Clutch fails to engage properly

- Poorly adjusted cable/linkage

- Normal friction plate wear from use

- Glazed friction surfaces from slipping

- Worn flywheel friction surface

- Weak pressure plate diaphragm springs

- Leaking engine rear main seal

- Leaking transmission input shaft seal

- Warped/overheated pressure plate or flywheel.

Why does my Clutch not engage?

There are many reasons why an AC clutch does not engage. It could be because of a blown fuse, a bad clutch coil, or an open on the wire to the clutch coil. It could also be of poor ground or a low-pressure lockout. There are many ways for AC compressor clutches to receive power.

How does clutch engages and disengages?

How does a clutch engage and disengage? The clutch is designed to engage and disengage the connection between the engine flywheel and the transmission input shaft. The clutch is operated by pushing on the clutch pedal inside the vehicle, which causes the clutch to disengage, and as the pedal is released the clutch will engage.

What should you do when AC compressor clutch not engaging?

What you can do if your AC clutch won’t engage

- Check the compressor’s oil levels. You may check your AC compressor oil level on the display glass thru a red line. ...

- Get rid of overcharged refrigerant. Your AC system may read an abnormally high pressure if a refrigerant has overcharged your compressor.

- Add refrigerant. ...

Does a clutch engage and disengage?

The clutch is operated by pushing on the clutch pedal inside the vehicle, which causes the clutch to disengage, and as the pedal is released the clutch will engage. What causes clutches to fail? Clutches tend to fail in one of two ways – either suddenly or gradually.

What causes a compressor to rotate?

How to fix AC compressor clutch?

How to tighten ac belt?

What is AC clutch?

Why does my AC make a squeaky noise?

What is a corroded CAN bus?

Why is my AC clutch not working?

See 2 more

What are the possible causes when clutch does not engage fully?

Clutch fails to engage properly A clutch that doesn't engage fully, or slips under heavy load, is the normal failure mode of a worn out friction disc of pressure plate that has lost its tension. When you press the clutch, your foot counters the diaphragm spring which presses the friction disc to the flywheel.

How do I get my clutch to engage?

The clutch is designed to engage and disengage the connection between the engine flywheel and the transmission input shaft. The clutch is operated by pushing on the clutch pedal inside the vehicle, which causes the clutch to disengage, and as the pedal is released the clutch will engage.

How do you diagnose a clutch problem?

Sprag Clutch Failure Symptoms Often Include:Clutch Pedal Makes Noises When Engaging and Disengaging.Clutch Pedal Chatters When You Accelerate.Clutch Pedal Pulsates.Clutch Pedal Remains Stuck to the Floor.Clutch Pedal Feels Loose or Spongey.Clutch Pedal is Hard to Engage.More items...•

What are the first signs of clutch failure?

What are the signs of manual clutch failure?When you press the clutch pedal, it's spongy, sticking, vibrating or loose.There's a squeaking or grumbling noise when the clutch pedal is pressed.You're able to rev the engine but notice that it's difficult to accelerate.You're having difficulty shifting gear.More items...•

How do I know if my transmission or clutch is bad?

You can experience shaking, grinding, slipping, overheating, or failure altogether. These might also be signs of a different type of necessary repair.

Is it my clutch or gearbox?

There's a simple test you can perform that will identify either way. Turn the engine off and see if you can select a gear. If you can then it's usually clutch trouble; if you can't then the problem will lie with the gearbox or gear linkage.

What are some common clutch problems?

Experiencing Clutch Problems? Here Are The Most Common Issues.The master or slave cylinder might start to leak. Hydraulic and cable-operated are two kinds of clutches. ... The throwout may wear out. ... The clutch disc may be worn out. ... The flywheel may become warped. ... Your pressure plate may be worn out.

How much does a clutch repair cost?

The cost to repair a clutch can range between $500 to $2,500. It really depends on the car. Performance cars, exotic cars, and European cars are more expensive to replace the clutch than Japanese economy cars. Four wheel drive vehicles cost more than two wheel drive vehicles.

How do you check a clutch master cylinder?

If the clutch fluid is low, look all over both master and slave cylinders and the pipe that connects them for signs of a leak. Pull back the lip of the dust cover on both cylinders. If there is hydraulic fluid inside the cover the piston seal is worn or damaged or the cylinder may be scored.

How many years does a clutch last?

The average lifespan of a clutch is anywhere between 20,000 to 150,000 miles. Luckily, your clutch will likely give you ample notice that something is going wrong. Don't get left at the side of the road with a vehicle that won't shift into gear.

How often should a clutch be replaced?

between 50,000 and 100,000 milesA clutch should last you between 50,000 and 100,000 miles before you need to replace it. When their lifespan comes to an end, it's vital to change your clutch as soon as possible as its vital to maintaining healthy performance of your vehicle.

Is it a good idea to drive with the clutch partially engaged?

Avoid driving the car in half clutch. In jams, drivers tend to run the car with the half clutch depressed. A clutch in a vehicle has two functions, to fully engage and fully disengage. If the clutch is half depressed, it will just rub against the flywheel producing heat.

Can you drive with the clutch engaged?

It's a common habit among learner drivers, but riding the clutch is something that anybody can do while driving a car. The basic principle of clutch control is to fully disengage the clutch when changing gear by pressing the clutch pedal to the floor with your left foot then and re-engage by lifting off the pedal.

What allows the operator to control the engagement and disengagement of the clutch assembly?

A clutch release mechanism allows the operator to operate the clutch. Generally, it consists of the clutch pedal assembly, a mechanical linkage, cable, or hydraulic circuit, and the clutch fork. Some manufacturers include the release bearing as part of the clutch release mechanism.

Is the clutch engaged in neutral?

If you place the transmission in neutral and take your foot off the clutch, the clutch is now engaged. The input shaft is now rotating. But because the transmission is in neutral, none of the gears is engaged, and no power is going through the transmission.

What causes a compressor to rotate?

The compressor belt and the armature plate of the compressor drive are engaged, which causes the compressor drive to rotate along with the engine. When the ac is turned off, the clutch is de-energized and the compressor belt and the armature plate of the compressor drive are disengaged.

How to fix AC compressor clutch?

Besides that, here are the most common steps to fixing the ac compressor clutch problem before taking your car to a professional: Use a mechanic’s stethoscope probe (view on Amazon) to listen to your clutch – To use the stethoscope, turn your engine ON. Place the probe on the ac clutch in an area that is still.

How to tighten ac belt?

The pulley connects the ac compressor clutch to the engine crankshaft so the ac compressor will come on when you turn your car on. To tighten the belt, turn your engine OFF. Examine the pulley belt for any contamination or cracks. Also, be sure to check for the correct tension. There should not be more than one quarter inch of play in the belt. If you feel play, then loosen the mount bolts at the base of the ac compressor. Then, loosen the top adjusting bolt. Pull the ac compressor against the belt until there is no longer slack. Retighten all the bolts. You can also diagnose a belt that needs replacing when you cannot defrost the windshield.

What is AC clutch?

The ac compressor clutch is a part that is electromagnetic and designed for the purpose of engaging and disengaging the ac compressor pulley from the ac compressor drive. The clutch becomes energized when the ac is turned on.

Why does my AC make a squeaky noise?

Grinding and squeaking noises – When the ac clutch is in ill repair, you may hear loud grinding or squealing noises seemingly coming from the ac compressor. There may be a worn bearing in the middle of the problem. It may be a rattling noise if the problem is in the pulley bearings.

What is a corroded CAN bus?

Corroded CAN bus harness wires – Corrosion in the CAN bus harness (view on Amazon) wires Is a very common problem that plagues the electrical wires and the connectors. The Controller Area Network (CAN bus) is the communication link between the parts in your car. The CAN bus also allows the engine communication units (ECUs) to communicate with each other by transforming r data over frames. Sensor problems arise when the CAN bus wires become open or corroded. The ac clutch is next in line for damage if the corrosion is not addressed in a timely manner.

Why is my AC clutch not working?

4 Reasons Why Your AC Clutch is Not Engaging. You turn on the air conditioning in your car so you can feel an icy cold breeze, only to find your ac won’t come on. Many times, this scenario means the ac compressor clutch is not engaging. Well, the summer heat can be blazing in some places where it is certainly no time for the ac to stop working.

Why is my clutch pedal not engaging?

Beside not engaging, or not disengaging, there can be other issues as well, such as noisy operation, or chattering on engagement. On older mechanical linkages, lack of periodic lubrication can lead to high effort or binding in pivots or cables, or a pedal that does not return smoothly. A bad throwout bearing can be a major headache in stop and go traffic, making horrible noises every time the clutch pedal is depressed. These are often annoyances more than anything else, especially since fixing them often involves removing the transmission/transaxle to get to the parts.

What does a bad throwout bearing mean?

A bad throwout bearing can be a major headache in stop and go traffic, making horrible noises every time the clutch pedal is depressed. These are often annoyances more than anything else, especially since fixing them often involves removing the transmission/transaxle to get to the parts.

How often do you press the clutch pedal?

In normal, modern stop-and-go driving, you probably press the clutch pedal in every few seconds. And on that one time when you press it and the car still creeps forward, you know you have a problem. Sometimes a part fails and the clutch goes from working normally, to not working in an instant.

What does it mean when a clutch doesn't engage?

A clutch that doesn't engage fully, or slips under heavy load, is the normal failure mode of a worn out friction disc of pressure plate that has lost its tension. When you press the clutch, your foot counters the diaphragm spring which presses the friction disc to the flywheel.

What is troubleshooting in mechanics?

Troubleshooting can seem like a mysterious “black art” only practiced by experienced, professional mechanics, when you don't know how certain systems in your car work. Figuring out the problem and solution is simply the result of having the right knowledge combined with an intelligent, systematic approach. If you work by process of elimination, ...

Why does my clutch slip?

If the spring pressure is not great enough , or the clearance between all the parts is too great, there won't be enough friction to transmit the power from the motor to the transmission. Friction discs wear and get thinner, and springs get weaker with time and use, which is why all clutches eventually start to slip.

Can a clutch go wrong?

There are several different ways that the clutch on a manual transmission equipped car can go wrong, but it is a simple mechanical system, or hydraulic/mechanical, and not hard to understand. Once you understand what the parts are, and how they interact, finding and fixing the problem should be easy. There are two basic ways a clutch fails - it either fails to disengage, or fails to engage fully.

Why is the PCM running?

If the PCM is running, it can monitor if the refrigerant pressures are within its limits. Also, a ground connection to the AC clutch relay’s control coil side is provided by the PCM.

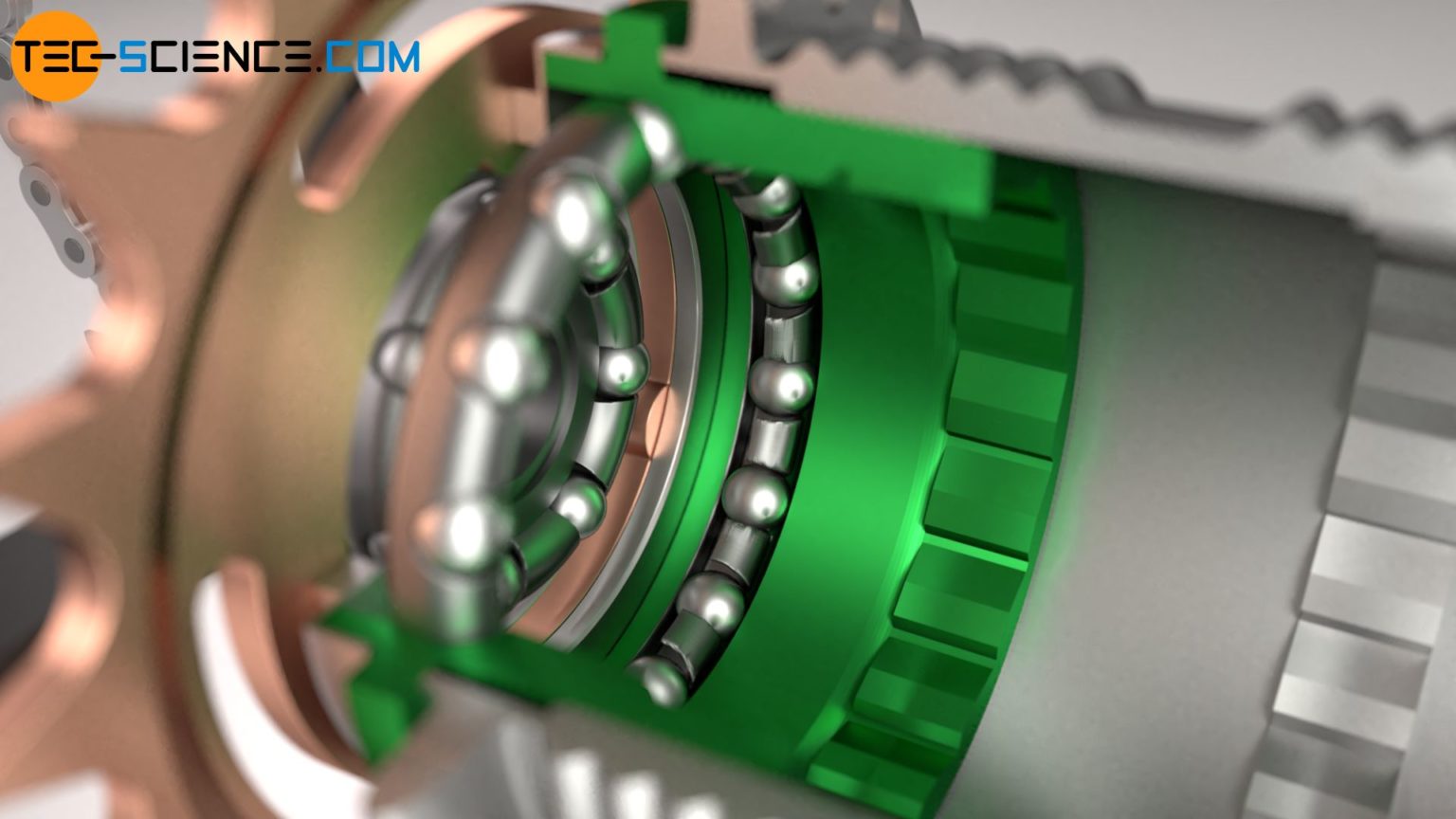

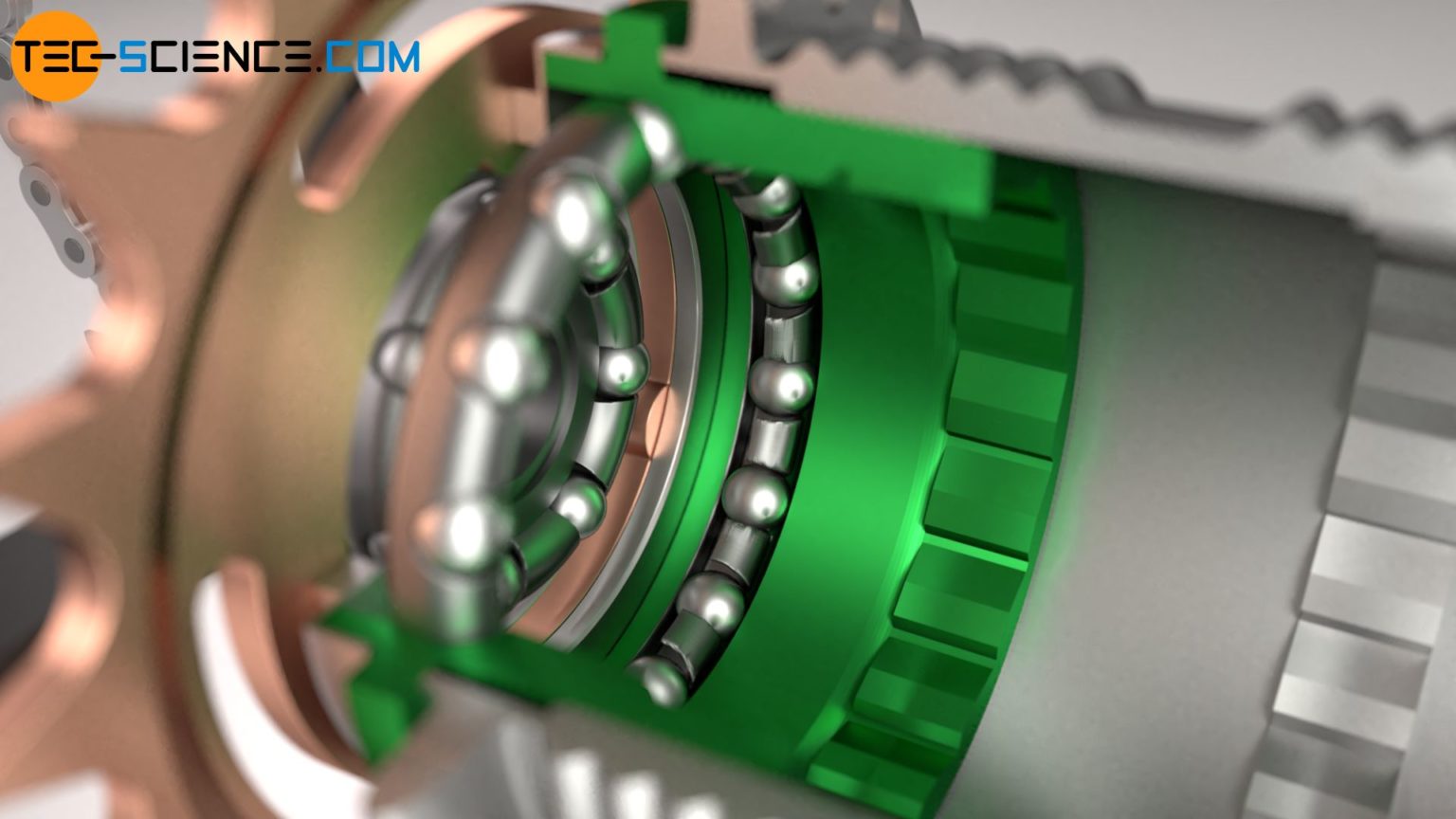

What is an AC compressor clutch?

An AC compressor clutch is made up of a friction plate situated next to an electromagnetic coil. Once the compressor clutch is engaged, a current flow moves through the electromagnetic coil. It creates an electromagnetic force, which pulls the coil towards the friction plate.

How does an AC compressor work?

The AC compressor is empowered by the flywheel of a car’s engine. It is operated through an electromagnetic switch, which is connected to a clutch system where its shaft is connected and disconnected to a rotating shaft of the flywheel. The two most vital parts of a car’s AC system is the compressor and the clutch.

What is the main function of a compressor?

Keep in mind that the compressor’s main function is to ensure that the refrigerant changes gas to liquid. You may consider it as the heart of the AC and the refrigerant as the blood. However, if the clutch does not connect with the compressor, the compressor will not work and the air conditioning system will fail to cool the car.

How to check if clutch is working?

Try checking if the clutch is in good condition by applying these steps: 1 Turn the AC controls to maximum air conditioning. 2 Start the car engine. 3 Look closely and observe the front part of your clutch. 4 Make sure that the clutch and the pulley is spinning simultaneously. 5 If the only rotating part is the pulley, then the clutch fails to run.

Why is my AC compressor clutch not engaging?

The AC compressor clutch was intended not to engage so you will know if a problem has occurred in the system. Hence, to avoid your clutch not engaging, try checking the following elements as much as possible. These include your Fuse, Coolant or Refrigerant, and Compressor Oil.

What are the two most important parts of a car's AC system?

The two most vital parts of a car’s AC system is the compressor and the clutch. Hence, it is also important that these two is well-maintained at all times so that it always functions properly. Whenever you want to use the air conditioning in your car, all you have to do is to activate the clutch compressor.

What causes a compressor to rotate?

The compressor belt and the armature plate of the compressor drive are engaged, which causes the compressor drive to rotate along with the engine. When the ac is turned off, the clutch is de-energized and the compressor belt and the armature plate of the compressor drive are disengaged.

How to fix AC compressor clutch?

Besides that, here are the most common steps to fixing the ac compressor clutch problem before taking your car to a professional: Use a mechanic’s stethoscope probe (view on Amazon) to listen to your clutch – To use the stethoscope, turn your engine ON. Place the probe on the ac clutch in an area that is still.

How to tighten ac belt?

The pulley connects the ac compressor clutch to the engine crankshaft so the ac compressor will come on when you turn your car on. To tighten the belt, turn your engine OFF. Examine the pulley belt for any contamination or cracks. Also, be sure to check for the correct tension. There should not be more than one quarter inch of play in the belt. If you feel play, then loosen the mount bolts at the base of the ac compressor. Then, loosen the top adjusting bolt. Pull the ac compressor against the belt until there is no longer slack. Retighten all the bolts. You can also diagnose a belt that needs replacing when you cannot defrost the windshield.

What is AC clutch?

The ac compressor clutch is a part that is electromagnetic and designed for the purpose of engaging and disengaging the ac compressor pulley from the ac compressor drive. The clutch becomes energized when the ac is turned on.

Why does my AC make a squeaky noise?

Grinding and squeaking noises – When the ac clutch is in ill repair, you may hear loud grinding or squealing noises seemingly coming from the ac compressor. There may be a worn bearing in the middle of the problem. It may be a rattling noise if the problem is in the pulley bearings.

What is a corroded CAN bus?

Corroded CAN bus harness wires – Corrosion in the CAN bus harness (view on Amazon) wires Is a very common problem that plagues the electrical wires and the connectors. The Controller Area Network (CAN bus) is the communication link between the parts in your car. The CAN bus also allows the engine communication units (ECUs) to communicate with each other by transforming r data over frames. Sensor problems arise when the CAN bus wires become open or corroded. The ac clutch is next in line for damage if the corrosion is not addressed in a timely manner.

Why is my AC clutch not working?

4 Reasons Why Your AC Clutch is Not Engaging. You turn on the air conditioning in your car so you can feel an icy cold breeze, only to find your ac won’t come on. Many times, this scenario means the ac compressor clutch is not engaging. Well, the summer heat can be blazing in some places where it is certainly no time for the ac to stop working.