What are types of closed cell rigid insulation are waterproof?

Waterproof rigid insulation is used on roofs. Expanded polystyrene, or XPS, extruded polystyrene, or EPS, and polyisocyanurate, or polyiso, are the three main types of rigid, closed-cell insulation materials. Each type is used in a variety of applications and under conditions where resistance to water and moisture is critical.

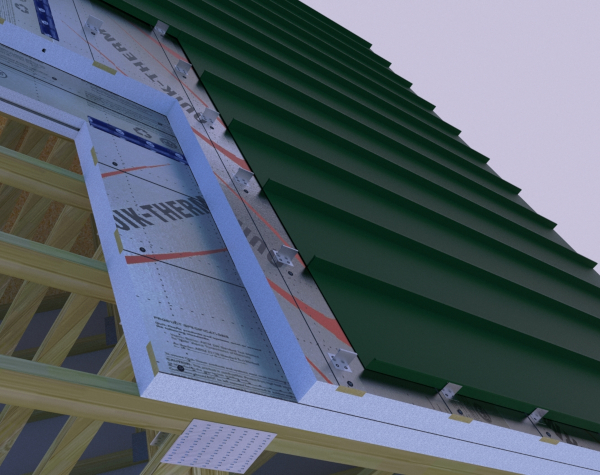

How do you install rigid insulation?

- Measure your cut with a straightedge ruler. If you're cutting the rigid foam for a specific project, measure the length and width you will need it to be.

- Mark your cutting line on the foam with a permanent marker.

- Lay the rigid foam insulation on a flat surface.

- Clamp the rigid foam to the flat surface.

What is closed cell insulation?

What is Closed Cell Spray Foam Insulation Made of?

- Two liquid components (ISO and resin) are mixed together. ...

- The “A” container is usually made up of methylene diphenyl diisocyanate and polymeric methylene diphenyl diisocyanate.

- The “B” container is typically a blend of polyols, catalysts, blowing agent, flame retardant, and surfactant.

Is closed cell foam waterproof?

While closed-cell spray foam insulation is made up of smaller cells that are completely sealed in a more solid structure and are waterproof. For the same reason, open open-cell spray foam insulation is a less expensive option because it can be used to patch up larger application surfaces with less material.

What is the R value of polyiso insulation?

What is XPS insulation made of?

What is rigid insulation?

What is EPS in concrete?

What is the R value of polyiso?

What is waterproof insulation?

What is XPS used for?

See 4 more

About this website

Is insulation board closed cell?

The majority of insulation products used in remodeling and new construction are closed cell, because they trap air for greater insulation value, and do not easily absorb moisture.

How do you know if insulation is open or closed cell?

Open cell foam is softer and more flexible, this means that the core density is lower. Typically, open cell foam has a core density around 0.5 pounds per cubic foot. Conversely, closed cell has a much higher core density due to the makeup of the cell structure.

Is foam board open or closed cell?

Closed cell foam is designed to expand to about 1″ of thickness when sprayed. With each inch offering an r-value of 7, multiple applications can be applied to achieve higher total r-values. Open cell foam is designed to expand to 3″ of thickness, meaning only one application is possible in most standard walls.

What is rigid insulation called?

Expanded Polyurethane Also known as EPU, this is a specific type of rigid foam insulation that's generally intended for insulated concrete forms.

Is Styrofoam insulation closed cell?

The word Styrofoam™ is often used to describe expanded polystyrene (EPS) foam; however, 'Styrofoam' is actually a trademarked term for closed-cell extruded polystyrene foam made for thermal insulation and craft applications.

What happens if closed cell insulation gets wet?

The accumulated water can cause intense shifts in temperature, making your home less energy efficient. Too much moisture also leads to humidity problems, built-up condensation, and even mold if you're not careful. Water can also destroy the insulation itself.

Is rigid foam board closed cell?

Rigid foam panels are all closed-cell, while spray foams are either closed- or open-cell, depending on the product. See the chart in the full article for the major foam insulations.

Is Polyiso open or closed cell?

Polyisocyanurate (Polyiso) is a closed-cell, rigid foam board insulation that is bonded to facers on both sides, which are composed of various organic and inorganic materials. Polyiso is used in roof, wall, ceiling and specialty applications within commercial and residential buildings of all types.

What is closed cell foam called?

EPDM, neoprene, EPDM/CR/SBR, and PVC/NBR are a few common types of closed cell foams, which can range in densities from 6 lb/ft3 (soft) to 19 lb/ft3 (hard). This type of material is ideal for sealing as it effectively reduces liquid and gas flow.

What is the difference between batt insulation and rigid insulation?

Fiberglass batts are commonly applied in attics and exterior walls, as they are good at preventing heat loss through the ceiling and wall panels. Loose-fill fiberglass is generally used to insulate curved or irregular architectural elements. Rigid foam boards are more moisture-resistant than fiberglass.

Is XPS foam closed-cell?

XPS (extruded polystyrene insulation) is manufactured using extrusion: a continuous process which results in a closed-cell structure with a smooth skin on the top and bottom of the board.

Does rigid insulation need a Vapour barrier?

Rigid foam insulation is it's own vapour barrier in this application, so you don't need to use the poly. Just make sure you tuck tape all the joints.

Can you spray closed cell foam over open cell foam?

No, you do not want to spray closed cell foam over open cell foam or fiberglass or cellulose.

Is it OK to have open insulation?

When insulation is exposed in areas you don't spend much time in, usually in basements and attics, you're not typically at risk of health issues. However, if you and your loved ones spend time in rooms with exposed insulation, it can lead to skin or lung issues.

Can closed cell spray foam insulation be left exposed?

The quick answer is yes and no, because spray foam can be left exposed in some areas of the home with others require a thermal barrier according to the code. If the area of the home that has been sprayed with foam is directly connected to the living space, then it has to be separated by a thermal barrier.

Is Polyisocyanurate waterproof? - DoItYourself.com Community Forums

Insulation, Radiant and Vapor Barriers - Is Polyisocyanurate waterproof? - I am laying a floating plywood floor that will be padded and carpeted over a cement sub-level basement floor. There doesn't appear to be a seepage problem, as the old, thin carpet that was directly on the cement didn't have any water damage. I

Can Foam Board Insulation Get Wet? – Home Efficiency Guide

Types of Foam Board Insulation. There are three types of foam board insulation, according to the U.S Department of Energy, such as:. Polyisocyanurate . This is the most expensive type of foam board insulation.

Open Cell vs Closed Cell Foam: Which Should I Choose?

Trying to decide what type of spray foam insulation you should use for your jobs? It’s trickier than it seems – though closed cell and open cell foam both insulate a home, they do it in different ways. In this guide we will examine open cell vs closed cell foam and help you pick the […]

Water Resistant - Foam Board Insulation - The Home Depot

Get free shipping on qualified Water Resistant Foam Board Insulation products or Buy Online Pick Up in Store today in the Building Materials Department.

What is rigid foam?

When most people think of insulation, they picture fiberglass batts and rolls—and that’s perfectly okay. However, we often forget to consider all our options. There are many different types of insulation available to us. One type that may be unfamiliar to you is rigid foam.

What are the benefits of using rigid foam insulation?

Although it’s not necessarily better than fiberglass, it does have some advantages that can make it worth considering as a replacement to other insulation types. Here are three reasons why you might want to consider using rigid foam insulation in your home:

What is the difference between closed cell insulation and open cell insulation?

Closed-cell insulation products like the rigid board are generally stronger, more durable, and resistant to natural elements. In addition, they have a higher R-value than open-cell insulation products. R-values measure the level of insulation capacity of different products. The higher the R-value, the more insulated your home will be.

What is the best insulation for basement walls?

When installing insulation in foundation walls or basements, homeowners should look for products made from either expanded polystyrene (EPS) or extruded polystyrene (XPS). While both types of foam products are naturally water-resistant, the XPS foam insulation board offers enhanced R-values and water resistance. On the downside, all XPS products will include HBCD flame retardants, and the blowing agents will negatively affect the ozone layer and contribute to global warming. Choosing thicker applications of the EPS foam board is usually the most environmentally friendly option for below-grade insulation. EPS board is almost always made from pentane blowing agents, which do not affect the ozone layer of our atmosphere.

How thick is rigid foam insulation?

They come in several different thicknesses ranging from ½ inch to 2 inches.

What type of insulation is used in a house?

The vast majority of houses across the country continue to use batts or mats of soft insulation. Fiberglass, cellulose, and even natural sheep wool insulation continue to be the most popular insulation alternatives for homeowners. Rigid board insulation is made from rugged, dense sheets of certain types of foam. The most commonly used foam products for rigid board insulation include polyurethane, polystyrene, or polyiso. Due to the chemical structure, these types of foams are considered to be "closed-cell." In contrast, the majority of insulation products are open cells.

What are the pros and cons of graphite?

Pros: Inclusion of graphite particles increase the thermal performance compared to EPS, increased vapor permeance to reduce the likelihood of trapped moisture

Is foam insulation fire resistant?

One of the downsides of rigid foam board insulation is that they do not offer superior fire resistance. Other options are far superior, in this regard, like mineral wool insulation, which is often made from rock. For this reason, EPS, XPS, and polyiso foam insulation boards almost always come with some sort of fire retardant.

What are the pros and cons of using blowing agents?

Cons: Most products include strong chemical flame retardants. The blowing agents used will deplete the ozone layer

What is the difference between closed cell foam and open cell foam?

As their names suggest, closed cell foams have a tight and closely packed together cellular structure whereas an open-cell foam has a cellular structure that is more scattered and broad.

Why is the shock absorption of closed cell foam lower than that of open cell foam?

Lower shock absorption. The shock absorption ability of a closed cell foam may be lower than that of an open-cell foam due to its tight cell structure

What is closed cell foam?

Closed cell foam is defined as a tightly knitted foam, totally enclosed by its walls. It’s made by subjecting a rubber compound to a gas under high pressure, such as nitrogen. Closed cell foam offers a wide variety of material and density options.

What are the disadvantages of closed cell foam?

Higher density and can break. Another disadvantage of closed cell foam is its higher density. This means that the foam – even though it comes with varying levels of densities, is quite firm and rigid when compared to the other conventional available options.

What is cross linked foam?

Cross linked foam is a type of closed cell foam. It is also a thick and sturdy variety, which can be beneficial for numerous applications.

What industries use closed cell foam?

Since this type of foam is offered in different types and for different and multipurpose use, industries such as automotive, medical, sports, and even construction , to name a few, benefit from closed cell foams.

Which is tougher, open cell or closed cell foam?

Closed cell foam is tougher and more rigid. Due to its greater rigidity, closed cell foam tends to be a tougher material than open-cell foam and generally maintains its shape for longer.

Why Do R-values Differ in Foam Board Products?

Since foam board comes in different variations with different compositions, each product has its own effectiveness in preventing heat energy loss. For instance, expanded polystyrene has a lower density and lighter mass. This means it has a lower R-value per inch as compared to other forms of foam board, such as polyurethane. Nonetheless, all of these types count as foam board and bring significant insulation properties to the table.

How Long Does Foam Board Insulation Last?

What good is an insulation that requires replacement after every couple of years? Foam board insulation is one of the most solid solutions out there that provides a durable barrier against the weather. Its closed-cell forms have a long life due to their high-density composition. Not to mention foam board’s resistance towards moisture, which is one of the key reasons behind insulation going bad before its due time. You can expect the R-value to remain constant as well because rigid board does not deteriorate with time. Therefore, durability is the last thing you need to worry about if you’re opting for foam board insulation.

Ready for Everything

R-TECH has been used successfully for numerous commercial, industrial and residential roofing, wall and below-grade applications. Panels are available in a wide range of sizes, thicknesses and compressive strengths up to 60 psi.

Advantages

Environmentally Friendly. Does not contain any dyes, 100% recyclable foam.

What is rigid foam board insulation?

Rigid foam board insulation is an innovative building and construction material that can significantly reduce a building's energy use and help control indoor temperature. Shop our selection of Rigid Insulation Browse Below and feel free to contact a member of our team on 786 224 0029 or via Live Chat. Read Our Guide to know more about Rigid Insulation.

What is a polyiso board?

Polyiso would be one of the best-performing insulation rigid foam insulation boards on the market today giving the highest R-values for the least thickness.

What is polyiso insulation?

Polyiso insulation can also be used whereby airtightness is required. Taping the joints and sealing the edges along with using airtight membranes will create an airtight home while maintaining a AAA rating for your homes insulation values.

Is EPS insulation good for carparks?

EPS insulation would be one of the least efficient rigid board insulations today. However, all is not lost as EPS has a high compressive strength and is great for carparks or floors that are carrying a little more weight than usual. Also, EPS insulation would be widely used in passive housing for the foundations.

Can polyiso be used in stud walls?

Polyiso insulation can be used in so many different locations and effectively can totally replace glass wool and mineral wool in almost every application. The most common places you will find Polyiso insulation would be stud walls, floors, cavity walls, roof spaces/ attics, and external walls.

Is XPS more expensive than EPS?

XPS would be in the region of 20-30% more expensive than EPS. However, XPS would be more widely used in the commercial/industrial insulation sector where compressive strength is a real requirement. Once again XPS like the other rigid board insulations is easy to cut and lightweight.

Is XPS the same as EPS?

XPS. Much like EPS in its appearance XPS is the big daddy of EPS. A foam board insulation such as Pink insulation foam FOAMULAR 250 XPS is stronger, just as light and far exceeds the compressive strength of its EPS counterpart.

Why Choose Insulation Supply, Inc.?

Better pricing, flexible quantities, volume discounts, hassle-free shipping/will-call and a huge stock of standard and clearance rigid foam insulation is a good place to start. Because of our partnership with Fortune 500 insulation manufacturer, Owens Corning™, we can offer insulation boards to you in any amount needed, all at a diminished price.

What R Value is Right for You?

R Value is defined as the ability of an insulating material to reduce heat flow. A higher value means a greater reduction in the exchange of heat. By meeting the guidelines set out by the U.S. Department of Energy, you can expect to save up to 20% on your home’s heating and cooling costs.

Would you like a quote?

Tell us how much you would like us to quote you. Specify size, density and any other applicable items for the most accurate pricing.

What is EPS foam?

EPS foam is the correct term for any form of expanded polystyrene. Expanded Polystyrene insulation is a lightweight, rigid, closed cell insulation. EPS is available in several compressive strengths to withstand load and back-fill forces.

What are the elements in EPS insulation?

EPS Insulation is composed of organic elements – carbon, hydrogen and oxygen – and does not contain chlorofluorocarbons (CFCs) or hydrochlorofluorocarbons (HCFCs).

How is EPS made?

EPS is created in a two-stage process: Raw beads are expanded using steam, creating pre puff beads, which are then cured in large bags before being conveyed to the mold.

When did ICA install pentane collection?

In 1994 ICA installed a pentane collection system for air quality control. The system captures the pentane that is released during production and reroutes it through our boiler. This reduces the amount of natural gas we use, saving natural resources while being environmentally responsible.

What size is a Hirsch mold?

ICA’s new state-of-the-art Hirsch mold allows us to manufacture block sizes anywhere from 37-1/2″ – 54″ x 49″ x 121-1/2″ – 220″. Although ICA does not stock any cut foam, regularly cut sizes are: 48 inches by 96 inches and 24 inches by 96 inches. Almost any size is available as a custom order.

Is expanded polystyrene CFC free?

Expanded Polystyrene has always been CFC- and HCF C-free. ICA is an environmentally conscientious manufacturing plant. Our in-house EPS trim is recycled and we accept recyclable EPS from our customers and the public, significantly reducing the amount of EPS that would potentially end up in landfills. In 1994 ICA installed a pentane collection system for air quality control. The system captures the pentane that is released during production and reroutes it through our boiler. This reduces the amount of natural gas we use, saving natural resources while being environmentally responsible. We continued our efforts to be mindful of our environment by installing solar panels and replacing our lighting with energy efficient fixtures. All of these actions help to keep the air of our planet cleaner and lessen the impact of landfills on the population.

What is the strength of a foamular?

With a variety of compressive strengths available up to 100 PSI, FOAMULAR® XPS stands up to the weight of growing media, pavers, water, plants, trees and even car and truck traffic on plaza decks.

What is FOAMULAR compatible with?

FOAMULAR® products are compatible with common exterior claddings and finishes, as well as other manufacturers’ products and hanging systems. High, Stable R-Values. Retains a minimum of 90% of R-Value over 20 years, even when exposed to moisture or in cases of facer delamination. Sustainability.

What is Owens Corning insulation?

Your comfort starts on the outside. Owens Corning® FOAMULAR® insulation resists moisture, keeping your basement and crawlspace dry. With its R-value of 5 per inch of thickness, FOAMULAR® helps you chase away the chill for a home that is cozy and comfortable.

What is foam insulation?

FOAMULAR® insulation is available in a wide range of thicknesses, sizes and strengths to meet nearly any project application need. From green roofs that require special strength and moisture resistance to keeping foundations protected from the cycles of the seasons, you’ll find a FOAMULAR® product designed for the coverage and performance your projects demand.

Is Owens Corning insulation durable?

Durable. Versatile. Resistant. Owens Corning® FOAMULAR® is a high-performing insulation, trusted by architects, engineers, builders and contractors to deliver superior insulating power and moisture resistance. Foamular® XPS is well suited to meet the needs for a wide variety of building applications.

Where does performance in the extreme start?

Performance in the extreme starts at the top of the enclosure. From standing up to historic weather events to complying with more stringent rainwater regulations to protecting mission critical processes, today’s roofs must deliver extraordinary performance.

Is foam insulation impervious to moisture?

Virtually impervious to moisture. FOAMULAR® XPS has up to 13X more resistance to water than EPS insulation.

What is the R value of polyiso insulation?

EPS ranges in R-values from 3.6 to 4.2 per inch, depending on the density of the rigid panel. Polystyrene has an R-value of 5 per inch, while polyiso has an R-value of 5.6 to 8 per inch , and the highest R-value of all closed-cell rigid insulation materials.

What is XPS insulation made of?

XPS is another waterproof, rigid insulation material. It is made from polystyrene pellets, which are mixed with various chemicals, then heated until the pellets liquefy. When the pellets cool, they turn into tiny beads. Then the beads are heated and injected into flat molds.

What is rigid insulation?

Rigid insulation is used in homes to insulate roofs and for below-grade applications such as insulating basements. XPS, EPS and polyiso keep homes sealed and protected against everything from rain to snow, ice and hail. Advertisement.

What is EPS in concrete?

Expanded polystyrene is commonly called beadboard. EPS is used for everything from everyday items, such as coffee cups, to producing insulated concrete forms, called ICFs, used to build concrete walls. While polyiso, XPS and EPS have some of the strongest waterproofing properties of all insulations, EPS is the weakest of ...

What is the R value of polyiso?

Polystyrene has an R-value of 5 per inch, while polyiso has an R-value of 5.6 to 8 per inch , and the highest R-value of all closed-cell rigid insulation materials. Cheryl Munson has been writing since 1990, with experience as a writer and creative director in the advertising industry.

What is waterproof insulation?

Expanded polystyrene, or XPS, extruded polystyrene, or EPS, and polyisocyanurate, or polyiso, are the three main types of rigid, closed-cell insulation materials. Each type is used in a variety of applications and under conditions where resistance to water and moisture is critical.

What is XPS used for?

The final product is rigid, dense and waterproof. As a result, XPS is commonly used for roofing and below grade to insulate cement slabs and foundation walls.