What gas do you use with a plasma cutter?

- Ignition gas that is used to light the arc and commence the metal cutting process

- Cutting gas that determines the cutting speed and the cutting finish

- Marking gas that is used for plasma marking

What does gas do plasma cutters use?

Plasma cutters work off of different types of gas, they could use compressed air (like your shop compressor), argon or oxygen. In this article, we will stick to hand-held plasma cutters so the majority of these machines will run off of compressed air.

What is the best plasma cutter brand?

The Hypertherm Powermax45 is the best plasma cutter you can buy. Hypertherm has been building high quality equipment for decades. Their reputation rests solidly on their product’s ability to do exactly what they say it will.

What are the uses of a plasma cutter?

The main advantages that plasma cutting offers are:

- Ability to cut a material thickness up to 150 mm with good quality.

- Cost is comparatively less, value for money cutting.

- Curves, odd shapes, and even intersecting cuts can be easily performed using plasma cutting.

- Very quick and efficient process.

- Can cut in water, resulting in smaller HAZ. ...

What gas do you need for a plasma cutter?

Gas is needed for a plasma cutter in order for it to work and create the plasma. As mentioned, the most popular gases to use are oxygen, nitrogen or argon. Some plasma cutter systems include multi-gas features so a variety of gases can be used for different applications.

Can you use CO2 for plasma cutter?

Use nitrogen plasma with CO2 to cut stainless and aluminum for the best results for the cost. For the most economical plasma cutting, clean compressed air is the best fit for cutting aluminum, mild and stainless steel.

Which plasma gas gives the best results for cutting mild steel?

Oxygen. When it comes to plasma gas, oxygen is the industry standard for cutting mild steel because it provides the best, clean cut quality and fastest cutting speed of any plasma gas.

Can you use compressor air for plasma cutter?

Air compressor system pressure is preset and is usually between 100 psi and 135 psi and output pressure is adjustable via the pressure regulator. Inlet pressures vary by system. For a small handheld plasma cutter running at 20-30 amps, you'll need as little as 80 psi (5.5 bar).

Can you use argon for plasma cutting?

Argon-Hydrogen Mixtures With a standard mix of 65% argon and 35% hydrogen, it produces the hottest plasma cutting flame and some of the cleanest cuts. Typically used for cutting stainless steel and aluminum, the argon-hydrogen mixture is required for cutting material over 3" thick.

What is F5 plasma gas?

The F5 gas mixture (5% Hydrogen and 95% Nitrogen) is mainly used for cutting stainless steel. The F5 blend provides fast, oxide-free cuts, however, Hydrogen gas introduces a lot of heat into the material.

How much air pressure does a plasma cutter need?

To be precise, the air pressure required for a plasma cutter is about 4-8 SCFM at 90-120 PSI. This plasma cutter air pressure is a generalization for cutting steel between 3/8" and 7/8" thick.

How thick can a 50 amp plasma cutter cut?

3/4 in.Designed for portable repair work and small business project use, CUT-50 Plasma Cutter cuts a thickness of 3/4 in., and the max severance thickness is 1.0 in. Type: DC Air Plasma Cutter. Supply Power: 110-Volt/230-Volt/60Hz/1-Phase.

Compressed air

Air is one of the most adaptable forms of gas on offer, and as you don’t have to purchase it, this dramatically lowers the cost of the overall cutting process. That being said, shop air is a superior choice as it is cleaned before sold, thus eliminating contaminants such as oil, mist and moisture.

Oxygen

If you want fast speeds with lower power levels when using your plasma cutting machines, then oxygen is the plasma gas for you. Ideal for cutting structura- low carbon and low alloy steel, it can be used for cutting materials with a variety of different thicknesses.

Nitrogen

If you need to cut large amounts of aluminium or stainless steel, then nitrogen is a great choice. This plasma gas offers excellent parts life but is not the best option for thick materials.

Hydrogen

Hydrogen plasma gas is classed as environmentally friendly as it reduces the emission of Co2. This gas contributes to increased productivity due to its high-speed cutting.

Argon

For materials that are greater than ½ an inch thick, argon is good to use. Argon does not react with metals when cutting, which is why it is classified as an inert gas.

Argon-Hydrogen

You can also use an argon hydrogen mix to cut through stainless steel and aluminium. This is usually a percentage of 35 hydrogen and 65 argon. This option offers maximum cutting capacities and is the hottest plasma gas available.

Plasma Gas

As well as the five named plasma gases above, plasma gas can also be further categorised into three different phases:

What gas is used for cutting aluminum?

Argon hydrogen. Argon hydrogen is the gas of choice for thick stainless and aluminum cutting (> 1/2") The mixture typically used is 35% hydrogen: 65% argon (H-35). Argon hydrogen is the hottest burning plasma gas and provides the maximum cutting capability. (Argon hydrogen is used in water injection torches up to 1000 amps for cutting up ...

What is the best plasma gas?

Air. Air is the most versatile plasma gas; it produces good cut quality and speed on mild steel, stainless, and aluminum. Air also lowers the cost of operation because it is not necessary to purchase gases. However air is not free. Shop air must be cleaned to remove contamination such as particulate, oil mist, and moisture.

What plasma should I use for mild steel?

For mild steel use oxygen plasma and air shield for the best, clean cut quality, lowest dross levels, minimal rework, excellent weldability and highest cutting speed/productivity. For best cut quality on stainless and aluminum under 1/2" use nitrogen plasma and air secondary for a good balance of cut quality and affordability.

What gas is used in multi gas torches?

In multi-gas torches, Argon hydrogen provides a straight cut and a very smooth almost polished surface on stainless steel. Some jagged dross may occur along the bottom edge. Nitrogen is typically used as the shield gas with argon hydrogen . The disadvantage of this combination is its expense.

What gas is used to cut mild steel?

Oxygen. Oxygen has become the industry standard for cutting mild steel because it provides the best, clean cut quality and fastest cutting speed of any plasma gas. (Plasma cutting aluminum plate or stainless plate with oxygen plasma gas is not recommended). Oxygen plasma gas reacts with carbon steel to produce a finer spray of molten metal, ...

What is the disadvantage of oxygen plasma?

This molten spray is more easily ejected from the kerf. The disadvantage of oxygen is the cost of the gas and the consumable parts life.

What is the starting gas for oxygen plasma?

However state-of-the-art oxygen plasma systems use inert starting gases (such as nitrogen ) with oxygen plasma to achieve similar parts life to nitrogen or air systems. These systems may have parts life in the 800-1500-start range.

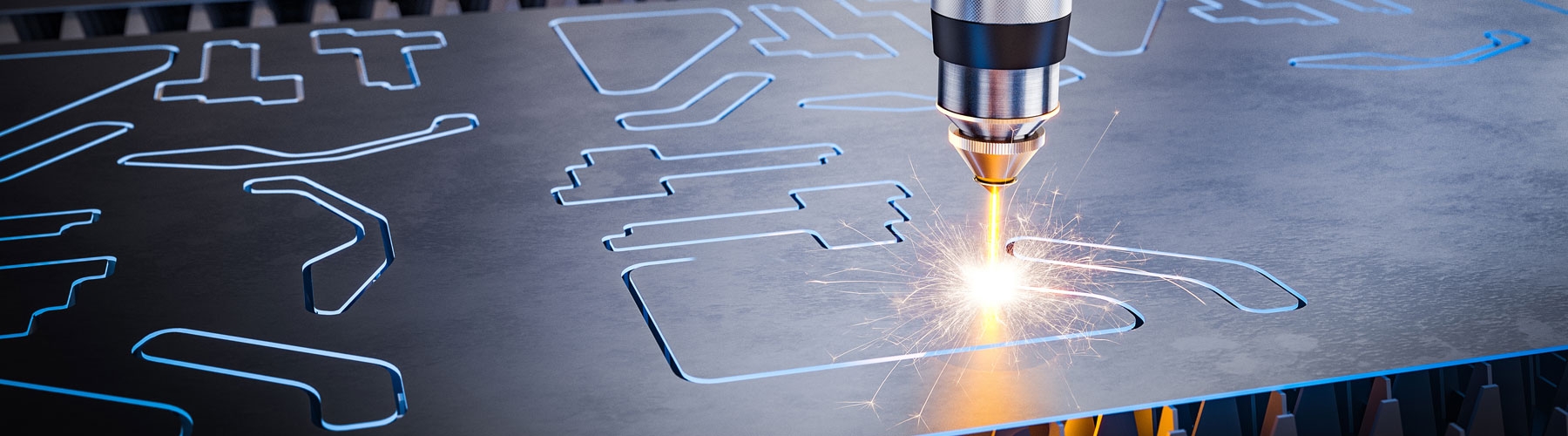

What is Plasma Cutting?

You are all aware that the matter around us has three states, solid, liquid, and gas. Take the example of water, it has three states, ice, water, and steam and they are differentiated by their energy levels; water relatively has more energy than ice, and so on.

How Plasma Cutter Works?

As seen in the earlier paragraphs, the cutting process in your Plasma Cutter comprises creating an electrical channel of ionized gas (plasma) between the plasma cutter nozzle and the workpiece; the electrical circuit is complete since the workpiece is connected to the DC power source.

Uses of a Plasma Cutter

Your plasma cutter machine can be used for many applications as under:

Plasma Cutter vs Laser Cutting

Laser cutting is a non-conventional and advanced machining process and there are no physical forces between the tool (Laser) and the workpiece.

Safety

The plasma arc used in your Plasma Cutter emits radiations due to very high temperature and there can be unpleasant fumes during cutting; hence, following safety precautions are necessary.

FAQ (Frequently Asked Questions)

Pure oxygen is a preferred gas for cutting mild steel and carbon steel since the chemical reaction between the oxygen in the plasma and the workpiece material aids in increasing the cutting speed and improving the quality of the cut edge.

How does a plasma cutter work?

How a Plasma Cutter Works 1 Power supply -- The plasma power supply converts single or three phase AC line voltage into a smooth, constant DC voltage ranging from 200 to 400VDC. This DC voltage is responsible for maintaining the plasma arc throughout the cut. It also regulates the current output required based on the material type and thickness being processed. 2 Arc Starting Console – The ASC circuit produces an AC voltage of approximately 5,000 VAC at 2 MHz which produces the spark inside of the plasma torch to create the plasma arc. 3 Plasma torch – The function of the plasma torch is to provide proper alignment and cooling of the consumables. The main consumable parts required for plasma arc generation are the electrode, swirl ring, and nozzle. An additional shielding cap may be used to further improve cut quality, and all the parts are held together by inner and outer retaining caps.

What are the consumable parts needed for plasma arc generation?

The main consumable parts required for plasma arc generation are the electrode, swirl ring, and nozzle. An additional shielding cap may be used to further improve cut quality, and all the parts are held together by inner and outer retaining caps.

What is secondary shielding gas?

A secondary shielding gas is also used which flows outside of the nozzle through a shield cap. The shape of the shield cap and the diameter of its orifice forces the shield gas to further constrict the plasma arc, resulting in a cleaner cut with very low bevel angles and smaller kerf.

What is plasma handheld?

Precision plasma systems (high current dens ity) are designed and engineered to produce the sharpest, highest quality cuts that are achievable with plasma.

How does a plasma arc form?

The plasma arc formation begins when a gas such as oxygen, nitrogen, argon, or even shop air is forced through a small nozzle orifice inside the torch. An electric arc generated from the external power supply is then introduced to this high pressured gas flow, resulting in what is commonly referred to as a “plasma jet”.

What safety equipment do you need for plasma cutters?

Here is some safety gear we recommend: Plasma helmet for eye and face protection. Welding jacket to protect your arms and torso.

What are the components of a plasma cutter?

Components of a Plasma Cutter 1 Power supply -- The power supply helps in converting an AC line voltage into a DC voltage. The DC voltage maintains the plasma arc throughout the cut. 2 Arc Starting Console – It helps produce the AC voltage which produces the spark inside of the plasma torch to create the plasma arc. 3 Plasma torch – It provides proper alignment and cooling of the consumables parts. The consumable parts are the parts you need to change from time to time. Examples of these parts are tip, swirl ring, nozzle, and electrode.

What is plasma torch?

Plasma torch – It provides proper alignment and cooling of the consumables parts. The consumable parts are the parts you need to change from time to time. Examples of these parts are tip, swirl ring, nozzle, and electrode. The plasma cutter is pretty simple. Try to pick a plasma cutter that runs on 110v or 220v.

Why use a plasma cutter?

As long as you don’t forget about the safety gear and precautions, then you’re good to go. The plasma cutter will help you save time and money. Plus, you get to create a smooth cut on metal that clients will be pleased with.

How does plasma cutter work?

When the electrons in the plasma are used at high speed, the plasma melts the metal to form a cut. Hence, a plasma cutter results in a faster and cleaner cutting process. For a more detailed discussion of how it works, the plasma arc is formed when gas is heated at a very high temperature.

How much does a Spectrum 875 plasma cutter weigh?

The miller plasma cutter offers one of the best cutting power in a small package. It only weighs 21lbs!

Why do you need to touch the metal on a torch?

This makes it easier and smoother to cut metal. Plus, it increases the life of the consumables in your torch. If you use a non-pilot arc machine, the tip of the torch needs to touch the metal in order to make a cut. It can affect your consumables and cost you more in the long run.

Compressed Air

Oxygen

- Oxygen has become the go-to gas for cutting mild steel because it offers clean cuts and faster cutting speeds on carbon steels up to a 1 ¼" thickness. While it isn't recommended for cutting stainless steel or aluminum, you can count on high-quality cuts with a smooth face and dross (mineral waste formed on the surface of molten metal) that's easy to remove from the kerf (the …

Argon

- Argon is a rare, inert gas, making it relatively expensive but unreactive with the metals it's cutting. Using argon gasimproves the stability of the arc and prevents atmospheric contamination of welding pools. While its high kinetic energy makes it an effective gas for plasma cutting, it can't work alone because of its low conductivity. As a result, argon must be paired with an appropriat…

Hydrogen

- Along with being an excellent thermal conductor, hydrogen has the properties needed to quickly cool hot metal surfaces. For these reasons, hydrogen is ideal for cutting aluminum and stainless steel. However, although it has excellent conductivity, its low atomic weight prevents it from having high kinetic energy. Just like argon, it must combine with other gases to produce a high-i…

Argon-Hydrogen Mixtures

- Because they have contrasting properties, combining hydrogen and argon creates an outstanding plasma-cutting flame. With a standard mix of 65% argon and 35% hydrogen, it produces the hottest plasma cutting flame and some of the cleanest cuts. Typically used for cutting stainless steel and aluminum, the argon-hydrogen mixture is required for cutting material over 3" thick. It i…

Nitrogen-Water Combination

- The nitrogen-water plasma cutter gas mixture uses nitrogen as the main gas and water as the secondary (shield) gas. The energy produced from the plasma gas splits the torch's water into its two components--hydrogen and oxygen. The hydrogen isolates the cutting zone from contamination, leaving a clean cut free of dross and oxides. Since it is converted into its essenti…

Primeweld Plasma Cutters and Multi-Process Welders

- PrimeWeld's top-of-the-line CUT60 Dual Voltage Plasma Cutteris a versatile machine appropriate for industrial settings or in a home workshop. At the same time, the CT-520DP Pilot Arc Plasma Cutter Combo and CT-520D Plasma Cutter/Stick Welder Combofeature a high-quality plasma cutter teamed up with a TIG and stick welder. And our plasma cutters work with a variety of gas…