The Role of Leaf Spring Bushings and How Replacment

- Adds a dramatic amount of performance and durability to any vehicle!

- For cars, trucks and SUVs.

- Helps the vehicle be in control – when maneuvering through turns, during standing start accelerations, braking, even...

- Made of Energy’s HYPER-FLEX™ performance polyurethane which lasts 5 -10 times longer than conventional...

What are leaf spring bushings made out of?

The material that most leaf spring bushings are made out of is rubber but other materials such as polyurethane have started gaining widespread use. The reason why rubber is slowly being replaced is because it degrades over time which can cause rattling in the suspension, extra wear on the springs/components, and a rougher ride.

What is a leaf spring on a bus?

The leaf spring is a pretty old design—it's a pack of arched steel strips that get progressively longer and are held together with shackles. The pack bows and flexes to absorb the energy of impact with bumps or potholes, and dates back to 19th century stagecoaches and buckboards.

What kind of bushings do you use for leaf springs?

Popular Leaf spring Bushing: Nylon bushings are designed for use with trailer suspension systems. Insert them into the eyes of leaf springs or the bolt holes of equalizers to ensure proper sizing for suspension bolts. Bronze bushing is designed for use with trailer suspension systems.

How to replace leaf spring shackles and bushings?

How to Replace Leaf Spring Shackles and Bushings 1. Block the front wheels and raise the rear with a jack under the third member, lowering the vehicle onto stands under... 2. Keep the jack under the rear end. Do one end of a single spring at a time, removing the bolt securing the spring into... 3. ...

When should you replace leaf spring bushings?

Usually when one of the leaves breaks, both leaf springs are replaced. It's technically possible to replace only the broken leaf, but often when one leaf breaks, other leaves might be worn-out, cracked or fatigued too.

Can you replace bushings in leaf spring?

Replacing the leaf spring shackles in newer vehicles or replacing the bushings within those shackles with OEM rubber or polyurethane bushings will restore your original ride quality. Polyurethane (poly) bushings are a little more expensive but will last longer than OEM rubber bushings.

How much does it cost to replace leaf spring bushings?

The average cost for leaf spring replacement is between $687 and $777. Labor costs are estimated between $165 and $208 while parts are priced between $523 and $569. This range does not include taxes and fees, and does not factor in your specific vehicle or unique location. Related repairs may also be needed.

Do leaf springs have bushings?

Most trailer leaf springs will have a bushing in the eyes of the spring.

How do you check leaf spring bushings?

0:306:11How To Check For Wear In Leaf Spring Pins & Bushings - YouTubeYouTubeStart of suggested clipEnd of suggested clipUm you wanna see if the bush is worn where the pin is so generally you'll get up and down movement.MoreUm you wanna see if the bush is worn where the pin is so generally you'll get up and down movement. With your arm spring. So you generally get a pry bar you get a pry bar in like so on your pry.

How many bushings does a leaf spring have?

First off, there are two bushing positions on the rear leaf spring shackle – one connects to the leaf spring (rear upper) and one connects to the frame (rear lower). The bushing that could be molded or common is the one that connects the shackle to the frame or the “rear lower” position.

How do I know if my leaf springs are worn out?

Look out for these tell tale signs that you need to replace your leaf springs:Squeaky sounds while your truck is in motion.Slouching on one side.Sagging in the back.Diminished handling.Trouble hauling and towing loads.Suspension bottoming out.Cracks on leaves.

Should truck leaf springs be replaced in pairs?

Stabilizer links are replaceable as a single part and generally do not require being replaced in pairs. Leaf springs may need to be replaced in pairs if: a match to the undamaged leaf spring cannot be identified or obtained. the undamaged leaf spring appears to be aged or worn."

Is it hard to replace leaf springs?

Leaf springs are an integral part of a vehicle's suspension system. They are relatively easy to replace on your own after you raise the vehicle up with a floor jack. A few bolts fasten the springs to the brackets underneath the car.

Should I grease my leaf spring bushings?

Leaf springs don't have zerk fittings and they're a pain to service once installed – properly greasing the bushings on initial installation is the best way to ensure silent operation as long as possible.

How do you lubricate leaf spring bushings?

0:302:43How To Lubricate Leaf Springs in 2 Minutes - YouTubeYouTubeStart of suggested clipEnd of suggested clipBetween the leaf springs you can use petroleum-based greases but people tend to say that that canMoreBetween the leaf springs you can use petroleum-based greases but people tend to say that that can damage the plastic or rubber that is between the leaf springs.

How do you stop leaf springs from squeaking?

0:563:17How To Fix Squeaking Leaf Springs - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere are two causes for newly installed leaf springs to squeak. And both involve torque too much orMoreThere are two causes for newly installed leaf springs to squeak. And both involve torque too much or too little too much torque would involve the eye. And or the shackle bolts.

How do you replace front leaf spring bushings?

5:4621:09Leaf Spring Bushing Replacement - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo with the bushing out and the bolt in my hand. I slide it into the wall bushing look at all thatMoreSo with the bushing out and the bolt in my hand. I slide it into the wall bushing look at all that slop. As you're four-wheeling and the front ends articulating there strain on the bushing.

How do you remove bushings from leaf springs?

0:153:33Use Everyday Tools to Remove Leaf Spring Bushings by @Gettin' Junk ...YouTubeStart of suggested clipEnd of suggested clipOr at least remove a leaf spring bushing from a leaf spring. Now there's a couple different ways toMoreOr at least remove a leaf spring bushing from a leaf spring. Now there's a couple different ways to do this but this video is gonna be about how to do it with just normal tools.

How do you replace a spring bush?

6:2111:53Leaf Spring Bushing Replacement - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can take it to a hydraulic press and press in these new bushings. If you can't fit them in withMoreYou can take it to a hydraulic press and press in these new bushings. If you can't fit them in with any hand tools or anything like that but hopefully this should be nice and easy.

How do you stop leaf springs from squeaking?

0:563:17How To Fix Squeaking Leaf Springs - YouTubeYouTubeStart of suggested clipEnd of suggested clipThere are two causes for newly installed leaf springs to squeak. And both involve torque too much orMoreThere are two causes for newly installed leaf springs to squeak. And both involve torque too much or too little too much torque would involve the eye. And or the shackle bolts.

How does a leaf spring work?

As leaf springs compress and extend, the arch changes causing the spring to get longer and shorter as they cycle. One end of the spring is fixed to the chassis, while the other end uses a shackle to account for this change in length. On rear axles, the shackle is always at the rear. The shackle can be above the spring (compression style) or below the spring (tension style). Tension style shackles require the spring to have more arch for the same ride height. Sometimes a “shackle flip” is used to gain lift by converting the shackle from a tension style to a compression style using the same springs.

What are leaf springs made of?

Details Matter. Leaf springs are made up of a main leaf, with eyes on each end that hold bushings and bolt to the vehicle. Multiple other leaves carry the weight of your rig. There are numerous options for how to configure these packs of spring steel to perform under your vehicle.

Why do you use bolt clamps on a leaf?

Bolt clamps are preferred to regular crush style clamps since they cause, you guessed it, less friction. Clamps prevent the leaf plates from “fanning out” laterally.

How do lift blocks work?

Lift blocks can be used between your axle and leaf springs in a spring-over configuration. They increase the distance between the axle and the spring pack. Blocks are an inexpensive way to make room for larger tires, only requiring longer U-bolts. Lift blocks should never be used in a front axle application, since the forces generated from steering put side loads on the blocks. Should the block break or the U-bolts loosen, there is the potential to lose all steering. We don’t have to explain to you why that is a bad idea.

What is a military wrap spring?

Some springs feature military-wrap spring eyes, where the second leaf wraps around the main leaf to form a double-wrap. This design element transmits less stress to the main leaf during extreme articulation. It also lessens the odds of spring separation in the case of main leaf failure and provides greater strength, support, and durability as a whole.

What is a high end leaf spring pack?

High-end spring packs solve this issue by tapering the leaves, so they are thinner at the ends. They also use Teflon pads between the leaves to reduce friction. Other features to look for when shopping for leaf springs include bolt clamps, shot-peened leaves, and military wrapped eyes.

What is the easiest suspension system for a 4x4?

The Simplest Suspension Is More Complicated Than You Think. While new Jeeps and SUVs these days typically come with coil springs, leaf springs still exist on the rear of most pickup trucks (Ram 1500s and 2500s being the exception). Leaf springs are the most simplistic and inexpensive suspension system for your 4×4.

How do leaf spring bushings work?

Leaf spring bushings are not very expensive, but it might take quite a bit of labor to press the old bushings out and new ones in. Weak leaf springs can twist, causing the change in the driveline angle (axle wrap), which often results in driveline vibrations felt during hard acceleration or when decellerating at 10-30 mph. Some manufacturers offer tapered shims for the leaf springs to correct the driveline angle, others recommend replacing weak leaf springs. Many truck enthusiasts install aftermarket traction bars that limit rotation of the axle.

Where is the front end of a leaf spring?

The front end of the leaf spring is connected to the mounting bracket attached to the frame. The axle is located to the leaf spring center bolt and secured by U-bolts. The rear eye of the leaf spring is connected to the frame through a shackle that can swing back and forth, allowing for spring expansion.

Why do leaf springs rust?

Many problems related to leaf springs are caused by faulty leaf spring hardware. For example, a rear shackle hanger is known to rust and break off in some trucks. It will also cause one of the sides to sit lower. Although the part is not very expensive, replacing a broken hanger (bracket) can be labor-intensive, but most shops offer a reasonable price for this kind of job.

How much to replace leaf springs on a pickup truck?

Replacing both leaf spring assemblies in an average light pickup truck in a repair shop will cost from $480 to $860 for two. Typically the hardware such as bolts and shackles will also need to be replaced. In some trucks, replacing leaf springs is fairly easy, although bolts are often seized; in others, the fuel tank or some other part is in the way and might need to be removed or lowered. If you are doing the job yourself, make sure to follow manufacturer's instructions and safety precautions. If you use your truck for hauling heavy loads, you might opt for upgrading to heavy-duty leaf springs, although they are more expensive and will cause a stiffer ride.

How to tell if leaf springs are bad?

However problems related to leaf springs are common. One of possible signs of a problem is when the rear of the truck is sagging or the truck leans to one side . When this happens, the headlights can also point higher, dazzling drivers in oncoming vehicles. Sagging leaf springs can be caught when doing the wheel alignment.

What are the tapered shims on leaf springs?

Some manufacturers offer tapered shims for the leaf springs to correct the driveline angle, others recommend replacing weak leaf springs. Many truck enthusiasts install aftermarket traction bars that limit rotation of the axle.

What is the difference between a mono leaf spring and a multi leaf spring?

Rear leaf spring in a truck. Some vehicles use mono-leaf springs, while most pickup trucks have multi-leaf rear springs, as they are better suited for heavy loads. Leaf springs not only support the load, but hold the rear axle in place.

What are Leaf Spring Bushings and What Do They Do?

Leaf spring bushings are the rubber pieces that reduce friction between your vehicle’s leaf springs and body. They’re designed to cushion, support, and protect the metal-on-metal connection of the stiff leaf springs with your truck or SUV frame. Without these bushings, you would hear a lot of vibration when driving down the road.

Detailed Instructions on How to Remove Leaf Spring Bushings

There are seven simple steps to remove your leaf spring bushings. Keep in mind that this is an active job, so make sure you have the right tools, safety gear, and lots of patience before starting.

Precautions for Beginners When Removing Leaf Springs

Avoid making these common mistakes when working on your truck or SUV’s suspension system:

How to Tell If Your Leaf Spring Bushings Need To Be Replaced

If you are experiencing excessive body roll or have noticed that your truck or SUV has become harder to control at high speeds, it could be time to consider replacing your leaf spring bushings. If the insides of your old ones are torn and ragged, then your best option is to replace them all.

Final Thought

It’s important to keep your truck or SUV’s suspension system in good shape. You can do this by replacing your leaf spring bushings when necessary, which will help reduce the risk of excessive body roll and other problems that could lead to an accident.

What is leaf spring?

The leaf spring is a pretty old design—it's a pack of arched steel strips that get progressively longer and are held together with shackles. The pack bows and flexes to absorb the energy of impact with bumps or potholes, and dates back to 19th century stagecoaches and buckboards. Source | Mike Aguilar.

How to reassemble rear leaf spring?

Reassemble the rear leaf spring/shackle assembly using the jack under the axle housing to raise or lower the housing as necessary to insert and tighten the bolt.

How to assemble Advance Auto Parts loaner suspension?

Assemble the Advance Auto Parts loaner suspension press on the leaf spring/shackle with the small end offset and pressing against both the inner and outer sleeves of the bushing but centered on the cup end.

How to release bushings on a press?

Crank down on the press with whatever you've got, whether that be a wrench, socket and ratchet combo, or an impact driver, until the bushing is released. Adjust the position of the press as needed as you go.

How to clean a shackle spring?

Clean the inside of the shackle/leaf spring with fine sandpaper or a ball hone on a drill.

How to raise rear wheel?

Block the front wheels and raise the rear with a jack under the third member, lowering the vehicle onto stands under the frame.

Do you need to replace shackles and bushings?

Another way to get the job done is to replace the shackles and bushings as an assembly. This is necessary in cases where age or rust have made the integrity of the shackles questionable. This is also true of most late-model vehicles where the shackles are consumable parts, like brake pads and shock absorbers.

How do bushings protect against stress?

Whereas cartilage protects against joint stress by preventing bone-to-bone contact, bushings safeguard metal joints from stress by preventing metal-to-metal contact. However, just as cartilage can wear down in a body as an individual ages, so too can bushings wear out in a vehicle.

When to change suspension bushings?

There is no set timeframe for when to change suspension bushings. They wear down at different speeds in different vehicles. It really depends on the environment where you operate the vehicle and the amount of stress you put it through on a regular basis. Basically, you will know when to change bushings in a car or truck when the symptoms of bad bushings make it difficult to operate your vehicle.

How long does it take to replace bushings on a truck?

The steps involved in bushing replacement are relatively easy to master and can usually be completed in under an hour once you get the hang of how it is done. However, the first time that you repair the bushings on your truck, the steps can take several hours to complete. Therefore, it is best to reserve this undertaking for a free afternoon.

What does a bad bushing feel like?

What do bad bushings feel like? Bushings often go bad when the rubber dries out. Consequently, a bad bushing will feel hard and inflexible. From the cab of a truck, bad suspension bushing makes riding feel more turbulent and jumpy.

Why do transmission bushings wear down?

Tie rods. Transmission mounts. Bushings are liable to become worn over time on various components due to friction, stress and age. Prolonged, recurrent exposure to engine heat can cause bushings to wear down at a hastened rate.

What is a shock absorber bushing?

Shock absorber bushes. For the suspension system of a truck, bushings are made to offer built-in flex, which helps with various vehicular functions like passive rear-wheel steering. The quality of the rubber material is what gives bushings their ability to buffer the tremors and noises of turbulence. When the quality of a set of bushings wears ...

How to tell if bushings are worn?

The Most Common Worn Bushings Symptoms. Typical tell-tale signs of worn bushings under a vehicle include the following symptoms : The vehicle makes rattling noises when driven over gravelly roads. The vehicle sounds as though it is clunking when you make sharp turns or hit the brakes.

How to tell if you need to replace leaf springs?

Look out for these tell tale signs that you need to replace your leaf springs: Squeaky sounds while your truck is in motion. Slouching on one side. Sagging in the back.

What are the Signs of Damaged Leaf Springs?

If you are not checking and inspecting your leaf springs regularly, then you might end up with problems that end up ruining your ride.

Why do leaf springs creak?

While further inspection is required to confirm worn-out or broken leaf springs definitively, using your senses is often enough to detect a problem. When you hear creaking and squeaking when traveling over rough terrain or a scraping noise as you drive, it's possibly due to issues with your leaf spring suspension.

How to tell if leaf springs are bad?

Even subtle clues your leaf springs are showing signs of wear and tear or failure is warning enough to take a closer look. Often, you can see if there are problems by parking on a flat surface and looking at your vehicle to see if one side sits lower than the other. If the car lies low on one side, then it’s time to remove the wheels and inspect further.

Do leaf springs work on a pickup truck?

In fact, you often don’t know exactly how important the performance of your leaf springs are until you find that they are not working correctly any longer.

Do leaf springs wear out?

The standard leaf springs on a car or truck are only rated to hold a certain amount of weight, and if you are routinely carrying heavy loads, this can affect the wear on your leaf springs. Our heavy-duty options are designed to increase hauling and towing capacity and stand up to the most challenging applications.

What is leaf spring?

Leaf springs are commonly used in heavy duty trucks, pickups, vans and SUV’s and are a critical part of the vehicles suspension. At some point they will reach the end of their life expectancy and will need to be replaced, but how do you determine what leaf spring you have on your vehicle?

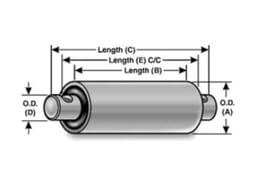

How to identify leaf spring?

One method of identifying a leaf spring is using the O.E.M. part number. O.E.M or stamping numbers are located on various areas of the leaf spring. You can quickly search for OEM part numbers and SRI numbers by entering the part number in the search box at the top of this page.

How to measure leaf springs for Mack trucks?

For a Camel Back style leaf spring, measure from the center bolt to the end of the main leaf in both directions along the arch. This is for Mack trucks only.

What is the first measurement of leaf springs?

The First Measurement. The first measurement is the Main Leaf Length. Leaf springs come in different types and will require a particular way to measure that style of leaf spring.

How to measure for eye to eye spring?

Eye To Eye. For an Eye to Eye leaf spring, use a straight edge to mark the center of the eyes and measure the arch at the center bolt. Always measure to the top of the main leaf and do not include any pads or spacers.

Where is the stamping number on a multi leaf spring?

Multileaf springs stamping numbers can most commonly be found on the side, top or bottom of the clip. They may also be found on the bottom of the last leaf beside the center bolt or on the end of the shortest leaf.

Where is the leaf spring measured?

The second measurement taken is the Leaf Spring Width. This is measured at the center bolt from side to side across the leaf.