How to put in double flares?

Method 2 Method 2 of 3: Preparing Your Tubing

- Cut the tubing to the required length with your tubing cutter. ...

- Chamfer the ends of the tubes that you'll be double-flaring. "Chamfering" is simply creating a slope at the end.

- Slide the fitting onto the line, with the threading facing the side you just cut. ...

- Mount your flaring base in a vice. ...

How do you insert double flared plugs?

Insert one edge of the flare of the plug through your ear, then gently pull down on the plug and pop the other edge of the flare through the ear. Do not force the plugs and stop right away if trying to insert them causes pain.

How to double flare a brake or fuel line?

Method 3 Method 3 of 3: Double Flaring Brake Lines

- Adjust the height of the tube so it reaches the height of your flaring anvil. The anvil is round piece with a small rod sticking out the top.

- Drop a few drops of brake fluid into the line and on the top of the anvil. ...

- Insert the rod of the anvil into the brake tube. ...

How to make a double flare brake line?

Steps Download Article

- Measure the length of brake line needed with measuring tape.

- Don hand and eye protection.

- Cut brake tubing to the desired length with tubing cutters or a hacksaw. ...

- Use a flaring tool or a double flare tool to form the tubing's flare. ...

- Put the cone of the tool over the end of the tubing. ...

What is a double flare tool?

What are the different types of flare tools?

Can flare tool cause leakage?

Can you use a double flare tool on a steel tube?

What are double flares used for?

The double flare is used for installations that require repeated tightening/untightening. The fitting moves against the folded over section causing that to wear and not the already thinned outer pipe wall. There is no difference between the pressure rating of single and double flares.

What is the difference between a single and double flare tool?

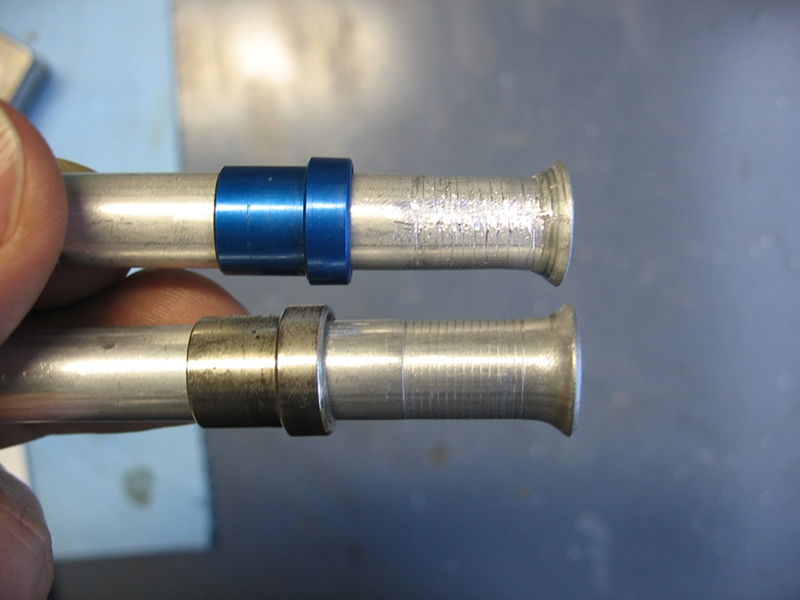

The single flare is very identical to the double flare. Although they look a lot alike, the double flare is much stronger and can hold more pressure build up inside the braking system. The double flare is a flare that is especially popular in vehicles imported from Europe.

What does double flaring mean?

Double flare plugs, on the other hand, have the flared edges on both sides as the name suggests. This makes them more secure for wearing, as it's not easy for them to just slip out.

What are flare tools used for?

What are Flaring Tools? Flaring tools use pressure to make a fabricated mechanical joint for joining or sealing copper tubing with a flare connection. Flaring allows you to connect tubes to each other or another kind of fitting. Flared ends tend to have an approximately conical shape.

When should I double flare my brake lines?

All brake lines need to be double flared, due to the high hydraulic pressure. If your brakes leak or the hoses crack, it could prove to be fatal. Single flared lines are suitable for low-pressure lines in other applications, but not your vehicle's brakes.

How do you use a double flare brake tool?

5:146:32Brake Line Double Flares - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt in fit the yoke with the flare and comb. Over the envelope. Get it so that it's nice and straightMoreIt in fit the yoke with the flare and comb. Over the envelope. Get it so that it's nice and straight. And then turn it down by hand then turn the flaring cone down on the anvil.

Do an fittings need a double flare?

AN or Army-Navy fittings require 37-degree single flares. This 37-degree tool looks the same, but notice that it does not come with the dies. For AN fitting, you need a single 37-degree flare.

When can I start wearing double flared plugs?

For double flared plugs, you will need a different method, but first, it's important to know that double-flared plugs and tunnels can only be worn on fully healed ears. If you have recently stretched your ears you should wait around four to eight weeks before trying to wear double flared plugs.

How do you make a perfect double flare?

2:363:35How To Make a Double Flare - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's important that you put even pressure as you are tightening the adapter down and you want toMoreIt's important that you put even pressure as you are tightening the adapter down and you want to tighten until the adapter hits the flaring bar.

What are the two types of flaring tools?

Two types of flaring tools are used to make flares on tubing: the impact type and the rolling type.

What are the different flaring tools?

The usability, too, and if There are four major types of flaring tool s, manual, hydraulic, single flare, double, or bubble flaring flare kit.

Why flare is required?

Flaring may be required for safety reasons. Extracting and processing oil and gas involves dealing with exceptionally high, and changeable, pressures. During crude oil extraction, a sudden or dramatic increase in pressure could cause an explosion.

What is the two types of flaring tools are used to make flare on tubing?

Two types of flaring tools are used to make flares on tubing: the impact type and the rolling type.

Are brake lines 37 or 45 degree flares?

The 45-degree inverted flare is the most common style of flare used in automotive hard lines like brake, fuel, and transmission fluid transfer.

Are flare wrenches necessary?

Because of the shape of flare-nut wrenches, this wrench type is absolutely necessary if you work in the automobile or plumbing industries. The open 5-sided design ensures that you can easily grip nuts so you can maximally tighten or loosen them.

Which tool is used to flare the metal tubes?

The tool used to flare tubing consists of a die that grips the tube and either a mandrel or rolling cone is forced into the end of the tube to form the flare by cold working. The most common flare fitting standards in use today are the 45° SAE flare, the 37° JIC flare, and the 37° AN flare.

Why use double flaring tool?

Implementing the double flaring tool set resolves your further labor and time too. The extra labor and time that requires after bubble flaring is pretty wasteful and boring.

What is a double flaring tool kit?

The double flaring tool kit is the best kind of tool. It is made at the end of the tubing being folded or rolled to itself. A layer is created that enacts the initial one. Enacting external pressure, you get the layer to be rigid and firm. Brake lines and other lines of steel and metals persist the double flaring tool kit.

What Is The Difference Between Double Flare and Bubble Flare?

We have discussed the double flare till now. Knowing its importance and steps, we have also gone through the bubble flare. Looks ridiculous, right? Surely not.

What is the best tool for joining tubing?

Overall, the double flaring tool is the best tool for making a path of joining the tubing end. It saves a lot of time and effort in getting the correct measurement and sizing.

What are the two types of flaring tools?

For the best compatibility of the users, two types of flaring tools are used at present. They are single flaring tools and double flaring tools.

What is double flaring?

With a double flaring tool, you can bend or fold the edge lining of the steel and make a layer of it. The layer sums up the connectivity of the flaring tool with the other components.

How many lip in a single flare plug?

There is only one lip in a single flare plug. In a double flare plug, you get to have a lip on both ends.

What is the best double flaring tool?

The ARES 18019 instrument is the best double flaring tool for the cash. Since you don’t have to analyze a double flare tool versus a single flare device any longer. This toolset accompanies both reinforcement highlights. Its five connectors upgraded the ability of what you can do with a flare instrument.

What is flaring toolbox?

Flaring devices are referred to for their proficiency as cutting instruments, so they ought to have the option to play out this capacity well. As referenced above, they are ideal for vehicle applications since the car extends, as a rule, manage funnels. In case you intend to purchase your flaring toolbox, ensure that the parts are good with your vehicle, explicitly your brakes.

What size connectors are used for flare instruments?

Its five connectors upgraded the ability of what you can do with a flare instrument. The sizes are – ¼ inch, 5/16-inch, half-inch, 3/16-inch, 3/8 inch. All connectors spread measurement sizes of 4.8mm to 12.7mm. Without the flexible connectors, you will get a shaper that can cut up to1/8 to 5/8-inch substantial.

What is a tight clamp mounted device?

This tight clamp mounted device has a freehand component with an aim to get bent if you got the chance to accomplish something. You would get an additional tool to clasp down on the highest point of the manual apparatus. It will assist you in indecently making brake fittings. We like the T-handle screws that can be utilized for holding the passes on and tube simultaneously.

Does flaring tool pay off?

A right flaring tool always pays off. But it is the perfect one that returns your investment. Read the following buying guide to save you getting ripped off. Consider the following things while purchasing the Best Double Flare Tool.

Is flaring a chore?

This line flaring tool is easy to utilize, and it gives extraordinary fulfillment as far as convenience. Flaring is certifiably not an essential chore.

Can you use a freehand siphon to make double flares?

The freehand pressure-driven siphon can be worked to make double flares on steel and light hardened steel materials. Just recall a specific something, if you can’t twist the hardened steel tubing without wrinkling the unit, don’t utilize it on that sort of material.

How to make a double flare?

Steps For Creating A Double Flare. Using the tube cutter: For the flare to have a beautiful, standard shape, you must have a clear, definitive, and clean cut. The whole cutting process can cause a leak, so be vigilant. Bubble flare: After cutting the tube, you should set the clamp on the flared tube.

When did double flares become popular?

Popularity. Since 1980, double flares have been widely used and often found in modern cars, especially those made in the United States. This type of flare can also handle high pressure, so it is preferred to use the most. Bubbles are often confused with doubles, but they are less common.

What are the two most common flares?

There are many types of flares on the market, but the two most popular ones are Bubble flare and Double flare .

What is a single flare brake?

Single flare is another type of flare that looks almost like a double flare on the surface. However, the Single isn’t strong and sturdy enough to handle high pressures.

What does depressing brakes do?

Depressing the brakes will reduce force and create compression in the master cylinder. As a result, hydrodynamic pressure is to act on the liquid, causing it to spread throughout the vehicle. From here, the brake system begins to do its job.

Do bubble flares work?

Flares play a significant role in helping brakes work better. Most automotive experts recommend Bubble flare vs Double flare for brake lines. However, to apply these products to your vehicle, you need to have a good understanding of them.

Is a bubble a double?

Bubbles are often confused with doubles, but they are less common.

What are the different types of flaring tools?

There are three types of flaring tools: manual, hydraulic, and leverage manual. Most of the time you will be dealing with a manual tool, usually mounted in a vise.

What tool do you use to flaring lines?

This is the most common tool you will find for flaring lines, the manual clamp. You can use these under the car on in a vise, making them very versatile.

How to cut brake line?

The first step is to cut the line. The end of the line must be clean and smooth. Some kits come with a tubing cutter, you need one regardless. Tubing cutters work best when the blade is tightened after every pass. You don’t want to load the brake line into the cutter and just crank down the cutting wheel.

What is leveraged manual flaring?

Leveraged Manual – The leveraged manual flaring tool uses dies and a swing-arm to press the flares into the line much faster and easier than a basic manual kit. These often cost a few hundred dollars, and are excellent for the builder that needs to make many flared lines, such as when restoring a car.

What type of flare do you need for a fitting?

For AN fitting, you need a single 37-degree flare. This kit looks like the double flaring kit, but does not have the dies and has a 37-degree head. Hydraulic – Hydraulic flaring tools are generally only used in shops where a lot of line flares are made on a regular basis, the average DIY mechanic does not need one.

Can you crank a flare press too hard?

The press is once again positioned over the line and threaded down. You just need to go hand-tight, don’t crank too hard on it or you can damage the flare.

Is it hard to make a double flare brake line?

It is not difficult, but if you have never done it before, it can seem like a bit of voodoo. There are several key points that you need to know before you get started, so get ready to learn how to make a double flare brake line.

What is a double flare tool?

These double flare tools are suitable for high-pressure jobs such as brake lines and other steel tubing heavy tasks.

What are the different types of flare tools?

Surely you need a flare tool for that work, but do you know there are different kinds of flare tools? Two popular types of flare tool are single flare tool and double flare tool.

Can flare tool cause leakage?

It is not suitable and can cause you problems in the future, such as crack and leakage. Such problems occur easily with a single flare tool.

Can you use a double flare tool on a steel tube?

It makes you flare twice at the end of the steel tube line with a double flare tool. You can handle the tough and pressured brake system with this tool with great ease. You will rarely face the problems of leakage or cracks that you faced in the single flare tools. In Europe and America, it is very popular to use in the heavy brake system.