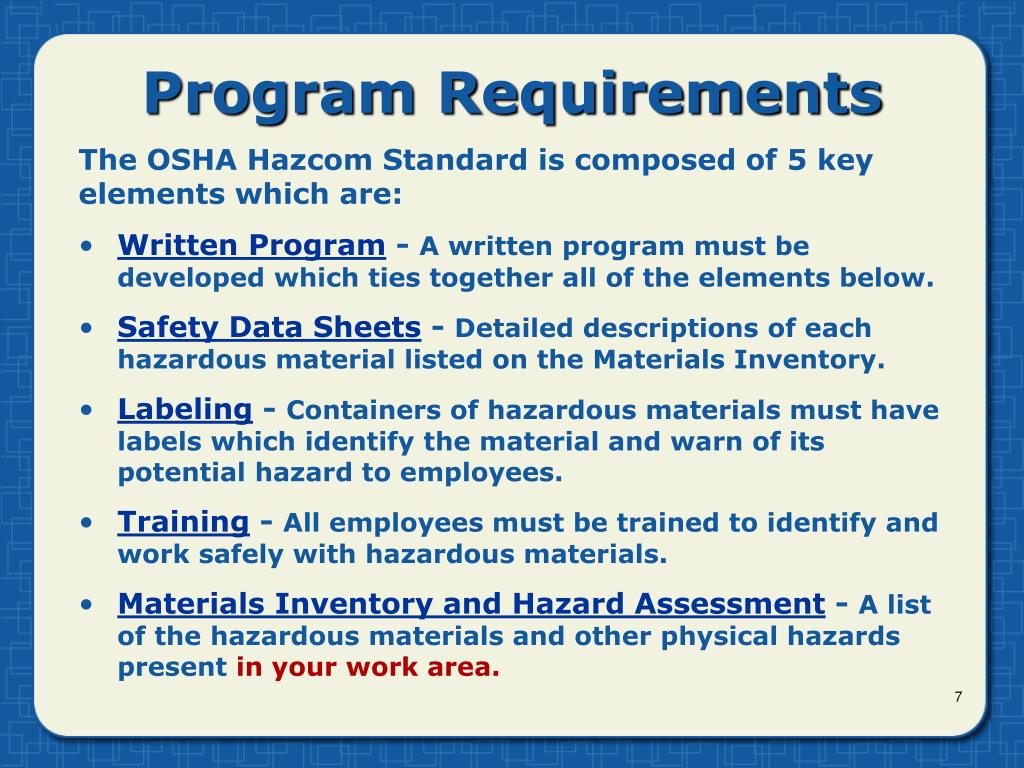

When approaching HazCom, remember its five key elements:

- materials inventory;

- safety data sheets;

- labeling;

- written program; and

- training.

What are OSHA’s hazard communication standards (HCS)?

This is why OSHA’s Hazard Communication Standards (HCS, also known as HazCom) exist. They require companies producing and/or using hazardous chemicals to provide employees with information and training relevant to the hazardous chemicals, their handling, protective measures, and any other significant safety concerns.

What does the hazard communication standard update mean for You?

This update will also help reduce trade barriers and result in productivity improvements for American businesses that regularly handle, store, and use hazardous chemicals while providing cost savings for American businesses that periodically update safety data sheets and labels for chemicals covered under the hazard communication standard.

Who is required to maintain a written hazard communication program?

5. Written hazard communication program If a company uses or produces hazardous chemicals, then the employer is required to maintain a written hazard communication program at the workplace. An employer will be asked to produce this program document during an inspection.

What information is required to ensure chemical safety in the workplace?

In order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information:

What are the four main requirements of the Hazard Communication Standard?

Hazard Communication StandardEnsuring the proper chemical labeling on containers.Providing Safety Data Sheets (SDSs)Providing information and training to employees about chemical hazards in the workplace.Developing and maintaining a written hazard communication program.

What are the main components of OSHA's Hazard Communication Standard?

When approaching HazCom, remember its five key elements:materials inventory;safety data sheets;labeling;written program; and.training.

What 3 main items are included in a work hazard communication program?

The program must include labels on containers of hazardous chemicals, safety data sheets (SDSs) for hazardous chemicals, and training for workers.

What 3 areas must the Hazard Communication Standard cover?

What are the major changes to the Hazard Communication Standard? The three major areas of change are in hazard classification, labels, and safety data sheets (SDS).

What is the appropriate standard for hazard communication?

2.1. 2 Hazard Communication Standard (HCS) (29 CFR 1910.1200) The HCS requires information on hazardous chemicals to be transmitted to employees through labels, material safety data sheets (MSDS), and training programs. A written hazard communications program and record keeping are also required.

What are the Hazard Communication label elements?

OSHA has updated the requirements for labeling of hazardous chemicals under its Hazard Communication Standard (HCS). All labels are required to have pictograms, a signal word, hazard and precautionary statements, the product identifier, and supplier identification.

What are the 5 elements of OSHA?

Understand and know the Occupational Safety and Health Administration's (OSHA) five types of workplace hazards and take steps to mitigate employee risk.Safety. Safety hazards encompass any type of substance, condition or object that can injure workers. ... Chemical. ... Biological. ... Physical. ... Ergonomic.

What are the 4 most important sections of SDS?

Identification: for the product and supplier. Hazards: physical (fire and reactivity) and health. Prevention: steps you can take to work safely, reduce or prevent exposure, or in an emergency. Response: appropriate responses in various situations (e.g., first-aid, fire, accidental release).

What are the 7 core elements of a safety program?

OSHA's 7 Core Elements of an Effective Safety and Health ProgramManagement Leadership.Worker Participation.Hazard Identification & Assessment.Hazard Prevention & Control.Education & Training Program.Evaluation & Improvement.Management of Contractors / Staffed Employees.

What are the 3 critical elements of safety?

While there are different approaches to ensuring worker safety and health, all effective programs share three core elements:Management leadership. ... Worker participation. ... A systematic “find and fix” approach.

What are the 4 key steps in the workplace procedures for hazard identification?

Sometimes using more than one control measure could be the most effective way to reduce the exposure to hazards.1 Eliminate the hazard. Remove it completely from your workplace. ... 2 Substitute the hazard. ... 3 Isolate the hazard. ... 4 Use engineering controls. ... 5 Use administrative controls. ... 6 Use personal protective equipment (PPE)

What are the 3 main hazards?

All hazards are assessed and categorized into three groups: biological, chemical and physical hazards.

What are 3 OSHA standards?

There are four groups of OSHA standards: General Industry, Construction, Maritime, and Agriculture. (General Industry is the set that applies to the largest number of workers and worksites). These standards are designed to protect workers from a wide range of hazards.

What are the 3 hazard categories?

GHS consists of three major hazard groups : Physical hazards. Health hazards. Environmental hazards.

How many hazard communication standards are there?

The Hazard Communication standard requires all the hazardous information of a chemical used in the workplace, which covers physical, health, and environmental impacts, to be effectively communicated to those working with it. There are five key factors of the Hazard Communication Standard.

What is the purpose of the Hazard Communication Standard?

Purpose. The purpose of this section is to ensure that the hazards of all chemicals produced or imported are classified, and that information concerning the classified hazards is transmitted to employers and employees.

Why is the Hazard Communication Standard important?

The purpose of the HAZCOMM standard is to ensure the HAZards of chemicals found in the workplace are effectively COMMunicated to employees so they can properly handle, store, and transport chemicals as well as properly protect themselves during normal use or upon accidental release.

What 3 elements are required on a workplace label?

Product name (matching the SDS product name). Safe handling precautions, may include pictograms or other supplier label information. A reference to the SDS (if available).

What are the 4 types of hazard management process?

Hazard control methods are often grouped into the following categories:Elimination (including substitution).Engineering controls.Administrative controls.Personal protective equipment.

What are the 5 types of hazards define each?

The six main categories of hazards are:Biological. Biological hazards include viruses, bacteria, insects, animals, etc., that can cause adverse health impacts. ... Chemical. Chemical hazards are hazardous substances that can cause harm. ... Physical. ... Safety. ... Ergonomic. ... Psychosocial.

What is a component of OSHA's Hazard Communication Standard for employees?

When working with hazardous chemicals, employees must have the proper information and training regarding handling the chemicals, protecting themselves against risk, and understanding any outstanding safety concerns.

What are OSHA's focus 4 topics?

State the course objectives so the participants are aware of the training expectations and continue the 4-hour session by presenting the four lessons: Fall Hazards; Caught-In or - Between Hazards; Struck-By Hazards; and Electrocution Hazards.

What is Hazard Communication Standard?

Hazard Communication Standard. In order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers.

What is Hazard Classification?

Hazard classification: Provides specific criteria for classification of health and physical hazards, as well as classification of mixtures.

How to ensure chemical safety?

In order to ensure chemical safety in the workplace, information about the identities and hazards of the chemicals must be available and understandable to workers. OSHA's Hazard Communication Standard (HCS) requires the development and dissemination of such information: 1 Chemical manufacturers and importers are required to evaluate the hazards of the chemicals they produce or import, and prepare labels and safety data sheets to convey the hazard information to their downstream customers; 2 All employers with hazardous chemicals in their workplaces must have labels and safety data sheets for their exposed workers, and train them to handle the chemicals appropriately.

What is the HCS?

The Hazard Communication Standard (HCS) is now aligned with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS). This update to the Hazard Communication Standard (HCS) will provide a common and coherent approach to classifying chemicals and communicating hazard information on labels and safety data sheets.

Why are employers required to train workers on the new labels elements and safety data sheets format?

Information and training: Employers are required to train workers on the new labels elements and safety data sheets format to facilitate recognition and understanding.

Do employers have to have labels for hazardous chemicals?

All employers with hazardous chemicals in their workplaces must have labels and safety data sheets for their exposed workers, and train them to handle the chemicals appropriately.

What is the purpose of Hazard Communication Program?

Remember, the purpose of the Hazard Communication Program is to reduce the likelihood of illness and injury related to chemical exposure. As the employer, you are responsible for increasing understanding and reducing risks for your employees. You can learn more in our Safety in 10 Webinar series.

How many elements are there in OSHA?

The OSHA standards help employers understand regulations and ensure employee safety, and is composed of five key elements. These five key elements are:

What is the GHS in OSHA?

The Globally Harmonized System for Classification and Labeling of Chemicals (GHS) aims to standardize how workplaces define hazards related to a chemical, classify them and then communicate the hazards and relevant protective measures on labels and safety data sheets. As such, SDSs are required to contain 16 sections (four of which aren’t mandatory) and OSHA mandates that they should include:

Why is hazcom important?

It requires companies producing and/or using hazardous chemicals to provide employees with information and training relevant to the hazardous chemicals, their handling, protective measures, and any other significant safety concerns in accordance with OSHA’s Right-to-Know Standard.

Who is responsible for labeling a chemical?

If the chemical is transferred to another container, the employer is responsible for properly labeling the new container.

1. Labeling Compliance

OSHA compliance officers, also known as CHSOs, will check carefully for label compliance with HCS while inspecting the facilities of importers, manufacturers, or distributors of hazardous chemicals.

2. SDS Compliance

During workplace inspections, OSHA CSHOs will check that employers have indexed an SDS for every hazardous chemical in their workplace. They’ll be hoping to find that all safety data sheets for all hazardous materials are present and that the information is both helpful and easy to access.

3. Training Compliance

Finally, CSHOs will also look for compliance with HCS regarding employee training requirements. They execute this by interviewing employees on the hazards of the chemicals they work with on-site and how to handle them safely.

Next-Level Compliance With GSM

GSM compliance experts understand the challenges that hazardous materials compliance standards pose to companies like yours. We give hazardous chemicals manufacturers, importers, and distributors a leg up by providing SDS authoring and management solutions that allow you to streamline your supply chain while staying OSHA HCS compliant.

What is Hazard Communication?

Hazard communication is addressed in specific standards for the general industry, shipyard employment, marine terminals, longshoring, and the construction industry.

Who needs MSDS?

MSDS's must be provided to employees who package/process drugs for distribution into final form if they contain hazardous chemicals. (2005, February 8).

What is the OSHA number for emergency notification?

To report an emergency, file a complaint with OSHA or ask a safety and health question, call 1-800-321-6742 (OSHA).

What are the five OSHA Hazard Communication Standard elements?

These are the Five elements of the Hazard Communication Standard. They are: Chemical Inventory, Written Program, Labels, Material Safety Data Sheets, and Training. The first element of the Hazard Communication Standard is for employers to develop inventories of all the hazardous chemicals they have at their worksite.

Why is OSHA decided to modify the hazard communication standard?

A. OSHA has modified the Hazard Communication Standard (HCS) to adopt the GHS to improve safety and health of workers through more effective communications on chemical hazards. Since it was first promulgated in 1983, the HCS has provided employers and employees extensive information about the chemicals in their workplaces.

How many words are on a hazardous chemical label?

Only one word will be on each label, to ensure it is clear to the user the severity of the hazardous chemical.

How many components are there in a GHS label?

In this article, we are going to explain the six components of a GHS label, as these are common across the board when it comes to GHS labeling.

What is GHS label?

GHS allows companies across the globe to have one common, coherent framework for classifying and communicating information related to chemicals. GHS requirements also applies to safety data sheets, but in this article we will only be focusing on labels. In this article, we are going to explain the six components of a GHS label, ...

What is global harmonised system?

Globally Harmonized System requirements are prevalent across various industries to meet global regulatory labeling and tracking challenges. Although it is common, many people still get a little confused about what GHS is exactly. GHS allows companies across the globe to have one common, coherent framework for classifying ...

What is the signal word on a chemical label?

2. Signal Word. A signal word is used to notify the severity of the hazard. There are only two words that might hold this place on the label: “Danger” (severe hazard) or “Warning” (less severe hazard).

Where is the ingredient on a GHS label?

1. Product Identifier/Ingredient Disclosure. This component of the GHS label is typically placed in the top left-hand corner of the label, and it identifies the hazardous chemical or ingredient that is in this product. It can state the name, code number, or batch number.

What is hazard communication?

As per OSHA’s HAZCOM or HCS regulations, employers must implement a formal hazard communication program that includes – details of chemicals handled, imported or produced at the workplace through labels on the containers, safety data sheets (SDSs or MSDSs), a written HCS plan, chemical inventory lists, and an effective training program.

When did OSHA issue the Hazard Communication Standard?

Most of these chemical-related hazards and accidents occur due to sheer negligence or ignorance by the employees or the employers. To ensure chemical safety in the workplace, OSHA issued the Hazard Communication Standard in 1983 ...

What is the scope of the HCS?

OSHA modified the HCS and broadened the scope to cover all industries where workers are potentially exposed to hazardous chemicals. In 2012, the Hazard Communication Standard was aligned with the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

What is the purpose of the Hazcom program?

OSHA’s HAZCOM is a U.S regulation standard developed to ensure a safe and healthy work environment. It requires employers across all industries to identify the hazardous substances, label them, and educate their employees about their possible hazards. For instance, companies dealing in hazardous waste handling will be required to ensure their workers complete the HAZWOPER training program before commencing the work.

What is the HAZCOM standard?

The HAZCOM standard is also called the “Employee Right-to-Know” and is described in 29 CFR 1910.1200.

What should workers exposed to hazardous chemicals at work be provided with?

Workers exposed to hazardous chemicals at work should be provided with education and training to identify and work safely with hazardous materials before their initial assignment. This can be achieved by: Conducting group sessions to explain SDSs, PPE and what to do in an event of an exposure or chemical spill.

What is an SDS?

An SDS is a written or printed material put around a hazardous chemical. If an SDS is missing, contact the supplier to get a copy of the same. Until the SDS is received, employers should document the request and record it in a file.

Labeling Compliance

- OSHA compliance officers, also known as CHSOs, will check carefully for label compliance with HCS while inspecting the facilities of importers, manufacturers, or distributors of hazardous chemicals. They’ll be looking to see that the hazard classifications on labels and in SDSs meet OSHA’s standard while also checking for updated labels that include any significant new informa…

SDS Compliance

- During workplace inspections, OSHA CSHOs will check that employers have indexed an SDS for every hazardous chemical in their workplace. They’ll be hoping to find that all safety data sheets for all hazardous materials are present and that the information is both helpful and easy to access. This information should be available in a comprehensive list of the hazardous materials on the p…

Training Compliance

- Finally, CSHOs will also look for compliance with HCS regarding employee training requirements. They execute this by interviewing employees on the hazards of the chemicals they work with on-site and how to handle them safely. Stay on the ball with a robust training program in addition to a written HazCom program that can be referenced as needed. Yo...

Next-Level Compliance with GSM

- GSM compliance experts understand the challenges that hazardous materials compliance standards pose to companies like yours. We give hazardous chemicals manufacturers, importers, and distributors a leg up by providing SDS authoring and management solutionsthat allow you to streamline your supply chain while staying OSHA HCS compliant. If you want to save time and …