Again, depending on how the riveted joints are done while joining (how rivets are arranged in the workpiece while joining), riveted joints are classified as the following types:

- Single Riveted Joints

- Double Riveted Joint

- Chain Riveted Joint

- Zig-zag Riveted Joint

- Diamond Riveted Joint

How many types of rivets are there?

There are four basic types of rivets; tubular, blind, solid and split.

What is rivet and type of rivet?

A rivet is a mechanical fastener composed of a head on one end and a cylindrical stem on another (called the tail) which has the appearance of a metal pin.

What are the different types of rivet joint failure?

1- Shearing stress failure in rivets 2- Tension stress failure in plate. 3- Bearing stress failure between plate and rivet. 4- Shearing stress failure in plate.

What is a riveting joint?

Rivet joints are permanent joints used mainly for fastening sheets and shaped rolled metal. They are used in lap, abutment, and double-cover plate joints. They can still be used for constructing a metal bridge, hoisting cranes, boilers, and pressure tanks.

What are the 3 types of rivets?

The general types of rivets are solid, blind, tubular, and metal piercing (including split rivets).

What is rivet used for?

Rivets are essential in the construction of buildings, cookware, jewelry, and so much more because they are cost-effective and the preferred way to permanently fasten a variety of materials like wood, metal, and plastic.

What are the 4 four important terms used in riveted joints?

Important Terms Used in Riveted JointsPitch. It is the distance from the centre of one rivet to the centre of the next rivet measured parallel to the seam. ... Back pitch. It is the perpendicular distance between the centre lines of the successive rows. ... Diagonal pitch. ... Margin or marginal pitch.

Why we use riveted joints?

Riveted Joints Are Stronger When two components are welded together, only the exterior of the components are joined together. On the other hand, using a rivet connects the two components from the inside, thus allowing for a stronger and more durable joint.

What are different types of rivet heads?

Types of RivetsSnap head or cup head rivets.Pan head rivets.Conical head rivets.Countersunk head rivets.Flathead rivets.Buffercated head rivet.Hollow head rivets.

Why rivet is permanent joint?

Rivets. Rivets are used to make permanent joints between two or more plates. Steel rivets may be closed when red hot; rivets of softer metals such as aluminium and copper may be closed cold. There are a number of types of riveted joint configurations for plates, two of which are shown in the figure.

What is the principle of riveting?

Riveting is another method of joining metals with the use of sheet metal screws. When done properly, it looks neat and serves a double purpose of joining the metal and adding decoration. The use of rivets may be determined by the kind of project and the materials used.

What is zig zag riveting?

When multiple joints are used, the arrangement of rivets between two neighbouring rows may be of two kinds. In chain riveting the adjacent rows have rivets in the same transverse line. In zig-zag riveting, on the other hand, the adjacent rows of rivets are staggered.

What is rivet in civil engineering?

rivet, headed pin or bolt used as a permanent fastening in metalwork; for several decades it was indispensable in steel construction. A head is formed on the plain end of the pin by hammering or by direct pressure.

What is rivet process?

Just in simple words the parts used to join together with the help of the rivet is known as the riveting process. The rivets are kind of the adjacent surfaces between the two parts to be joined. A straight metal piece will be inserted via the hole or cavity provided for the two materials to be joined.

What are different types of rivet heads?

Types of RivetsSnap head or cup head rivets.Pan head rivets.Conical head rivets.Countersunk head rivets.Flathead rivets.Buffercated head rivet.Hollow head rivets.

What makes a rivet?

A rivet is a permanent mechanical fastener with head-on at one end and a cylindrical stem called a tail at the other that has the appearance of a metal pin. Rivets are non-threaded fasteners typically made of steel or aluminum. Before being installed, rivets consist of a smooth cylindrical shaft with a head at one end.

Rivets and Types of Riveted Joints:

It is almost impossible that huge structures such as bridges, skyscrapers, airplanes, locomotives, etc., would be built without the inclusion of th...

Types of Riveted Joints:

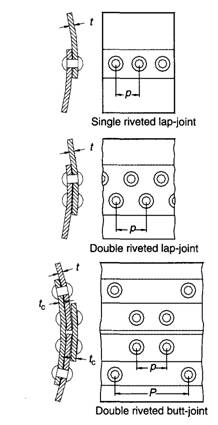

Based on the arrangements of the plates, Riveted Joints are classifieds into two types: Lap Joint. Butt Joint.

Cover Plates Used, the Butt Joints Is Further Divided into Types

Based on the number of cover plate used, the butt joint is further divided into two types: #1. Single Strap Butt Joint In butt joints, if only one...

Lines of Rivets Used the Rivets Joints Are Classified into Different Type:

Based on the numbers of lines of rivets used, the rivets joints are classified into a different type:- #1. Single Riveted Joint If a single line of...

Based on the Arrangement of Rivet Riveted Joints:

Based on the arrangement of rivets, Riveted Joint are classified into two types: #1. Chain Type Riveted Joint In a multi-line riveted joints, if al...

Type of Failures in Riveted Joints:

Crushing failure of plates. Shear failure. Tearing of plate occurring in the margin area. Tensile failure of plates. Shear failure occurring in the...

Advantages of Riveted Joints:

It can be used for non-ferrous metals. Quality inspection of a riveted joints is very easy and cheap. It is more reliable. At the time of dismantli...

Disadvantages of Riveted Joints:

The cost of labor is high. Due to holes, plates become weak. Overall cost, including labor costs, is high relatively. Stress is concentrated near t...

Applications of Riveted Joints:

These joints are most commonly used for fastenings sheets & shaped rolled metals. Riveted joints are used to join metal that cannot be welded or he...

How many rows of rivets are in a double riveted joint?

In this double riveted joint with the chain arrangement of the rivets, there are two rows of rivets, which are arranged opposite to each other as shown above in the lap joint (left side figure).

What is the arrangement of rivets opposite to each other called?

The arrangement of the rivets opposite to each other is called the Chain Riveted.

What is a rivet?

What is a Rivet? Well, A Rivet is a permanent fastening element mostly used for fastening light metals of plates in Boiler shells, structural works, Shipbuilding, and bridges. In the previous article, we have discussed the Riveted joint method , Different Rivethead types, and the materials used for the Rivets according to the Indian Standards. In this article, we are going to discuss the different types of Riveted Joints.

What is the arrangement of rivets staggered in such a way every rivet is in the middle of the two?

The arrangement of the rivets staggered in such a way every rivet is in the middle of the two rivets of the opposite row is called the Zig-zag Riveted.

What is a riveted joint?

Riveted joints are those that can not weld or join by any means other than using rivets causing permanent joints of two separated components, known as Rivets Joints.

What is a single row lap joint?

When a Single straight line of rivets is used in the lap joint, then it is called a Single row lap joint.

What is a double row zig zag lap joint?

When a Double line of rivets is placed in the zig-zag dimension, then it is called a Double-row zig-zag lap joint.

What is a riveted joint?

The riveted joint is a permanent joint cause rivet is a permanent mechanical fastener. A rivet is a cylindrical shaft that has a head on one end and the opposite end known as a tail. Rivets are generally made of mild steel but at times they are also made of brass, copper, and aluminum, etc. Used in structures, bridges, sheet metal operations, ...

How are riveted joints made?

In this type of riveted joint, two elements are joined in a straight line from edge to edge. The clamping is built using an outer casing plate, it is then riveted upward through parallel drilled holes.

What is the diameter of a rivet?

Rivets with this kind of heads are used most of all. This type of rivets is shown in the figure. The head is of a semi-circle in shape. Its diameter is 1.6D and its height is 0.7D. The joints of this rivet are very strong. That is why it is widely used in bridges made of iron material.

What are the advantages of riveting?

Following are the advantages of rivet joints: 1 The fabrication cost of the riveting process is cheaper. 2 Dissimilar metals can also be added, even non-metallic joints are also done with riveted joints. 3 The riveting process requires low maintenance cost. 4 The operation of the riveting process is easy.

What is a conical rivet?

The conical head rivet is shown in the figure. The conical shape is given is used for light jobs. A conical shape is given to the head by a hammer. The diameter of its head is 0.75D and the height of its head is 2D.

How is riveting carried out?

Riveting is carried out with the help of dies and backup dies that place a rivet in between them and, by the use of force, the rivet is set into parts to join.

What is the upper part of a rivet called?

The upper-most part of rivet is called “head”. These are made of different type according to different jobs.

How many rows of rivets are in a lap joint?

Single riveted joint: The riveted joint has one row of the rivet in a lap joint or when there is only one row of the rivet on each plate of butt joint. Double riveted joint: Two rows of rivets are used in a lap joint or two rows of rivet are used in each main plate of but joint.

What is chain riveted?

Chain riveted: The rivets in the adjacent rows are opposite to each other (in same transverse line).

What is lap joint?

Lap joint: In lap joint, plates overlapped each other. The rivets are inserted in the overlapped region. Butt joint: In this type of riveting, the plates to be joined is kept in alignment butting/ touching, without forming an overlap.

What is a single strap butt joint?

Single strap butt joint: Type of but joint in which only one cover plate is placed on the main plate. Double strapped but joint: Type of but joint which uses two cover plates. One cover plate is placed both sides of the main plates then riveted. Based on how many rows of rivets in joint.

Riveted joints

Riveted joints are the joints that are perpetual, comprising of fundamentally two parts that are controlled together by the bolt, head at the top, and tail (barrel-shaped stem) at the base.

1. Lap joint

As the name suggests, in this type of joint, two-member slightly overlap each other. These two members joined together through the coincident holes.

2. Butt Joint

In this type of joint straight edges of the members are joined by using the cover plate. Clamping is done by using this cover plate. ( as shown in the figure )

An Overview of Rivets

In a nutshell, a rivet is a mechanical fastener or connector with a head and tail at opposite sides. It has a head, a smooth cylindrical body, and a tail that looks more like a metallic pin.

Materials Used for Rivets

There are several metal materials for manufacturing rivets. They include steel, copper, brass, aluminum, copper, and stainless steel. Designers and manufacturers choose these different materials to satisfy their needs.

Different Types of Rivets Available for Manufacturing

There are several different types of rivets available. However, they are broadly divided into the following categories.

What are Rivets Used For?

Rivet’s primary purpose is to ensure a firm and reliable tightening of two or more metallic or wooden materials. When you do this, you have a joint stronger than that of a screw with the same diameter.

Conclusion

Rivets are a better substitute for screws, bolts, and nuts. They prove more efficient and reliable than all other connectors. Today, different types of rivets have various purposes. This is a result of the dynamic nature of machines and structures. However, you have to choose suitable metal rivets for your applications to get the best results.

What is a riveted joint?

Rivets – Types, Failures Of Riveted Joint, Terms Used In Riveting. Rivets are short ductile and cylindrical bars that are used for making a permanent mechanical joint. The process of forming a riveted joint is called riveting. A rivet is divided into 3 parts i.e., the head at one end, the tapered tail, and shank, ...

What material should rivets be?

The material of rivet should be tough and ductile.

What is the difference between cold and hot riveting?

But the lateral contraction is slight and there will be longitudinal tension which holds the plates firmly together. The cold riveting process is used for structural joints while hot riveting is used to make leak-proof joints.

What is pitch in rivets?

Pitch: It is the distance from the centre of one rivet to the centre of the next rivet measured parallel to the seam. It is usually denoted by p.

What is butt joint?

Butt-joint: A butt joint is that in which the main plates are Kept in alignment with each other and a cover plate (called strap) it is placed either on one side or on both sides of the main plates. The cover plate is then riveted together with the main plates.

What is a snap head rivet?

The snap head rivets are usually employed for structural work and machine riveting. The countersunk heads are used in shipbuilding where the flush surface is required. The conical or conoidal head is mainly used in the case of hand hammering. Pan heads have the maximum strength but are difficult to shape.

How many parts are in a rivet?

A rivet is divided into 3 parts i.e., the head at one end, the tapered tail, and shank, the portion between the head and tail as shown in the figure. As it is a permanent joint it cannot be disassembled without the failure of the machine component. The material of rivet should be tough and ductile.