3 Common Lag Bolt Uses

- 1. Decking Lag bolts are very useful to fix decking boards down and join the structural components that the boards fix onto.

- 2. Roof Beams A roof beam is one of the main load-bearing components of a roof. The roof beam takes the roof’s weight, including the joists and purlins. A building’s structure relies heavily on the integrity of a roof beam. ...

- 3. General Framing

Do you need to pre drill for lag bolts?

Thereof, do you need to pre drill for lag bolts? Normal wood screws thread as they enter the wood, where lag screws require a hole to be drilled first. Lag screws also use a nut to add extra strength and security to help hold things together. Used for intense load applications, lag screws can support a much heavier load than the average sheet ...

How much weight will a lag bolt take?

How much weight can a lag bolt hold? If a lag screw with a 5/16-inch shaft is installed correctly, it can withstand pull-out, or withdrawal, of up to 212 pounds in close-grain hem, fir and redwood, and up to 266 pounds in larch Douglas fir, according to information from the American Wood Council.

How do you install lag bolts?

How do you install lag bolts? To install a lag screw, first you have to align the materials you’re going to screw together. When they’re lined up, clamp them together so they stay in place. Then, using a bit with a slightly smaller diameter than your lag screw, drill a hole all the way through the materials where you want the screw to go. ...

Can you install a lag screw into concrete?

You can install a Lag Screw into concrete. They are made specifically for the installation of lag screws into masonry materials. To install a lag shield into concrete first drill a hole that is the same diameter as the outside diameter of the lag shield.

Where can you use lag bolts?

What Are Lag Screws Used For? Lag screws are often used in construction to fasten pieces of lumber together. A lag bolt provides a longer-lasting connection due to its length and is used for materials that may be subjected to a massive force or will bear a heavy load.

Should I use lag bolts or screws?

Structural screws serve as many functions as lag bolts, but are considerably easier and more efficient to use. Since structural screws are made from hardened heat treated steel, they can be significantly thinner than lag bolts while being capable of holding as much or more weight than traditional lag bolts.

Do you need to pre drill for lag bolts?

You must drill pilot holes so that you do not splinter the wood or damage the lag screw. Any screw with a large diameter needs a pilot hole for easier and quicker installation. Drilling a pilot hole ensures that your lag screw won't break when you install it with a power drill. Torque can snap the head right off.

Are lag bolts stronger than wood screws?

Lag screws are some of the toughest types of screws out there. Also called lag bolts, lag screws are generally used to connect heavy lumber and other materials that bear an intense load. They're different from other more common screws such as wood screws, sheet metal screws and self-drilling screws.

How much weight will lag bolts hold?

Shear strength of the hardware isn't going to be a real concern. A single 1/4" Grade 5 lag bolt, in a configuration like this, will fail at roughly 13,000 lbs. Even 1/8" lag screws (well down into "numbered" screw sizes) will have a shear strength of over 3,000 pounds.

How deep should a lag bolt go?

It very much depends on what you are attaching to what. As a rough guide that I use for most things with wood screws is that the total screw length should be at least double the thickness of what you are attaching, with a minimum of 4-6 times the screw diameter going into the material.

Do lag bolts need nuts?

These wood screws boast coarse threading, but that threading does not encompass the length of the screw. Normal wood screws thread as they enter the wood, where lag screws require a hole to be drilled first. Lag screws also use a nut to add extra strength and security to help hold things together.

Why is it called a lag bolt?

The name lag screw comes from their original use in securing barrel staves, also known as lags. A lag screw requires a hole drilled at the same diameter as the shaft of the screw, a gimlet point helps pull the screw into the hole and tap its thread.

How do you screw in lag bolts?

To install a lag screw, first you have to align the materials you're going to screw together. When they're lined up, clamp them together so they stay in place. Then, using a bit with a slightly smaller diameter than your lag screw, drill a hole all the way through the materials where you want the screw to go.

How do you pre drill for lag bolts?

1:332:23how to PROPERLY install “lag bolts” (pilot holes sizes ) - YouTubeYouTubeStart of suggested clipEnd of suggested clipIf you have a half inch lag bolt you'll drill it with a 5 16. And if you have a 9 16 lag bolt you'llMoreIf you have a half inch lag bolt you'll drill it with a 5 16. And if you have a 9 16 lag bolt you'll drill it with a 23 64. Make sure that your drill.

Will lag bolts hold in plywood?

A 3/4" piece of plywood spanning an area big enough for a 65" TV isn't going anywhere as long as its properly attached to studs on either side. Lag bolts will work fine.

Are lag bolts structural?

Lag screws are traditionally specified for many structural loads in wood construction. However, recent innovations in engineering for self-tapping wood screws have made them an increasingly popular, labor-saving alternative to lag screws.

Are lag screws stronger?

With their longer and thicker design, lag screws are exceptionally strong and durable, making them ideal for woodworking applications in which multiple heavy objects are joined together. They are called “lag screws” because they were originally used to secure wooden lags.

How much weight can a structural screw hold?

80-100lbsMost screws will hold anywhere from 80-100lbs of weight. However, this number can fluctuate based on the screw's length, width, quality, thread type, how it was installed, and the type of impact that the screw has to withstand.

What screws have the best shear strength?

GRK Fasteners' RSS™ Rugged Structural Screw is made of specially hardened steel to provide you with the highest tensile, torque and shear strength available. The sharp threads and points on the RSS screws instantly bite into the materials, reducing any splitting effect generally caused by smaller shanks.

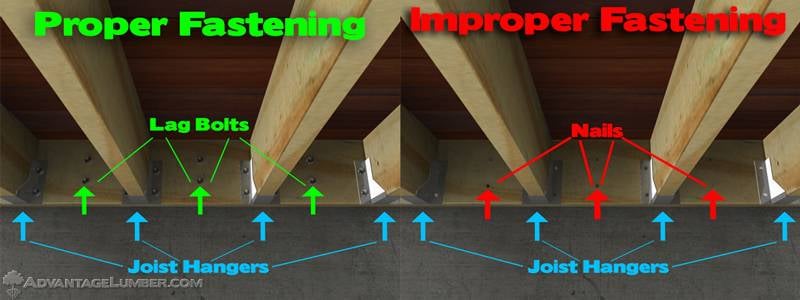

What screws to use with joist hangers?

The most common material used for joist hangers is galvanized metal. Because joist hangers are galvanized, the ideal types of fasteners are galvanized metal to avoid corrosion. Nails work well as long as they are sized correctly, but manufacturer-specified specialty screws can also work.

What Are Lag Bolts?

They do this because lag bolts are heavy-duty bolts with threads that grip the medium when a hole has first been drilled. This is called self-tapping. The tapered point or gimlet point of the bolt helps pull the bolt into the hole and secure its threads.

What Media Use Lag Bolts?

Roofing and lam beams aren’t the only media requiring bolts that can hold a lot of weight. Let’s say you want to add a deck to your house. Decks offer family time and enjoyment of fun in the sun, outdoor cooking, and friendly gatherings. They add value to a house. How to secure a deck to the house? Joints are attached to the house upon which the surface of the deck will be built. The joints are secured by lag bolts.

How to measure lag bolt?

Measure the width of the two media you’re using. The lag bolt you choose should be ¼ inch shorter than the combined width of the pieces. Generally, 5/16 inch bolts should do the job, but if the medium is heavier, then top with a 3/8 inch bolt.

Why do lag bolts have a tapered point?

This is called self-tapping. The tapered point or gimlet point of the bolt helps pull the bolt into the hole and secure its threads. Lag bolts sport a hex head which is where the label hex lag screw originates.

What type of bolts are used for roofing?

You use lag bolts, of course. Another building medium is sheet metal. This is often used in roofing. This kind of roofing consists of corrugated steel that is galvanized and coated with zinc, aluminum, and silicon to provide layers of protection. They are secured to the underlayment with lag bolts.

What is the tensile strength of a bolt?

For items that must hold serious weight, bolts with a tensile strength of at least 77,000 per square inch or psi are required. Thus when we build something that will take quite a bit of weight, we need lag bolts.

Do Lag Bolts Need Pilot Holes?

Yes. The trick to getting the best fit between bolt and hole is to drill the pilot hole smaller than the bolt. This ensures the threads of the bolt will dig into the wood for a solid hold. Now, we consider the types of wood: soft and hardwoods:

How to use lag bolts?

Drill a pilot hole with a bit slightly smaller than the bold you plan to use. Drill the hole as deep as the bolt needs to seat. Typical projects that might use lag bolts include a backyard deck, wooden playground equipment, and repairs to the roof or foundation. Lag bolts are commonly used to attach a wood structure like a deck to a concrete ...

What is a lag bolt?

Lag bolts are the fastener to call on when you’re building heavy objects or connecting heavy construction materials like wood, concrete, or steel.

Why is a lag bolt called a bolt?

It gets referred to as a bolt most of the time anyway because of the hex head it shares in common with bolts. Lag bolts have as much as nine times greater grip in wood than a regular nail, which allows them to support a lot more weight.

How thick is a lag bolt?

They differ from normal wood, self-drilling, or sheet metal screws because of their size, with most at least one inch long and .25 inch thick.

How many types of bolts are there?

There are at least 28 kinds of bolts and more than 30 types of screws for you to choose from. An option found on both lists is a lag screw, more commonly called a lag bolt. These extremely sturdy fasteners are used when dealing with heavy building materials that need to hold up an intense load.

How much weight can a 5/16 inch lag bolt hold?

Using a 5/16 inch-diameter lag bolt instead can allow you to support 200-to-300 pounds depending on the kind of wood. And the ability to support more grows with the length of the bolt.

Do you need a drill bit to use lag bolts?

You will need a drill bit appropriate for the material you’re drilling through, but no other construction tools other than a ratchet or nut driver to tighten the bolt. Align your materials.

When Should You Use Lag Bolts?

Well, a lag bolt is used when you need to connect pieces of wood to very large and heavy materials that need to bear intense loads and weight.

What is a lag bolt?

Generally speaking, lag bolts are used to connect lumber and other heavy materials that are required to bear large loads. On the other hand, you wouldn’t use them to connect a pair of 2x4s that do not need to bear any load.

How big should a lag bolt be?

The first thing that you need to do is to get your lag bolts. In terms of choosing the size, the rule of thumb is that the lag bolt should be 1/4-inch shorter than the accumulated width of the two pieces being fastened. Moreover, for most general-purpose projects, lag bolts that are 5/16-inch in diameter should be more than enough. However, there are also much larger lag bolts out there used for super heavy duty construction purposes, ones as wide as 1-1/4-inch in diameter.

What happens if the pilot hole is the same size as the bolt?

If the pilot hole is the same size as the bolt, then the threading becomes useless.