by author Q: When a bimetallic strip is heated, it (a) Does not bend at all (b) Gets twisted in the form of an helix

What happens when a bi-metal strip is heated?

when a bi metallic strip such as a combination of either iron and brass or steel and copper , brass or copper expands more on heating than iron or steel, thus when the bi metallic strip is heated , one side expands in length ( linear expansion) more than the other causing the strip to bend in a curve . Related Questions.

What is bimetal heating?

By introducing heat to a bimetal – or what is known as auxiliary heating – the function of a device containing the bimetal can be controlled. Circuit breakers and time delay devices are examples of these devices.

Why does the brass side of a bi-metallic strip bend inwards?

From the chart below you can see that brass has a higher rate of expansion per degree than iron or steel. therefore on heating the bi-metallic strip, the brass side would expand more and would cause the strip bend towards the iron/steel side and then on cooling, it would return to normal. Often used in thermal switches.

How do Bimetals work?

Bimetals work with the propensity of metals to expand when heated, and contract when cooled. The resulting change of curvature, or bending, in response to temperature change, is a fundamental property of all thermostatic bimetals.

What would happen to the bimetal strip when it is heated?

When the bimetallic strip is heated, the metal with higher thermal expansion will bend more. Thus they bend towards the metal having a lower thermal expansion.

What causes a bimetal element to change with a temperature change?

A bimetal strip has two different metals connected back to back. These metals expand and contract at different rates when heated or cooled. Why are two different metals used to produce movement in bimetal elements? The metals expand and contract at different rates as temperature changes.

When a bimetal device is heated the steel expands faster than the brass which causes the device to warp?

the brass expands faster than the steel which causes the device to warp. the motion of the bimetal strip is then used to perform some useful task. bimetal controls can be attatched to an electrical component or valve to stop start or modulate electric current or fluid flow.

What is a bimetallic strip and how does it function when heated?

The bimetallic strip constitutes one of the most trouble-free and durable thermometers. It is simply two strips of different metals bonded together and held at one end. When heated, the two strips expand at different rates, resulting in a bending effect that is used to measure…

How does a bimetal switch work?

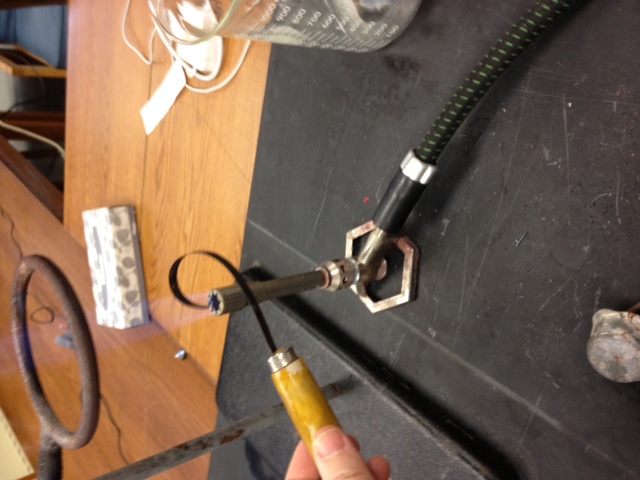

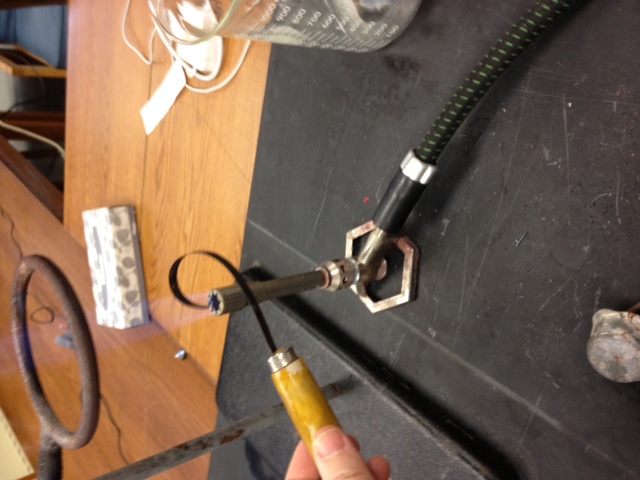

The bimetallic strip consists of two thin strips of different metals, each having different coefficients of thermal expansion. Thermal expansion is the property of a metal to change its shape or volume with a change in temperature. The metal strips are connected along their length by fusing them together or riveting.

How does a bimetal sensing element make and break an electrical circuit?

In bimetal thermostats, the sensor is made of two strips of dissimilar metal bonded into one element. When the temperature changes, unequal expansion of the two metals causes the strip to bend into an arc. The movement either makes or breaks an electrical contact.

How can the biMetal strip be extended to have more travel per degree of temperature change?

How can the biMetal strip be extended to have more travel per degree of temperature change? A longer strip will have more travel per degree. To unlike metals commonly brass and steel. Diaphragm expands with internal pressure increases, and contracts with internal pressure decreases.

Does heat expand brass?

However, since brass expands (or contracts) more than iron when its temperature is raised (or cooled), the bimetallic strip will bend one way or another depending on the temperature being above or below room temperature.

What two metals can be used in the biMetal device or the rod and tube?

What two metals can be used in the bimetal device or rod and tube? Two unlike metals, commonly brass and steel.

Why does a bimetallic strip curve when it is heated or cooled?

Brass and Iron together form the bimetallic strip. The rate of expansion and contraction of brass is more when compared to Iron, that is, brass expands more than Iron when heated and contracts faster than iron when cooled. As a result, the bimetallic strip bends with the change in temperature.

Does heat make metal expand or contract?

What does heat do to metal? The expansion (or contraction) of any material is due to the kinetic energy of its atoms. When a material is heated, the increase in energy causes the atoms and molecules to move more and to take up more space— that is, to expand. This is true of even a solid such as a metal.

Why do substances expand when their temperature is increased?

Substances expand when their temperature increases because the molecules have more energy and move faster and farther apart.

How can the biMetal strip be extended to have more travel per degree of temperature change?

How can the biMetal strip be extended to have more travel per degree of temperature change? A longer strip will have more travel per degree. To unlike metals commonly brass and steel. Diaphragm expands with internal pressure increases, and contracts with internal pressure decreases.

Why does a bimetallic strip bend when heated or cooled?

The strip consists of two strips of different metals which expand at different rates as they are heated. The different expansions force the flat strip to bend one way if heated, and in the opposite direction if cooled below its initial temperature.

What do you think would happen when a bimetallic strip is cooled below room temperature?

When the temperature is lower than normal room temperature, the length of the brass will be less than the length of the iron, and so the bimetallic strip will become "U-shaped" with the brass on the topside.

What is thermal biMetal?

A bimetal or thermostatic metal is a sheet or strip of two or more composite materials having different coefficients of linear thermal expansion bonded by riveting, brazing or welding.