How does Quality Function Deployment (QFD) work?

Quality Function Deployment (QFD) is an incredibly helpful method in this area. So, how can you use this technique to move your company forward? How exactly does the QFD method work? Quality Function Deployment (QFD) is a systematic analysis of customer requirements that is used to improve the quality of your products.

What is QFD in business?

QFD is a focused methodology for carefully listening to the voice of the customer and then effectively responding to those needs and expectations. First developed in Japan in the late 1960s as a form of cause-and-effect analysis, QFD was brought to the United States in the early 1980s.

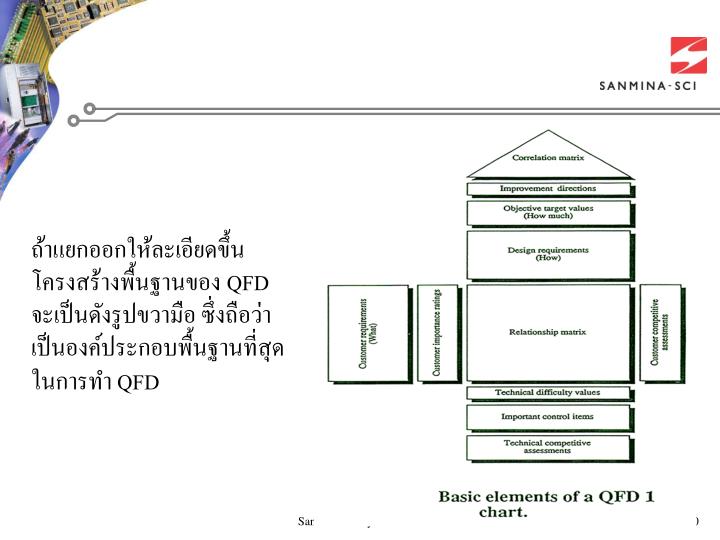

What is a house of quality in QFD?

When you give the QFD matrix a specific form, this representation is referred to as a house of quality. This technique allows you to systematically work out customer requirements and then present them in a clear way. QFD is mainly used in quality management, but it is also used in product management and product development.

What are the phases of QFD?

Phase one of QFD translates your VOC to the specific design requirements of the service you plan to offer. Phases two and three develop specific components of your service and specific process requirements to deliver your service. Phase four will develop your quality control processes to be sure you’re delivering your service with high quality.

What is QFD used for?

Quality function deployment (QFD) is a structured process that uses a visual language and a set of inter-linked engineering and management charts to transform customer requirements into design, production and manufacturing process characteristics.

What is a QFD in Six Sigma?

Quality Function Deployment (QFD) is a process for planning products and services. It starts with the Voice of the Customer (VOC) which becomes the basis for setting requirements. From that, the organization identifies the what's – the most important needs of the VOC.

What are the types of QFD?

The diagram shown here will also help you understand the QFD methodology here....The details are as follows:Product Planning QFD. ... Component Deployment QFD. ... Process Planning QFD. ... Quality Control QFD.

What is a QFD model?

Definition: Quality Function Deployment, or QFD, is a model for product development and production popularized in Japan in the 1960s. The model aids in translating customer needs and expectations into technical requirements by listening to the voice of customer.

What are the 4 phases of QFD?

The comprehensive process of QFD is divided into 4 major phases: Product Planning, Product Development, Process Planning, and Production Planning. Each matrix or visual representation used under each of the 4 phases is related to the previous one.

Why is QFD called the House of Quality?

House of quality – the process explained The first and often most important matrix in QFD is called the house of quality because it's shaped like a house with a roof and body. In this matrix, you start by separating customer needs from technical requirements and evaluating the two factors independently of each other.

What is QFD example?

For example, if a customer priority is strong battery life, and your product is a lightweight lithium battery, that would rank as a strong relationship between the two.

How do you conduct QFD?

How to use the House of Quality templateAdd customer needs and ratings. ... List design requirements. ... Weigh the relationship between customer needs and design requirements. ... Complete the correlation matrix. ... Add competitor research.

Why Quality Function Deployment is important?

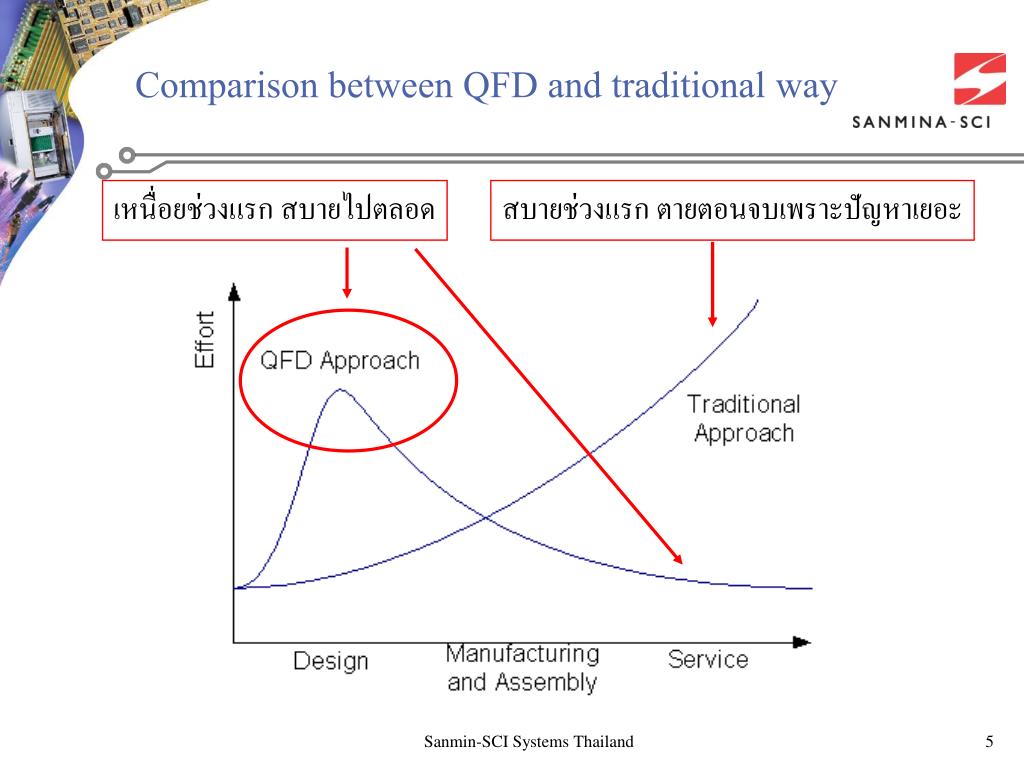

Shorter Development Time and Lower Cost: QFD reduces the likelihood of late design changes by focusing on product features and improvements based on customer requirements. Effective QFD methodology prevents valuable project time and resources from being wasted on development of non-value added features or functions.

What is Quality Function Deployment explain with an example?

• Quality function deployment or "QFD" is a flexible and comprehensive Decision making technique used in product or service development, brand marketing, and product management • Quality Function Deployment (QFD) is a structured approach defining to customer needs or requirements and translating them into specific ...

What is QFD in total quality management?

Quality function deployment (QFD) provides a systematic process for integrating TQM into new product development activities. QFD combines various design engineering and managerial tools to create a customer‐oriented approach to developing new products.

Why Quality Function Deployment QFD is very important in a Six Sigma project?

By using QFD, you are forced to focus your development efforts on your customer's needs and specific requirements. This provides discipline to your development process.

What is QFD in total quality management?

Quality Function Deployment (QFD) is a process and set of tools used to effectively define customer requirements and convert them into detailed engineering specifications and plans to produce the products that fulfill those requirements.

What are QFD and FMEA?

QFD can be viewed as the defender of the customer needs, while FMEA is the defender of the voice of the engineer [3]. As quality is deployed into the design through the use of tools such as the House of Quality, at the same time the DFR process begins with input from the HoQ.

What is QFD in PMP?

The Quality Function Deployment (QFD) identifies key characteristics for the new product development. It begins by collecting the needs of the customer (also known as Voice of the Customers). Once the VOCs are collected, they are then sorted and prioritized objectively so that the goals can be set to achieve them.

What is QFD in business?

This technique allows you to systematically work out customer requirements and then present them in a clear way. QFD is mainly used in quality management, but it is also used in product management and product development. Ultimately, this method involves all areas of the company.

What is QFD in manufacturing?

Quality Function Deployment (QFD) is a systematic analysis of customer requirements that is used to improve the quality of your products. QFD originated in Japan in the 1960s and 70s and was primarily developed by Yōji Akao. Mitsubishi and Toyota, as well as many other companies, have used this method to better tailor their products and services to their target market and accelerate growth. As part of this method, customer requirements, product performance, and the products offered by the competition are all taken into consideration.

What are the advantages of QFD?

Another advantage of Quality Function Deployment – when implemented early and effectively – is that it can reduce development costs and times. As this method focuses on customer requirements with a well-thought-out method and is not based on assumptions, you can use it to make specific plans. Not only does QFD support companies by helping them to increase their revenue, but it also helps them to work in a more streamlined manner during production.

What is the purpose of QFD?

The main aim of QFD is to improve a product or service so that it will be better received by the market. The focus here is also on customer satisfaction. Ideally, it’s best to apply QFD during the product planning phase, but you can also make adjustments to the product later on the basis of a QFD analysis.

What happens at the end of the Quality Function Deployment process?

At the end of the Quality Function Deployment process, a clear catalog of measures will be produced. The knowledge gained must now be communicated and implemented in product development, product management, production, sales, and marketing.

Is quality function deployment a fixed model?

Quality Function Deployment is not a rigid, fixed model. It has undergone many further developments since it was first used by Yōji Akao (e.g. such as those implemented by Bob Kind or Emil Jovanov). Even Akao himself believed that it was incredibly important for each person to adapt the concept to their own situation. Something that all variants of the method have in common is that they proceed step by step, starting with a customer survey and finishing with production or the product launch.

Can you enter all the information collected in the QFD matrix and build ahouse of quality?

You can now enter all the information collected in the QFD matrix and build ahouse of quality.

Acronyms & Abbreviations

Get instant explanation for any acronym or abbreviation that hits you anywhere on the web!

A Member Of The STANDS4 Network

Get instant explanation for any acronym or abbreviation that hits you anywhere on the web!

Why is QFD important?

Every business, organization, and industry has customers. Meeting your customers’ needs is critical to success. Implementing QFD can enable you to drive the voice of your customers throughout your organizational processes to increase their satisfaction and delight.

Why is QFD important to understand?

Understanding this linkage and the cascading of the how of one phase feeds into the what of the next phase is the secret of being able to successfully use QFD.

What is QFD in Six Sigma?

A structured methodology and mathematical tool used to identify and quantify customers’ requirements and translate them into key critical parameters. In Six Sigma, Q FD helps you to prioritize actions to improve your process or product to meet customers’ expectations.

What is the power of QFD?

The power of QFD is that it is your customers’ needs driving the technology, and not the technology driving your customers’ needs.

When was QFD invented?

QFD was developed in Japan by Yoji Akao in about 1966 while working for Mitsubishi. Toyota and other auto manufacturers started using the approach later on.

Can you complete a QFD without completing each previous house?

The QFD phases, or Houses, are structured and the elements linked. You can’t complete the QFD without completing each previous House.

Can QFD be used to replace a process?

If you already have a functioning development process, QFD can be used to help support and enhance your current process, not replace it.

QFD stands for Quality Function Deployment

This definition appears very frequently and is found in the following Acronym Finder categories:

Samples in periodicals archive

Quality Function Deployment (QFD), Value Analysis/Value Engineering (VE) and Design for Manufacture and Assembly (DFMA) are among these techniques.