See more

What is shewhart known for?

Shewhart reported that bringing a process into a state of statistical control—where there is only chance‐cause (common‐cause) variation—and keeping it in control was needed to reduce waste and improve quality. Shewhart is referred to as the “father of statistical quality control”.

Why did shewhart invent control charts?

Shewhart) or process-behavior charts, are a statistical process control tool used to determine if a manufacturing or business process is in a state of control....Control chartFirst described byWalter A. ShewhartPurposeTo determine whether a process should undergo a formal examination for quality-related problems2 more rows

Who learned the statistical control from shewhart?

Walter A. ShewhartScientific careerFieldsphysics, engineering, statisticsInstitutionsWestern ElectricInfluencedW. Edwards Deming5 more rows

What is Six Sigma of Walter A Shewhart?

Six Sigma Concept It is a standard statistical unit used to measure and describe the distribution of any process about its mean. Shewhart's ideas and statistical concepts were embraced in clinical laboratories for several years.

What are the two types of variations as explained by Dr Shewhart?

Common and Special Causes of Variation Shewhart invented a new way to think about variation and how to use it to drive improvement. He identified two types of variation – variation from assignable (common) causes and variation from chance (special) causes.

Who is known as the father of statistical quality control?

This special issue is devoted to celebrate the Quasquicentennial (125th) Birth Anniversary of the Father of Statistical Quality Control – Dr Walter Andrew Shewhart. Dr Walter Andrew Shewhart (Born: 18 March 1891 – Died: 11 March 1967) was a versatile genius as he was a physicist, an engineer and a statistician.

What is the inference of process is in control according to Walter Shewhart?

What is the inference of "Process is in control" according to Walter Shewhart? Process has chance causes - The only time the process is said to be in control is when the common causes of variation contribute to the variability of the process.

Who is the grandfather of TQM?

Walter Shewhart -The original notions of Total Quality Management and continuous improvement trace back to a former Bell Telephone employee named Walter Shewhart.

Who invented SQC?

Walter ShewhartThe pioneer of statistical quality control Walter Shewhart and his wife Edna. His important work was recognized through the creation of the specialized Shewhart award, honoring scientists' contribution to the field. Statistical quality control in clinical chemistry and haematology has a tradition of almost 60 years.

What is the focus of Six Sigma?

The Six Sigma method is focused on limiting fluctuation within business processes and quality management of process output by implementing problem-solving statistical methods. Conversely, the primary focus of Lean Six Sigma is to eliminate waste and improve existing processes.

What are the five phases of Six Sigma?

The Six Sigma Methodology comprises five data-driven stages — Define, Measure, Analyze, Improve and Control (DMAIC). When fully implemented, DMAIC standardizes an organization's problem-solving approach and shapes how it ideates new process solutions.

What is the purpose of control charts?

The control chart is a graph used to study how a process changes over time. Data are plotted in time order. A control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit. These lines are determined from historical data.

Why are control charts used?

A control chart is used to monitor a process variable over time. That variable can be in any type of company or organization - service, manufacturing, non-profit and, yes, healthcare.

Who introduced the concept of control chart?

1 Control charts. The first monitoring method based solely on data was proposed in 1931 by Shewhart and called control chart (Shewhart, 1931).

What is the purpose of a control chart quizlet?

A control chart that tracks the range within a sample. It indicates that a gain or loss in uniformity has occurred in dispersion of a production process. A quality control chart used to control the number of defects per unit of output.

What did Shewhart propose?

Shewhart proposed that to improve quality and reduce scrap, common-cause variation should be controlled. In this way, any process can be brought under statistical control. In order to distinguish between special cause and common cause variations, first the process should be brought to a state of statistical control.

What is ASQ in engineering?

ASQ – American Society for Quality. ASQ of individuals who are passionate about methods of quality control. Members of ASQ contribute to industry with their ideas of quality control and experience. Shewhart was ASQ’s first honorary associate, he efficaciously brought together the principles of statistics, economics and engineering.

What are the two categories of variation?

Shewhart acknowledged two classes of variation namely ‘special‐cause’ and ‘common‐cause variation . These two categories can also be termed as ‘ assignable‐cause’ and ‘chance‐cause’’ variation respectively. A control chart was designed by him to explain these two categories of variations. Shewhart proposed new attributes and variables in his control charts. Shewhart proposed that to improve quality and reduce scrap, common-cause variation should be controlled. In this way, any process can be brought under statistical control. In order to distinguish between special cause and common cause variations, first the process should be brought to a state of statistical control. After bringing a process to this state, it would be likely easy to forecast future outputs and also to manage processes in economical ways. Shewhart’s principle paved way for modern scientific analysis of process control.

What was Shewhart's greatest achievement?

Another important element in Shewhart’s achievements was his quality of bringing out ideas and knowledge of other individuals. Shewhart always believed that statistical theory would serve the needs of industry. He was a man of science who worked patiently to develop ideas which made the world better.

When was Six Sigma invented?

Six Sigma as a measurement standard in product variation can be traced back to the 1920’s when Walter Shewhart showed that three sigma from the mean is the point where a process requires correction. Walter Andrew Shewhart was an American Physicist and statistician, he is referred as the ‘Father of Statistical Quality Control’.

What is the meaning of the sigma?

‘Sigma’ is a Greek letter, it is a mathematical term which is used to denote standard deviation. It is a standard statistical unit used to measure and describe the distribution of any process about its mean.

Why is reducing variation important?

Reducing variation to improve quality resulted in manufacture of precise things. The concept was applicable in different fields like automobiles, electronics and constructions etc.

What was Walter Shewhart's contribution to the quality world?

Shewhart's Contribution to the Quality World. Walter A. Shewhart was a giant among giants in the quality movement during the first half of the 20th century. His mentoring of other engineers at Western Electric and his groundbreaking work with control charts arguably led a quality revolution and launched the quality profession.

Where did Shewhart teach?

Shewhart lectured extensively on the subjects of quality control and applied statistics in India, at the University of London, at Stevens Institute of Technology and at the graduate schools of the U.S. Department of Agriculture. He also was a member of many societies and governmental agencies.

What did Deming do with Shewhart?

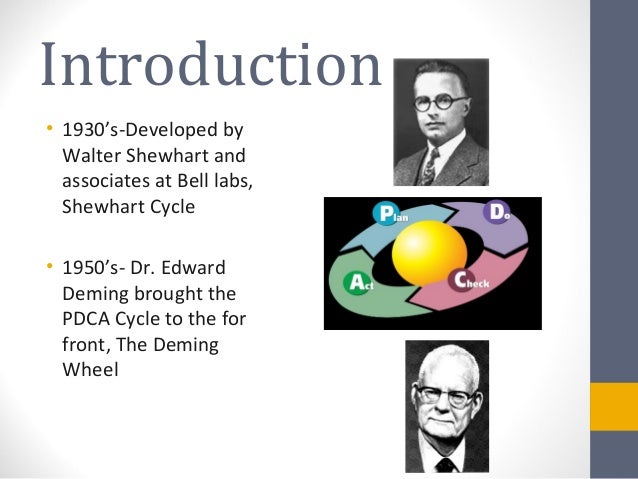

Deming continued to champion Shewhart’s ideas, methodologies and theories throughout his career. While working with Japan, Deming further developed some of Shewhart’s methodological proposals of scientific interference, which had been named the Shewhart Cycle and was represented by the plan-do-check-act elements.

What was the purpose of the Shewhart book?

Shewhart’s book popularized statistical control and its use then spread throughout industry. From the 1930s forward, Shewhart’s interests expanded from industrial quality to wider concerns in science and statistical inference. In 1934, W. Edwards Deming and another physicist, Raymond T. Birge, published a paper on measurement error in science.

What did Hewhart believe?

Shewhart believed that statistical theory should serve the needs of industry and society as a whole. He challenged the norms of his day and showed manufacturers the better way that revolutionized industry.

What is Shewhart's principle?

Shewhart’s principle was that bringing a process into a state of statistical control would allow the distinction between assignable and chance cause variations. By keeping the process in control, it would be possible to predict future output and to economically manage processes.

When did Shewhart die?

Upon his death in 1967, there were a multitude of commentaries from many contributors who were themselves important figures in the development of the quality field. An excerpt from a speech by the chairman of the committee that awarded the first ASQ Shewhart Medal captured Shewhart’s character in the following:

What did Walter Shewhart do for Bell Labs?

This ensured greater economic gains in the form of reducing the need for repair of the equipment the labs produced. He referenced what constituted "common causes" and "special causes" of production issues. He analyze these with his famed Shewhart charts or control charts, Walter Shewhart laid the statistical foundation upon which all modern industry would be built.

Where did Walter Shewart work?

After his very brief term in academia, Shewart spent the better part of his career at Western Electric, and the aforementioned Bell Labs. He exceled both as an engineer (from 1918-1924) to technical advisor (from 1925-1956). An accomplished lecturer speaking both overseas and domestically, Walter Shewart garnered international respect and acclaim at such places as Rutgers University and Princeton. Here, he served in the capacity of both honorary professor to the former and contributing advisor to the department of mathematics of the latter.

What is the Shewhart cycle?

Walter Shewhart also created the Shewhart Cycle or PDSA (plan, do, study, act) cycle, the scientific method for learning through action as well as observation. To illustrate: if a company isn't experiencing the success it would like in a given area, the company is wise to brainstorm ideas for improvement.

What awards did Shewart receive?

Shewart received concrete awards in addition to the accolades of his peers and superiors. He received the Holley Medal of the American Society of Mechanical Engineers. He gained Honorary Fellowship of the Royal Statistical Society and American Society for Quality.

Where did Walter Shewhart go to college?

In addition to being a visionary in this way, it's no surprise Walter Shewhart excelled as a mathematician at the University of Illinois, where he earned his undergraduate degree and post graduation degrees. He went on to study at the University of California at Berkeley, where in 1917 he earned his doctorate in physics.

Who is Walter Shewart?

Walter Shewart was also an accomplished author, penning the landmark books Economic Control of Quality of Manufactured Product in 1931 and Statistical Method from the Viewpoint of Quality Control in 1938, as well as countless other widely respected articles for professionally specific journals.

Who is the most famous person to contribute to the modern industry?

Touch devices users can use touch and swipe gestures. One of the most notable contributors to modern industry is Walter Shewhart, a quality control pioneer. He started his rise to guru status as a Bell Telephone employee in 1918.

How many times did Shewhart read Lewis's book?

There is little doubt that Shewhart was profoundly influenced. He later confessed to Deming that he had read Lewis' book 14 times before he began to understand it. This absorption of Lewis' alternative perspectives and the increased public demands on Shewhart's time may have been factors in the reduction of his academic output, which amounted to only three short papers between 1932 and 1937.

Why did Deming go to Japan?

MacArthur quickly assembled teams that would help the country rebuild itself using American best practice. As part of this, Deming went to Japan to assist in the preparation of Japan's first post-war census.

What is the purpose of the Shewhart diagram?

Shewhart's 1924 diagram and the short text which accompanied it, set forth all of the essential principles of modern process quality control. The diagram monitored a production process over a period of time using the percentage of defective products as an index. In addition to the upper and lower tolerance limits for the product, Shewhart introduced two wider limit lines at three standard deviations above and below the arithmetic mean and proposed that if a value exceeded these values there was some sort of problem with the process. To emphasise this Shewhart wrote this point indicates trouble against a point above the upper limit in his diagram.

Where did Walter Shewhart live?

After only six months at La Crosse, Walter Shewhart left to join the Western Electric Engineering Department at 463 West St, New York ( to conduct research mainly for war purposes ). Walter and his wife rented a small apartment just south of Prospect Park in Brooklyn, as he began his 38 year career with the US telecoms giant.

Why did Shewhart visit Berlin?

During his three month trip he found time to visit Berlin to meet with industrial researchers. Shewhart's German visit is credited with persuading the German Standards Committee (Deutsche Normenausschluss) to standardise their statistical methodology.

When did Shewhart write his memo?

Later in 1924 Shewhart distilled some of his ‘relatively complex underlying theory’ into a much more accessible format when he sent his boss George Edwards a one page memo. About a third of that page was given over to a simple hand drawn diagram which we would now recognise as a control chart.

Where was Western Electric made?

Most of this equipment was being manufactured at Western Electric's massive Hawthorne Works in the Chicago suburb of Cicero. Just two months later, the US government took Western Electric and its parent AT&T group into public ownership. In October 1918 Shewhart wrote to Professor Slate (one of his old UC supervisors) revealing that his first research project at Western Electric had been on a device to be used by aviators which had attracted an initial government order of 40,000.

What is the Shewhart cycle?

He also developed the Shewhart Cycle Learning and Improvement cycle, combining both creative management thinking with statistical analysis. This cycle contains four continuous steps: Plan, Do, Study and Act. These steps (commonly refered to as the PDSA cycle), Shewhart believed, ultimately lead to total quality improvement. The cycle draws its structure from the notion that constant evaluation of management practices -- as well as the willingness of management to adopt and disregard unsupported ideas --are keys to the evolution of a successful enterprise.

Who is the grandfather of total quality management?

Walter Shewhart- The Grandfather of Total Quality Management.

His Background, Life and Work

What Or Who Influenced Walter A. Shewhart?

- A number of Quality heroes were contemporaries of Walter Shewhart’s while he was at Bell Laboratories. Indeed, his manager was George D. Edwards, who went on to become the first president of the American Society for Quality Control(renamed in 1997 as the American Society for Quality). Walter also went on to mentor and influence and mentor W. Edwards Deming, while …

What Was Walter Shewhart’s “Invention” and How It Influenced The sector?

- Walter Shewhart developed a critical insight that, while all processes exhibit variation, some variation is inherent to the specific process. From this thinking, he invented the Statistical Process Control (SPC) technique in 1924. The technique has been used across a range of industries ever since. He also invented the Control Chart – which is to this day known also as the ‘Shewhart cha…

Contributions to Process Improvement

- Walter Shewhart was hugely important in his contributions to process improvement, helping to reduce variation when SPC went mainstream. He was also instrumental in introducing SPC to post-war Japan. In 1931 he published ‘Economic Control of Quality of Manufactured Product’ – which you can still buy today! Let’s find out more about the techniques he...

Reducing Variation – to Improve Quality

Six Sigma Concept

- ‘Sigma’ is a Greek letter, it is a mathematical term which is used to denote standard deviation. It is a standard statistical unit used to measure and describe the distribution of any process about its mean. Shewhart’s ideas and statistical concepts were embraced in clinical laboratories for several years. Clinical laboratories used these concepts in proficiency testing and quality control operati…

ASQ – American Society For Quality

- ASQof individuals who are passionate about methods of quality control. Members of ASQ contribute to industry with their ideas of quality control and experience. Shewhart was ASQ’s first honorary associate, he efficaciously brought together the principles of statistics, economics and engineering. Shewhart developed highly effective tools specificall...