Applications of A Dovetail Joint

- The dovetail joint is used for joining both sides of a wooden drawer

- You can use it to make small boxes for jewelry and other small items

- It can be used to join guitars and violin’s neck and body

- The joints are ideal for cabinet shelf side joining

- These are used to join vertical and horizontal partitions of different structures

How to make a dovetail joint by hand?

Step-by-Step Instructions

- Preparing the Timber. Before starting on the cut, first begin with the layout, which is the most critical of the process. ...

- Measure the Depth of the Dovetails on both piece. ...

- Mark the Tails. ...

- Cut the Tails. ...

- Cleaning the Tails. ...

- Measure the Pins. ...

- Cut the Pin Board. ...

- Clean the Pins. ...

- Assemble both pieces together. ...

- Finishing. ...

How to choose a dovetail jig?

Points to Consider when Choosing a Dovetail Jig

- HOW much do you want to pay – the more you pay, the more features you get

- WHAT type of dovetails do you want – through, half-blind, sliding, variably-spaced

- HOW often will you use it – if you use a dovetail jig every day you can justify paying more and quickly learn how to use all the capabilities

How to operate a dovetail jig?

- Always wear goggles or safety glasses and a dust mask. A router cutter spinning at 20,000 rpm is loud and can create a lot of waste. ...

- Double-check that the jig is secure before you cut. Stability is vital. ...

- Don’t rush when setting up the jig. ...

- Handle the templates with care. ...

- Check out instructions online. ...

How do I make a dovetail?

There are three commonly used methods for making dovetail joints:

- Cut the joints by hand, by marking out the dovetail side and the pin side; then, use a coping saw and chisel to cut out the negative spaces. ...

- Cut the joints using a band saw or table saw. This method is labour-intensive and will not guarantee precise joints.

- Cut the joints using a box making jig with a template attached, on a table-mounted router. ...

Why is dovetail joint important?

Why the Dovetail is Important. What makes the dovetail joint so important for cabinet drawer construction is its resistance to being pulled apart. The interlocking pieces create a strong joint with just the quality wood. This joint is made even stronger with glue.

Are dovetail joints still used?

They are still used today by many experienced custom furniture makers. Dovetail joints are not only used to make a strong joint for drawer construction, but cabinet makers often use them to join the tops, bottoms and sides of cabinet cases, as was done on antique furniture.

What are the advantages and disadvantages of dovetail joints?

The interlocking dovetail joint has a large gluing area, further adding to its strength. Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

Are dovetail joints necessary?

The best drawers use dovetail construction. Dovetail refers to the type of joint that connects one side of the drawer box to another. This joinery is very important in ensuring that the drawer does not fall apart, even under heavy use.

When did they stop using dovetail joints?

Hand-cut dovetailing was the default until 1860 when uniform machine-cut joints were introduced. But fine cabinetmakers persisted in fitting their joints by hand until the early 1900s, and cabinetmakers in Europe cut dovetails by hand well into the 1930s.

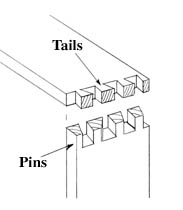

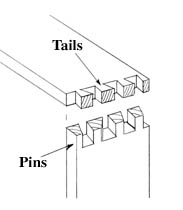

Why do they call it dovetail?

Dovetail joints are made up of two parts called pins and tails. When a master craftsman wants to marry two boards together, they cut a series of pins on one board and matching tails on the other. They are trapezoidal in shape, resembling the tail feathers of a dove (hence the name dovetail).

What is the strongest wood joint?

Mortise and Tenon Woodworking Joints One of the strongest woodworking joints is the mortise and tenon joint. This joint is simple and strong. Woodworkers have used it for many years.

What is the weakest wood joint?

A butt joint is the easiest of all simple wood joints but also is the weakest. The cut end of one board butts-up against the edge of another piece at a right angle. The key to every type of wood joint is having smooth, square cuts on the boards, and the butt joint is no exception.

Do you glue dovetail joints?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Why are dovetail joints so strong?

The 'DOVETAIL JOINT' is very strong because of the way the 'tails' and 'pins' are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

Are dovetail joints difficult?

However, dovetails also have a reputation as a difficult joint to master. But cutting dovetails by hand only looks difficult. It's actually just a process of sawing and chiseling to a line. It's that easy.

Can you cut dovetails with a jigsaw?

If you're scratching your head at the mention of my jigsaw, or if you've never considered using your jigsaw to cut intricate joinery, you're in for a treat. I often use my jigsaw to cut dovetail pins and tails. (It's best if you turn down the variable speed setting to gain additional control of the cut.)

What are the disadvantages of dovetail joints?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Are dovetail joints better?

Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

Are dovetail joints difficult?

However, dovetails also have a reputation as a difficult joint to master. But cutting dovetails by hand only looks difficult. It's actually just a process of sawing and chiseling to a line. It's that easy.

What is the purpose of dovetailing in cooking?

Dovetailing is the art of taking leftover ingredients from a previous meal and using them to create a fabulous meal the next day — ideal for when you and the kids have a busy schedule for the week. And it can save you time and money.

What Is A Dovetail Joint?

Dovetail Joint Definition: What is a dovetail joint? A dove·tail or / ˈdəvˌtāl/ joint is an interlocking joinery technique used by carpenters or woodworkers for building strong custom wood drawers. There are many different types of Dovetail Joint techniques used in woodworking such as, through dovetail joint, secret mitred dovetail joints, secret double-lapped dovetail joints, sliding dovetail joints, and half-blind dovetail joints. View more information about each type below.

Why are dovetail joints so strong?

Dovetail joints are extremely strong due to the way their pins and tails are shaped. The interlocking pins and tails make it more difficult to pull apart the joint and almost impossible to pull apart after gluing. Dovetail joints are commonly used in jewelry boxes, dovetail drawers, furniture, and cabinets where more strength is needed.

What is a secret mitred joint?

A secret mitred joint is also know as a full-blind mitred dovetail and full-blind dovetail joint. Secret mitred joints are used in box work and cabinet construction and offers the best strength out of all of the dovetail joints. These joints are used for box work or fine cabinet construction where strength is needed without a joint you can see.

What is the difference between a dovetail joint and a dovetail joint?

Through dovetail. The only difference between half-blind dovetail joints and through dovetail joints is that half-blind joint end grain can only be seen on one side vs. through joint grain that can be seen of both sides of the boards.

What is a half blind dovetail joint?

A half-blind dovetail joint also known as the single-lap dovetail joint is exactly opposite of a through joint because the end grain is not visible on the boards. Sockets house the tails at the end of the boards so the dovetail ends are invisible. Half-blind dovetail joints are commonly used for attaching drawer fronts.

What is a secret double-lapped dovetail joint?

The secret double-lapped dovetail joint is kind of the like the mitred joint but has a visible section of end grain on a single edge of the joint. similar to the secret mitred dovetail, but presents a very thin section of end grain on one edge of the joint.

How many types of dovetail joints are there?

What are the different types of dovetail joints? There are 5 different types of dovetail joint methods available.

Through Dovetail

The most basic method of creating a dovetail is called a through dovetail. Here, two pieces of wood are joined together at their ends with a finger-like interlocking method which is seen from all outside surfaces. This method is used in everyday practice for joining the corners of frames, boxes, cabinets, and other items.

Half-Blind Dovetail

A half-blind dovetail enables the woodworker to hide the joint from the front end. The tails are housed in sockets in the ends of the board that is to be the front of the item so that their ends cannot be seen. Half-blind dovetails are commonly used to fasten drawer fronts to drawer sides.

Secret Mitered Dovetail

The secret mitered dovetail joint (also called a mitered blind dovetail) is used in the highest class of cabinet and box work.

Sliding Dovetail

The sliding dovetail is a method of joining two boards at right angles, where the intersection occurs within the field of one of the boards that is not at the end. This joint provides the interlocking strength of a dovetail. Sliding dovetails are assembled by sliding the tail into the socket.

What is a dovetail joint?

The shape of the dovetail itself is highly regarded for its tensile strength and resistance to being pulled apart. The dovetail joint is composed of two parts: the pin, and the tail.

Why is a dovetail joint so strong?

The reason for the dovetail joint being so incredibly strong is that the pressure put on the joint is evenly distributed throughout the entire workpiece. Each pin and each tail is entirely reliant on one another, and meet the reliance with an entire team of support.

When is the Dovetail Used?

Within woodworking, the dovetail can be found in larger projects like timber framing and in constructing log buildings. It’s also used in smaller woodworking projects like cabinetry and other high-quality furniture construction (like holding together the sides of drawers to its front). The dovetail can be made even smaller than that! It’s also a joinery method used in antique jewelry boxes!

What angle to use for dovetail joint?

Any angle can be used to create a dovetail joint, but the angle you choose should reflect the strength of the piece of wood being used. For softer woods, it is a good idea to use an obtuse angle for your joint locking, and for harder woods, it is safe to use a more acute angle.

What is a dovetail in woodworking?

Within woodworking, the dovetail can be found in larger projects like timber framing and in constructing log buildings. It’s also used in smaller woodworking projects like cabinetry and other high-quality furniture construction (like holding together the sides of drawers to its front).

Where can I find a dovetail joint?

The dovetail joint can be found anywhere, and it’s a surefire way to distinguish between time periods of furniture manufacturing. Head on down to your local antique, find a chest of drawers and chances are you’ll find a dovetail joint that’s been holding that drawer together successfully since 1891 probably. The dovetail joint kind of looks like two hands being held together, and if that doesn’t warm the cockles of your heart I don’t know what will. (Y’know, how love lasts through the test of time and all that? Get it?)

What are the different types of dovetails?

5 Types of Dovetail. 1. Through Dovetail: also referred to as a plain dovetail, the joint meets at a 90-degree angle and both grains are entirely visible. Since the dovetail is so aesthetically appealing, the joint needn’t be covered. 2.

What is a dovetail joint?

Dovetail joints often hold two boards together in a box or drawer, almost like interlocking the fingertips of your hands. As the dovetail joint evolved through the last one hundred thirty years, it becomes a clue for the age and authenticity of antique furniture. The type of dovetailed joint, especially in drawers, reveals much about furniture construction and dating. With just a little study of these examples, it is easy to spot true hand made construction vs. machine made furniture.

When did dovetails become popular?

These were cut with a jig or pattern, and an apprentice could create a very well fitting and attractive joint. Popular here into the 1890’s, these joints never gained acceptance outside of the U.S. and Canada. European cabinetmakers continued their hand-cut dovetails well into the 1900’s.

When were sliding drawer joints used?

Other drawer joints include sliding keyhole or French dovetails that were have been used since the 1890’s. Here is an oak cylinder roll desk from about 1895 with keyhole dovetailed drawers.

Where did the name "dovetail" come from?

The name “dovetail” comes from the appearance of the joint, resembling the triangle shape of a bird’s tail. The earliest examples are from furniture placed with mummies in Egypt thousands of years ago, and also in the burials of ancient Chinese emperors.

What was the next technological development in joinery?

The next technological development in joinery was again American. In the 1890’s, American furniture began to be mass produced, with interchangeable parts and speedy production for the growing and affluent middle class. The slow and laborious crafting and carving, one piece at a time, by a master woodworker was not suited to the new mass market. Steam power, transferred by pulleys and leather belts, operated saws, carving machines and routers that could copy an original pattern exactly.

What is a dovetail joint?

The dovetail joint is considered one of the strongest joint methods in making things like drawers and cabinets. For this, woodworkers apply different techniques and some prefer to hand cut dovetail jigs but using a dovetail jig can be quick, easy and efficient to create your dovetail joints.

What is through dovetail?

Through Dovetail. The through dovetail is one of the most basic methods of making a joint. In this process, two wooden pieces are joined together at their ends with a finger-like dovetailing method, which can easily be seen from it’s exterior. It’s the most common practice used in everyday projects for joining the corners of frames, boxes, ...

How To Use A Dovetail Jig?

Before using your dovetail jig, make sure that all attachments and parts of the tool are assembled correctly with no loose parts.

How Many Types of Dovetail Attachments?

Deciding which type of dovetail jig to opt for on your next DIY project is dependent on several factors, such as design and function. These joints are used to look attractive in terms of visual appearance.

What is a MLCS dovetail jig?

“The MLCS Dovetail Jig 6410 is a jig that enables the user to cut wooden supplies precisely and in different ways. This jig is capable of making half-blind, rabbeted half-blind, and dovetail joints”.

What is a secret mitered dovetail joint?

It offers the strength found in the respective joint but is hidden from both the outside and inside corners by creating the outer edge to meet at a 45-degree angle while hiding the dovetails internally within the joint.

What is a half blind dovetail joint?

A half-blind dovetail joint permits the woodworker to hide the joint from the front. In this process, the joints are kept in sockets in the ends of the workpiece, which is normally at the front of the product so that their ends cannot be seen. These joints are commonly used to fasten drawer fronts to their sides.

What is a dovetail joint?

Dovetail is a type of wood joint where no screws, nails, or other such hardware tools are used. In this joint, two wooden pieces are connected via interlocking structures called pins and tails. It isn't easy to pull apart the wooden pieces joined by the dovetail technique, and that's why it's said to be the epitome of authentic craftsmanship. However, creating the pins and nails using a hand saw or other cutting tools is not correct. That's why you need one of the best dovetail jigs in 2021, which we have sorted out only for you to display the level of excellence through your craftsmanship.

What Type Of Dovetail Joints Can A Jig Create?

With a dovetail jig, you can create different types of joints in the wooden workpieces. Some of them include:

What Are The Main Parts You Can Find In The Dovetail Jig?

In a dovetail jig, the first thing you will see is a template made from aluminum or steel. This template has a teeth-like edge based on which the pins and tails are created in the wooden pieces.

Why Using A Dovetail Jig Is Beneficial For Woodworkers?

With a dovetail jig, you can make accurate and precise dovetail joints with no irregular or weird cuts.

What material is used to make dovetail jigs?

Lastly, it would be best to focus on the material type with which the dovetail jig is manufactured. Starting from steel to copper, several metals and alloys are used in constructing the jigs. Therefore, based on the material type, their durability, stability, and performance will differ a lot.

Do you have to have prior knowledge to use dovetail jigs?

A: If you are a beginner and don't have prior knowledge or training for using the dovetail jigs, it's best to begin with a simple product having one fixed template. Also, please look for the products which don't require too many adjustments before the actual operation.

Why is it called a dovetail joint?

It's called a "dovetail" joint because the flat-bottomed triangular shape of the wood insert looks like a dove's tail. Whether that tail is fat, skinny, symmetrical or used sparingly reveals a clue to the origins of the piece.

When were dovetail joints first used?

Woodworkers cut dovetail joints in the latter part of the 17th century in England, using small delicate saws and wood chisels. The marks are often visible, especially on the inside or underside of a piece. The joints were less delicate at first -- fairly wide and blunt, cut crudely with rare exceptions. But the style developed into a very thin, precise and fragile-looking joint. In the late 1890s, scalloped dovetails were the rage, but the trend shifted back to the classic triangular shape after a few years. Hand-cut dovetailing was the default until 1860 when uniform machine-cut joints were introduced. But fine cabinetmakers persisted in fitting their joints by hand until the early 1900s, and cabinetmakers in Europe cut dovetails by hand well into the 1930s.

What is a dovetail in cabinetry?

By Benna Crawford. Dovetails are interlocking carved wood joints used in cabinetry to connect two pieces of wood -- drawer fronts and sides, cabinet or cupboard corners. The technique produces a sturdy, long-lasting connection.

How many dovetails do country carpenters use?

Meanwhile, country carpenters were turning out sturdy and polished dovetailing in their handmade pieces -- but favored two or three large dovetails, fairly symmetrical, over the more delicate and numerous joints in which master carpenters took pride.

When was dovetailing invented?

American Aberration. American woodworkers played around with the ancient dovetailing concept and invented a version of their own in 1870. Eastlake and Victorian-style wood furniture, especially case furniture, displays a round dovetail known as a "pin and cove.".

How were the lintels connected at Stonehenge?

The massive horizontal stone lintels at Stonehenge were connected by dovetailing, more rounded than triangular. A 17th-century Chinese canopy bed at the Victoria and Albert Museum is held together with dovetailing. The use of the joinery technique stretches back into prehistory, but its utility is still relevant.

What was the Egyptian footstool?

The Pharaoh's Footstool. Egyptian pharaohs were buried with fine furnishings and chests of valuables and rare spices to accompany them to the afterlife. Boxy shapes with joined wood angles were connected by dovetailing, a fact that contributed to the intact state of the grave goods when the pyramids and burial chambers were excavated.

The Anatomy of A Dovetail Joint

When Is The Dovetail used?

- Within woodworking, the dovetail can be found in larger projects like timber framing and in constructing log buildings. It’s also used in smaller woodworking projects like cabinetryand other high-quality furniture construction (like holding together the sides of drawers to its front). The dovetail can be made even smaller than that! It’s also a joinery method used in antique jewelry b…

The History of The Dovetail

- It is said that the dovetail joint predates written history. That’s more than a test of time, that’s a test of fire, drought, nuclear bombs, hurricanes, volcanic eruptions, cyclones, FIRE CYCLONES (yes that’s a thing, youtube it). There is a stone pillar temple in India called the Vazhapphally Maha Siva, which is held together by dovetail joints. It is unclear as to when it was first built (somewhe…

5 Types of Dovetail

- 1. Through Dovetail:also referred to as a plain dovetail, the joint meets at a 90-degree angle and both grains are entirely visible. Since the dovetail is so aesthetically appealing, the joint needn’t be covered. 2. Half-Blind Dovetail:this method is used when the joint doesn’t want to be seen from the front. The same joint is used, only there is a small border of flush wood that is left in the fron…

FAQ

- Can you use a dovetail joint with plywood?

It is said that harder woods are usually more compatible with the dovetail joint. It is doable with plywood, but it’s apparently not the ideal choice. Here’s a forum where they discuss this topic at length: Fine Woodworking. - Where can I buy a dovetail jig?

If you’re looking to create your own dovetail joint, here’s a great source for various dovetail jigs: Busy Bee Tools.