasteurization in simple words?

pasteurization, heat-treatment process that destroys pathogenic microorganisms in certain foods and beverages.

What Is Pasteurization? Learn About the History and Benefits of ...

As recently as the nineteenth century, humans risked serious illness or even death by drinking liquids—such as milk, juice, or even water—that were several days old. By contrast, today’s beverages have a long shelf life thanks to the pasteurization process, named for the nineteenth century French scientist Louis Pasteur.

Milk Pasteurization Definition, Procedure, Types, Purpose

Pasteurization Type Typical Product Typical Storage Temperature Holding Time; Batch, vat: Milk: Refrigerated: 145°F (62.8°C) 30 min “ Viscous products, or products with more than 10% fat or added sweetener

Pasteurization - an overview | ScienceDirect Topics

Pasteurization. Pasteurization is now defined as the process of heating every particle of milk or milk product in properly designed and operated equipment to any of the one specified pasteurization time–temperature combinations (Food and Drug Administration, 2011), most commonly 72°C for 15s, and is effective in destroying human pathogens or reducing their presence to a safe level.

Why is pasteurization important?

Today, pasteurization is used widely in the dairy industry and other food processing industries to achieve food preservation and food safety.

What is pasteurization of milk?

Pasteurization or pasteurisation is a process in which packaged and non-packaged foods (such as milk and fruit juice) are treated with mild heat, usually to less than 100 °C (212 °F), to eliminate pathogens and extend shelf life. The process is intended to destroy or deactivate organisms and enzymes that contribute to spoilage or risk of disease, including vegetative bacteria, but not bacterial spores.

What did Louis Pasteur's pasteurization experiment prove?

Louis Pasteur's pasteurization experiment illustrates the fact that the spoilage of liquid was caused by particles in the air rather than the air itself. These experiments were important pieces of evidence supporting the idea of the germ theory of disease.

When was pasteurization first used?

A traditional form of pasteurization by scalding and straining of cream to increase the keeping qualities of butter was practiced in Great Britain in the 18th century and was introduced to Boston in the British Colonies by 1773, although it was not widely practiced in the United States for the next 20 years.

What is the process of pasteurizing milk?

General overview of the pasteurization process. The milk starts at the left and enters the piping with functioning enzymes that, when heat-treated, become denatured and stop the enzymes from functioning. This helps to stop pathogen growth by stopping the functionality of the cell.

Why was milk pasteurized?

Pasteurization was originally used as a way of preventing wine and beer from souring, and it would be many years before milk was pasteurized. In the United States in the 1870s, before milk was regulated, it was common for milk to contain substances intended to mask spoilage.

How to make wine not acidic?

To remedy the frequent acidity of the local aged wines, he found out experimentally that it is sufficient to heat a young wine to only about 50–60 °C (122–140 °F) for a short time to kill the microbes, and that the wine could subsequently be aged without sacrificing the final quality. In honour of Pasteur, this process is known as "pasteurization". Pasteurization was originally used as a way of preventing wine and beer from souring, and it would be many years before milk was pasteurized. In the United States in the 1870s, before milk was regulated, it was common for milk to contain substances intended to mask spoilage.

What is pasteurization in science?

Pasteurization (or pasteurisation) is the process by which heat is applied to food and beverages to kill pathogens and extend shelf life. Typically, the heat is below the boiling point of water (100 °C or 212 °F).

Why is pasteurization important?

Early pasteurization of wine and beer was intended to improve flavor. Canning and present-day pasteurization of food primarily target food safety. Pasteurization kills yeast, mold, and most spoilage and pathogenic bacteria. The effect on food safety has been dramatic, particularly regarding milk .

Why is liquid pasteurization used?

Liquid pasteurization occurs in a closed system to avoid contamination during cooling. MiguelMalo / Getty Images. Food may be pasteurized after it has been packaged into a container. For glass containers, hot water is used to attain the desired temperature, to avoid shattering the glass.

What is the name of the French chemist who invented the process of pasteurization?

Pasteurization is named in honor of French chemist Louis Pasteur. In 1864, Pasteur developed a technique to heat wine to 50–60 °C (122–140 °F) before aging it to kill microbes and reduce acidity. However, the technique had been in use since at least 1117 AD in China to preserve wine. In 1768, Italian scientist Lazzaro Spallanzani demonstrated ...

How does pasteurization affect food?

How Pasteurization Affects Food. Pasteurization greatly reduces the risk of food poisoning and extends shelf life by days or weeks. However, it does affect the texture, flavor, and nutritional value of foods.

When did Pasteur use the boiling method?

In 1795, French chef Nicolas Appert sealed foods in glass jars and immersed them in boiling water to preserve them (canning). In 1810, Peter Durand applied a similar method to preserve foods in tin cans. While Pasteur applied his process to wine and beer, it wasn't until 1886 that Franz von Soxhlet suggested pasteurization of milk.

What was the most likely explanation for Pasteur's experiments?

The most likely explanation is that Pasteur's experiments demonstrated particles in the air, as opposed to pure air, caused food spoilage. Pasteur's research pointed toward microorganisms as the culprit for spoilage and disease, ultimately leading to the Germ Theory of Disease.

What is thermal processing?

The term thermal processing applies to a range of heat treatments used for food processing. In general, the point of thermal processing is to kill pathogens and inactivate enzymes that cause negative changes to the food during storage. The most common type of thermal processing is the kind that happens in the kitchen at mealtime.

What is the reaction between proteins and sugars that causes browning?

The Maillard reaction, a chemical reaction between proteins and sugars, occurs at higher heats and causes browning, discoloring the milk.

Why does milk taste cooked?

Protective enzymes in milk are inactivated, making it more susceptible to spoilage. The Maillard reaction, a chemical reaction between proteins and sugars, occurs at higher heats and causes browning, discoloring the milk. The milk may taste "cooked.".

Does pasteurization kill microorganisms?

Pasteurization constitutes one of the milder forms of thermal processing. Ultra-high temperature and sterilization methods kill all microorganisms in the food, while milder heat treatments like thermization and pasteurization only kill some of them.

Does pasteurization of milk kill pathogens?

The pasteurization of milk kills off the most heat-sensitive pathogens but retains the qualities of milk that consumers expect: creamy texture, fresh flavor and milky-white color.

What is the chemical used to pasteurize almonds?

This was due to a string of salmonella outbreaks in the early 2000's. Many large almond processors use a pasteurization chemical called propylene oxide, or PPO. While PPO passes FDA safety guidelines, we feel that added chemicals are not necessarily ideal ...

Why do we steam pasteurize almonds?

That's why we choose to steam pasteurize our almonds. This is a flash heating process using natural water steam that kills bacteria. The almonds are exposed to steam for 8 seconds at 210-215F. Then for 44 seconds they are moved through a high-heat dehydration tunnel to remove the moisture resulting from the steam.

Do almonds need to be pasteurized?

Almonds processors are required to pasteurize, but not required to explain how on their packaging. Roasted almonds go through high heat roasting and are pasteurized through this process without PPO treatment. However, most roasted nuts have high levels of salt and flavorings which may not be what you are looking for.

What Is Pasteurization?

Commonly seen on packages and containers of milk is the term pasteurized. But exactly what is pasteurization? What does pasteurize mean? Pasteurization is a process used to treat foods and packaged foods with heat to neutralize pathogens, slow spoilage and prevent the spread of those same pathogens. But why is it called pasteurization?

How Does Pasteurization Work?

The ideal temperature for heating in pasteurization depends on the food product. Milk is pasteurized at 135 degrees Celsius for two seconds, or 15 seconds at 71.5 degrees Celsius. Acidic foods such as fruit juices are heated to deactivate enzymes and kill some spoilage microbes like yeast and bacteria.

What is pasteurization in food?

See Article History. Pasteurization, heat-treatment process that destroys pathogenic microorganisms in certain foods and beverages. It is named for the French scientist Louis Pasteur, who in the 1860s demonstrated that abnormal fermentation of wine and beer could be prevented by heating the beverages to about 57 °C (135 °F) for a few minutes.

Why is pasteurization important?

Pasteurization is most important in all dairy processing. It is the biological safeguard which ensures that all potential pathogens are destroyed. Extensive studies have determined that heating milk to 63 °C (145 °F) for 30 minutes or 72 °C (161 °F) for 15 seconds…

What is the term for the application of beta rays to food to increase storage time?

Pasteur ization of some solid foods involves a mild heat treatment, the exact definition of which depends on the food. Radiation pasteurization refers to the application of small amounts of beta or gamma rays to foods to increase their storage time.

How long does it take to pasteurize milk?

Pasteurization of milk, widely practiced in several countries, notably the United States, requires temperatures of about 63 °C (145 °F) maintained for 30 minutes or, alternatively, heating to a higher temperature, 72 °C (162 °F), and holding for 15 seconds (and yet higher temperatures for shorter periods of time).

How long can you keep milk in a sterile container?

Ultra-high-temperature (UHT) pasteurization involves heating milk or cream to 138–150 °C (280–302 °F) for one or two seconds. Packaged in sterile, hermetically sealed containers, UHT milk may be stored without refrigeration for months. Ultrapasteurized milk and cream are heated to at least 138 °C for at least two seconds, but, because of less stringent packaging, they must be refrigerated. Shelf life is extended to 60–90 days. After opening, spoilage times for both UHT and ultrapasteurized products are similar to those of conventionally pasteurized products.

Overview

History

The process of heating wine for preservation purposes has been known in China since AD 1117, and was documented in Japan in the diary Tamonin-nikki, written by a series of monks between 1478 and 1618.

Much later, in 1768, research performed by Italian priest and scientist Lazzaro Spallanzani proved a product could be made "sterile" after thermal processing. …

Pasteurization process

Pasteurization is a mild heat treatment of liquid foods (both packaged and unpackaged) where products are typically heated to below 100 °C. The heat treatment and cooling process are designed to inhibit a phase change of the product. The acidity of the food determines the parameters (time and temperature) of the heat treatment as well as the duration of shelf life. Param…

Effects on nutritional and sensory characteristics of foods

Because of its mild heat treatment, pasteurization increases the shelf-life by a few days or weeks. However, this mild heat also means there are only minor changes to heat-labile vitamins in the foods.

According to a systematic review and meta-analysis, it was found that pasteurization appeared to reduce concentrations of vitamins B12 and E, but it also increased concentrations of vitamin A. A…

Novel pasteurization methods

Other thermal and non-thermal processes have been developed to pasteurize foods as a way of reducing the effects on nutritional and sensory characteristics of foods and preventing degradation of heat-labile nutrients. Pascalization or high pressure processing (HPP), pulsed electric field (PEF), ionising radiation, high pressure homogenisation, UV decontamination, pulsed high intensity light, high intensity laser, pulsed white light, high power ultrasound, oscillating ma…

Products that are commonly pasteurized

• Beer

• Canned food

• Dairy products

• Eggs

• Milk

See also

• Food irradiation

• Flash pasteurization

• Pascalization

• Homogenization

• Pasteurized eggs

Further reading

• Raw milk expert testimony dated: April 25, 2008 Case: Organic Dairy Company, LLC, and Claravale Farm, Inc., Plaintiffs, vs. No. CU-07-00204 State of California and A.G. Kawamura, Secretary of California Department of Food and Agriculture, – Expert Witnesses: Dr. Theodore Beals & Dr. Ronald Hull

• An alternate view on the alleged safety of pasteurized vs. natural milk from Johns Hopkins University: Realmilk.com, Webmaster (12 August 2015). "The Johns Hopkin…

Commonly Pasteurized Products

History of Pasteurization

How Pasteurization Works

Improving Food Safety

How Pasteurization Affects Food

Recent Advances

- In the modern era, pasteurization refers to any process used to disinfect food and inactivate spoilage enzymes without significantly diminishing nutrient levels. These include non-thermal as well as thermal processes. Examples of newer commercial pasteurization processes include high-pressure processing (HPP or pascalization), microwavevolumetric h...