Saw Blade Terminology

- TOOTH CONFIGURATIONS FLAT TOP (FT) Used on saw blades for cutting soft and hardwood along the grain (ripping). ...

- TOOTH ANGLES HOOK (RAKE) ANGLE 6° - 22° Soft materials or rip blades require an angle of about 18° to 22°, hard materials about 6°. ...

- GENERAL

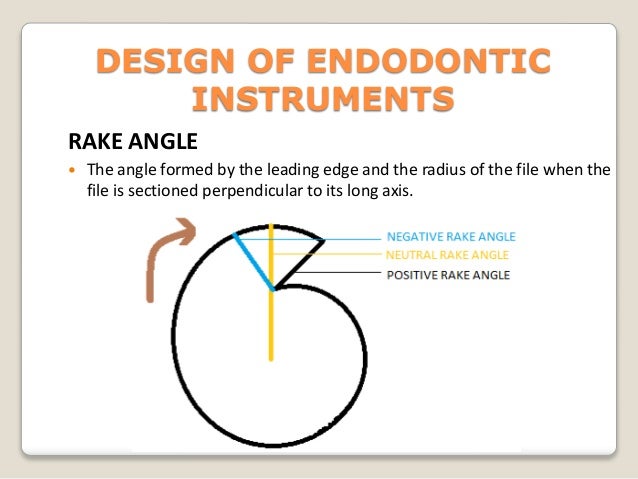

What is a rake angle in dentistry?

Rake is the angle that the front of the tooth makes with a line drawn perpendicular to the point line, and lying in the plane of the saw plate (Figure 9). It is created by rotating the file about its longitudinal axis (as shown in Figure 5).

What is the rake angle of a table saw?

The rake or hook angle is the amount of forward or backward lean each tooth has. A hook angle can be thought of as the angle at which the tip enters the material. If the saw tip enters the material at an angle it will be more efficient than if it slaps down f

What is the angle of the cutting face of tooth?

This is the angle of the cutting face of the tooth. At 0 degrees, the tooth is vertical and cut very aggressively. One can actually lean the tooth forward to create a positive rake and a very aggressive cut, but also one that is hard to push and start while leaving the undercut tooth a bit weaker.

What is the difference between low rake angle and Fleam angle?

A low rake angle cuts fast but can feel grabbier and also make take more experience to handle. Changing this angle will help you adjust to harder and softer wood as well. Fleam is the angle across the face of the tooth or perpendicular to the tooth line.

What is rake angle on circular saw blade?

The rake or hook angle is the amount of forward or backward lean each tooth has. A hook angle can be thought of as the angle at which the tip enters the material. If the saw tip enters the material at an angle it will be more efficient than if it slaps down flat.

What is the best TPI for cutting wood?

TPI is the number of teeth the blade has per inch. If you're looking to cut wood or other soft materials, you'll need a blade with a TPI of 6 up to 20. For harder materials like metal, a TPI between 14 up to 36 is more suitable.

How do you measure the angle of a hook?

Draw a line through the center of your heads from the tip of knife slot. Then use a protractor (or whatever you have) to measure hook angle off that line. From contributor B: The hook angle can be adjusted a little bit by the grind of the knife or by extending the knife further out of the head.

What is the distance between saw teeth called?

Tooth Pitch - The distance from the tip of one tooth to the tip of the next tooth. TPI - The number of teeth per inch as measured from gullet to gullet. Gullet - The curved area at the base of the tooth. The tooth tip to the bottom of the gullet is the gullet depth.

Why does my circular saw burn the wood?

A dull blade will make it hard to cut quickly, and the slower the feed rate of the saw, the more friction against the wood and the greater the likelihood of scorch marks. Pushing the stock through the saw too slowly is a common cause of saw blade burn. Sometimes a blade that feels dull might only be dirty.

What is a 40 tooth saw blade used for?

A 40-tooth blade works fine for most cuts through plywood. Blades with 60 or 80 teeth should be used on veneered plywood and melamine, where the thin veneers are likely to blow out on the underside of the cut, a characteristic known as tearout.

What rake angle is typically used with a carbide tipped cutting tooth?

Steeper angles, from 18 to 22 degrees, are most effective for ripping and cutting softer materials.

What is blade hook angle?

The hook angle is the amount of forward or backward lean of each tooth. Generally speaking, a higher hook angle will give you an aggressive cut and a fast feed rate.

What is a positive hook on a saw blade?

A table saw wants a blade with a relatively high positive hook which helps hold the wood down to the table and helps pull the wood through the saw. A radial arm saw or even a miter saw, wants a blade with a neutral or negative hook to keep the saw from wanting to bite into the wood and come out at you.

What is the angle of cutting teeth in hand saw blade?

Most desirably, the cutting edges vary from a cutting angle of 16° to 17° at the leading portion of the saw blade to an angle of 12° to 13° at an intermediate portion and are in the range of 8° to 9° at the trailing portion, the surface angle of the tip edge formed between the cutting edge and back edge of each tooth ...

Why is tooth spacing important in saw blades?

More teeth means a smoother cut, fewer teeth means that the blade removes more material. Crosscut blades have more teeth and make smoother cuts across the grain of the material, rip blades have fewer teeth, are optimized to cut with the grain, and remove a lot more material.

What TPI is best for cutting metal?

Cutting thinner metals, including sheet metal, requires a finer cut. Use 18-24 TPI bi-metal blades. For thicker metals such as steel pipe, angle irons, or tubing, use 14-18 TPI bi-metal blades. For aluminum, an 8-10 TPI blade is best.

Is more TPI better?

Woodworkers quickly learn that the number of teeth-per-inch (TPI) on the blade has a big impact on the quality of a cut. The general rule of thumb is "the more TPI, the smoother the cut." The true answer, however, is just a little more complicated than that, as you'll learn once you understand how saw teeth work.

What is 18 TPI for cutting?

Blades 12-18 TPI are typically used for metal and denser materials as well as finish cuts in wood. The 18-24 TPI range is almost always used for metal cutting.

How many teeth should my saw blade have?

Why does having the right number of teeth on your saw blade matter?Number of teeth touching the materialExpected outcomeLess than 2 teethA really rough cut that may rip and tear your material2 to 4 teethA nice smooth cutMore than 4 teethA very slow cut that may cause burn marks on the material being cutJun 3, 2019

What is a 180 tooth saw blade used for?

Designed for cutting a variety of materials, including plywood, vinyl siding, and plastic, the CRAFTSMAN 10-in 180-tooth high-speed steel miter/table saw blade set is a must-have for your workshop.

Why is rake angle important?

Rake angle is the most important factor while designing a cutting tool. It is provided so that chips from the workpiece can flow easily and also it provides a smoother machining operation.

What is a positive rake angle?

Positive Rake Angle: If the slope of the cutting tool is away from the cutting edge in the opposite direction or at the inner side then this type of rake angle is called the Positive (+) rake angle. Positive Rake Angle tools are generally made up of HSS.

What is zero rake angle?

Zero Rake Angle: As the name denotes zero rake angle that means there will no angle between the rake surface and cutting plane. Here the face of the cutting tool makes a 90-degree angle about the cutting edge at the inner side.

What happens if you don't set the rack angle?

If we do not set the rack angle properly it can damage the tool as well as damage the workpiece surface. The flow of chips depends on the rake angle. If chips do not flow smoothly than a built-up edge may forms. Wrong Rake Angle can decrease the life of the cutting tool.

What are the two parameters that we need to keep in mind before designing a tool?

Rake Angle and Clearance Angle is the only two important parameters we need to keep in mind before designing a tool. Here are some of the important significance of Rake Angle:

What is a low rake angle?

A low rake angle cuts fast but can feel grabbier and also make take more experience to handle. Changing this angle will help you adjust to harder and softer wood as well. Fleam is the angle across the face of the tooth or perpendicular to the tooth line.

What is the angle of the cutting face of a tooth?

This is the angle of the cutting face of the tooth. At 0 degrees, the tooth is vertical and cut very aggressively. One can actually lean the tooth forward to create a positive rake and a very aggressive cut, but also one that is hard to push and start while leaving the undercut tooth a bit weaker.

Why use a high fleam saw?

As such high fleam saws should be used in softer woods that won’t push back so much on the more fragile teeth.

What does "set" mean on a saw?

Set is the amount of offset the teeth have to either side of the tooth line. When we set the teeth we are bending them away from the saw plate to widen the kerf and allow the saw to run without binding. Like the other elements this is a good thing but too much goes wrong very fast.

Can you add more set to a saw?

More set can be added and set can be removed but I find it easier to add more than take it away. Often times the setting process is helpful in adjusting a saw that isn’t running true too so the best thing is to skew to the finer set and then make several test cuts altering the set to get the right feel.

Does a Japanese saw have a positive rake?

You will find a positive rake on some Japanese saws but the pulling motion and much harder steel adds in some variables that ameliorate the negative effects of positive rake. The more you relax the rake, or increase the angle the tooth slants away from the cut the easier the saw is to push.

What is a hook angle?

The rake or hook angle is the amount of forward or backward lean each tooth has. A hook angle can be thought of as the angle at which the tip enters the material. If the saw tip enters the material at an angle it will be more efficient than if it slaps down flat. A 20 degree positive hook angle is used on rip blades to pull the wood into the blade.

What angle should a sliding miter saw blade be?

To prevent self-feeding, sliding miter saws and radial-arm saws require a blade with a negative tooth angle. In general, a blade with a positive hook angle is a faster-feeding blade and one with a negative hook is less aggressive.

Is it dangerous to use a saw blade with a positive hook angle?

Using a saw blade with a positive hook angle to cut metal, such as aluminum trim, can be dangerous unless the aluminium it clamped both sides of the cut because the blade will have a strong tendency to grab the material causing the operator to lose control. However, if it is clamped both sides of the cut, the positive rake blade will give you ...

What are the angles on each tooth?

Inside each tooth are angles that are inside and outside the top and side plate of every tooth. These are the top plate angle and the side plate angle.

How to sharpen a tooth?

Engage the chain brake. Set the file gauge to the right depth, length and angle so that you can sharpen it rightly. Start filling with long smooth strokes until you begin seeing that the tooth looks bright. Count the number of strokes that give you that.

How sharp should a chain saw be?

However, most users have agreed that a standard chain should be sharpened around 25-30 degrees for cross-cutting and ripping wood grain, ...

When to sharpen chainsaw teeth?

When to Sharpen a Chainsaw Teeth. When the chain is entirely blunt is the right time to re-sharpen. Most times, a blunt chain will show you these signs: Dust residue accompanying the cut wood instead of small wood chips. You put pressure on the engine to cut. The chain saw bounces, and it’s unstable when working.

How to sharpen a tooth when filling outside?

When you are done filling the outside tooth, file the inside as well. Switch the chain to the other side and file when you are done to sharpen both sides. Set your depth gauge and measure teeth at the front and back to check the depth and see if it is the correct height.

What does more teeth mean in a saw?

Typically more teeth mean cleaner cuts but a slower feed rate. See our formula for Calculating Saw Blade Tooth Quantitiy and Feed Speed. A saw (or saw blade) has to make three kinds of cuts; the cut into the material the cut through the material and the cut as the blade exits the material.

What angle to use for rip blades?

A 20 degree positive hook angle is used on rip blades to pull the wood into the blade. Standard hook angles range from 5 to 15 degrees positive. Steeper angles, from 18 to 22 degrees, are most effective for ripping and cutting softer materials. Hard materials require a shallow angle such as 6 degrees.

What angle should a sliding miter saw blade be?

To prevent self-feeding, sliding miter saws and radial-arm saws require a blade with a negative tooth angle. In general, a blade with a positive hook angle is a faster-feeding blade and one with a negative hook is less aggressive.

Why is a saw blade with a negative hook angle dangerous?

Using a saw blade with a positive hook angle to cut metal, such as aluminum trim, can be dangerous because the blade will have a strong tendency to grab the material causing the operator to lose control. To prevent self-feeding, sliding miter saws and radial-arm saws require a blade with a negative tooth angle.

How many parts are in a saw blade?

There are about a hundred parts to saw blade depending on how you break them down. These are the saw tip, braze alloy, gullet size and shape, shoulder size and shape, expansion slots and the saw plate or steel saw body.

What is the clearance angle on a saw blade?

The angle between the lower face of a saw blade and the material being cut. Radial Clearance Angle (Radial Side Clearance) The clearance angle on the side of the tooth. You measure down the side of the tip and it is the difference between front and back.

What is the difference between a high shear blade and a low shear blade?

The edges of a saw blade can separate material by; shear, fiber pullout, chipping or cutting. The thinner and sharper the edge, the better it cuts. High shear is like the blade of an axe. Low shear is like the back of the axe. A flat, square tip has low shear, is very strong and works well in soft materials. A tip with a point on one side has ...