A manual impact driver is a tool that delivers a strong, sudden rotational force and forward thrust when struck on the back with a hammer. Manual impact drivers consist of a heavy outer sleeve that surrounds an inner core that is splined to it.

How to use a manual impact driver?

- Select the appropriate driver bit.

- Insert the bit into the quick-release chuck.

- Place the direction of rotation selector in the correct position for operation.

- Hold the impact driver with one hand.

- Place the bit on the screw head and slowly depress the switch trigger.

- Start the bit slowly for more control.

- As the screw is driven, impacting will begin.

How to use an impact driver?

Part 3 Part 3 of 3: Using an Impact Driver

- Understand and attend to any relevant safety concerns. Depending on the environment and situation a user finds themselves in, all safety concerns should be understood and noted to avoid ...

- Insert the appropriate bit. Determine the proper bit for the task required and insert it into the QCC.

- Fasten grip onto the handle. ...

How to use a hand impact driver?

Proto® 3/8" Drive 13 Piece Hand Impact Driver Set

- Designed to loosen hard to turn bolts and nuts.

- Hand impact driver has heavy-duty spring for added torque.

- Popular interchangeable bits are packaged in plastic blow-molded case for easy storage.

When to use an impact driver vs. drill?

- Easy on wrist and arm because torque is applied by the tool

- Reduces chance of stripped screws

- Smaller than most drills

- High power ratio when compared to its size

How do you use a manual impact driver?

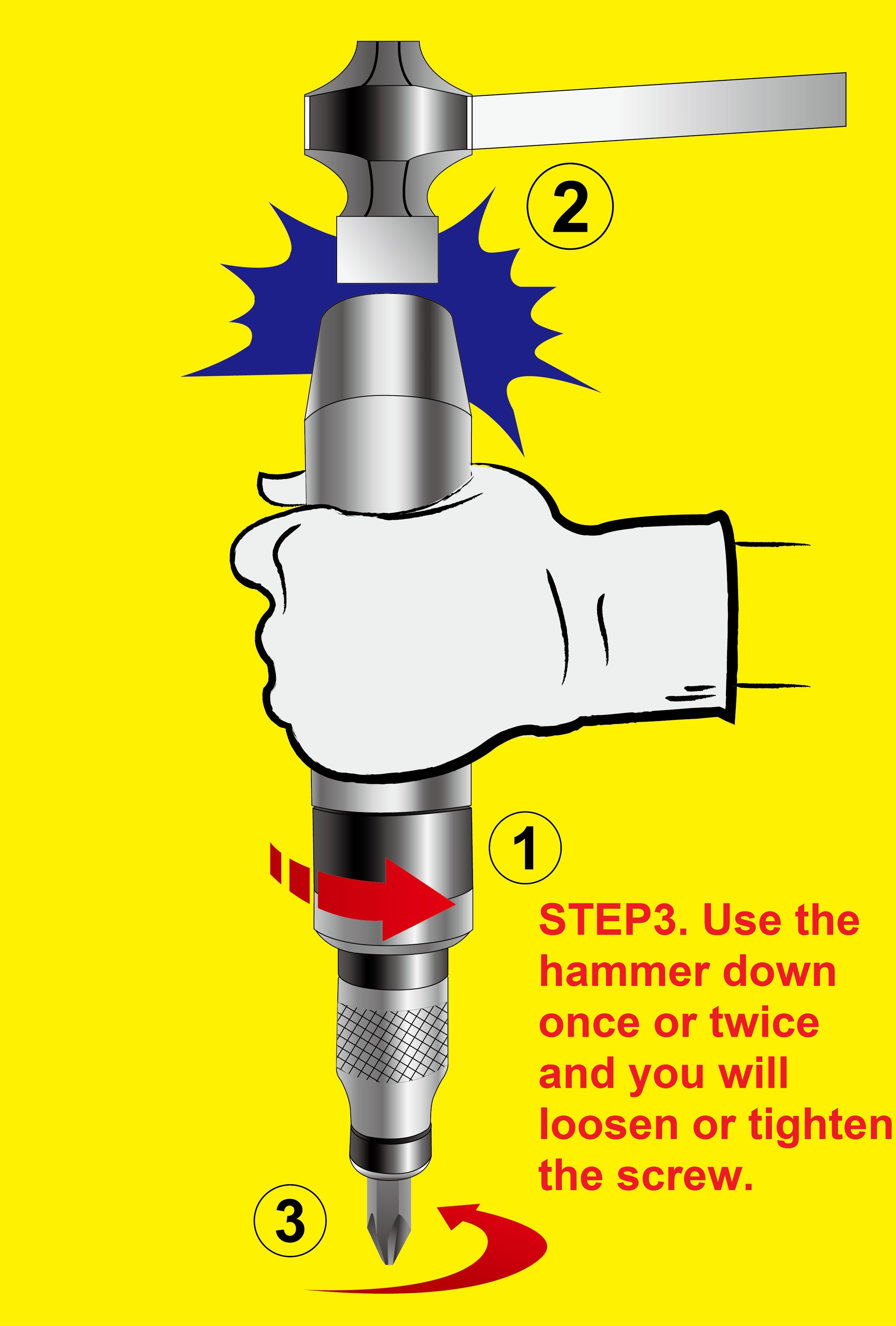

How to Use a Hand Impact DriverInstall the bit adapter and bit or the appropriate socket on the tool.Grasp the tool firmly in your left hand (if you're right-handed).Strike the top of the impact driver with a hammer. Wear heavy gloves to minimize injury if you accidentally hit your hand with the hammer.

What is the only purpose for an impact driver?

Like the cordless drill, an impact driver uses rotational force to drive a screw and saves its bursts of quick power when it feels resistance. You would use an impact driver for long screws or large fasteners when working with wood. An impact driver is also lighter than the hammer drill, making it easier to handle.

Is an impact driver the same as a driver?

The main difference between a drill and an impact driver boils down to power and rotational action. Unlike drills, impact drivers are made with quick release shanks that accept all one-quarter-inch hex driver bits. Impact drivers produce lots of rotational force, capable of driving the largest wood screws in seconds.

When should you not use an impact driver?

When Not to Use an Impact Driver? 5 SituationsNon-Hex Shank Bits. Impact drivers are very useful tools indeed, but something that does need to be said about them is that the special mechanism they use for their bits only accepts hex-shaped bits. ... Short Screws. ... Soft Materials. ... Precision Work. ... Drilling Holes.

Can I use an impact driver as a drill?

Impact drivers are not designed to drill holes and they can't take all of the accessories that a cordless drill can. However, if you need to drive a lot of screws – especially screws that are either thick or long – a cordless impact driver is going to outperform a cordless drill every time.

Can I use an impact driver to remove lug nuts?

Can an Impact Driver Remove Lug Nuts? Yes, technically. You would need to use a hex shaft to square drive adapter in order to attach a lug nut socket to the tool. However, an impact driver may not have enough torque to break loose a lug nut that's rusted/frozen or over tightened.

Do impact drivers have a clutch?

An impact driver doesn't have a clutch or multi-speed operation. Most drills feature a tool head that either requires loosening with a chuck or your hands. An impact driver features a collet that only fits hex-shaped tool bits.

Is an impact driver better than a drill?

The impact driver is much stronger than a drill in terms of the way it can deliver that extra torque to break loose stuck bolts and screws or drive them deeper into the material.

Can I use impact bits in a regular drill?

Is it safe? Given that regular drill bits output lower levels of torque than impact drivers, it's pretty safe to use impact-driver bits with regular drills. In fact, these bits are engineered to deal with higher levels of stress which makes them even safer to be used with a regular drill.

Can I use an impact driver as a screwdriver?

Can Impact Drivers Be Used as Screwdrivers? Good news! The primary purpose of an impact driver is to drive screws. While an adapter (such as this one by Makita) can be used to in order for impact drivers to be used as drills, impact drivers are generally designed to drive screws.

Do impact drivers damage screws?

Impact drivers do not have torque control but they are extremely powerful. As a result, when using an impact driver for delicate applications involving smaller screws and softer materials, it's easy to damage the screw or work surface.

Do impact drivers work in reverse?

In a word: Yes. Looking at our Pro brands, most standard impact drivers show an 8%–25% difference compared to the oil impulse's 3.4%. The takeaway? Standard impact drivers actually do seem to hit harder in reverse than in forward.

Why is an impact driver better than a drill?

The impact driver is much stronger than a drill in terms of the way it can deliver that extra torque to break loose stuck bolts and screws or drive them deeper into the material.

What is an impact driver vs hammer drill?

A hammer drill exerts greater force directly into the bit as it hits the material being drilled, while an impact driver increases the force being delivered perpendicular to the bit. If you're using a hammer drill, picture someone slamming the back of the drill harder into surface being drilled.

Can you drill into concrete with an impact driver?

3:386:12Hammer Drill VS Impact Driver | What's The Difference? - YouTubeYouTubeStart of suggested clipEnd of suggested clipBut here's the thing we would never actually use the hammer drill mode to fasten in wood if we didn'MoreBut here's the thing we would never actually use the hammer drill mode to fasten in wood if we didn't want to use that we just throw it into the drill driver mode. And that's the way to go so now

Why use impact driver?

Because they automatically add extra rotational force when they encounter resistance—two to three times more torque than a drill —you’ll find using an impact driver is easier on your hand and wrist. So, if your project involves a lot ...

What is the difference between a hammer drill and an impact driver?

There are a few differences between impact drivers and hammer drills. The main difference between a hammer drill and an impact driver is the type of force used. Hammer drills use a hammering action to exert extra force when needed, as though a hammer was hitting the back of the drill.

What is the purpose of a hammer drill?

You can use hammer drills to drive bolts into concrete, brick, masonry, or heavy metal. Like the cordless drill, an impact driver uses rotational force to drive a screw and saves its bursts of quick power when it feels resistance. You would use an impact driver for long screws or large fasteners when working with wood.

Why are drills so versatile?

Drills are versatile. Some have more settings for both speed and torque, and some even have an impact setting. They also can tackle many kinds of small projects because they can use a wide variety of bit types. Experts agree that when building your tool collection, begin with a drill.

Can impact drivers be used to drill holes?

Impact drivers are for driving fasteners, not drilling holes. However, in a pinch, if you have the proper bit, you can drill a hole in light-gauge steel or softwood with a standard hex-shank drill bit.

Do impact drivers run on cordless batteries?

Impact drivers run on cordless battery packs. The higher the voltage, the longer the battery life and the more power your driver will have. Finally, consider the weight of the driver. If you plan to use it to install fasteners overhead, you’ll want something that won’t fatigue your arm or wrist. Advertisement.

There Are so Many Tools: What Is an Impact Driver?

The wise handyman has a variety of powerful tools for driving fasteners such as bolts and wood screws into diverse materials. If you think you need something more than a typical screwdriver, seek tools that seem similar but have different names, such as a hammer drill, cordless drill, or impact driver (drill driver).

How Do Impact Drivers Work?

Do you want to know how to use an impact driver? Although the power generated by an impact driver may appear to be a tiny miracle, these useful gadgets are based on quite simple principles. Internally, it’s very similar to a drill in that it has a motor that initiates rotational force.

What Are the Differences Between Impact Drivers and Hammer Drills?

The type of force employed by hammer drills and impact drivers is the fundamental distinction. When extra force is required, hammer drills utilize a hammering action, as if a hammer were hitting the drill’s end.

What Can an Impact Driver Not do?

An impact driver, unlike a compact drill, has no selectable settings or speed settings and is all or nothing. As a result, if precision is required, this is not the instrument to use. Limit the usage of impact drivers to DIY projects where the size or location of the holes is less important than the amount of torque required to complete the task.

What Makes Impact Drivers Versatile?

Impact drivers can be utilized for various fastening applications due to the impact action and rotating force they offer. However, it is the quick-change drive connected to the head that may offer it the most versatility.

Should You Start with a Drill or an Impact Driver?

Start with a drill, then upgrade to an impact driver when the right project presents itself.

What Are the Types of Impact Drivers?

When the industry is dominated by cordless impact drivers, it is easy to fall into the trap of thinking that all impact drivers are exactly the same. Although it is understandable that customers prefer battery-powered impact drivers since they’re more convenient, they are not your only choice.

10 Best Impact Driver Review

The manual impact driver niche is another workshop tool category with a variety of tools from different manufacturers.

Frequently Asked Questions

A manual impact driver is a tool that consists of an internal spring mechanism encased in a heavy metallic outer sleeve.

Final Verdict

Like most workshop tools, there is a slew of manual impact drivers available from different manufacturers, with each of them claiming to deliver the best results.

Why do impact drivers use motors?

Impact drivers use motors that supply more significant levels of torque than a drill and they use an impact action that helps to drive fasteners through more rigid materials when under load. If that sounds familiar, it’s because that impact action is similar to the function of an impact wrench and a hammer drill.

What is pneumatic impact screwdriver?

Pneumatic. Officially known as a “pneumatic impact screwdriver,” this type of impact driver is far less common in today’s electricity-driven world. These models offer all the typical benefits of an impact driver, only it relies on air pressure rather than electricity.

What is an impact wrench?

The most significant factor is that an impact wrench is a dedicated tool that features a permanently mounted ¼-inch, 3/8-inch, or 1/2-inch socket drive. And because impact wrenches are explicitly intended for dealing with stubborn nuts and bolts, they’re generally far more powerful than impact drivers.

Why is impact important?

The impact function is crucial for driving fasteners through hard materials, but that’s not the only time it comes in handy. Say you’re driving fasters in a tight spot that you can’t get a drill in, nor can you apply much pressure because you’re at an awkward angle.

What happens when the hammer is under load?

The magic happens once the fastener provides enough opposition. The hammer can cam away from the anvil and depress the spring when the system is under load.

Do impact drivers work with drills?

A: Yes. Impact drivers are intended to take the place of a drill when driving long fasteners or dealing with harder materials. The quick-change collet allows the user to attach many different bits specifically intended for such a purpose. The thing to remember is that impact drivers are more powerful than drills.

Can you use an impact wrench with an impact driver?

But don’t expect it to perform as well as an impact wrench that’s intended for this line of work. Your working experience with an impact driver in this setting depends on the model you choose.

Why use impact driver?

When used properly, it helps you stop your drill from damaging screws and the surface you are drilling into. Since they do not have torque control, you will have to be extra careful when using an impact driver; otherwise, you will have a lot of stripped screws and damaged surfaces on your hands.

How do impact drivers work?

Impact drivers essentially work by combining the rotational motion with a hammering action to generate high torque. If you have no idea what that means, picture it this way. Imagine while you are turning a screw, you started tapping it with a hammer in the direction of rotation. The screw would go in faster.

How much torque does an impact driver give?

An impact driver gives a blow to the screw around 50 times a second, which produces upwards of 5 times more torque than your average cordless drill.

What is the difference between impact drill and drill driver?

The major difference, when compared to a standard drill/driver, is that it has a special impact driving mechanism that kicks-in, when the force exerted by the motor is not enough. Another key difference is that the impact drivers have hexagonal-shaped collets instead of a traditional 3 jaw chuck. You can also use the impact drill/driver ...

What is the drive source of an impact driver?

The drive source of the electric impact driver is the electric motor. If you can afford it, get an impact driver with a brushless motor. They are more energy-efficient, do not heat-up like regular motors and draw less battery power.

Why do people buy impact drivers?

One of the reasons people buy an impact driver is that it is easy on your wrists. You will likely be holding an impact driver for long periods of time, so make sure it is comfortable to use.

Is an impact driver better than a cordless drill?

Higher Torque: As discussed before, impact drivers are much more powerful (about 5 times as powerful) when compared to cordless drill/driver. So, when you need drive screws in tough material, you will be able to do them faster and better with an impact driver.

What is Impact Driver?

An impact driver is a type of power tool which uses a spinning bit to drive screws or drill holes. These tools are powered by electric motors, and hence, the name “impact driver”. They are also called “sledgehammers” due to their high-pitched sounds.

Common uses of an impact driver

An impact driver is a versatile tool that is used for many different purposes. It’s commonly used in construction to drive fasteners into wooden beams, metal plates, and various other types of materials. In power tools, it is used to drive sockets into the wood, and various other types of materials.

The wide list of impact drivers uses

The impact driver is used to drive a variety of fasteners, including screws, nails, and sometimes, rivets. This tool is a great alternative to using a regular hammer to drive those types of fasteners because it has a very quick trigger action and delivers an extremely powerful blow.

Final Words

Impact drivers are designed to give you added leverage when driving screws or similar fasteners. They’re very useful when you need to quickly install things like anchors, bolts, screws, and sheet metal. Impact drivers are great for driving screws, nails, or similar types of fasteners into wooden, metal, or other surfaces.

10 Best Impact Driver Review

Manual Impact Driver Buyer’s Guide

- What to Look for When Buying the Best Manual Impact Driver

We’ve taken the time to identify a few factors that will help you decide which impact tool to buy.

Frequently Asked Questions

- How Does a Manual Impact Driver Work?

A manual impact driver is a tool that consists of an internal spring mechanism encased in a heavy metallic outer sleeve. The outer sleeve is made of a tough metal to ensure it withstands the impact from the hammer blows. The Manual impact driver works by converting the impact from … - How to Use a Manual Impact driver

Before you get started with your impact driver, the first thing to do is to prepare your work tools and the work surfaces. Consider cleaning the screw surface if it has dust or dirt in it to ensure proper contact. Another essential step is to prepare the right driver bits suitable for the desired j…

Final Verdict

- Like most workshop tools, there is a slew of manual impact drivers available from different manufacturers, with each of them claiming to deliver the best results. Our team of experts went through the task of testing the various manual impact drivers to save you the stress of going from one disappointing tool to another. After rigorous testing, we concluded that the Lisle 29200 man…