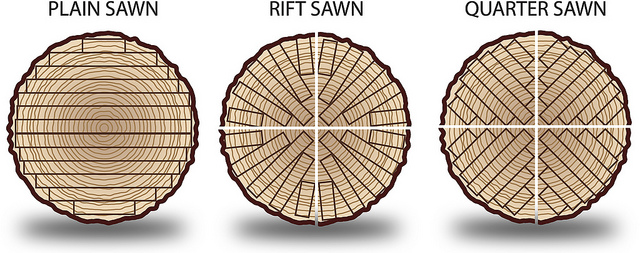

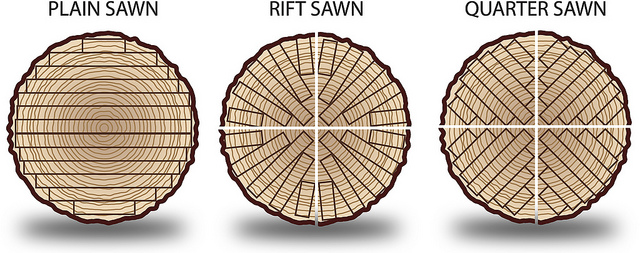

Logs are cut with the grains intersecting the face of the board at an approximate 60-degree angle. The log is sawn into four quarters and each quarter of the log is sawn perpendicular to the growth rings at an angle, therefore being named rift and quartered. This creates the traditional long lined grain that rift and quartered is known for.

Why is rift sawn lumber more expensive than quarter sawn lumber?

What is a rift sawn board?

How Do You Get Rift-sawn Wood from a Tree?

Why is rift sawn lumber more stable?

What is rip sawn lumber?

What happens when rift sawn wood dries?

Does rift sawn lumber contract?

See 2 more

What is better rift-sawn or quarter sawn?

Due to the position of the growth rings in the cut, Quarter Sawn lumber is more dimensionally stable than Plain Sawn. It resists expansion and contraction on plank's width. Rift Sawn lumber is the most elite of the cuts.

Is rift and quarter sawn the same?

Rift sawn lumber, also known as straight grain, is cut at the sawmill with the grains intersecting the face of the board at an angle between 30 and 60 degrees and quarter sawn lumber is cut with the grains intersecting the face board the board at an angle between 60 and 90 degrees.

Is rift or quarter sawn more expensive?

Each of these boards is cut radially perpendicular to the growth rings of the tree. There are large triangles of waste left from between each board. As a result, rift sawn lumber is costly to produce and therefore, the most expensive type of planks available from a log.

Why is rift-sawn better?

Rift-sawn Lumber Benefits Because the grain is so consistent on rift-sawn lumber, the end product is more stable. The end grain of the wood ends up perpendicular to the board's face. This reduces board twist and “cupping”.

How can I tell if my wood is quarter sawn?

3:056:21Plain Sawn vs Quarter Sawn - YouTubeYouTubeStart of suggested clipEnd of suggested clipLet's start again by looking at the end grain. The end grain on this one we can tell it's quarterMoreLet's start again by looking at the end grain. The end grain on this one we can tell it's quarter sawn because the annual rings. Are about 90 degrees to the face. Instead of rounded.

Is quarter sawn wood more expensive?

Quarter sawn wood is more expensive because it is more labor intensive to produce and the manufacturing process produces more waste than plain sawn lumber. At the sawmill, each log is sawed at a radial angle into four quarters, hence the name, then each quarter is plain sawn.

What are the disadvantages of rift sawn?

Cons to Rift Sawn Lumber Cost: Because it is so labor-intensive, rift-sawn wood costs more than quarter-sawn or plain-sawn lumber. Waste: Rift-sawn wood produces the most wood waste of the three methods, which is another reason that it's more expensive.

What is rift sawn lumber used for?

Rift sawn lumber is usually used with oak to avoid the flecks that are common in the species. The annular rings or a rift sawn board are about 30-60 degrees to the face of the board, but 45 degrees is the most optimum. Similar to quarter sawn lumber, rift sawn lumber is also referred to as radial grain.

How can you tell if a board is Quartersawn?

A board with growth rings running roughly parallel—usually in arches—relative to the face of the board is called a plain-sawn (or flat-sawn) board. If the growth rings are at a steep angle relative to the face, the board is said to have quartersawn grain.

Is rift sawn expensive?

By far, rift sawn lumber is both the most expensive and least common option on the market. Here, the annular rings look best at 45 degrees but can fall anywhere between 30-60 degrees.

Is Rift white oak expensive?

The rift sawn white oak flooring price is the highest. Because of the high waste and low supply, rift sawn is the most expensive lumber for oak flooring. It's also the highest grade and the most dimensionally stable of the four cuts.

Is quarter sawn oak worth it?

Additionally, quarter sawn wood is some of the most durable and stable lumber choice you can find. It is easy to work with and produces almost no twisting, warping, or cupping.

What is another name for quarter sawn lumber?

radially-sawnQuarter sawing or quartersawing is a woodworking process that produces quarter sawn or quarter-cut boards in the rip cutting of logs into lumber. The resulting lumber can also be called radially-sawn or simply quartered.

What does the term quarter sawn mean?

Quartersawn wood is literally cut into quarters before it is run through the mill. The “point” is set at the top of the cut. In this way, the wood is sliced with the grain largely perpendicular to the face. The widest lumber is taken from the center of each of the four quarters.

What is rift and quarter sawn oak flooring?

Planks are cut that radiate out from the center of the log after it is quartered. The result is a straighter grain and striking, iridescent medullary rays known as flecking. Rift sawn planks are also quarter sawn but are cut from the outer third of the log exclusively.

What is Rift wood?

Rift sawn lumber is typically narrow with a very straight grain pattern on the face of the board. Rift sawn lumber is usually used with oak to avoid the flecks that are common in the species. The annular rings or a rift sawn board are about 30-60 degrees to the face of the board, but 45 degrees is the most optimum.

What is the annual ring of a rift sawn log?

In rift sawn lumber the annual rings are typically between 30-60 degrees, with 45 degrees being optimum.

What is the best temperature for rift sawn lumber?

In rift sawn lumber the annual rings are typically between 30-60 degrees, with 45 degrees being optimum. Manufactured by milling perpendicular to the log’s growth rings producing a linear grain pattern with no flecking. This method produces the most waste, increasing the cost of this lumber.

Is quarter sawn lumber more expensive than plain sawn lumber?

QUARTER SAWN. More expensive than plain sawn material. Quarter sawn wood has an amazing straight grain pattern that lends itself to design. Quarter sawn lumber is defined as wood where the annular growth rings intersect the face of the board at a 60 to 90 degree angle.

What is rift flooring?

Thus rift and quartered flooring is traditionally associated with a formal setting in Select, or an English country house setting in Character. In this country it was characteristic of Mission and Craftsman architecture, as well as older Victorian homes of the late 19th century.

What is a quartered floor?

From a technical perspective, rift and quartered flooring is made from planks where the growth rings intersect the face of the flooring at an angle from 30 degrees to 90 degrees. In the photograph to the right, the planks A to C and 1 to 3 are quartersawn—the growth rings intersect the face of the piece at an angle from 70 degrees to 90 degrees. The remaining pieces are riftsawn—the angle of intersection of the growth rings to the face is from 30 degrees to 65 degrees.

Can you separate rift from quartered flooring?

Though we can separate rift from quartered flooring in some species, we generally put both types of planks together in a flooring shipment under the title “Rift and Quartered”. This flooring has two important physical characteristics.

Why are quartersawn and rift sawn boards different?

The reason for the different cuts is that compared to plain-sawn boards, both quartersawn and rift-sawn boards are less likely to cup, and will experience less seasonal expansion and contraction across their widths . There are also notable differences in appearance, which is important to a carpenter or woodworker.

What is the difference between quartersawn and rift sawn lumber?

There are also notable differences in appearance, which is important to a carpenter or woodworker. Quartersawn lumber will have straight, uniform grain on two sides—the top and the bottom. Rift-sawn lumber will have that same straight, uniform grain on the top and bottom, but will also have nice parallel grain on the two edges.

What is a quarter saw?

From the sawyer’s perspective, quartersawing a piece means slicing a log into four quarters, and then each of those quarters is set flat and cut into pieces at a 45° angle. It’s less common, but the sawyer might also choose to rift-saw (often called rift-cut) a log. In this case, the log is cut into a similar-looking set of four quarters, but then each of those quarters is rotated between cuts. Compared to plain-sawing a board, both quartersawing and rift-sawing will indeed yield less usable lumber, and may require a lot more handling, hence the higher cost.

How to make a rift and quartered log?

Rift and Quartered grain is achieved through a specific milling technique that differs from the more common, plain sawn style. Logs are cut with the grains intersecting the face of the board at an approximate 60-degree angle. The log is sawn into four quarters and each quarter of the log is sawn perpendicular to the growth rings at an angle, therefore being named rift and quartered. This creates the traditional long lined grain that rift and quartered is known for.

What woods are rift and quartered?

Many wood species can be cut in a rift and quartered grain; it is often known to be more stable with less expansion and contraction cause by changes in temperature and humidity. Making it more desirable and usable in a wider range of applications. While rift and quartered grain is most common with White Oak, Tesoro Woods’ Great Northern Woods ...

Why is rift sawn lumber more expensive than quarter sawn lumber?

Rift sawn lumber is more expensive than quarter sawn wood due to the amount of labor involved in cutting each individual plank as well as the wasted wood.

What is flat sawn wood?

Plain sawn (aka Flat Sawn) wood is the most readily available type of wood to purchase. Milling this kind of material is faster as each log is sliced through the center. There is also very minimal waste involved. When you combine a larger yield of lumber with faster milling times, you also end up with a more affordable piece of lumber.

How many quarters of lumber do you need to make a plank?

More physical labor and time are required to make a piece of lumber, or flooring plank quarter sawn. By cutting a log into four quarters, then plain sawing each quarter, you end up with lumber that naturally resists cupping. This results in a material that has a more unique, linear grain pattern.

Is quarter sawing more waste than plain sawn lumber?

Keep in mind, the increased labor and benefits bring a higher cost per board foot. Quarter sawing produces more waste than typical plain sawn lumber.

What is a rift and quartered?

Also rift and quartered is the preferred choice for use over radiant heat flooring when approved. While rift and quartered is generally used in white oak flooring, Hurst Hardwoods provides it in many different species, lengths and widths of solid and engineered flooring.

What percentage of a piece must have rift characteristics?

Rift Only/Rift Sawn - at least 75% of the piece must contain rift characteristics: in cross section the angle of the annual ring tangent to the face of the piece to be between 30 and 60. Grain lines to be mostly parallel to the length of strips and medullary ray flecks less than 1/16" wide.

What is live sawn flooring?

Live Sawn - also referred to as French cut, live sawn will produce boards that can have all of the characteristics of each cut in the same piece of flooring. This provides a unique look and used in the manufacturing process of European French Oak Flooring.

What is a rift sawn plank?

Similar to quarter sawn lumber, rift sawn lumber is also referred to as radial grain. The most stable boards, and also the most wasteful to produce , are rift sawn planks. Each of these boards is cut radially perpendicular to the growth rings of the tree. There are large triangles of waste left from between each board.

Why use rift sawn lumber?

Rift sawn lumber is usually used with oak to avoid the flecks that are common in the species.

Why is rift sawn lumber more expensive than quarter sawn lumber?

It delivers a cut that takes more time and energy. It just uses more of the tree’s available wood than a direct rift-sawn pattern. Because it generates more waste, rift-sawn lumber generally costs more than plain sawn or quarter sawn wood.

What is a rift sawn board?

Rift sawn boards are essentially choice cuts from a quarter sawn milling method. To actually set out and make rift-sawn lumber directly would waste a considerable amount of the original tree. Each piece gets cut towards the center. The method seems overly difficult and produces fewer boards than either quarter-sawn wood or rip sawn and plain-sawn milling.

How Do You Get Rift-sawn Wood from a Tree?

Not all mills use the exact same manufacturing method. In general, rift-sawn lumber simply gets pulled from quarter sawn wood. The mill cuts the wood into quarters before running it through the mill. With its “point” set at the top of the cut, the mill slices the wood with the grain mostly perpendicular to the face. You can then remove the widest rift-sawn lumber from the center of each of the four quarters.

Why is rift sawn lumber more stable?

Because the grain is so consistent on rift-sawn lumber , the end product is more stable. The end grain of the wood ends up perpendicular to the board’s face. This reduces board twist and “cupping”. You can see the practicality of this when putting down wood on a deck.

What is rip sawn lumber?

With these and other species, the exposed wood grain plays an important part in its use within a project. Most sawmills make lumber via a process called rip-sawing. We also call this plain sawn lumber. It’s an efficient method that utilizes almost every square inch of a tree to make usable boards. The hardiest wood is made using a quartersawn method but selects the rift-sawn pieces which are most directly aligned towards the center of the tree. This generates a grain that crosses the wood and allows it to expand only along its length-side.

What happens when rift sawn wood dries?

As rift-sawn wood dries, the board has less tendency to warp or pull into an odd shape. This is what we mean by the boards being more “stable”.

Does rift sawn lumber contract?

It’s important to understand how rift-sawn wood and quarter sawn lumber expands and contracts with moisture and humidity. All wood has some movement, but rift sawn wood moves along the width of the board and not its height. The bigger, and far more beneficial advantage, however, is that rift-sawn lumber rarely twists or “cups”. It’s especially suitable for rigid boards, carpentry, and other applications where you can’t tolerate any significant board warping.