What is GMP and why is it important?

What is GMP? Good Manufacturing Practices or GMP is a system that consists of processes, procedures and documentation that ensures manufacturing products, such as food, cosmetics, and pharmaceutical goods, are consistently produced and controlled according to set quality standards.

What is a GMP guideline and regulation?

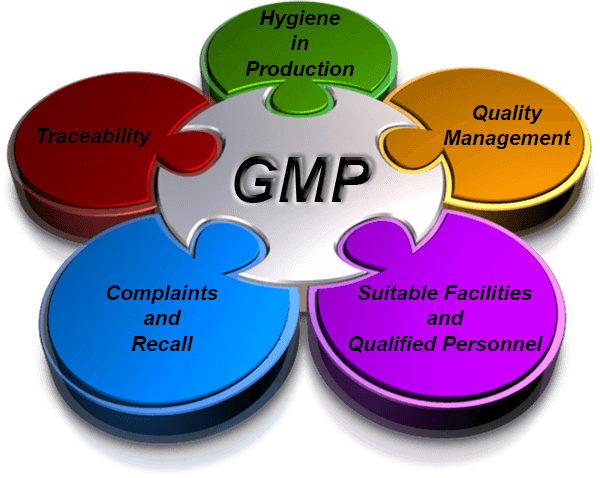

GMPs examine and cover every aspect of the manufacturing process to guard against any risks that can be catastrophic for products, such as cross-contamination, adulteration, and mislabeling. Some areas that can influence the safety and quality of products that GMP guideline and regulation address are the following :

What qualifies as a cGMP area?

Our CGMP folks agree with Treesei and Miregmgr; what you have described would qualify as a "GMP area", so long as you've established both a physical environment and a set of procedures that eliminate any possible cross contamination from other areas.

What are the different grades of GMP?

Under the GMP requirements, the manufacturing of sterile medicinal products can be distinguished into 4 grades: Grade A, B, C & D. High-risk operations (filling zone, stopper bowls, open ampoules, and vials, making aseptic connections) A cGMP Grade A environment is equivalent to an ISO 5, for both at rest and in operation.

What does GMP area mean?

Good Manufacturing Practice (GMP) is a system for ensuring that products are consistently produced and controlled according to quality standards. It is designed to minimize the risks involved in any pharmaceutical production that cannot be eliminated through testing the final product.

What does GMP meaning?

Good Manufacturing PracticesCurrent Good Manufacturing Practices are regulations set by the U.S. FDA to ensure drug products for human use meet the minimum quality requirements for patient safety.

What is a GMP approved facility?

GMP compliance means that a manufacturing facility meets specific industry-standard quality specifications in a number of areas that assure proper design, monitoring, and control of manufacturing processes and facilities.

What are the GMP requirements?

704(a) of the FD&C Act. Rigorous adherence to good manufacturing practice minimizes the risk of adulteration or misbranding of cosmetics....GuidelinesBuilding and Facilities. Check whether. ... Equipment. Check whether: ... Personnel. Check whether: ... Raw Materials. Check whether: ... Production. ... Laboratory Controls. ... Records. ... Labeling.More items...•

What are examples of GMP?

GMP: Good Manufacturing PracticesQuality management.Sanitation and hygiene.Building and facilities.Equipment.Raw materials.Personnel.Validation and qualification.Complaints.More items...

What are the 3 importance of GMP?

Good Manufacturing Practices help ensure the proper design, monitoring, and control of manufacturing processes and facilities, while securing the identity, strength, and quality of their products.

What is a non GMP facility?

non-GMP Batch means any Batch intended for non-clinical use, including those intended to meet the requirement for pre-clinical use pursuant to cGLP requirements, such as, for example, a batch intended for use in GLP toxicology studies.

What does GMP mean in construction?

guaranteed maximum price contractLump sum — or fixed price — and cost-based contracts are the two main players in this arena, the latter of which is the basis for the cost-plus-fee with a guaranteed maximum price contract, or GMP.

What are the 5 main components of GMP?

5 Key Components of Good Manufacturing PracticesPrimary Materials and Products.Premises.People.Procedures.Processes.

Who is responsible for GMP?

Who is responsible for GMP Compliance? Everyone. Quality and GMP Compliance are independent of job title and salary and have no boundaries. Building quality into processes, systems, documentation, and the employee's mindset makes sustainable compliance more achievable.

What is a GMP inspection?

A GMP audit is a comprehensive, third-party inspection of a production company. It is meant to identify operational flaws and legal violations. Along with specific inspection results, GMP audits are meant to communicate a set of standards and guidance on how to meet these standards.

What is a GMP document?

What is GMP documentation? As a component of Good Manufacturing Practices, GMP documentation ensures the quality and traceability of manufacturing processes, maintenance and quality checks. The documents fall into two major categories: procedural or instructional, and compliance records.

What are the 5 elements of GMP?

5 Main Components of GMPProducts. The primary materials (or raw ingredients) used to create a medical device or other relevant solution need to be of the highest quality. ... People. Hiring well-qualified people will encourage GMP compliance as well. ... Processes. ... Procedures. ... Premises.

What does GMP mean in pharma?

Good Manufacturing PracticeThe main regulatory standard for ensuring pharmaceutical quality is the Current Good Manufacturing Practice (CGMPs) regulation for human pharmaceuticals. Consumers expect that each batch of medicines they take will meet quality standards so that they will be safe and effective.

What does GMP stand for in food?

Good Manufacturing Practicesprogram. These include: Good Manufacturing Practices (GMPs) Good Manufacturing Practices* (GMPs) are the basic operational and environmental conditions required to produce safe foods.

What is a GMP certificate?

GMP stands for good manufacturing practice, and it is a system that ensures products consistently adhere to quality standards. GMP regulations were put in place by the Food and Drug Administration (FDA) to minimize the risks involved in producing goods, such as supplements and other pharmaceuticals.

What is GMP in manufacturing?

GMP guidelines are not prescriptive instructions on how to manufacture products. They are a series of general principles that must be applied during manufacturing. When a company is setting up its pharmaceutical quality system, manufacturing processes and control, there may be many ways to fulfil GMP requirements.

How does GMP help?

Additionally, GMP can help boost pharmaceutical export opportunities. The majority of countries worldwide only accept the import and sale of medicines that have been manufactured to internationally recognised GMP standards.

What is good manufacturing practice (GMP)?

Good manufacturing practice (GMP) is a concept that ensures products are consistently produced and controlled according to quality standards. It is designed to minimize the risks to the patient involved in any pharmaceutical production.

Why is GMP so important in pharma engineering?

The pharmaceutical industry has a responsibility to ensure their safe and sufficient supply, and this must be taken into consideration in pharma engineering and consulting projects from the outset.

What is GMP investment?

Investing in GMP means investing in quality medicine. It saves costs, minimizes risks, and improves the standard of drugs worldwide.

Why must manufacturing facilities be controlled?

Manufacturing facility design, operating principles and environmental conditions must be controlled in order to prevent cross contamination of drug products, and to prevent cross contamination from labelled or unlabelled material or products.

Should the process remain in a state of control throughout the product lifecycle?

The process should remain in a state of control throughout the product lifecycle and improvements done as needed.

What is GMP?

GMP or ‘Good Manufacturing Practice’ is the area of quality assurance which ensures that medicinal (and some food) products are consistently produced and controlled to the quality standards appropriate for their intended use and as required by the product specification. In this respect, GMP is concerned with both quality control and production.

What are the basic rules of GMP?

The Basic Rules of GMP. > Operators must be adequately trained to carry out and document procedures. > Instructions and procedures should be written in clear and unambiguous language. These instructions are often referred to as ‘SOP’s’ or ‘Standard Operating Procedures’.

What are the consequences of not complying with GMP?

Failure of manufacturers to comply with GMP regulations can result in very serious consequences such as seizure, recall, fines and ultimately imprisonment.

Is GMP covered by legislation?

Although this area of GMP is not strictly covered by legislation, it is the responsibility of the equipment manufacturer to understand the importance of hygienic design and the training of competent staff to design and construct equipment that meets the specific needs of the end user and comply with GMP requirements.

What is a CGMP grade environment?

A cGMP Grade A environment is equivalent to an ISO 5, for both at rest and in operation. This means that whether employees are working or not, the cleanliness inside the cleanroom must maintain Grade A levels (ISO 5).

What is a grade A area?

The Grade A area is dedicated to high-risk operations such as fill/finish (filling zone), stopper bowls, open ampoules, vials, and making aseptic connections.

What is a grade D airborne particle?

For Grade D, the airborne particle classification is the equivalent of an ISO 8 cleanroom at rest. While in operation, the particle classification is not predefined; it will depend on the nature of the processes taking place inside the zone. This is what we call a Clean Non-Classified (CNC) area.

What is the maximum particle size for a grade B cleanroom?

At rest, the Grade B cleanroom needs to meet a maximum of 3,520 particles (0.5 μm) per cubic foot. In operation, the number of permitted airborne particles increases to 352,000 (0.5 μm) for each cubic foot of air.

How many micrometers are in a cubic foot of airborne particles?

To achieve Grade A cleanliness level, the number of airborne particles smaller than 0.5 micrometers should not exceed 3,520 per cubic foot.

What is a GMP contract?

A guaranteed maximum price contract is a document that sets the maximum price a customer will have to pay for a contractor's services, no matter how much cost the services actually accrue. It effectively puts a cap on the contract's price, ensuring that companies or organizations can't charge the consumer more.

Different ways to plan a GMP contract

There are a few different ways to plan for a GMP contract to help it save the contractor and the customer the most amount of money, including:

Disadvantages of a GMP contract

Here are a few disadvantages of a GMP contract and some possible solutions for them:

What is GMP in manufacturing?

Every food, drug, and medical device manufacturer aims to operate their business in accordance with the principles of Good Manufacturing Practice (GMP). It’s much easier to be GMP compliant if the design and construction of the facilities and equipment are right from the start. It’s important to embody GMP principles and use GMP to drive every decision.

Who conducts GMP audits?

Audits must be conducted to assess whether you are following the GMP rules. External bodies such as the Food and Drug Administration (FDA) or the Therapeutic Goods Association (TGA) will conduct these audits.

Why lay out the production area?

Lay out the production area to suit the sequence of operations. The aim is to reduce the chances of cross contamination and to avoid mix-ups and errors. For example, don’t have final product passing through or near areas that contain intermediate products or raw materials.

What is packaging and labelling?

Packaging and labelling are areas where mix-ups and errors occur. To enable traceability, assign a batch or lot number to each product. Before a new batch or lot is processed, inspect packaging and labelling areas to ensure that it contains no material from a previous batch. Follow all procedures and carefully document your work.