The 2G test is a standard welding test for both pipe and structural steel welding. A 2Gtest will require you to weld a horizontal workpiece prepared by beveling the edges where the weld will occur. Prepping the material is as important as the welds.

What does 2G welding position mean?

Jun 03, 2020 · The 2G test is a standard welding test for both pipe and structural steel welding. A 2Gtest will require you to weld a horizontal workpiece prepared by beveling the edges where the weld will occur . Prepping the material is as important as the welds.

What is the 2G position in welding?

Jan 04, 2020 · The 2G welding certification position is a plate in the horizontal position that is beveled. This one test covers the 1G and 2G positions. 2G (groove weld) Test Position. Click to see full answer. Also asked, what is a 2g Weld? 2G is a groove weld position that involves placing the weld axis in a horizontal plane or approximately horizontal.

What is the best welding position?

The 2G welding certification position is a plate in the horizontal position that is beveled. This one test covers the 1G and 2G positions. 2G (groove weld) Test Position.

How to TIG weld aluminum Part 2?

A 2G weld test checks your proficiency at producing welds that meet specific criteria for the finished weld and includes: Welding two horizontal beveled plates. Proper setup. Making the weld with or without a backer plate.

What is a 2G welder?

In the 2G welding position, the pipe is in the vertical position and can be rotated along the vertical (Y) axis. The welder's position remains stationary. Welding is performed on the side of the pipe in a horizontal direction.Oct 8, 2019

What is a 3G weld test?

What is a 4G welding test?

What does 2G welding position stand for?

How can I pass 1g weld test?

What is a 5F weld?

What is the hardest welding test?

What does 6G welding mean?

What position is 1G?

What is 5G and 6G welding?

What is the easiest position to weld?

Also referred to as a “downhand” position, the flat position weld is the easiest and often the first weld that new students learn. The metals to be joined are placed flat, and the welder passes the electric arc over them, moving across the workpiece in a horizontal direction.Aug 13, 2020

What position is 3G in welding?

Pipe and Plate Weld Joint Positions

Normally there are six welding positions with certain numbers and letter i.e. 1G, 2G, 3G, 4G, 5G, and 6G/6GR. All the positions are used in various angles and shapes while performing welding. Generally, the ways and ideas of welding are similar in different countries.

6G Welding Positions-

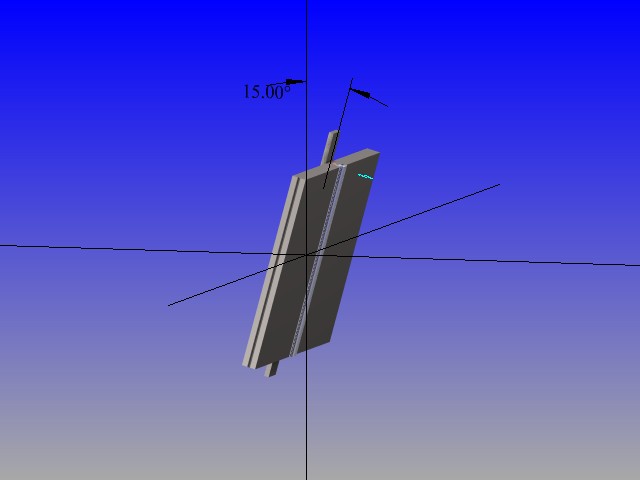

This is one of the hardest types of welding positions for welders to perform. The position is a pre-condition for getting certified. To some extent, this position is similar to 5G/PH/PJ but the pipe stands at 45° to the other one. Other names are 6G Uphill/H-L045 and 6G Downhill/J-L045 Position.

What is 1G welding?

The 1G pipe welding certification position is a pipe in the horizontal position and the pipe is rolled when welding. This is basically welding in the flat position. The 1G pipe welding certification is rarely used.

What is the coding system for welding?

The positions are flat, horizontal, vertical, and overhead. There is also a coding system to identify the welding position. The coding system for plate and structural welding is as follows: 1 is for the flat position. 2 is for the horizontal position. 3 is for the vertical position.

What is a welding certification?

Definition: Welding Certifications are technically a hands-on welder qualification test that is conducted by certified welding inspector that will determine if the person or machine can produce a sound quality weld up to the code or welding procedure needed for a Company, job site or a particular industry standard.

What is the largest organization in America that certifies welders?

The largest organization in America that certifies welders is the American Welding Society . The welding certification procedures they have approved have been tested many time to ensure that if followed the welder taking the welding certification follows the rules and has the skills will pass the test.

What does it mean to be a certified welder?

When the term "Certified Welder" is used it only means that welder is certified under the welding procedures they have tested under. There is not a single welding certification that covers all types of welding.

What is the coding system for plate and structural welding?

There is also a coding system to identify the welding position. The coding system for plate and structural welding is as follows: 1 is for the flat position. 2 is for the horizontal position.

What size pipe do you need to weld a fillet?

These two tests usually cover all the positions and most codes allow fillet welds on pipes that are a minimum diameter of 24″.

Introduction

Magnum NDT technicians encounter several unique welding positions when performing non-destructive testing. In untrained hands, welding can be a safety hazard. That is why professional standard organizations such as ASME, AWS, ISO, JWES make rules and classifications for welding positions.

1G Position

In the 1G welding position, the pipe is in the horizontal position and can be rotated along the horizontal (X) axis. The welder's position remains stationary. Welding is performed on the top of the pipe. This is the most basic welding position that can be performed.

2G Position

In the 2G welding position, the pipe is in the vertical position and can be rotated along the vertical (Y) axis. The welder's position remains stationary. Welding is performed on the side of the pipe in a horizontal direction.

6G Position

In the 6G welding position, the pipe slopes at approximately 45° from the horizontal (X) axis or 45° from the vertical (Y) axis. The pipe is in a fixed position, so the welder must move around the pipe to perform the welding. This is an advanced welding position that requires a great deal of experience and technical expertise.

Levels of Experience

A welder's mastery over each welding position acts as a certification that qualifies him or her to perform more types of welding work. In other words, mastery over each position levels up a welder's qualifications. For instance, if a welder only a 1G position qualification, he cannot conduct welding in more advanced positions such as 2G, 5G, or 6G.

What does it mean to pass the 4G welding test?

Passing The 4G Weld Test. Once a welder passes the 4G weld test or certification, that means the welder can now operate overhead positions for welding projects. Since welding is an easy career to study, but rigorous in training, it is important to note that passing this test requires a few key tips and tricks.

Why do welders need to be comfortable during the 4G test?

By finding a comfortable position to work with the welding during the 4G test, it can enable you to work with the molten metal easier. Welders who have taken this test have preferred that during the test, the welder should be in a position that is comfortable enough to see the puddle of the molten metal rather than the arc.

What are the different welding positions?

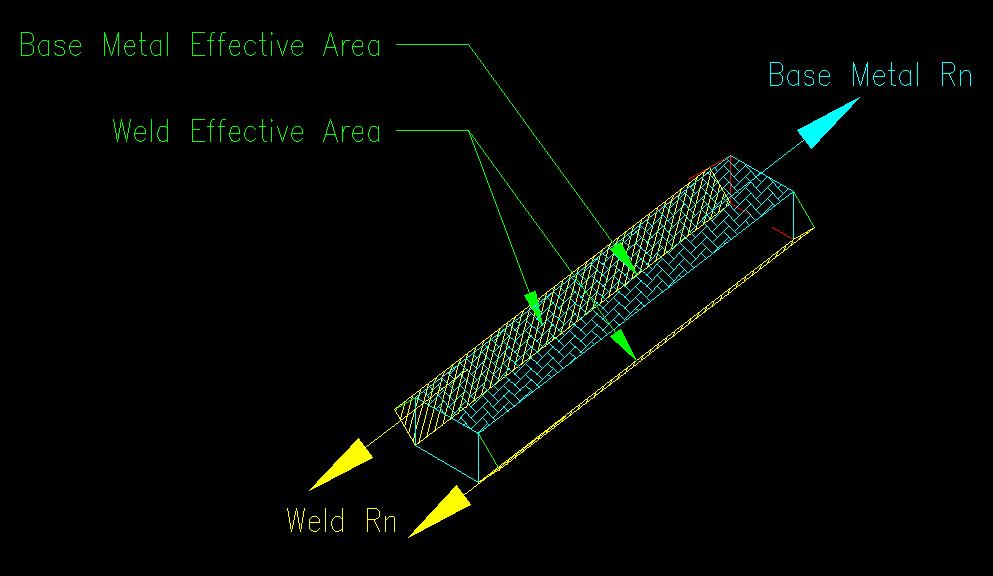

For these four positions, there are two categories that each welder gets tested on: 1 Fillet (F): welding two metals into a perpendicular angle. They are shaped like the letters T and L. They are shaped triangularly and used to connect pipes. 2 Groove (G): welding two metals through the middle so that they are joined together in the process. They are squared shaped and usually flat compared to the fillet weld.

What is 4G welding?

What exactly is 4G weld testing? 4G weld testing is a type of welding procedure and certification that allows a welder to perform in order to increase his skills and abilities as a welder. With this certification, the welder can now be able to handle the process of groove welding, a type of welding that enables the metal to be joined together in an ...

Is 4G the same as 1G?

Welders use this tip as they understand that the process of a 4G weld is the same as a 1G weld, except it is done upside down. The same is dealt with the electrode angles, the travel speed, and even amperage.

Can you burn your hands during a 4G welding test?

Sometimes there can moments during the 4G welding test that can cause some major if not severe burn injuries in your palms, knuckles, or hands. Of course, it is highly recommended to wear gloves since you are playing with serious flames, the way in which the welding rod should be positioned is in a manner that doesn’t cause burn damage to your hands. This allows the work to be done efficiently and not cause any further burns in your hands.

What does "hard welding" mean?

Meaning, the ability of welding metals to be joined together in an overhead position. Since this is the fourth, that most likely means that it is the hardest to do from the rest of the welding positions. More on what they are will be mentioned down below.