A Large Flange Rivet is also sometimes called an Oversize Rivet, Large Flange Pop Rivets, or simply Flange Rivets. This type of rivet has a larger head, allowing the load to be spread over a larger load-bearing area, making Large Flange Rivets a good choice for use with softer materials.

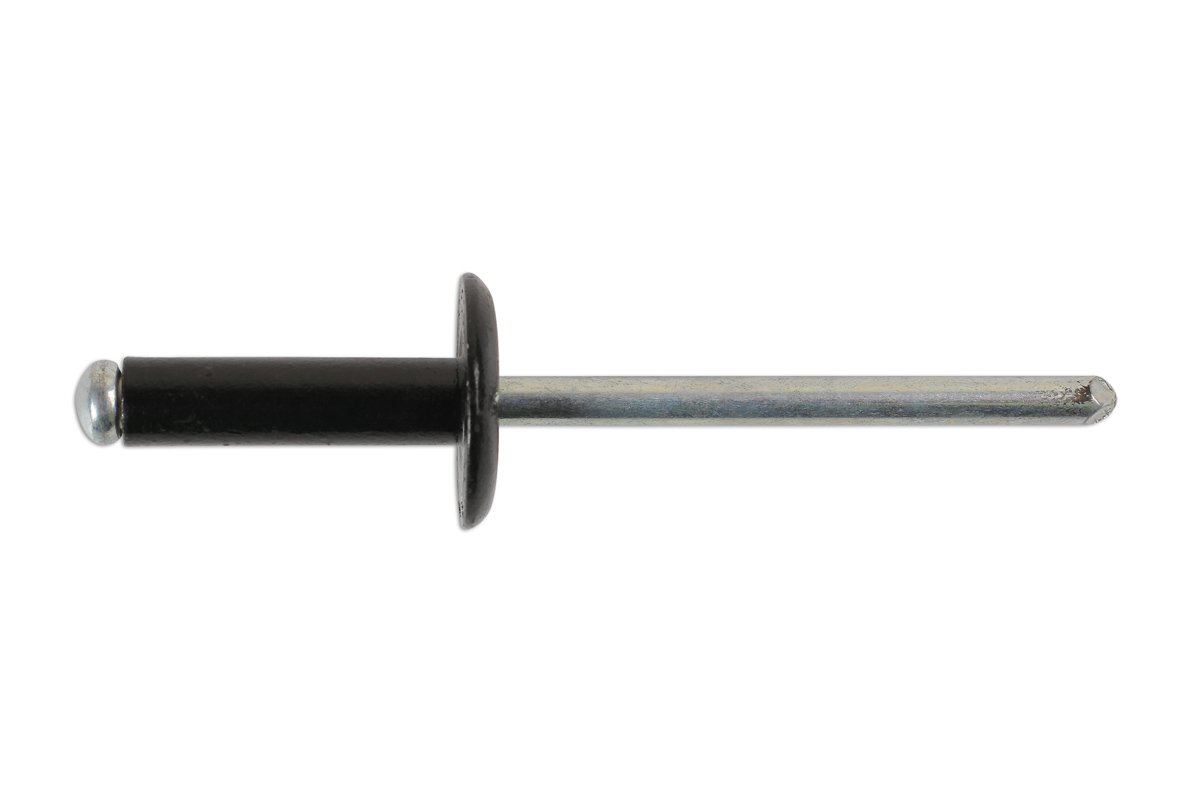

What does a rivet look like?

It has a head, a smooth cylindrical body, and a tail that looks more like a metallic pin. Rivets are usually made of aluminum or steel, but there are some made with other materials. These types of fasteners are not tightened like the usual bolt and nuts.

What is a flare rivet?

These splits cause the shaft to fold and flare out (similar to the wings on a toggle bolt's nut) as the mandrel is drawn into the rivet. This flare (or flange) provides a wide bearing surface that reduces the chance of rivet pull-out. This design is ideal for high vibration applications where the back surface is inaccessible.

What are rivets used for in construction?

Use for covering irregular holes as well as extra holding power when fastening soft, thin materials to a rigid backing. Made of aluminum, rivets are lightweight, nonmagnetic, and have good corrosion resistance. They join material when you only have access to one side. The low-profile domed head creates a finished appearance.

What is a pop rivet?

A pop rivet is also known as a blind or hollow rivet and is used where you are only able to work with one side of the rivet. A special pop rivet gun or tool pulls the mandrel head into the body of the rivet, which then expands against the blind side of the join.

How do you use a flange rivet?

0:061:04How to Use Blind Rivets / Pop Rivets / Flange Head Rivets - YouTubeYouTubeStart of suggested clipEnd of suggested clipJust big enough to suit the blind rivet shaft diameter. Then simply slide the rivet's pin into theMoreJust big enough to suit the blind rivet shaft diameter. Then simply slide the rivet's pin into the tool and pass the rivet through the work. Piece.

What are the four types of rivets?

There are four basic types of rivets; tubular, blind, solid and split. There are two basic types of threaded inserts; press-in and blind.

What are the two types of rivets?

The general types of rivets are solid, blind, tubular, and metal piercing (including split rivets).

What is a rivet and what is it used for?

A rivet is a mechanical fastener with a plane unthreaded shaft that's inserted through holes to join two or more parts together. A permanently formed head at each end prevents the rivet from removal from the hole. The shaft prevents any radial movements of the components.

How do you identify different types of rivets?

Tubular Rivets: With a Hollow EndCompression Tubular Rivets – these rivets consist of two parts with an interference fit during the fastening process. ... Full Tubular Rivets – they have deeper holes than their counterparts. ... Semi-Tubular Rivets – these types of rivets have their holes in the field end.

What is the strongest type of rivet?

Multi-Grip Rivet. The multi-grip is our strongest standard rivet choice, for many this rivet helps reduce stock options as one multi-grip rivet replaces a few different size open end rivets.

Why are rivets no longer used?

Indeed, the latest steel construction specifications published by AISC (the 14th Edition) no longer covers their installation. The reason for the change is primarily due to the expense of skilled workers required to install high strength structural steel rivets.

What is the difference between a blind rivet and a pop rivet?

Blind rivets, also commonly referred to as POP Rivets, are mainly used in applications where there is no access to the rear (blind side) of the joint. Rivets have a two-piece construction; one is called the rivet body, shell, or hat and another is called the stem or mandrel.

What is the difference between a blind rivet and a solid rivet?

The blind end expands, and the mandrel is snapped off. Unlike solid rivets, blind rivets can be installed in joints from only one side of the part—making them “blind” to the opposite side.

What are large flange rivets used for?

Aluminium Large Flange Rivets are a simple and cost effective method for securing two or more components together from one side. Typically used in sheet type products, the Standard Rivet is a general purpose fastener ideal for use across various applications.

What are rivets in Heart of Darkness?

Rivets hold things together, and Conrad uses the rivets as symbols of the ways in which the Company, the Manager, Marlow, Kurtz, and Kurtz's fiancée (his Intended) attempt to "hold together" their beliefs and ideas. These ideological "rivets" are seen in numerous ways.

What is the most common type of rivet?

Solid rivetsSolid rivets may be the most common type of rivet. They are versatile and simple to install, and are often used in applications where reliability and safety are important. They can be made of aluminum, copper, brass, steel, titanium, and nickel-based alloys.

What is the most common type of rivet?

Solid rivetsSolid rivets may be the most common type of rivet. They are versatile and simple to install, and are often used in applications where reliability and safety are important. They can be made of aluminum, copper, brass, steel, titanium, and nickel-based alloys.

What is the difference between pop rivet and blind rivet?

Blind rivets, also commonly referred to as POP Rivets, are mainly used in applications where there is no access to the rear (blind side) of the joint. Rivets have a two-piece construction; one is called the rivet body, shell, or hat and another is called the stem or mandrel.

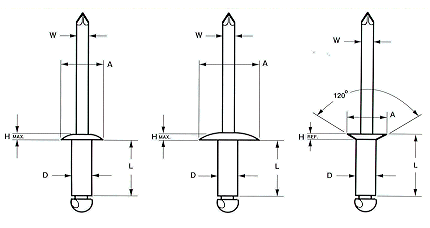

What are the different types of rivet head?

Following are the different types of Rivets:Snap head or cup head rivets.Pan head rivets.Conical head rivets.Countersunk head rivets.Flathead rivets.Buffercated head rivet.Hollow head rivets.

What rivets to use on steel?

Zinc is a common coating for steel rivets. An Almac® coating combines aluminium and zinc for corrosion resistance and works particularly well with aluminium rivets and materials. Copper rivets with coated carbon steel add strength.

What Is a Rivet?

A rivet is a permanent mechanical fastener with head-on at one end and a cylindrical stem called a tail at the other that has the appearance of a m...

How Is Riveting Done?

This is a common process that you may already be aware of. But still for Let's see it now. First, a hole is made or punched in the place or parts t...

Material Use in Rivets:

The material of rivets must be hard and ductile. They are typically made of steel low carbon steel or nickel steel, brass, aluminum, or copper, but...

Riveting Definition:

Riveting is a forging process that uses power to fix parts together by gripping and engaging with the use of a metal part called a rivet.

Types of Rivet:

#1. Blind Rivet #2. Solid Rivet #3. Drive Rivet #4. Semi Tubular Rivets #5. Split Rivets #6. Threaded Rivets #7. Oscar Rivet #8. Flush Rivet #9. Fr...

How Do Rivets Work?

When installed, the rivets are either drilled, placed, or punched into a hole, subsequently deforming the tail, holding the rivet in place. The riv...

Applications of Riveting:

These are some applications of riveting. Rivet joints are permanent joints mainly used for fastening sheets and shaped rolled metal. Used for aircr...

Limitations of Riveting:

Riveting takes more labor time than welding. Additional operations such as layout and drilling holes are necessary. The labor cost of rivet joints...

What is a rivet?

A rivet is a mechanical fastener composed of a head on one end and a cylindrical stem on another (called the tail) which has the appearance of a me...

How do rivets work?

Rivets are either drilled, placed or punched into a hole, before the tail is deformed by pounding or smashing to hold the rivet in place. Riveting...

What are the different types of rivet?

There are eight widely used types of rivets, which include blind rivets, drive rivets, flush rivets, friction-lock rivets, oscar rivets, self-pierc...

What is a pop rivet and how does it work?

A pop rivet is used where you are only able to work with one side of the rivet. A pop rivet gun or tool pulls the mandrel head into the body of the...

What is a rivet?

A rivet is a mechanical fastener composed of a head on one end and a cylindrical stem on another (called the tail) which has the appearance of a metal pin.

What is a drive rivet?

Drive rivets – This type of blind rivet has a short mandrel which protrudes from the head and is driven in with a hammer causing the end inserted into the hole to flare.

What is a Pop Rivet and How Does it Work?

A pop rivet is also known as a blind or hollow rivet and is used where you are only able to work with one side of the rivet. A special pop rivet gun or tool pulls the mandrel head into the body of the rivet, which then expands against the blind side of the join. Once it meets the face of the join’s blind side the mandrel snaps, causing the stem to eject to create a tight joint. A pop rivet can be used as a replacement for nuts and bolts, screws, welds and adhesives.

What is a Friction Lock rivet?

Friction-lock rivet – Available as countersunk or dome shaped, these early forms of blind rivet where the first to be widely used in aerospace applications these rivets resemble an expanding bolt.

What are the different types of rivets?

There are eight widely used types of rivets, which include: Blind rivets (also known as hollow or pop rivets) – These are used when it isn't possible to see the other side of a join. This type of riveting is very fast to apply and is used in a variety of sectors including aerospace, shipbuilding and electronics.

How does a rivet deform?

The rivet is deformed by pounding or smashing of the tail, which makes the material flatter and usually causes the tail to be expanded by about one and a half times the size of the stem's original diameter.

Do self piercing rivets need a hole?

Self-piercing rivets – These rivets do not need a drill or punched hole as the end includes a chamfered poke to pierce materials to be joined. Self-piercing rivets go through the top sheet of material but do not fully pierce the bottom sheet, creating a water or gas-tight joint.

How does a rivet work?

On installation, the rivet is placed in a punched or drilled hole, and the tail is upset, or bucked (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place.

How to upset a rivet?

Rivets may also be upset by hand, using a ball-peen hammer. The head is placed in a special hole made to accommodate it, known as a rivet-set. The hammer is applied to the buck-tail of the rivet, rolling an edge so that it is flush against the material.

What is a universal head rivet?

A typical technical drawing of a universal head solid rivet. Solid rivets are one of the oldest and most reliable types of fasteners, having been found in archaeological findings dating back to the Bronze Age. Solid rivets consist simply of a shaft and head that are deformed with a hammer or rivet gun.

How to buck a rivet?

Rivets small enough and soft enough are often bucked. In this process the installer places a rivet gun against the factory head and holds a bucking bar against the tail or a hard working surface. The bucking bar is a specially shaped solid block of metal. The rivet gun provides a series of high-impulse forces that upsets and work hardens the tail of the rivet between the work and the inertia of the bucking bar. Rivets that are large or hard may be more easily installed by squeezing instead. In this process a tool in contact with each end of the rivet clinches to deform the rivet.

What is semi tubular rivet?

Semi-tubular rivets (also known as tubular rivets) are similar to solid rivets, except they have a partial hole (opposite the head) at the tip. The purpose of this hole is to reduce the amount of force needed for application by rolling the tubular portion outward. The force needed to apply a semitubular rivet is about 1/4 of the amount needed to apply a solid rivet. Tubular rivets are sometimes preferred for pivot points (a joint where movement is desired) since the swelling of the rivet is only at the tail. The type of equipment used to apply semi-tubular rivets range from prototyping tools to fully automated systems. Typical installation tools (from lowest to highest price) are hand set, manual squeezer, pneumatic squeezer, kick press, impact riveter, and finally PLC-controlled robotics. The most common machine is the impact riveter and the most common use of semitubular rivets is in lighting, brakes, ladders, binders, HVAC duct work, mechanical products, and electronics. They are offered from 1/16-inch (1.6 mm) to 3/8-inch (9.5 mm) in diameter (other sizes are considered highly special) and can be up to 8 inches (203 mm) long. A wide variety of materials and platings are available, most common base metals are steel, brass, copper, stainless, aluminum and most common platings are zinc, nickel, brass, tin. Tubular rivets are normally waxed to facilitate proper assembly. An installed tubular rivet has a head on one side, with a rolled over and exposed shallow blind hole on the other.

Why are rivets not heat treated?

Such riveted structures may be insufficient to resist seismic loading from earthquakes if the structure was not engineered for such forces, a common problem of older steel bridges. This is because a hot rivet cannot be properly heat treated to add strength and hardness. In the seismic retrofit of such structures it is common practice to remove critical rivets with an oxygen torch, precision ream the hole, then insert a machined and heat treated bolt.

How big of a hole should a rivet be?

To become a proper fastener, a rivet should be placed in hole ideally 4–6 thousandths of an inch larger in diameter. This allows the rivet to be easily and fully inserted, then setting allows the rivet to expand, tightly filling the gap and maximizing strength.

What is a threaded flange?

Threaded flanges have an internal (female) thread, a threaded pipe is screwed into it. This is relatively easy to fit but not suitable for high pressure and temperature. Socket-welded flanges have a plain hole with a shoulder at the bottom.

What is a pipe flange?

Pipe flanges. Pipe flanges form a rim that radially protrudes from the end of a pipe. They have several holes that allow two pipe flanges to be bolted together, forming a connection between two pipes. A gasket may be fitted between two flanges to improve the seal.

What is a flange in a beam?

A flange is a protruding ridge or rim, often used to increase strength or spread the load. For example, sectional beams often have flanges that carry most of the load and that are connected by a web joining the flanges together.

An Overview of Rivets

In a nutshell, a rivet is a mechanical fastener or connector with a head and tail at opposite sides. It has a head, a smooth cylindrical body, and a tail that looks more like a metallic pin.

Materials Used for Rivets

There are several metal materials for manufacturing rivets. They include steel, copper, brass, aluminum, copper, and stainless steel. Designers and manufacturers choose these different materials to satisfy their needs.

Different Types of Rivets Available for Manufacturing

There are several different types of rivets available. However, they are broadly divided into the following categories.

What are Rivets Used For?

Rivet’s primary purpose is to ensure a firm and reliable tightening of two or more metallic or wooden materials. When you do this, you have a joint stronger than that of a screw with the same diameter.

Conclusion

Rivets are a better substitute for screws, bolts, and nuts. They prove more efficient and reliable than all other connectors. Today, different types of rivets have various purposes. This is a result of the dynamic nature of machines and structures. However, you have to choose suitable metal rivets for your applications to get the best results.

What Is a Rivet and How Does a Rivet Work?

A rivet is a type of mechanical fastener that used to connect or assembly parts permanently through unique installing methods. It’s consists of a smooth cylindrical shaft connected with a head on one end, the head has a larger diameter than the shaft. How does a rivet work? Put the rivet into a drilled hole in the material being fastened, make the smaller end deformed using external impact to flatten this end and secure it tightly. Once the rivet is installed, it will not fall off unless it is deliberately destroyed. A rivet is also a CNC machining part that can be processed with aluminum, copper and more materials.

What is rivet fastener?

Rivets are one of the most classic fasteners used in mechanical applications, their permanency and firmness make them different from other fastening components . To suit varying requirements, there is a wide range of rivets are designed for different styles.

What is a rivet compression tool?

A rivet compression or crimping tool can also deform this type of rivet. Solid rivets are driven using a hydraulically, pneumatically, or electromagnetically actuated squeezing tool or even a handheld hammer. Solid rivets are suitable for the applications where require high reliability and safety, including aircraft structural parts ...

How do rivets work?

How does a rivet work? Put the rivet into a drilled hole in the material being fastened, make the smaller end deformed using external impact to flatten this end and secure it tightly. Once the rivet is installed, it will not fall off unless it is deliberately destroyed. A rivet is also a CNC machining part that can be processed with aluminum, copper and more materials.

What are blind rivets used for?

Blind rivets can be used for different purposes at home applications, attaching nameplates, signs, hinges, door knobs, handles, and ceiling decorations, as well as woodworking and industrial applications.

What is a solid rivet?

– Solid rivets: also known as round rivets, solid rivets are one of the oldest fasteners, have the most basic construction: a shaft and a head, which is deformed with a hammer or rivet gun.

What are flush rivets?

For example, the flush rivets, also known as countersunk rivets, primarily used on external metal surfaces where need good appearance and elimination of unnecessary aerodynamic drag. Their typical uses are the exterior of the aircraft.

Have a riveting emergency?

We can help. Our unmatched on-hand supply of rivets, threaded inserts, tools and repair parts can usually be shipped immediately from our stock.

What is a semi tubular rivet?

Semi tubular rivets are similar to solid rivets but contain a hole at the end of the rivet opposite the head. Semi tubular rivets also require less force needed for application and assembly.

What is a rivet?

A rivet is a mechanical fastener consisting of a smooth, cylindrical shaft with a head. Upon installation, the end of the shaft expands, creating a “shop head” and fastening objects in place. There are many types of rivets: blind rivets, solid rivets, tubular rivets, drive rivets, split rivets, shoulder rivets, tinners rivets, mate rivets, ...

What is a drive rivet?

A drive rivet is a type of blind rivet that is installed by driving the center pin into the body of the rivet using a hammer in order to cause the other end of the rivet to flare out and fasten materials together.

What is threaded insert?

Threaded inserts and rivet nuts provide a uniquely strong permanent thread through sheet materials and other materials where installation is only possible from one side.

What is riveting in manufacturing?

Rivets are the unsung heroes of the manufacturing industry. They offer supreme fastening capabilities for light and heavy-duty applications alike, and they have been used for decades on everything from submarines to aircraft to sheet-metal assemblies.

What are the different types of rivets?

There are four basic types of rivets; tubular, blind, solid and split. There are two basic types of threaded inserts; press-in and blind. Also featured are a number of special rivets and fasteners on this page. Click on any of the rivets above for available dimensions and additional information.

What is a low profile domed head?

A low-profile domed head creates a finished appearance. The combined thickness of material must fall within the rivet's material thickness range. Shear strength is the amount of force it takes to break a rivet from the side, and tensile strength is the amount of pull a rivet can withstand without breaking.

What tool is needed to install blind rivets?

A blind rivet tool (sold separately) with a nosepiece that matches the rivet's diameter is required for installation.

What are domed rivets made of?

Use for covering irregular holes as well as extra holding power when fastening soft, thin materials to a rigid backing. Made of aluminum, rivets are lightweight, nonmagnetic, and have good corrosion resistance. They join material when you only have access to one side. The low-profile domed head creates a finished appearance.

What is a blind rivet?

In addition to gripping a much wider range of material thicknesses than standard blind rivets, these have a 50% larger head diameter that distributes pressure where the head meets the material surface. Use for covering irregular holes as well as extra holding power when fastening soft, thin materials to a rigid backing. Made of aluminum, rivets are lightweight, nonmagnetic, and have good corrosion resistance. They join material when you only have access to one side. The low-profile domed head creates a finished appearance.

What is zinc plated rivet?

The zinc -plated finish provides mild corrosion resistance. These rivets have a 50% larger head diameter than standard domed head blind rivets, distributing pressure where the head meets the material surface. Use for covering irregular holes as well as extra holding power when fastening soft, thin materials to a rigid backing. They join material when you only have access to one side. The low-profile domed head creates a finished appearance.

What is a 50% larger head diameter?

In addition to gripping a much wider range of material thicknesses than standard blind rivets, these have a 50% larger head diameter that distributes pressure where the head meets the material surface. Use for covering irregular holes as well as extra holding power when fastening soft, thin materials to a rigid backing.

Is 18-8 stainless steel good?

18-8 stainless steel has good corrosion resistance and may be mildly magnetic. These rivets have a 50% larger head diameter than standard domed head blind rivets, distributing pressure where the head meets the material surface.

Overview

Types

There are a number of types of rivets, designed to meet different cost, accessibility, and strength requirements:

Solid rivets are one of the oldest and most reliable types of fasteners, having been found in archaeological findings dating back to the Bronze Age. Solid rivets consist simply of a shaft and head that are deformed with a hammer or rivet gun. …

History

Rivet holes have been found in Egyptian spearheads dating back to the Naqada culture of between 4400 and 3000 B.C . Archeologists have also uncovered many Bronze Age swords and daggers with rivet holes where the handles would have been. The rivets themselves were essentially short rods of metal, which metalworkers hammered into a pre-drilled hole on one side and deformed on the other to hold them in place.

Sizes

Rivets come in both inch series and metric series:

• Imperial units (fractions of inches) with diameters such as 1/8" or 5/16".

• Système international or SI units with diameters such as 3 mm, 8 mm.

The main official standards relate more to technical parameters such as ultim…

Applications

Before welding techniques and bolted joints were developed, metal framed buildings and structures such as the Eiffel Tower, Shukhov Tower and the Sydney Harbour Bridge were generally held together by riveting, as were automobile chassis. Riveting is still widely used in applications where light weight and high strength are critical, such as in an aircraft. Many sheet-metal alloys are prefera…

Joint analysis

The stress and shear in a rivet is analyzed like a bolted joint. However, it is not wise to combine rivets with bolts and screws in the same joint. Rivets fill the hole where they are installed to establish a very tight fit (often called interference fit). It is difficult or impossible to obtain such a tight fit with other fasteners. The result is that rivets in the same joint with loose fasteners carry more of the load—they are effectively more stiff. The rivet can then fail before it can redistribute …

Installation

There are several methods for installing solid rivets.

• Manual with hammer and handset or bucking bar

• Pneumatic hammers

• Handheld squeezers

• Riveting machines

Testing

A hammer is also used to "ring" an installed rivet, as a non-destructive test for tightness and imperfections. The inspector taps the head (usually the factory head) of the rivet with the hammer while touching the rivet and base plate lightly with the other hand and judges the quality of the audibly returned sound and the feel of the sound traveling through the metal to the operator's fingers. A rivet tightly set in its hole returns a clean and clear ring, while a loose rivet produces a …