What are positive displacement pumps and their types?

What are Positive Displacement Pumps and their Types?

- Positive Displacement Pump. Pumps that discharge volumes of liquid separated by periods of no discharge. ...

- Types of Positive Displacement Pumps. Note: We have another type of classification is there, it is Linear type pumps. ...

- Reciprocating Positive Displacement Pumps. ...

- Rotary Positive Displacement Pumps. ...

What are the characteristics of a positive displacement pump?

Thinking positive: the characteristics of positive displacement pumps

- Types of positive displacement pumps. There are two main types of positive displacement pump. ...

- Rotary pumps. In rotary pumps, the pumping cavity is generally formed by closely fitting elements that revolve continuously within a fixed casing.

- Flow versus speed. ...

- Overpressure protection – relief valves. ...

What is an example of a positive displacement pump?

Types of Positive Displacement Pumps

- Rotary Pumps. In rotator type pump, the liquid can be supplied using a rotary, and its rotation moves the liquid from the lake to the releasing pipe.

- Reciprocating Pumps. ...

- Linear Pumps. ...

- Difference between Positive Displacement & Non-Positive Displacement Pump. ...

- Applications of Positive Displacement Pumps. ...

What is a negative displacement pump?

What is the difference between the positive and non-positive displacement pump?

- rotary lobe pump

- progressing cavity pump

- rotary gear pump

- piston pump

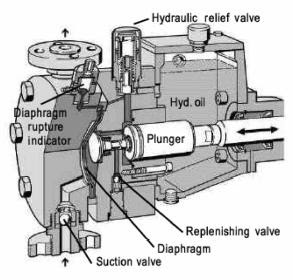

- diaphragm pump

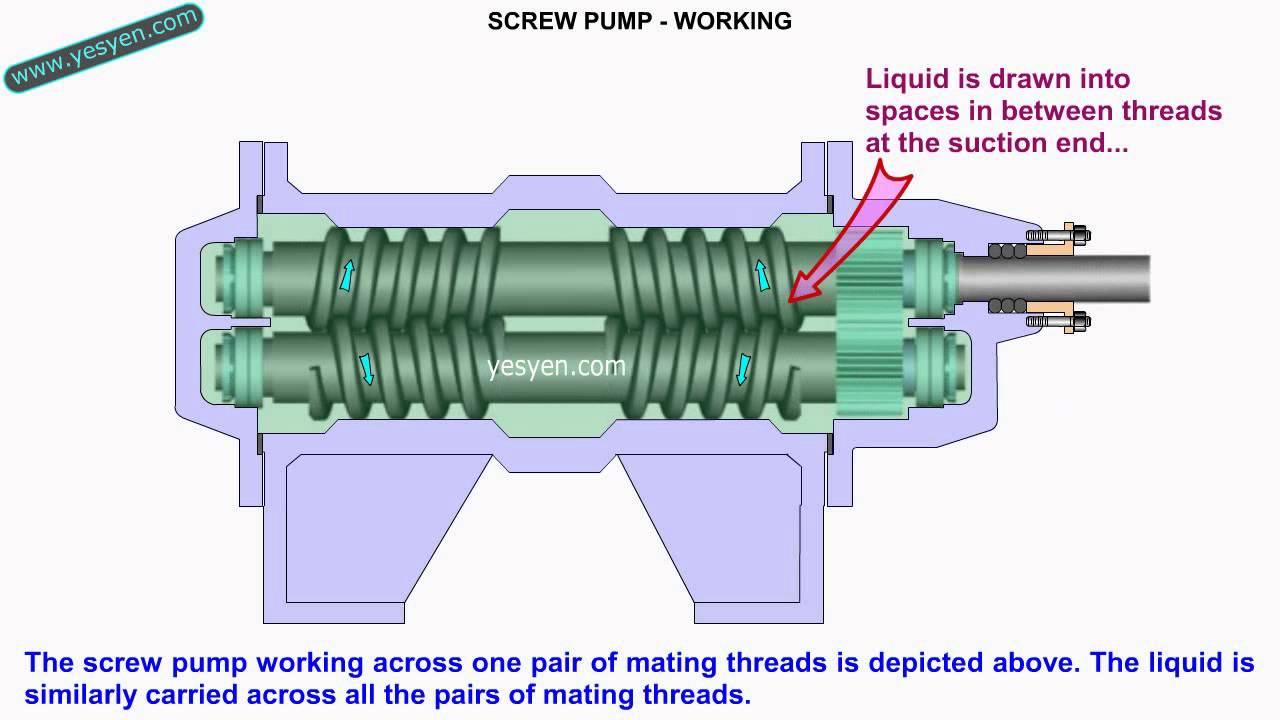

- screw pump

- gear pump

- vane pump

- regenerative (peripheral) pump

- peristaltic

What type of pump is a rotary pump?

positive displacement pumpRotary pumps are a type of positive displacement pump where for each revolution, a fixed volume of fluid is moved. These pumps are self-priming and provide near constant delivered capacity no matter the pressure.

Which type of pump is positive displacement pump?

Positive displacement pumps, which lift a given volume for each cycle of operation, can be divided into two main classes, reciprocating and rotary. Reciprocating pumps include piston, plunger, and diaphragm types; rotary pumps include gear, lobe, screw, vane, and cam pumps.

Is a rotary Lobe pump a positive displacement pump?

Rotary lobe pumps are positive-displacement type pumps that use two or more lobes rotating around parallel shafts in the pump's body to move liquids.

Which type of pump is not positive displacement pump?

centrifugal pumpA centrifugal pump is categorised as a non-positive displacement pump. Traps a certain amount of liquid and forces it from the suction to the discharge port. Flow rate remains constant as change in pressure.

What are the 3 types of positive displacement pump?

The main different types of Positive Displacement Pumps are; Progressive Cavity Pump (PC Pump) Gear Pump – Internal & External. Vane Pump (Impeller Pump)

What are rotary pumps and example?

Rotary Pumps The best examples of these pumps mainly include screw pump, internal gear, flexible impeller, sliding vane, helical twisted roots, circumferential pump, etc. These pumps are classified into three types namely gear pumps, screw pumps, and rotator vane pumps.

What are the four kinds of positive displacement pump?

Comparing 4 Types of Positive. Displacement Pumps.INTERNAL GEAR PUMPS.EXTERNAL GEAR PUMPS.LOBE PUMPS.VANE PUMPS.

What is an example of a positive displacement pump?

Examples of rotary positive displacement pumps are gear pumps, screw pumps, progressive cavity pumps, rotary piston pumps, water ring pumps, rotary vane pumps, roller vane pumps and peristaltic pumps.

What is difference between centrifugal pump and rotary pump?

Centrifugal pumps differ from rotary pumps in that they rely on kinetic energy rather than mechanical means to move liquid. Liquid enters the pump at the center of a rotating impeller and gains energy as it moves to the outer diameter of the impeller.

What are non positive pumps?

What is a non-positive displacement pump? A non-positive displacement pump's output flow rate can change in response to the pressure on the outlet. They use Newton's first law of motion to move fluid against the system resistance.

Which is the non-positive displacement compressor?

Centrifugal compressors are non-positive displacement type. Rotating impeller imparts KE to the air which is converted to PE as air passes through the diffuser.

Is a water pump non-positive displacement?

A pump that is used to circulate coolant around an engine block, or a centrifugal pump used in an industrial plant to move fluid from one holding tank to another, is usually a non-positive displacement pump.

What are non-positive displacement pump used for?

Non-positive displacement pumps are basically used for low pressure applications and are designed to work for a maximum pressure of 18 to 20 bar. Efficiency - In positive displacement pumps, efficiency increases with increasing pressure.

What is a positive displacement pump?

Rotary pumps are positive displacement pumps that use rotational, rather than reciprocating, motion during their pumping cycle. They can be designed to pump liquids, solids, gases or mixtures of all three. Like reciprocating pumps, their capacity per rotation is independent of driven speed.

What is the capacity of a rotary pump?

The capacity (Q) of a rotary pump is proportional to its displacement (D) times it driven speed (rpm) less slip (S).

What is slip in a reciprocating pump?

Slip is similar to that in a reciprocating pump and is defined as the quantity of fluid that leaks from OTO to OTI per unit time. It depends on the clearances between the rotors and case and the operating pressure. Generally, slip increases in direct proportion to pressure and is most marked in designs like the flexible member pump. Flexible vane pumps (aka rubber impeller pumps) are especially subject to slip at higher pressures and tend to be inherently protected against over pressure.

What is a progressing cavity pump?

Since each CTIO volume appears to move intact through the entire length of the pumping chamber, this particular design is often referred to as a progressing cavity pump. These pumps will accommodate a wide range of liquids and viscosities and are often used to pump sewage sludge and other process solutions with concentrated solids.

Why are peristaltic pumps used?

Peristaltic pumps are popular in chemical applications because corrosive fluids are completely contained in the tubing and do not come into contact with other parts of the pump. Figure 1 (image courtesy of Allweiler Pumps) In Figure 1 the rotor is turning counterclockwise.

What is the rotational pump cycle?

These acronyms stand for open to inlet/closed to outlet, closed to inlet and outlet, and open to outlet/closed to inlet and are equivalent to the suction and discharge strokes of a reciprocating pump.

How many gears are in a peristaltic pump?

It consists of two gears (rotors), one of which is driven by a shaft. The other acts as an idler and rotates through meshing action with the driven gear. Unlike the peristaltic pump, the gear pump has close tolerances between its rotors and the walls of the pump case.

How do positive displacement pumps work?

Positive displacement pumps add energy to a fluid by applying force to the liquid with a mechanical device such as a piston or plunger. A positive displacement pump decreases the volume containing the liquid until the resulting liquid pressure equals the pressure in the discharge system. That is, the liquid is compressed mechanically, causing a direct rise in potential energy. Most positive displacement pumps are reciprocating pumps in which linear motion of a piston or plunger in a cylinder causes the displacement. In rotary pumps, another common positive displacement pump, a circular motion causes the displacement. There are several manufacturers of positive displacement pumps which are often found in high-pressure services. As shown in Fig. 2.1, positive displacement pumps are classified as either:

Why are positive displacement pumps used as metering pumps?

Positive displacement pumps are often used as metering pumps because they accurately control flow rates by changing the speed at which the pump is driven without regard to the back pressure. They are also used to pump relatively small volumes of liquids against high pressures.

Why is it not necessary to take into consideration the coupling between pulsations in the suction and discharge pipes?

However, in many cases, it is not necessary to take into consideration the coupling between pulsations in the suction and discharge pipes because a pressure wave cannot propagate through a positive displacement pump. A positive displacement pump acts as a source with known capacity.

What is the valve that protects a pump from damage?

These pumps are normally protected from damage caused by downstream valve closing or other line blockage with a pressure-relief valve, placed between the pump and the first valve downstream.

What should a PD pump be protected by?

Thus, a PD pump should be protected by a high-pressure shutoff sensor and alarm system and also a bypass line containing a rupture disk or pressure relief valve.

What is the subscript d of a discharge pipe?

The subscript d is given to the quantities at the outlet of the pipe and the subscript p to the quantities at the pump outlet. If the outlet end of the pipe is open, Pd =0. This leads to the relation:

When to use a peristaltic pump?

Peristaltic pumps are used when either accurate metering is required or it is important that no contamination should enter the sample. As can be seen from Figure 39.14, the only material in contact with the sample is the special plastic tubing, which may be replaced very easily during routine servicing.

How does a rotary pump work?

Rotary pumps have rotating gears instead of the backward and forwards motion of cylinders like reciprocating pumps. In some cases, they can operate sealless with the speed of the rotating component creating a liquid ring. This liquid ring traps gas between the liquid ring and pump chamber to create a superficial seal while running. This motion also creates suction at the inlet.

What are the two types of rotary pumps?

Two other common rotary types are lobe pumps and vane pumps . Lobe pumps operate almost identically to external gear pumps except the lobe shape means there is no direct contact. This reduces the certainty of wear that comes with gear pumps. Vane pumps mount aspherical components on a shaft that is off-center from the inner chamber. The spherical component contains moveable vanes within that extend when the space increases. These vanes, when extended, trap fluid between them as they rotate toward the discharge port. This flexibility of the vanes comes from spring-loaded designs, or they are put under hydraulic pressure.

How does an internal gear pump work?

An internal gear pump operates by using different sized gears where a smaller one rotates around larger stationary gear. This functions similarly to external gear pumps, creating flow by trapping fluid between the cavities of the two gears. Both internal and external pumps need to be well lubricated by the fluid they pump and should never run dry because of the friction mechanics inside. They are ideal for high viscosity fluids such as oils and paints.

What is a gear pump?

Gear Pumps are a common type of rotary pump that consists of two interlocking gears. They can be either internal or external with distinction depending on the size and rotation motion of the gears.

What are the three types of external gear pumps?

There are three types of external gear pumps: spur, helical, and herringbone.

What is a Rotary Pump?

Rotary pumps are positive displacement pumps, which mean they pump a fixed amount of liquid after each revolution and are mostly used to treat viscous fluids. Regardless of the resistance to which the pump is pushing, a fixed amount of fluid is pushed with each revolution of the pump.

Functions of Rotary Pumps

They can work on fluids that have a very high viscosity. However, as viscosity rises above a certain threshold, the most effective speed decreases. This is determined by clearance and shear action.

Rotary Pump Parts

A fixed case comprising gears, cams, vanes, screws, plungers or related components, which are actuated by a rotation of the driving shaft, which are some of the types of the rotary pump.

Rotary pump design

These pumps have been developed to minimise leakage from the discharge side to the suction side with very narrow gaps between their revolving and fixed sections. As they run at comparatively slow speeds, they are vulnerable to corrosion and unnecessary wear at higher speeds, which lead to greater clearances and lower pumping power.

Types of Rotary pumps

Rotary pumps are broadly classified based on the type of their rotating element.

Internal Gear pumps

Internal gear pumps carry fluid from the inlet to the outlet ports between the gear teeth. On a stationary pin, the outer gear (rotor) drives the inner or idler gear. When the gears emerge from the mesh, voids form, and liquid flows into the cavities.

External Gear Pumps

Gears that come in and out of mesh are often seen in external gear pumps. Water runs towards the pump as the teeth emerge from the mesh, which is brought to the discharge side of the pump between the teeth and the casing. The liquid is pulled out the discharge port while the teeth return to mesh.

What is positive displacement pump?

With a positive displacement pump, a certain volume of liquid is discharged due to the thrust exerted on it by a moving member for each cycle of pump operation.

What is rotary pump?

A rotary pump is classified according to the type of element that actually transmits a liquid that is by a gear, lobe, vane, and screw-type are popular that are in use .

What is a plunger pump?

The plunger pump comprises a cylinder with a reciprocating plunger in it. In the head of the cylinder, the suction and discharge valves are mounted on opposite sides as shown in the above figure. In the suction stroke, the plunger retracts and suction valves open causing suction of fluid to enter into the cylinder.

What is the purpose of a reciprocating pump?

A reciprocating pump depends on a reciprocating motion to transmit a liquid from a pump’s inlet to the outlet. Piston, plunger, and diaphragm cause reciprocating action, which sucks the liquid from the suction, and a fixed amount of liquid is discharged by pushing them into the cylinder.

What is a lobe type pump?

Lobe-type positive displacement pumps are similar to external gear pumps in operation. They are available in single lobe, double, tri-lobe, and four-lobe construction. Particle size pumped can be much higher in lobe pumps than any other positive displacement pumps.

What is the advantage of a diaphragm pump?

The main advantage of the diaphragm pump is that there is no possibility of leakage unless the diaphragm gets damaged. The capacity of a pump is directly proportional to the diameter of the diaphragm, stroke, and rate of reciprocation.

How many types of pumps are there?

Basically, pumps are classified into two types.

What is a rotary pump?

Rotary Pumps. Rotary pumps all utilize a range of rotating or moving chamber that traps fluid and moves it from the intake side to the discharge side of the pump. Screw Pump – Screw pumps can have a single shaft with large threads on it, but it is more common to see two or three. The center shaft drives the other shafts like a screw gear.

How many types of positive displacement pumps are there?

To make it a bit easier to understand, we have broken down the most common positive displacement pumps into nine basic types based on their mechanics. These two categories of pump movement types are called ...

How does a plunger pump work?

A plunger pump works differently from a piston pump as the piston fits loosely in the cylinder, as opposed to a tight-fitting seal that a piston pump provides. The mass of the piston displaces the fluid in the cylinder as it is lowered, forcing it out the discharge side.

What happens to fluid in a rotor pump?

Any fluid trapped in the progressive cavity will eventually discharge out of the pump during operation.

How does a diaphragm pump work?

Diaphragm Pump – Instead of driving a rigid plunger or piston to displace fluid, a diaphragm pump works by utilizing a flexible elastomer cover or diaphragm. When the diaphragm expands it draws fluid into the pump and when it expands, sends the fluid out of the discharge side of the pump, utilizing check valves to ensure a one-way flow. One feature in diaphragm pumps is that it does not require a seal because the wet and dry sections of the pump are completely separate from each other.

What is a piston pump?

Piston Pump (Axial Piston Pump) – The mechanism consists of a reciprocating piston inside of a cylinder with check valves at both the intake and discharge. When the piston is on the suction stroke, the chamber inside of the cylinder expands, the pressure drops, the pressure valve on the suction side is opened, allowing fluid through the intake. By definition, check valves permit flow in one direction only, which greatly helps prevent backflow. As the valve on the suction side opens, the valve on the discharge side closes. On the discharge stroke, the piston pushes on the fluid in the cylinder, raising the pressure, closing the suction valve, and opening the discharge valve, pushing the fluid out. The benefits of a piston pump are good efficiency and capable of generating a high amount of pressure.

How does a reciprocating pump work?

Reciprocating pumps work on the principle of a chamber expanding and contracting, or reciprocating, to change the pressure within the pump to draw fluids in, and then direct it out the discharge, utilizing a series of check valves to ensure the liquid flows in one direction.