The honing guide is useful if you want to achieve an exact angle, however there is a bit of leeway when sharpening as chisels can be sharpened anywhere between 25-35° and plane blades can be sharpened anywhere between 25-30°.

When should the honing guide be placed on the board?

This should be done as the front part of the honing guide is against the front end of the board. This needs to be done when both the guide and the iron are already against their own surfaces.

What is honing and how does it work?

Have you heard of honing? It’s a machining process used in the manufacturing industry that’s used to improve the texture of a workpiece’s surface. From automotive engines and airplane components to knives and gears, honing is used in a wide range of manufacturing applications.

How do you use an 809 honing guide?

Two plastic rollers at the back end of the 809 guide are made to roll on either a sharpening plate (glass, granite, etc.) and keep the blade at a constant angle during sharpening or honing. The knob in the center of the General 809 honing guide is used to set the blade to the desired honing angle.

How to use a honing guide on a rectangular block?

As you place a chisel or plane iron on a honing guide, with the bevel facing down, that is, towards that part where the wheel is, the tool’s cutting edge will have contact with your rectangular block, regardless of the degrees that you have selected. This should be done as the front part of the honing guide is against the front end of the board.

Is a honing guide necessary?

Honing guides are dependable. Honing guides make sharpening easy and repeatable. Some people prefer not to use honing guides and that's OK. There are no hard-fast rules in my woodshop and there shouldn't be any in yours.

How do you use a honing guide for plane blades?

4:055:25Side Clamp Honing Guide - YouTubeYouTubeStart of suggested clipEnd of suggested clipPressure on the corners. If that's what you like. To do to keep the edge straight and square simplyMorePressure on the corners. If that's what you like. To do to keep the edge straight and square simply use even pressure without rocking. This is a simple affordable basic honing guide.

How do you use a honing guide to sharpen a chisel?

0:085:39How to Sharpen A Chisel With Diamond Hones and a Honing GuideYouTubeStart of suggested clipEnd of suggested clipGetting a good edge is really about the back of the chisel flat plane on the bevel. And where theyMoreGetting a good edge is really about the back of the chisel flat plane on the bevel. And where they intersect let's get started with flattening the back.

How do you set up a honing guide?

1:203:18Honing Guide PROTRUSION STOP | 2 Minute Tuesday - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd all we're gonna do is get the plate in our honing guide like this get it snug tough in there butMoreAnd all we're gonna do is get the plate in our honing guide like this get it snug tough in there but it's still able to move forward and backwards.

What angle should a plane blade be sharpened?

25 degreesThe primary bevel for chisels and plane blades is normally 25 degrees (a time-tested angle). If you look at the blade diagram above its perfectly acceptable, from a sharpness perspective, to hone the primary bevel flat and hone the back of the blade flat and where these two meet you can achieve a sharp cutting edge.

How do you sharpen a chisel without a honing guide?

Sharpening Chisels Without Honing GuideStep 1: Sharpening Stones. You need some water or oil stones to get the chisel sharp. ... Step 2: Clear the Back. You start on the coarsest stone with the chisel's back. ... Step 3: Get It Sharp. ... Step 4: Polish. ... 20 Comments.

What is the best angle to sharpen a wood chisel?

30 degreesA new chisel has just one bevel, usually 25 degrees. But the tool should be sharpened at 30 degrees, which creates a new bevel.

What is the best stone to sharpen chisels?

Diamond stonesDiamond stones are the easiest stones to maintain. They never require flattening or any prep. Simply splash water on them to use them and dry them off when you're done sharpening. Like the water stone, diamond stones use water to remove the swarf.

What is the best way to sharpen a chisel?

Flatten the bottom of the chisel by holding it flat to your sharpening stone and working it back and forth lengthwise on coarse, then medium, then fine grits. Sharpen the bevel (below) with the chisel face down on its bevel. Draw it back and forth on the coarse/medium/fine stones without tipping it.

What is honing oil made of?

Composition. The two most common classes of honing oil are petroleum based (typically mineral oils), and non-petroleum (typically water or vegetable oil) based. Common additives include chlorine, sulfur, rust inhibitors, and detergents. Honing oil has just the right consistency for sharpening stones.

How do you make a honing jig?

0:034:42How to make a Sharpening Jig - YouTubeYouTubeStart of suggested clipEnd of suggested clipYou can see how simple the designers is 3d sketch a file it's made up of four small plywood pieces aMoreYou can see how simple the designers is 3d sketch a file it's made up of four small plywood pieces a few screws and two bearings I've decided with my widest plane blades and mine 58 millimeters.

Veritas Side-Clamping Honing Guide

This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have loaded, select the print option again.

Veritas Short-Blade Honing Guide

This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have loaded, select the print option again.

Veritas Mk.II Standard Honing Guide

This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have loaded, select the print option again.

Veritas Mk.II Deluxe Honing Guide Set

This image has not been loaded. To print the images, close the print view and scroll to the bottom of the article. Once all of the images have loaded, select the print option again.

What Is Honing?

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish.

Why We Need Honing Process?

Honing machines are metal abrading tools and the honing process utilizing hard tooling or honing stones and perishable abrasives stones for the correction of

Process mechanics

Since honing stones look similar to grinding wheels, it is tempting to think of honing as a form of low-stock removal grinding. Instead, it is better to think of it as a self-truing grinding process.

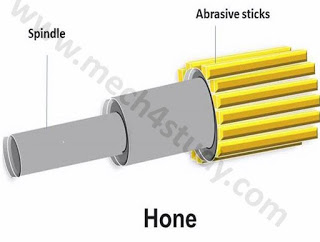

Honing tools

Honing uses a special tool, called a honing stone or a hone, to achieve a precision surface. The hone is composed of abrasive grains that are bound together with an adhesive. Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1500 mesh grit).

Limitations Of Honing Process

Honing is thought of as a slow process. However, new machines and stones have shortened hone times considerably.

What is the 809 honing guide?

Two plastic rollers at the back end of the 809 guide are made to roll on either a sharpening plate (glass, granite, etc.) and keep the blade at a constant angle during sharpening or honing. The knob in the center of the General 809 honing guide is used to set the blade to the desired honing angle.

How long is a pinnacle guide?

The standard Pinnacle guide comes with 14″-long rails, enough to accommodate stones or honing plates up to 3″ wide and 11-1⁄2″ long; optional 20″-long rails let you use longer stones and honing plates. Small thumbscrews on the side of the carriage let you set both primary and secondary honing angles.

Can you use #SS1 with wide bench stones?

CONS: Can’t use the #SS1 with wide bench stones and, unless the stone/plate is narrow, you can’t use the full surface of the stone (Alisam also makes the wider #SS3). If subsequent stones vary in thickness, you need to readjust the projection of the blade each time.

Is a jig good for honing?

PROS: Because of the jig’s low center of gravity, it’s especially good for honing short blades as well as thick tools, like mortise chisels. CONS: When honing wide plane blades (2-1⁄2″ or so), the guide’s wheels end up so far apart that the guide only works on honing plates or very wide bench stones.

Why use a honing guide board?

This only means that the use of a honing guide board will help you accomplish things faster.

What is the ruler trick on iron?

For this, you can use the famous “ruler trick” wherein you can easily use an extremely thin metal ruler that is laid on one edge of the 8000 grit stone.

Is it easier to flatten honing stones?

As such, it becomes quicker and easier for you to flatten the stones out compared to working on removing all of the needed steel just to give the tool its flat shape.

Do woodworkers need sharpening tools?

At any point in your career as a woodworker, there will come a time wherein you need to sharpen your tools, such as planes and chisels. Tools that are dull will not accomplish much, and they can also pose risks to your safety. One way to deal with this is to use a honing guide board. Individuals who promote the use of a honing guide board are those ...

What Is Honing?

- Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinders...

Why We Need Honing Process?

- Honing machines are metal abrading tools and the honing process utilizing hard tooling or honing stones and perishable abrasives stones for the correction of 1. Diameter 2. Shape 3. Surface finish 4. Positional tolerances of bores The honing process was developed to allow for the perfection of bore geometry, size control, final surface finish, and surface structuring. Honing pr…

Process Mechanics

- Since honing stones look similar to grinding wheels, it is tempting to think of honing as a form of low-stock removal grinding. Instead, it is better to think of it as a self-truing grinding process. In grinding, the wheel follows a simple path. For example, in plunge grinding a shaft,the wheel moves in towards the axis of the part, grinds it, and then moves back out. Since each slice of the wheel …

Honing Tools

- Honing uses a special tool, called a honing stone or a hone, to achieve a precision surface. The hone is composed of abrasive grains that are bound together with an adhesive. Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1500 mesh grit). Smaller grain sizes produce a smoother surface on the workpiece. The purpose of the honing to…

Advantages of Honing Process

- Less complex or low-cost fixtures.

- It is highly accurate.

- It can be used for both long and short bores.

- It maintains the original bore centerline.

Limitations of Honing Process

- Honing is thought of as a slow process. However, new machines and stones have shortened hone times considerably.

- Horizontal honing may create oval holes unless the work is rotated or supported. If the workpiece is thin, even hand pressure may cause a slightly oval hole.

Application of Honing Process

- Finishing automobile crankshafts journals

- Finishing round holes

- Finishing hollow cylindrical parts

- Finishing Engine cylinder, bearings, gun barrels, ring gauges, shafts and flange faces, piston pin, automobile crankshaft journals etc.