What are Biosafety Cabinets?

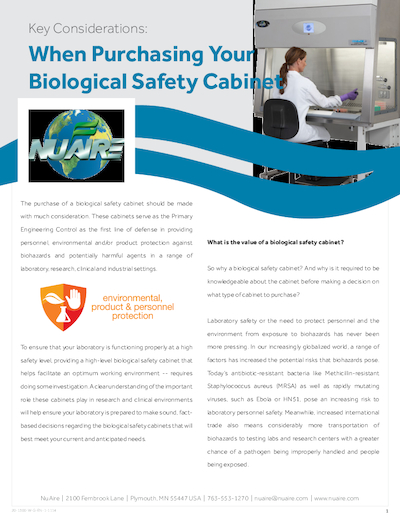

- I. Introduction. Biological Safety Cabinet is the primary engineering control that provides user, sample, and environment protection against biohazards.

- II. Biosafety Cabinet Guide to models. ...

- III. Must-have features of a BSC. ...

- IV. Factors to Consider When Selecting a Biosafety Cabinet. ...

- V. Safety Tips When Using Biosafety Cabinets. ...

How to safely operate your biosafety cabinet?

Preparing to work in the BSC

- Wear appropriate personal protective equipment. ...

- Check certification sticker to confirm that BSC has been certified within the past 12 months.

- Operate cabinet blowers for at least 5 minutes prior to starting work.

- Disinfect cabinet surface prior to starting work.

- Set the sash at the correct height, 8” to 10” depending on manufacturer’s guidelines.

What is a biological safety cabinet used for?

A biosafety cabinet (BSC) is a primary containment device used with biological material. While handling biological agents, it is the biological equivalent of using hazardous chemicals inside a fume hood. Like a chemical fume hood, a biosafety cabinet protects the user from hazardous material using directional air flow.

How does a biological safety cabinet work?

- HEPA filtered downflow.

- None of the air is recirculated within the cabinet or work area.

- 100 % of the HEPA filtered air is exhausted from the cabinet.

- The cabinet must be hard ducted into an external ventilation system.

- All ducts and plenums are under negative pressure.

What do all biosafety cabinets have in common?

What do all biosafety cabinets have in common? There are 3 main classes of Biological safety cabinets (BSCs) – the thing they all have in common is that they protect the worker/environment from the cultures. Class II BSCs are the most common cabinets found in the lab and are the type of cabinet used for mammalian cell culture.

How does a biosafety cabinet keep you safe?

It protects the samples in the BSC from contamination by permanently cleaning the cabinet interior from aerosols. Potentially contaminated air from both air streams is filtered and either recirculated back into the work zone or the lab, or ducted out of the building.

What is biosafety cabinet and types?

Biosafety cabinets are divided into three classes: I, II and III. Class I provides protection for the user and surrounding environment, but no protection for the sample being manipulated. Class II provides protection for the user, environment and sample, and is divided into four types: A1, A2, B1 and B2.

What are the 3 biological safety cabinets?

There are three kinds of safety cabinets, Classes I, II, and III. Class II and Class III biological safety cabinets provide personnel, environmental as well as product protection. Whereas the class I safety cabinet, which is the most basic one, provides personnel and environmental protection only.

Is a biosafety cabinet a fume hood?

A chemical fume hood is designed to remove chemical fumes and aerosols from the work area while a biosafety cabinet is designed to provide both a clean work environment and protection for employees who create aerosols when working with infectious agents or toxins.

What is a Class III biosafety cabinet?

Class III biosafety cabinets are totally airtight enclosure equipped with non-opening, totally sealed front windows. This separates the worker from the hazardous specimen with a solid physical barrier, providing optimal protection. Another term for a Class III cabinet is a “glove box.”

What is a BSC?

One of the most notable scientific devices is the biological safety cabinet (BSC). Of course, these fulfill a dual purpose of keeping workers safe while also maintaining quality. It’s one of the instruments that are vital enough to need regular certification. But, what exactly do labs use biological safety cabinets (BSC) for? In this post, we’ll discuss just that, plus how they work, BSC classes I, II, and III, and more.

What is a biological safety cabinet?

Biological safety cabinets are generally required to comply with that country or region's standards. This requirement may be governed by an institutional body such as the TGA, FDA or WHO. Within Australia, for example, Class II BSCs are required to meet construction standards entitled AS2252.2. Those standards reference several other standards, such as AS2243.3. AS2243.3 classifies the level of risk that microorganisms pose based on their pathogenicity, mode of transmission, and host range, along with current preventative measures and effective treatments.

What is a Class II biosafety cabinet?

Class II Biosafety Cabinet Types using color to illustrate where it is safe to handle hazardous chemistry with microbiology. (Blue is recirculated air where it is NOT safe to use hazardous chemistry. Red is single pass air and is safe for chemical use. Purple is uncertainty due to location of the BSCs smoke-split)

What is a BSC?

A biosafety cabinet ( BSC )—also called a biological safety cabinet or microbiological safety cabinet —is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with (or potentially contaminated with) pathogens requiring a defined biosafety level. Several different types of BSC exist, differentiated by the degree of biocontainment required. BSCs first became commercially available in 1950.

What are class II cabinets?

There are five types: Type A1 (formerly A), Type A2 (formerly A/B3), Type B1, Type B2 and Type C1. Each type's requirements are defined by NSF International Standard 49, which in 2002 reclassified A/B3 cabinets (classified under the latter type if connected to an exhaust duct) as Type A2, and added the Type C1 in the 2016 standard. About 90% of all biosafety cabinets installed are Type A2 cabinets.

Why is a B2 cabinet so expensive?

The Type B2 cabinet (also known as a Total Exhaust BSC) is expensive to operate because no air is recirculated within. Therefore, this type is mainly found in such applications as toxicology laboratories, where the ability to safely use hazardous chemistry is important.

What is the inflow velocity of a Type A cabinet?

The Type A1 cabinet, formerly known as Type A, has a minimum inflow velocity of 75 ft/min. The downflow air, considered contaminated, splits just above the work surface (the BSCs smoke split) and mixes with the inflow.

Can you change a filter after a cabinet is decontaminated?

Changing the filter should be limited to trained persons as the filter is potentially contaminated. This can be done either after the cabinet has been decontaminated using a gaseous procedure (using formaldehyde, chlorine dioxide, or vaporized hydrogen peroxide) or a "bag-in/bag-out" procedure.

What is the purpose of biosafety cabinets?

The primary purpose of biosafety cabinets is to protect the laboratory personnel and the environment from the pathogenic microorganism as aerosols might be formed during the processing of such microorganisms . Biosafety cabinets are only used for certain risk group organisms and for processes that might result in aerosol formation.

What level of biosafety is the lab cabinet?

These cabinets can be used for all four Biosafety levels (1, 2, 3, and 4) . But these are the most important for the manipulation of biological materials in the Biosafety level 4. These cabinets are mostly custom-built for specific laboratories with lab equipment built inside the chamber.

What is the difference between a laminar hood and a biosafety cabinet?

But, laminar hood only provides protection to the sample and not to the personnel and the environment, whereas biosafety cabinets protect all three. The use of biosafety cabinets or other such physical containment is not required in the biosafety level 1, but depending on the risk assessment, some processes might require such containment.

Why are cabinets called glove boxes?

The cabinets are provided with rubber gloves that are attached to the system to be used during operations in the cabinet. This is why these cabinets are also termed ‘glove boxes’. The cabinet even has a transfer chamber that facilitates the sterilization of materials before they leave the glove box.

Why are BSCs important?

BSCs are an essential part of biosafety as they minimize the formation of aerosol, protecting the environment, the pathogen, and the laboratory personnel. Besides, most BSCs also function to sterilize biological materials that are kept inside the cabinets.

What is a class II biosafety cabinet?

How Biosafety Cabinets Work. The Class II Type A2 biosafety cabinet is the most common cabinet on campus. It uses a curtain of air and HEPA filters to provide both containment and a sterile environment.

What is a clean bench?

Clean bench or laminar flow hoods are for use with nonhazardous sterile work (such as PCR or media preparation). They should not be used with hazardous materials (including biological material, hazardous chemicals, or radionuclides).

What is a BSC?

A biosafety cabinet (BSC) is a primary containment device used with biological material. While handling biological agents, it is the biological equivalent of using hazardous chemicals inside a fume hood. Like a chemical fume hood, a biosafety cabinet protects the user from hazardous material using directional air flow.

What size filter is used to separate biological material from air?

This particle size is the Most Penetrating Particle (MPP) size. Fibrous material is used to separate biological material from air passing through the filter.

Why do we need animal transfer stations?

Animal transfer or cage changing stations are generally used to reduce allergens when working with animals. They must not be used with animals containing hazardous material including biological material, hazardous chemicals, or radionuclides.

Can Class II A2 cabinets be connected to a building exhaust?

Per a 2016 update to NSF/ANSI standard 49, Class II Type A2 cabinets may no longer be connected directly to the building exhaust (hard or direct ducted) due to the following safety reasons:

Can you use an open flame in a biosafety cabinet?

Do not use an open flame in a biosafety cabinet: Chamber is a sterile environment and does not require a heat source for sterility. Disposable or autoclavable loops/spreaders are available to replace flame sterilization of metal loops or metal/glass plate spreaders.

What is a biological safety cabinet?

Biological Safety Cabinets offer protection from microbiological contamination in the laboratory environment, including both operator and product protection. They are utilized by a wide range of scientific, research and development organizations within both the commercial and non-commercial sectors, including pharmaceutical, medical, ...

What is a class 2 cabinet?

A Class 2 Biological Safety Cabinet has a front aperture through which the operator can carry out work inside the cabinet. Notably, it provides both worker and materials protection. Class 2 Biological Safety Cabinets are the most in use bio-containment devices protecting worker, product and environment from potentially dangerous microbiological ...

What are the different types of biosafety cabinets?

Based on the degree of biocontainment, the biosafety cabinet is classified into three classes such as Class I Biosafety Cabinet, Class II Biosafety Cabinet, and Class III Biosafety Cabinet. Classes of Biosafety Cabinet. Class I. Class II. Type A.

What is a BSC?

The biosafety cabinet (BSC) also known as the microbiological safety cabinet or biological safety cabinet, are an enclosed, and ventilated laboratory workspace that is designed to protect the laboratory worker and the surrounding environment from infectious pathogens. The exhaust air inside the biosafety cabinet pass through a HEPA filter ...

What is bioafety cabinet?

Bioafety cabinets are used in the laboratory for procedures in which either the reactants are to be protected from contamination by the worker or environment you can learn here as the worker needs protection or safety during handling of infectious material or both of these are to be protected from each other.

What should be placed inside a cabinet before starting the experiment?

PRECAUTIONS AND MAINTENANCE. All the material required for the experiment or procedure to be carried out should be placed inside the cabinet before starting the actual work. The cabinet shall then be switched on. If UV light is required it should also be switched on.

Overview

A biosafety cabinet (BSC)—also called a biological safety cabinet or microbiological safety cabinet—is an enclosed, ventilated laboratory workspace for safely working with materials contaminated with (or potentially contaminated with) pathogens requiring a defined biosafety level. Several different types of BSC exist, differentiated by the degree of biocontainment the…

Purposes

The primary purpose of a BSC is to serve as a means to protect the laboratory worker and the surrounding environment from pathogens. All exhaust air is HEPA-filtered as it exits the biosafety cabinet, removing harmful bacteria and viruses. This is in contrast to a laminar flow clean bench, which blows unfiltered exhaust air towards the user and is not safe for work with pathogenic agents. Neither are most BSCs safe for use as fume hoods. Likewise, a fume hood fails to provid…

Classes

The U.S. Centers for Disease Control and Prevention (CDC) classifies BSCs into three classes. These classes and the types of BSCs within them are distinguished in two ways: the level of personnel and environmental protection provided and the level of product protection provided.

Class I cabinets provide personnel and environmental protection but no product protection. In fact, the inward flow of air can contribute to contamination of samples. Inward airflow is maintai…

Ergonomics

Biosafety cabinets are used on a daily basis for hours. Besides protection of user and sample material, the human design factors (ergonomics) of the work become more and more important. This includes reduction of the noise level (for a more convenient working atmosphere), a height adjustable stand or stool and footrest (for optimized sitting position), panorama side windows (more light within cabinet), 10° angled front sash (enables better sitting position), strong light so…

Ultraviolet lamps

The CDC does not recommend the installation of UV lamps in BSCs. The American Biological Safety Association supports this position, citing the safety risk to personnel, shallow penetration, reduced effectiveness in high relative humidity, and the frequent need to clean and replace the bulb. UV lamps should not be used as a primary source of surface decontamination within a BSC. However, these assertions have been formally disputed in at least one peer-reviewed article whi…

Maintenance and service

Biological safety cabinets are generally required to comply with that country or region's standards. This requirement may be governed by an institutional body such as the TGA, FDA or WHO. Within Australia, for example, Class II BSCs are required to meet construction standards entitled AS2252.2. Those standards reference several other standards, such as AS2243.3. AS2243.3 classifies the level of risk that microorganisms pose based on their pathogenicity, mode of trans…

Work practices

As with work on open bench tops, work performed within a BSC must be performed carefully and safely. To avoid contamination and the risk of personnel exposure, the CDC advises investigators to follow best practices to reduce and control splatter and aerosol generation, such as keeping clean materials at least 12 inches (30 cm) from aerosol-generating activities and arranging the work flow "from clean to contaminated". In particular, open flames, not necessary within the clea…

See also

• Fume hood

• Laminar flow cabinet