What are the essential variables in welding?

- 5 essentials for proper welding procedures.

- 1) CORRECT ELECTRODE SIZE.

- 2) CORRECT CURRENT.

- 3) CORRECT ARC LENGTH or VOLTAGE.

- 4) CORRECT TRAVEL SPEED.

- 5) CORRECT ELECTRODE ANGLE.

- 8 FACTORS to consider in selecting arc welding electrodes.

What are the essential and non-essential variables in welding?

Jun 13, 2020 · What are the essential variables in welding? 5 essentials for proper welding procedures. 1) CORRECT ELECTRODE SIZE. 2) CORRECT CURRENT. 3) CORRECT ARC LENGTH or VOLTAGE. 4) CORRECT TRAVEL SPEED. 5) CORRECT ELECTRODE ANGLE. 8 FACTORS to consider in selecting arc welding electrodes.

What changes to essential variables require a requalification of a welding procedure?

In most of welding process, The P number, F number, A number PWHT, thickness (out of specified range) are essential variable. Based on requirements of ASME Code Section IX all essential variable, nonessential variable and supplementary essential variable (such as Group Number) must be indicated in the welding procedure specification.

Should variables be included in a welding WPS?

Nov 02, 2021 · In most of welding process, The P number, F number, A number PWHT, thickness (out of specified range) are essential variable. What are the nine essential variables of welding? joints, base metals, filler metals, positions, preheat, PWHT, gas etc. (including ranges, if any) under which the welding process must be performed. Erin ⭐ Answeregy Expert

What are the factors to consider when selecting welding electrodes?

categorizing every welding variable as either an essential or nonessential variable. Note, that as we said previously, essential variables are those that have a significant influence on the mechanical properties, such as tensile strength and ductility. Nonessential variables are those that do not have a significant influence on

What are essential variables?

Essential variables are those that will affect the mechanical or metallurgical properties of a weldment. If they are changed outside their qualified range a new procedure has to be qualified. The essential variables will be determined by the code that is being used so you do not need to guess what they are.

What are essential and non essential variables in welding?

Welding variables that are critical to making acceptable welds are categorized as essential variables. Welding variables that do not have a profound influence on the mechanical properties of the weld or those that are associated with the skills of the welder are categorized as nonessential variables.

What are the 5 essentials of welding?

WELDING PROCEDURES5 essentials for proper welding procedures.1) CORRECT ELECTRODE SIZE.2) CORRECT CURRENT.3) CORRECT ARC LENGTH or VOLTAGE.4) CORRECT TRAVEL SPEED.5) CORRECT ELECTRODE ANGLE.8 FACTORS to consider in selecting arc welding electrodes.

What are the variables of the welding code in welding process?

Such variables are typically the welding process, type and thickness of base metal, filler metal type, electrical parameters, joint design, welding position, and others.

Is welding process an essential variable?

Section QW-401: general Note that a change from one welding process to another welding process is an essential variable and requires requalification.

Is welding position an essential variable?

Since the WPS appears to be qualified in accordance with ASME Section IX, welding position is not an essential variable, thus a supporting PQR welded in the flat or any other position qualifies the WPS for all positions.Aug 7, 2007

What is the importance of Essentials of welding?

Welding is an essential component of many industries such as the automotive industry, the construction industry, the aviation industry, and more. Without this form of metal work, so many things, including many buildings, gates, and fences, small kitchen appliances, vehicles - and even space travel - would not exist.Dec 18, 2017

What are the 3 variables of WPS?

Three types of variables are mentioned in the code, these are; Essential Variable. Non essential Variable. Supplementary Essential variable.Jul 26, 2018

Is electrode size an essential variable?

Depending on the weld position and electrode size, the welder will have difficulties controlling the appearance of weld defects. But electrode size will not affect mechanical properties. Having this in mind, it is just natural that it is a non-essential variable that you may want to control anyways.Oct 11, 2015

Is backing an essential variable?

For welder qualification, backing is invariably classed as an essential variable. This is because being able to produce a sound weld root using backing does not demonstrate he has skill required to make a sound weld without backing.

What is the gas on the back side of a weld called?

This situation is typical for welding stainless steels, nickel based alloys and titanium alloys amongst others. The shielding gas provided on the back side of the weld is called a backing gas.

What is transfer mode welding?

The transfer mode deals with the way in which molten weld metal is transferred from the consumable electrode to the weld pool. It is only applicable for some of the welding processes. When welding with Gas Metal Arc Welding, (GMAW) there are different transfer modes possible depending on the interaction of the following:

What is autogenous welding?

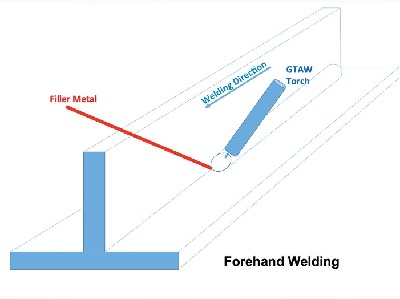

Some welding processes do not use a consumable electrode. This means that they allow you to weld without adding any filler metal. This is called autogenous welding. GTAW and PAW are examples of such welding processes.

What is the process of welding that allows you to use separate pieces of metal?

Apart from fusing the two parts of the joint without adding any filler, welding processes that allow autogenous welding also allow you to use separate pieces of metal that are placed in the joint and then fused. Typically these would be in the form of a ring of metal placed in the root of a pipe but joint, and then melted along with the ends of each pipe to complete the weld root. These additional “pieces of metal” are called inserts.