Can you use plywood to make round concrete forms?

Yes, you can use plywood to make round concrete forms. Plywood and 2-by-4 supports are often used to create concrete forms. The form’s stability and strength are aided by the plywood’s relative rigidity. The drawback of wood forms is their inability to change their shape.

How do you make concrete forms round?

Continue reading the article if you want to make round concrete forms. In the middle of the area where the form will be, drive a wooden stake into the ground. Tie a piece of rope around the stake and secure it. Once you’ve measured 4 feet along your string, you’re ready to attach the marker can at its furthest end.

What can I do with small concrete circles?

Small concrete circles, such as might be used for paving stones, can be poured into small plastic commercial forms or into cake pans. Be sure to oil the form well before pouring! You should be able to reuse these forms several times. Daisy Peasblossom Fernchild has been writing for over 50 years.

Can You pour a circle of concrete?

Pouring a circle of concrete requires a firm form. If the circle is to cover a large area, the sides of the form will need to be braced to prevent bulging or malformation of the planned shape. Concrete forms are usually made of wood; but wood does not readily bend into a circular shape.

What can I use for curved concrete forms?

Hardboard is inexpensive form material and is easy to flex into smooth curves. Hardboard siding is intended for exterior walls, but it's also great stuff for forming curves because it's flexible and cheap.

How do you make a curved form of concrete?

4:2012:24How To Form A Curved Concrete Sidewalk - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo for that one we're just using instead of using a 16 foot long azac board and having to cut it we'MoreSo for that one we're just using instead of using a 16 foot long azac board and having to cut it we're using just a piece of quarter inch plywood that we ripped down.

What material is used for concrete forms?

TimberTimber is the most commonly used material for formwork. For the best results, invest in timber formwork that is easy to work with, lightweight, and dried thoroughly. Also, make sure the timber doesn't have any loose knots that could pop out and allow the wet concrete to seep through the hole.

How do you make a round circle concrete?

2:297:41Forming A Perfect Circle Concrete Pour! - YouTubeYouTubeStart of suggested clipEnd of suggested clipSo I'm just gonna kind of pre Bend this a little bit. Start it right here is where they're gonna beMoreSo I'm just gonna kind of pre Bend this a little bit. Start it right here is where they're gonna be a step. So this arc that goes around this way we're gonna double stack. Some of these forms.

How do I create a curved formwork?

To make a broad curved edge with formwork, simply bend the timber into shape and peg it in place. If you want to make a tighter curve, do the job in stages. Start by pegging a broad curve in place. Then pour water over the timber to make it flexible.

What kind of plywood do you use for concrete forms?

For concrete forming, the plywood industry produces a special product called Plyform®, which is recommended for most general forming uses.

Can I use pressure treated lumber for concrete forms?

Pressure-treated wood is required whenever you attach framing lumber or furring strips directly to concrete or other exterior masonry walls below grade. Note that this requirement is only for exterior walls, as these may wick moisture onto the lumber.

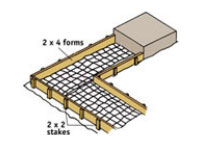

Can I use 2x4 for concrete forms?

Prior to placing concrete forms: Construct the form with 2x4 or 2x6 lumber and secure in place by wood stakes and deck screws. Excavate the slab area to a depth of about 7 inches, allowing 3 inches for a gravel base and 4 inches for concrete.

Can you use regular plywood for concrete forms?

Nearly all types of plywood panels can be used in concrete-forming, from common roof and wall sheathing to sanded panels.

How do you make a round mold of concrete?

0:236:12How To Make a Round Concrete Table top - Concrete Lazy SusanYouTubeStart of suggested clipEnd of suggested clipThe first step is to build the mold for the concrete. We'll start by making the circular base of theMoreThe first step is to build the mold for the concrete. We'll start by making the circular base of the mold out of melamine. And to get a perfect circle I like to drill a hole in a scrap piece of wood.

What sizes does sonotube come in?

Available in standard diameters from 12" to 48" in standard lengths of 12' and 20'. Multiple sections can easily be spliced together for longer lengths. Custom lengths also available. For the most demanding applications, choose Sonotube commercial concrete forms.

How do you build a curved concrete sidewalk?

0:129:26Curved Concrete Sidewalk Pour (Tip: What I use for Forms) - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd we formed all this up we use pvc forms. These white forms are pvc and they bend really nice soMoreAnd we formed all this up we use pvc forms. These white forms are pvc and they bend really nice so it makes form in a curved sidewalk. Really easy they are expensive to buy though.

Can you shape concrete?

To make shapes out of concrete you will want to build a form. The inside of the form will define the shape you are creating. Then when you fill your form with cement and let it harden you shake loose or break open the form and have your finished object set in solid concrete.

How do you edge concrete?

0:181:33How to Edge Concrete with a Edging Trowel - YouTubeYouTubeStart of suggested clipEnd of suggested clipGoes through the back you keep it slightly higher in the back when you're trying to smooth theMoreGoes through the back you keep it slightly higher in the back when you're trying to smooth the concrete out. Now. Here's you know the proper way right they're slightly.

How do you make a concrete curb?

3:096:36How to Make a Concrete Landscape Curb - YouTubeYouTubeStart of suggested clipEnd of suggested clipEasier. Once I had the concrete mixed to about the consistency of cake batter. I use the shovel toMoreEasier. Once I had the concrete mixed to about the consistency of cake batter. I use the shovel to shovel it into the form. It's important to tamp the concrete to release as many air bubbles as.

What is concrete forming plywood?

Home » Products » Panels » Concrete Form Plywood. Plywood is an ideal material for concrete forming. It produces smooth surfaces and can be used repeatedly – some overlaid panels up to 200 times or more. The thinner panels can be bent easily for curved forms and liners.

What type of plywood is used for concrete forms?

The most common type of plywood used for concrete forms is 1/2-inch exterior-grade plywood.

What is the material for concrete forms?

The material for concrete forms can be anything that can hold wet concrete in place until it dries. This can be wood, metal, or plastic.

What is the plywood for formwork?

Plywood is a versatile material with many applications. It can be used for making furniture, cabinets, shelving, and paneling. It is also often used as a formwork material for pouring concrete.

Can I cut concrete with a grinder?

Yes, a grinder can be used to cut concrete. However, it is important to use the correct type of grinder and blade for the specific type of concrete you are cutting.

How do I create a curved formwork?

One way is to use a flexible material such as plywood or plastics. Another way is to use a system of curved beams and headers.

What do you use for flexible concrete forms?

Hardboard is inexpensive form material and is easy to flex into smooth curves. Hardboard siding is intended for exterior walls, but it’s also great stuff for forming curves because it’s flexible and cheap.

What type of plywood do you use for concrete forms?

Virtually any ” Exterior ” rated APA panel can be used for concrete formwork because all such panels are manufactured with moisture resistant adhesive. For concrete forming, the plywood industry produces a special product called Plyform®, which is recommended for most general forming uses.

Can you use MDF for concrete forms?

Product Overview. This MDF Bender Board product has a wide variety of applications. It can be used for curving concrete sidewalk forms as well as temporary landscape applications.

Can you pour a 2 inch concrete slab?

If done properly, new concrete can often be poured right over an existing slab. For this to be feasible, the contractor needs to pour at least 2 inches thick, use smaller aggregate, and incorporate reinforcement such as welded wire mesh or fiber mixed into the concrete.

How do you make a homemade sidewalk?

Use 1″ x 4″ x 4′ boards to create forms for the sides of the walkway. Drive wooden stakes along path at 4′ intervals, placing them just outside the planned pathway. Attach 1″ x 4″ x 4′ boards to the inside of the stakes with screws to create the form for the concrete. Make sure all form boards are plumb and level.

Do I need rebar in my concrete?

Rebar is not necessary for every concrete project. The general rule of thumb is that if you are pouring concrete that is more than 5 inches in depth, you are probably going to want to add in some rebar to help reinforce the entire structure.

What type of concrete is used for sidewalks?

QUIKRETE ® Concrete Mix is a good general-purpose mix for sidewalk and slab work. T-square, measuring tape, mason’s line, pickax, rake tample, hammer or half-hatchet, darby or bull float, hand float, finishing trowel, bricklayer’s trowel, edger.

What is the best way to pour a concrete circle?

Pouring a circle of concrete requires a firm form. If the circle is to cover a large area, the sides of the form will need to be braced to prevent bulging or malformation of the planned shape. Concrete forms are usually made of wood; but wood does not readily bend into a circular shape. The correct approach for creating a form for a concrete circle will be influenced by the size and purpose of the object.

What is the best wood to use for a circle?

Plywood. Plywood can be used for large circles where the arc is wide and gentle. They can be scored on the back with cuts about 2/3 the depth of the board, spaced about every half inch along its length. This will increase the flexibility of the wood as the cut spaces will expand as pressure is applied to bow the board.

What is a commercial polyform?

Commercial Poly Forms. Pre-made industrial poly-forms may be the ideal form when working with circles with a three foot radius or larger. Although somewhat expensive, they are reusable, which would make them a good investment for small contractors.

Can you use small circles for paving stones?

Small Circles. Small concrete circles, such as might be used for paving stones, can be poured into small plastic commercial forms or into cake pans. Be sure to oil the form well before pouring! You should be able to reuse these forms several times. Advertisement.

What is metal forming used for?

Certainly metal forming is used for large projects such as streets, roadways, and highways.

What is hydraulic cement?

Concrete is a combination of water, aggregate (sand, rock) and the primary one Portland cement.

What is the technique used to cut a small edge?

If your only doing a small edge, like a garden edging, you can use a normal stick of timber and use a technique called ‘kerfing’. You cut multiple cuts into a face of timber, without cutting all the way though it, and the thin layer of timber left isused to make the round edge. 6.4K views. Khush Raj Singh.

Can bender board be used on concrete?

In these cases we use a plastic form such as one would use in landscaping for dirt retention. We have used many things to effect a concrete circle. Basically one could use anything malleable enough to effect the circle, yet strong enough to hold the concrete. We have used metal strips (very thin metal), to create radius corners for patios and keep a stock on hand of plastic retainers 20 feet long by 3 5/8 inches specifically for bends and turns. They are multiuse whereas Bender board is a single use form.

Can sheet metal hold concrete?

It is very bendable and still has strength to hold concrete if staked and fastened correctly. For any radius less than a foot or so, sheet metal also works well. We have used low-cost metal forms for large, round foundations in sewer plants and for water storage container footings.

What do you use for curved formwork?

Including bent plywood, laminated veneer lumber, and synthetic lumber.

How do you do round form?

The easiest way to do round form is to use a tool called a rotary cutter.

What can be used as concrete forms?

several things can be used as concrete forms such as wood boards, metal sheets, or plastic sheets.

How do you keep concrete from sticking to wood?

You can keep concrete from sticking to wood by using a variety of materials as a barrier between the concrete and the wood. These materials include sheet metal, tar paper, and plywood.

Do I need a release agent for concrete forms?

Using release agents for making concrete forms is not necessary, but it can help the forms to last longer and release the concrete easier.

What is Bender board used for?

Bender board is primarily used as an edging material for landscaping and gardening projects. It is made from flexible, yet durable materials, so it can bend and curve around gardens and flower beds. It can also be used to create walkways, paths, and borders.

What is the best way to keep concrete from sticking to concrete?

To keep concrete from sticking to the forms, they are often coated with a low-grade oil, or form-release agent. This also keeps the forms cleaner and allows them to be used multiple times before being discarded.

What is concrete used for?

Concrete is a unique product that begins its life as a semi-solid, can be manipulated and worked to assume most any shape, and then hardens to assume that shape. This ability to fill voids and assume shapes is what makes concrete the most-used building material on the planet. None of this would be possible without concrete forms.

Why is concrete used in flatwork?

Because the majority of the weight of the concrete in flatwork applications is spread across a prepared subbase -- which relieves much of the weight pushing against the form -- these forms are most often wood, with metal being used for larger commercial or highway work.

What is the most important factor in concrete form installation?

No matter the type of form or forming system used, the most important factor to achieving good results is how the forms are installed. Forming is often overlooked in concrete construction, but using the right forming system and having it professionally installed can have a significant impact on the concrete's strength and appearance. Proper form installation will result in a uniform and smooth surface, with clean edges and few surface defects.

Why do you put inserts on concrete?

Inserts are often attached to the inside of the forms to provide decorative edging or artistic relief. As more states and municipalities look for ways to beautify concrete construction projects, the use of decorative form liners is growing as well.

How tall is a concrete pier?

In contrast, a concrete form used to construct a bridge pier or high-rise building foundation will hold back hundreds to thousands of square feet of concrete, with the height of the form ranging from 12 inches to 20 feet.

How much does a square foot of concrete weigh?

A square foot of conventional concrete weighs about 150 pounds, and a typical concrete project may require hundreds to thousands of square feet of concrete to be placed at one time. All that weight needs to be held back by concrete forms, which is why most forms are made from rigid wood or metal.

What is concrete form?

A concrete form or formwork is a support or mold that the concrete is poured into. Temporary or permanent, the formwork is built into the shape that the user wants the concrete to take when the liquid concrete begins to dry. Photo: istockphoto.com. 2. Timber is the most commonly used material for formwork.

Why is concrete form important?

1. Concrete forms are necessary to ensure that the concrete sets properly during a construction project. Concrete is used regularly in construction projects. For example, it can be poured to create supports for a fence or gate or as a foundation for a new shed. However, when concrete is initially mixed, it isn’t a stiff compound ...

What is insulating concrete?

Insulating concrete forms are essentially concrete walls that are poured between two layers of insulating material to create a strong and insulated foundation.

What is formwork made of?

Another type of material used to make formwork is resin-bonded plywood. These sheets of plywood will typically be attached to timber frames to create large, inexpensive concrete forms. However, plywood is less durable and rarely reusable.

Why is timber used in concrete?

This is because timber is cost-effective, lightweight, durable, and flexible, allowing the concrete to shift while it sets without pieces breaking off or putting strain on the formwork. For the best results, invest in timber formwork that is easy to work with, lightweight, and dried thoroughly.

How long does it take for concrete to set?

Photo: istockphoto.com. Poured concrete is a viscous solution that can take up to 48 hours to properly set. During the setting time, the concrete needs to be contained in a concrete form. Concrete forms or formwork are the supporting materials or molds that are used when working with concrete. They also determine the final shape ...

Can you use concrete slabs without formwork?

Many people either don’t know about concrete form s or they don’t want to have to pay for timber or plywood to set up formwork because the extra cost is too high. Unfortunately, without the use of formwork, it’s all too easy for construction projects to go awry, leaving the concrete slab for the new shed or workshop uneven and difficult to use as support. So, while it’s a bad idea to go without concrete forms, there are ways that can help save on the cost of these materials.

What is concrete form?

Plastic forms can be used for straight lines or curves. Concrete forms are typically erected out of plywood and 2-by-4 supports. Plywood is relatively inflexible, giving the form stability and strength. The downside to wood forms is the inflexibility in shape. Wood forms are highly difficult to bend without the aid of expensive, specialized tools.

How to make a plastic form?

Place the start of the plastic form along the line. Drive a ground stake into the ground with a mallet on the outside of the form. Most plastic forms have holes on the exterior edge for the ground stake to fit through for added stability. Advertisement.