Full Answer

What is takt time and how is it calculated?

Takt time represents the average amount of time needed to adequately meet customer demand while not operating over capacity. Takt time is calculated with the following equation:. Takt time = T a ÷ D. In this formula you need the total production time (T a) and the rate of customer demand (D) in order to find Takt time.Total production time is not just the amount of time a machine is running ...

What is the difference of Takt time vs cycle time?

Takt time is important to understand customer demand and request, and ensures greater efficiency within the flow and reduced wasted time and resources. Cycle time, on the other hand, is the average time being spent on a product, from start to completion. It tells how often a part is completed by a particular process.

How often should we change takt time?

How often should we change takt time? Deep question. The answer is: I don’t know; it depends! Let’s make sure we’re on the same page on what takt time is. Takt time is commonly defined as daily work time divided by daily customer demand.

What is lead time vs. cycle time vs. takt time?

Many people confuse takt time, cycle time and lead time, but you don’t have to be one of them! In a nutshell, takt time equals the time between starting to work on one unit and starting the next. Cycle time equals the average time it takes to finish one unit. Lead time equals the total time it takes from receiving an order to delivering an item.

What takt time tells us?

Takt time is the rate at which you need to complete a product in order to meet customer demand. It comes from the German word “Takt,” meaning beat or pulse in music. Within manufacturing, takt is an important measure of output against demand.

Is lower takt time better?

Essentially, the takt time calculation is the basis for matching supply and demand within your company. Takt time can be said to be “high” or “low” as the term itself “takt” is a German word meaning pulse. That means, if client or project demand is high, takt should also be high; if demand is low, takt may be low.

What takt means?

Definition of takt 1 : a beat or pulse in music. 2 : measure sense 4c(1) 3 : tempo.

What is takt time vs cycle time?

In a nutshell, Takt Time is the time between starting to work on one unit and starting the next. Cycle Time is the average time it takes to finish one unit. Lead Time is the total time it takes from receiving an order to delivering an item.

Why is takt time important?

Put simply, takt time refers to the amount of time a manufacturer has per unit to produce enough goods to fulfil customer demand. Frequently used within lean production lines, takt time is an essential tool in ensuring that goods flow through each build station in the most efficient manner.

What happens if takt time is greater than cycle time?

In a perfect world Takt Time should match Cycle Time. If there is a mismatch between Takt Time and Cycle Time it can create a lot of headaches. If Cycle Time is more than Takt Time it means the process is not sufficient enough to keep up with demand.

How can I increase my takt time?

To begin aligning your process to the takt time, start dividing the work that goes into the process into value adding and non-value adding activity. Eliminate the non-value adding time and balance the workload of the operators. Bring the individual cycle times closer to the takt time. Keep the line balanced.

How do you calculate takt time in seconds?

The classic calculation for takt time is:Available Minutes for Production / Required Units of Production = Takt Time. ... 8 hours x 60 minutes = 480 total minutes. ... 480 – 45 = 435. ... 435 available minutes / 50 required units of production = 8.7 minutes (or 522 seconds) ... 435 minutes x 5 days = 2175 total available minutes.More items...•

How does takt time change as demand rate increases?

Takt time and cycle time only depend on demand. How does the takt time change as the demand rate increases? The takt time increases.

Is takt time the same as throughput?

TAKT Time, Cycle time, Lead Time, Throughput time :- TAKT time is based on customer demand whereas cycle time is based on process. Throughputtime is the measure of the time required for a material, part or sub assembly to pass through a mnufacturing process following the release of an order to dispatch of the product.

Which are the Lean principles?

According to Womack and Jones, there are five key lean principles: value, value stream, flow, pull, and perfection.

What is meant by cycle time?

Cycle Time Definition Cycle Time is the amount of time a team spends actually working on producing an item, up until the product is ready for shipment. It is the time it takes to complete one task.

What is Takt time?

Takt time, or simply Takt, is a manufacturing term to describe the required product assembly duration that is needed to match the demand. Often confused with cycle time, takt time is a tool used to design work and it measures the average time interval between the start of production of one unit and the start of production ...

How is Takt time adjusted?

Takt time may be adjusted according to requirements within a company. For example, if one department delivers parts to several manufacturing lines, it often makes sense to use similar takt times on all lines to smooth outflow from the preceding station. Customer demand can still be met by adjusting daily working time, reducing down times on machines, and so on.

What are the benefits of takt time?

Once a takt system is implemented there are a number of benefits: The product moves along a line, so bottlenecks (stations that need more time than planned) are easily identified when the product does not move on in time.

What is takt planning?

Takt, as used in takt planning or takt-time planning (TTP) for construction, is considered one of the several ways of planning and scheduling construction projects based on their utilization of space rather than just time, as done traditionally in the critical path method.

When customer demand rises so much that takt time has to come down, what happens?

When customer demand rises so much that takt time has to come down, quite a few tasks have to be either reorganized to take even less time to fit into the shorter takt time, or they have to be split up between two stations (which means another station has to be squeezed into the line and workers have to adapt to the new setup)

How many hours between production starts?

For example, if the customer demand is 10 units per week, then, given a 40-hour workweek and steady flow through the production line, the average duration between production starts should be 4 hours, ideally. This interval is further reduced to account for things like machine downtime and scheduled employee breaks.

What is net available time?

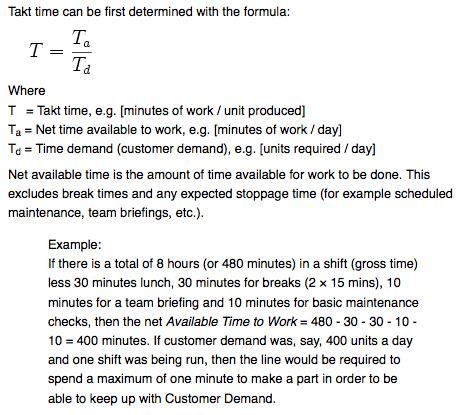

Net available time is the amount of time available for work to be done. This excludes break times and any expected stoppage time (for example scheduled maintenance, team briefings, etc.).

How to calculate takt time?

With takt time being the total available working time divided by the number of units that a customer demands, determining its value should not be hard, provided that you have the accurate data on hand.

What is the challenge of takt time?

A common challenge with takt time is that it can vary from order to order. Once your processes are optimized, and you’re on your way with the 5S initiative, it would be beneficial to look at introducing Heijunka to ensure customers ordering is more leveled, contributing to your production also remaining level.

Why should you gauge the takt time?

Because takt time ties to how often and how much of a product your customer demands, calculating it allows you to gauge the speed you need to be working to satisfy the customer. If your team produces too slowly, then the customer may move their business elsewhere. If you manufacture too much or too quickly, the inventory will increase, leading to waste and a profit reduction.

What is cycle time?

The cycle time describes how long it takes to produce one unit of a product from start to finish - it concerns active working time only. The takt time relies on how soon the customer needs the product and calculates the total time for completing the delivery. Lead time measures between the customer placing the order and receiving it; production queues, rework, and transport included.

What is Takt time?

Takt time is the maximum amount of time in which a product needs to be produced in order to satisfy customer demand. The term comes from the German word "takt," which means "pulse." Set by customer demand, takt creates the pulse or rhythm across all processes in a business to ensure continuous flow and utilization of capacities (e.g., man and machine).

How to align process to takt time?

To begin aligning your process to the takt time, start dividing the work that goes into the process into value adding and non-value adding activity. Eliminate the non-value adding time and balance the workload of the operators. Bring the individual cycle times closer to the takt time. Keep the line balanced.

What is takt time?

Takt time is a quick calculation that allows you to verify that your processes can keep up with customer demand. It can be a tricky value to maintain, as it is always in flux whenever the customer changes the demand level.

Why is takt time important?

When setting up a production line with multiple steps, it is best to level-load the line so that each step in the process takes approximately the same amount of time, and that all steps take less time than the takt time.

How much larger should takt time be?

It is recommended that your takt time be between 5% and 17% larger than your cycle time.

Does takt time change?

Companies have been known to state that their processes have a takt time value; they do not . Takt time is a function of customer demand and available time, and for many products, takt time is in constant flux as customer demand changes. A change to the system will not impact takt time, but it will impact cycle time.

Is cycle time less than takt time?

It is important to know the cycle times of your processes, and compare them with the takt time, to verify that cycle time is always less than takt time.

Does a change to a system affect takt time?

A change to the system will not impact takt time, but it will impact cycle time. Note that if you duplicate and run additional production lines or increase the hours available for use on a production line, takt time changes.

What is Takt time?

Want to learn about takt time? Takt time is an essential metric used in the manufacturing process that functions as the heartbeat of your production line. It lets you manage every business operation efficiently and without waste. Toyota used and perfected takt time in its famous Just-in-Time manufacturing system.

Why is Takt time called Takt?

That’s why it’s no coincidence that that takt time is named after ‘Takt’: a German term for the baton used by an orchestra conductor to regulate the tempo of the song. Similar to how a conductor uses their baton to manage the pace of the orchestra, using takt time helps you regulate the speed of the production line.

How Do You Calculate Takt Time?

At first glance, measuring takt time seems like a complicated process, but the calculation is actually quite simple.

What Is The Purpose Of Takt Time?

The takt time calculation can be used to predict future production problems and identify a potential bottleneck.

What Are The Benefits Of Takt Time?

Even though takt time is an extremely simple concept, it’s powerful enough to supercharge the manufacturing unit of your company.

What Is The Difference Between Takt Time And Cycle Time?

While both cycle and takt times are used by Lean practitioners, they’re used to measure different things and are used at different times in the production cycle.

Why use takt time in lean manufacturing?

Since your production system is usually consistent, it’s easy to plan out your shift schedule. That is if you use takt time to create a value stream map.

What is TAKT time?

Organizations are always looking for ways to decrease wasted time and resources while providing more attractive products to customers. This is LEAN thinking. TAKT time is a metric used in the LEAN methodology to measure the FLOW of the process Consists of input, value-add, and output. Learn More... .

TAKT time formula

TAKT time is often incorrectly defined as overall build time (or the amount of work required to build a service or product). But it refers to the time required to build a single service or product (from start to finish) to meet customer demand (in other words, to not produce a product in the prediction of demand).

Importance and benefits

TAKT time allows organizations to understand their capacities. Businesses can calculate the speed of equipment and staffing needed to produce at a consistent pace to meet customer demand.

In conclusion

TAKT time refers to the amount of time it takes to produce a product to meet customer demand. Businesses can use this tool to create a continuous workflow. It allows organizations to better understand their capacity, their constraints, and reduce waste. Teams can quickly see their success and react to disruptions.

Overview

Takt time, or simply Takt, is a manufacturing term to describe the required product assembly duration that is needed to match the demand. Often confused with cycle time, takt time is a tool used to design work and it measures the average time interval between the start of production of one unit and the start of production of the next unit when items are produced sequentially. For calculations, it is the time to produce parts divided by the number of parts demanded in that tim…

Etymology

Takt time is a borrowing of the Japanese word takuto taimu (タクトタイム), which in turn was borrowed from the German word Taktzeit, meaning 'cycle time'. The word was likely introduced to Japan by German engineers in the 1930s.

The word originates from the Latin word "tactus" meaning "touch, sense of touch, feeling". Some earlier meanings include: (16th century) "beat triggered by regular contact, clock beat", then in m…

History

Takt time has played an important role in production systems even before the industrial revolution. From 16th-century shipbuilding in Venice, mass-production of Model T by Henry Ford, synchronizing airframe movement in the German aviation industry and many more. Cooperation between the German aviation industry and Mitsubishi brought Takt to Japan, where Toyota incorporated it in the Toyota Production System (TPS).

Definition

Assuming a product is made one unit at a time at a constant rate during the net available work time, the takt time is the amount of time that must elapse between two consecutive unit completions in order to meet the demand.

Takt time can be first determined with the formula:

Where T = Takt time or Takt, e.g. [work time between two consecutive units] Ta = Net time availa…

Implementation

Takt time is common in production lines that move a product along a line of stations that each performs a set of predefined tasks.

• Manufacturing: casting of parts, drilling holes, or preparing a workplace for another task

• Control tasks: testing of parts or adjusting machinery

Takt in construction

With the adoption of lean thinking in the construction industry, takt time has found its way into the project-based production systems of the industry. Starting with construction methods that have highly repetitive products like bridge construction, tunnel construction, and repetitive buildings like hotels and residential high-rises, implementation of takt is increasing.

According to Koskela (1992), an ideal production system has continuous flow and creates value …

Benefits of takt time

Once a takt system is implemented there are a number of benefits:

• The product moves along a line, so bottlenecks (stations that need more time than planned) are easily identified when the product does not move on in time.

• Correspondingly, stations that don't operate reliably (suffer a frequent breakdown, etc.) are easily identified.

Problems of takt time

Once a takt system is implemented there are a number of problems:

• When customer demand rises so much that takt time has to come down, quite a few tasks have to be either reorganized to take even less time to fit into the shorter takt time, or they have to be split up between two stations (which means another station has to be squeezed into the line and workers have to adapt to the new setup)