What are the characteristics of good cutting fluid?

It means a cutting fluid should have excellent cooling and lubricating properties. Cutting fluids can be applied to the tool and workpiece in the following three ways. In this method tool and workpiece are supplied with high volume of the cutting fluids which are generally in liquid condition.

Why use cutting fluid in smooth machining?

This is helpful in smooth machining operations and increases tool life. Let us learn more about cutting fluids with types, properties, purpose, and applications in this article. At the end of this article, there will be a link to download a cutting fluid PDF copy for your future reference. What is cutting fluid? What does cutting fluid do?

What are the different types of cut fluid?

Cutting fluids are an important element of manufacturing that helps the manufacturing industries in metal cleaning and producing processes. There are different types of cutting fluids like gaseous, synthetic, semi-synthetic, straight oils, etc.

Can water be used as a cutting fluid?

Water alone is a good coolant but, it cannot be used as a cutting fluid because of its corrosive and non-lubricating properties. Mineral oils are added to the water to make proper cutting fluid also called as Semi-Synthetic Cutting Fluid. Examples of liquid-type are kerosene, motor oil, etc.

What is cutting fluid write the function and properties of cutting fluid?

Cutting fluids are most commonly used during the metal cutting process. Its main role is to avoid production of heat during the machining process. It keeps a check on the rise in temperature and the damage caused due to heat. Cutting fluids also reduce the friction significantly between two objects.

What are the three main functions of a cutting fluid?

3 Functions of A Cutting Fluid They provide lubrication. Lubrication reduces friction. ... They help remove heat. Even though they provide lubrication, some frictional heat is produced. ... They prevent the welding of workpiece material onto the tool.

What are the main applications of cutting fluids?

Drilling, broaching, milling, threading with high speed steel tools are typical examples of these operations where the use of cutting fluids is essential. Another important application of cutting fluid is in operations where low surface roughness and/or tight dimensional tolerances are required.

What are the types of cutting fluids?

Types of cutting fluidsSoluble oils (emulsions) Soluble oils are stable emulsions formed by the addition of mineral oil to water in specified proportions (usually 1-20% of oil to water). ... Straight oils. ... Synthetic fluids. ... Semi-synthetic fluids. ... Cooling. ... Lubrication. ... Improvement of tool-life. ... Removal of chips.More items...

What are the properties of cutting tool materials?

Properties of cutting tool material: Hot or Red Hotness: It is the ability of the cutting tools to withstand high temperatures without losing its cutting edge. Wear Resistance: ... Toughness: ... Thermal Conductivity: ... Co-efficient of friction: ... Thermal Stability: ... Cost:

What are 2 major types of cutting fluids?

Types of Cutting Fluids:#1. Straight Oil. Stroth oils are non-emulsifying. ... #2. Soluble Oil. Soluble oils are made by mixing mineral oil, water, & coupling agents. ... #3. Mineral Oil. ... #4. Synthetic Liquids. ... #5. Semi-Synthetic Fluids. ... #6. Solid and Paste Lubricants. ... #7. Cutting Oil. ... #1. Machining Process Type.More items...

What is another name for cutting fluids?

Cutting fluid also name as Coolant or lubricant is used for improving the cutting condition and also the tool life.

What is the function of cutting?

Cutting is a technique where the operator moves a material (workpiece) such as metal and the tool in relation to each other in order to shape the workpiece into the desired form through shaving, drilling, etc.

What is meaning of cutting fluid?

Definition of cutting fluid : a fluid used especially for cooling, lubrication, rust prevention, or chip flushing in a machine metal-cutting operation or for other special effects in other metal working operations.

What are the functions of cutting fluids in metal cutting practice?

The functions of cutting fluids are: To cool the tool as well as the workpiece. To reduce the friction between the chip and the tool face by providing lubrication.

What is the role of cutting fluid in metal cutting?

The main purpose of using cutting fluid is to decrease cutting temperature, reduce friction between tool and workpiece, extend tool life, and improve machining efficiency and surface quality.

Which of the followings are two main function of a cutting fluid in machining improve surface finish on the workpiece?

(b). 23.10 Which of the following are the two main functions of a cutting fluid in machining (two bestanswers): (a) improve surface finish on the workpiece, (b) reduce forces and power, (c) reducefriction at the tool-chip interface, (d) remove heat from the process, and (e) wash away chips? Answer. (c) and (d).

What is the purpose of using lubricant?

Lube reduces friction, so lessens your risk of injury during sex. And if you're using condoms, lube also makes it less likely that it'll break or fall off, therefore increasing your protection against STIs including HIV.

What is cutting fluid?

Cutting fluid is the liquid used in the metalworking process like cutting, drilling, milling, turning to reduce the heat produced due to the deformation and machining process to lubricate for reducing friction and wear and tear on the workpiece. Picture Credit To Wikipedia.

Why use cutting fluid support?

Cutting fluid support to minimize the friction & heat produced between tool and workpiece as an increase in the temperature can reduce the tool’s life.

How does cutting fluid reduce the cost of a tool?

Reduction in the cost of the tool as cutting fluids increases the life of the tool by reducing the wear and tear of the tool . The production speed increases as cutting fluid reduce fiction and heat produced due to deformation so cutting functions can be performed at a higher speed.

What is the name of the fluid that is added to water to make cutting fluid?

Mineral oils are added to the water to make proper cutting fluid also called as Semi-Synthetic Cutting Fluid. Examples of liquid-type are kerosene, motor oil, etc.

Why is cutting fluid high in flash point?

Very High Flash Point: Having a lower flash point can lead to inflammation so, cutting fluid must have a high flash point to avoid accidents. High Stability: The oxidization of cutting liquid with the air present in the atmosphere must be very less.

Why are fluids dangerous?

Some fluids cause health hazards due to chemicals and additives added while preparation. If not used properly can cause health issues. Some metal is affected due to the use of cutting fluids so, we have to use it carefully. Some of the materials get affected due to thermal shock so again use it carefully.

Why are vegetable oils used?

These have excellent lubrication ability. Vegetable oils were generally used due to their environment-friendly properties like biodegradability but they are little in use because of their bad smell.

What is cutting fluid?

Cutting fluid is a liquid or solid substance used in the machining process to cool down the tool, lubricant machine parts, reduce wear and tear, aid in the smooth machining operation, and help is getting better quality parts.

Why is cutting fluid important in machining?

During machining operations, a lot of heat is generated. Cutting fluid helps to reduce that heat and cools the tool : this increases tool life and smooth machining operations.

Why should a cutting fluid have a low viscosity?

It should have a low viscosity so that cutting fluids can reach every corner.

Why is cutting oil used in machine parts?

Also, when cutting oils are uses in machine parts, it eliminates the corrosion by the chemical reaction.

What is mineral oil?

Mineral oil is a light mixture of higher alkalies from mineral sources, particularly a distillate of petroleum. Mineral oil is used in heavy-duty production machines. Mostly suitable for cutting steel.

Why are semi-synthetic fluids used?

Semi-synthetic fluids have 5-20% of oil in order to ease in lubrication. So semi-synthetic fluids help in both cooling and lubrication.

What is a soluble oil?

Soluble oil or emulsions. Soluble oil is a mixture of petroleum oil ( more than 50%) and water. When petroleum oil mixes with water, it forms a milk-like substance. Soluble oil is often used with other emulsifiers ( sodium sultanate, fatty acid, etc.) and additives.

Flooding

In this method tool and workpiece are supplied with high volume of the cutting fluids which are generally in liquid condition.

Jet application

In this method the cutting fluids which may be either gas or liquid are applied with high pressure on the tool and workpiece.

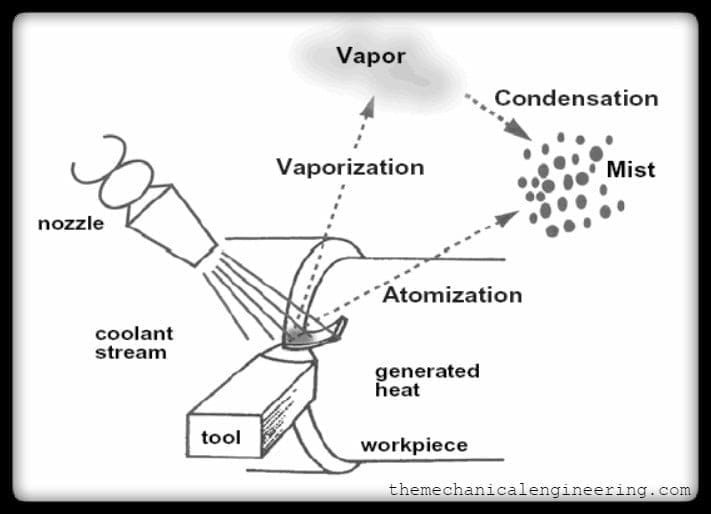

Mist application

In this method the cutting fluids are mixed with a gas (generally air) and applied to tool and workpiece. Mist application combines the properties of above mentioned both methods i.e. flooding and jet application.