Types

- Blind rivets. Blind rivets, commonly referred to as "pop" rivets (POP is the brand name of the original manufacturer, now owned by Stanley Engineered Fastening, a division of Stanley Black ...

- Oscar rivets. ...

- Drive rivet. ...

- Flush rivet. ...

What are the main uses for Pop Rivets?

Types

- Blind rivets. Blind rivets, commonly referred to as "pop" rivets (POP is the brand name of the original manufacturer, now owned by Stanley Engineered Fastening, a division of Stanley Black ...

- Oscar rivets. ...

- Drive rivet. ...

- Flush rivet. ...

How do you use a pop rivet gun?

The main parts that make up a rivet are as follows:

- Mandrel head

- Mandrel

- Rivet pin

- Rivet head

How to remove pop rivets without surface damage?

- Quantity Per Pack

- Corrosion Resistance

- Packaging Type

- Packaging Type

- Quantity Per Pack

- Quantity Per Pack. ADS Closed End Rivets, Size: M2.5~M4.8 Size: M2.5~M4.8

- Quantity Per Pack. Aluminum Blind Rivets, Size: 3.2 mm to 6.4mm

- Quantity Per Pack. Size: 3.2 MM TO 6.4MM

- Usage/Application

- Quantity Per Pack

Can you use pop rivets on wood?

There are no specialised pop rivets for wood but you can use a standard or blind pop rivet for riveting into the wood. I recommend that you choose an Aluminium ‘Pop rivet’ for riveting wood. The reason for this is that hard rivets can split the wood if near the edge. But if you are riveting near the middle of hardwood a hard Monel rivet is fine. Aluminium pop rivets are easier to use because they are softer.

What is a pop rivet and how does it work?

A POP Rivet is a blind fastener which can be inserted and set from one side of the work piece. Depending on the application, they can be used as replacements for welds, adhesives, screws, nuts and bolts. A typical POP Rivet is made up of two key parts; the rivet body and the setting mandrel.

Why is it called a pop rivet?

Together, the two companies created a rivet design with a mandrel head that would pop off after the rivet was set. The new fastener was called a pop rivet, after the popping sound heard when the rivet tool broke off the mandrel head inside the shank.

Is a pop rivet stronger than a screw?

For typical workshop applications, where pop rivets are usually used, threaded fasteners will provide superior strength. Pop rivets use a hollow shaft, reducing their ability to resist shear loads. The strength of the materials used also depends on the power of riveting tools available.

Is a pop rivet permanent?

Pop riveting will permanently fix two pieces of thin material together. It can be used for thin materials like aluminium, acrylic or high impact polystyrene.

What is the difference between a rivet and a pop rivet?

Pop rivets are used in a blind setting like blind rivets, but the material application is a little different. It can be used with plastic, metal, and wood while offering a longer-lasting setting than traditional blind rivets.

What is the purpose of rivet?

A rivet is a mechanical fastener with a plane unthreaded shaft that's inserted through holes to join two or more parts together. A permanently formed head at each end prevents the rivet from removal from the hole. The shaft prevents any radial movements of the components.

Why are rivets no longer used?

Indeed, the latest steel construction specifications published by AISC (the 14th Edition) no longer covers their installation. The reason for the change is primarily due to the expense of skilled workers required to install high strength structural steel rivets.

Can I use a screw instead of a rivet?

The need to replace rivets with screws may arise from a mechanical failure of the rivets or from a need for access behind some riveted sheet metal. It is your choice whether you utilize a simple sheet-metal screw or a short machine screw with a nut to hold the screw in place.

How much weight can pop rivets hold?

McMaster rates pop rivets in tensile strength as well as shear strength. A 3/16" aluminum blind pop rivet has a shear strength of 310lbs and a tensile strength of 500lbs.

Are rivets stronger than Weld?

Last, but not least, generally, riveting is not as strong as welding. If you need the two parts to be capable of withstanding forces that draw the pieces apart, riveted joints will be more likely to fail compared to a properly welded joint.

How do you install a pop rivet?

1:262:38How to Install a Pop Rivet - YouTubeYouTubeStart of suggested clipEnd of suggested clipTogether all the way and then release be sure to pull the handles as far apart as possible afterMoreTogether all the way and then release be sure to pull the handles as far apart as possible after each stroke. Continue this procedure until the pop rivet breaks.

How do you remove a pop rivet without a drill?

Removing Pop Rivets With a ChiselPosition the edge of your chisel (or screwdriver) against the edge of the rivet at a shallow angle. ... Strike the butt of the chisel sharply with a hammer.Repeat, until the head of the rivet shears away. ... Shake or tap the work surface to make the mandrel fall out.

What are the parts of a pop rivet?

Generally, the pop rivet is mainly dividing into two parts named rivet body and mandrel. The rivet body is also called the hat, and the mandrel is also called a stem.

How to install a pop rivet & pop rivet gun?

As per the application, select the suitable size of the blind rivet. It is possible by measuring the diameter of the rivet.

What is a standard blind rivet?

Standard Blind Rivet is a common type of blind rivet which are using to fasten two workpieces.

How to use a 3/16 drill bit?

In this example, drill size is 3/16 inch, and place that 3/16-inch drill bit. Place the workpiece together very tightly and drill the whole throughout the workpiece to join together. Insert the pop rivet in the adapter fully and insert the pop rivet in the drilled hole. Squeeze the handle of the pop rivet gun tightly and release with force. Be sure to pull the handles as far apart as possible after each stroke.

How to tighten a blind rivet gun?

It can be done by unthreading & removing the adapter currently in use and install a new adapter in the tip of the blind rivet gun. It is by tightening the adapter against spring tension. They will take a fair amount of force to tighten. Do not crosshead the adapter while tightening. Place the removed adapter in the handle for safe storage.

Why does Mandrel's head expand the rivet pin?

Mandrel’s head expands the rivet pin because of extra force given by the rivet body causes two workpieces to fasten and joined together.

What is rivet pin?

The rivet pin is the prime part of the rivet. It will be stuck in a hole of the workpiece where we have to fasten the workpiece.

What is a POP Rivet?

Pop rivets, also known as blind rivets, are a type of rivets. They are used in applications where there is limited or no access to the rear side (blindside) of the parts to be joined.

How do pop rivets work?

Pop rivets consist of two parts. A pop rivet gun is placed on the rivet, pulling the mandrel into the rivet body, causing it to expand and grip the parts to be joined. Once gripped, the mandrel snaps, permanently holding the rivet in place.

What are the different types of blind rivets?

A blind rivet, sometimes called a pop rivet, has a hollow cylindrical pin (body) that is attached to the head. A mandrel, a long, narrow pin with a head, goes through the recess of the body, with the head serving as a stop at the opposite end of the body to the rivet head.

What is a multi grip rivet?

Multi-grip rivets are similar to standard rivets but have indents located on the rivet body. The indents expand and provide multiple grips when the mandrel is pulled through the body. These rivets are for fastening metal to plastic and plastic to plastic.

How does a grooved rivet work?

The tail of a grooved rivet will expand inside the material as the mandrel is withdrawn, rather than forming a new head on the other side of the material. The rivet grips the material with friction and not with a second head, while the head at the other end grips the object that is connected to the material.

How does a rivet gun work?

A rivet gun is placed on the rivet and pulls the mandrel into the rivet body, causing it to expand and hold the parts to be joined. Once gripped, the mandrel snaps and holds the rivet permanently in place. This results in a localized connection.

What is a grooved rivet?

Grooved rivets are perfect for securing metal to wood and metal to building materials such as cement, brick, and wood.

How to install a pop rivet?

The first step of pop rivet installation begins with drilling a hole through the parts to be joined. Insert the rivet through the drilled hole, and bring the body into contact with the material to be joined. Place a pop rivet gun on it, and pull the mandrel into the rivet body. This causes expansion and gripping of the parts. Once engaged, the mandrel snaps, permanently holding the rivet in place. The result? A firm and permanent connection.

How to remove a rivet?

Removing a rivet may appear to be a complicated process, but it’s simple with proper equipment. Use a drill bit to push tiny rivets through the surface. If drilling can’t penetrate a difficult rivet, grind off the head and bore through it. Sans a drill, remove the rivet’s head and drive it through the surface using a hammer and chisel.

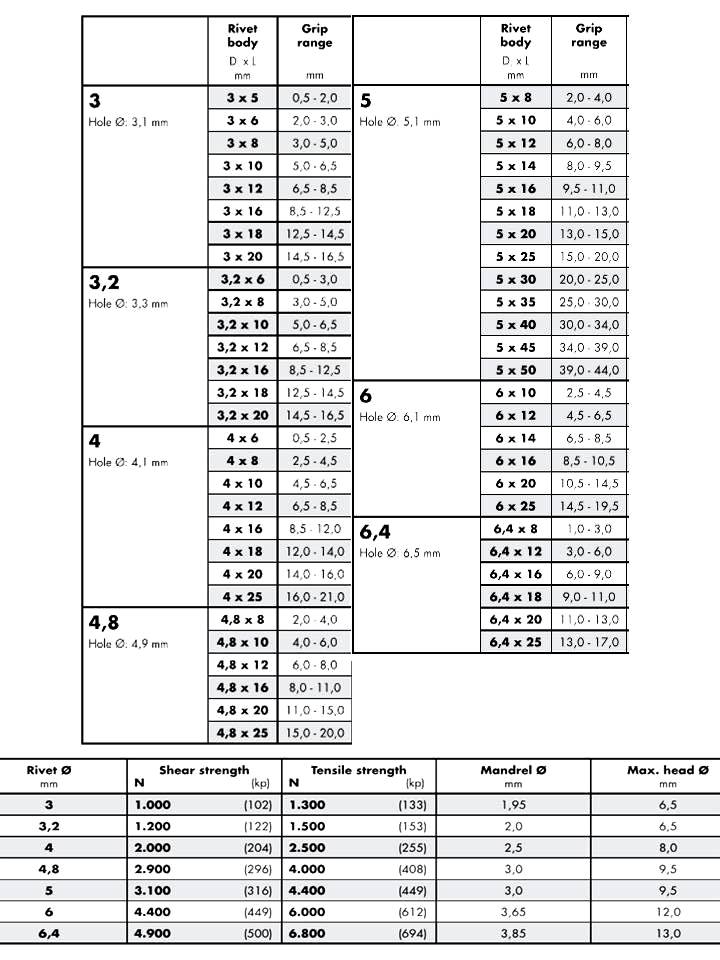

How to determine the right rivet size?

Selecting the right rivet begins with determining the rivet’s grip range. Grip size range is the width of material to be affixed together. select the correct length for your rivet. A rivet’s length measures from the underside of the head to the stem’s tip.

How much should the length of a rivet be?

The rivet’s length should be equal to the thickness of both the fastened items + 1.5 times the diameter of the stem of the fastener.

What is a blind rivet?

Blind rivets, often called pop rivets, are a type of rivets. They’re utilized when limited or no access to the backside (blindside) of the parts exists. Depending on the application, they can replace welds, adhesives, screws, nuts, and bolts.

Where to place drill bit on rivet?

Place the drill bit against the divot in the center of the rivet.

What is the phone number for pop rivets?

Have more questions? Request a consultation or call the POP tools experts at (972) 986-6792 if you need support for POP rivet tools.

Where is the rivet body inserted?

The rivet body is inserted into the hole of the materials you are joining.

How does a pop tool work?

The POP tool pulls the mandrel through the body of the rivet and sets the rivet. This forms a strong, tight, reliable joint. The mandrel then breaks flush with the head falls away.

Where was the pop rivet invented?

The pop rivet was invented in Scotland shortly before World War I. In the United States, inventors such as Carl Cherry and Lou Huck experimented with other techniques for expanding solid rivets, such as the pull-through method.

Who owns Pop rivets?

POP is actually the name of the original brand that invented and marketed these types of rivets. The company was acquired by Stanley tools in 2013.

How to put rivets in a gun?

Insert your rivet into your pre-drilled hole. Firmly press your rivet into the pre-drilled hole, with the nub completely clearing the hole. Pull on the gun's trigger to pull the mandrel through. This will lock your rivet in place. The mandrel can be thrown away after you're done.

What is blind rivet?

Blind rivets have a few main features: A tubular rivet. A mandrel, or center wire with a nub at the end. The process for riveting is based on a pulling motion, and the fact that the rivet is made from a soft metal.

How to measure rivet length?

The length of your rivet should be at least 1.5 times the thickness of both of your work pieces together. So if you are riveting together two pieces of aluminum which are each 3mm, you should add them together and multiply by 1.5 to give you 9mm for your rivet length.

What were blind rivets before?

Before blind rivets were invented, you had to have access to both sides of your work piece. For complex machinery, this could be a huge hassle as it would often mean that whatever you wanted to repair had to be disassembled. Blind rivets have a few main features: A tubular rivet.

What do you need to start riveting?

What you'll probably need if you want to start riveting: A good POP Riveting Gun. A set of rivets to fit your gun, preferably in assorted lengths as you'll need those depending on what your working on. Ask Question.

What is a pop rivet tool?

Lightweight manual pop rivet tools are ideal for simple tasks such as joining metal sheets or thin materials. If you need to repair a metal panel or connect two pieces of acrylic, for example, a manual pop rivet tool can probably handle the job. Most manual tools have a squeeze handle that sets the pop rivet, and for tougher jobs, you can use a manual tool with a longer lever handle to apply more force.

Who invented pop rivets?

Pop rivets have been around for almost a century and were originally developed by the George Tucker Eyelet Company in England, which made hooks and eyes for boots. In 1934, the company, which would decades later become part of STANLEY Engineered Fastening, was approached to develop a new type of fastener for aircraft manufacturing. The result was the POP® rivet, which was revolutionary because it could be set from one side—or the “blind side”—of a workpiece to connect two pieces.

Why are pneumatic rivets used?

Pneumatic rivet tools are ideal for big jobs with repetitive rivet installation because they are fast, powerful, and consistent in their installation.

What is pneumatic riveting?

Some jobs, such as aircraft manufacturing, require more rivets than you would want to install by hand. Pneumatic rivet tools are ideal for big jobs with repetitive rivet installation because they are fast, powerful, and consistent in their installation. Pneumatic rivet tools are extremely fast and reliable, but they do require a compressor and hose to provide power, which is why they aren’t as popular for use on job sites or in remote locations. Some of the most well-known makers of pneumatic rivet tools include Atlas, FAR, Gesipa, Lobster, and STANLEY.

Why are pop rivets so popular?

Overall, pop rivets are popular and reliable because they install quickly and easily, producing strong and reliable fastenings. When installed correctly, pop rivets and the installation tool won’t mar the surface of the material being joined, which means a more professional finish, too.

When did pop rivets start?

Believe it or not, “pop rivet” is typically just another name for a blind rivet. It all started in 1934 , when George Tucker Eyelet Company was approached by an aircraft manufacturer that needed help developing a fastener that could be set from just one side of the material.

What is a Blind Rivet?

A revolutionary fastener, the blind rivet is so named because it can be installed when you don’t have access to—or can’t see—the back side of the item being riveted. Prior to the invention of the blind rivet, the use of solid rivets and bolts meant that you needed access to both sides of a project in order to use a rivet hammer on one side and a bucking bar on the other. This complicated process made countless projects with a “blind” side impossible to complete.

How do blind rivets work?

Comprised of a rivet and an integrated mandrel, blind rivets are installed in a tight hole that passes through whatever material you’re riveting. A riveter is then used to pull the mandrel back while holding the rivet in place. As the mandrel is pulled back, it deforms the rivet by pushing the sides outward until the mandrel snaps.

What kind of material are blind rivets made of?

These fasteners typically come in steel, stainless steel, nickel-copper alloy, and other grades of aluminum. When looking for blind rivets, we recommend always trying to match the rivet and mandrel materials to avoid corrosion and weakening in the rivet (e.g., stainless steel/stainless steel construction).

What is a multigrip rivet?

Multi-grip: These rivets are designed for when you don’t know how long the rivet needs to be. They’re more expensive than standard ones, but can be useful in situations where excess rivet length hanging off the back could interfere with moving parts.

Can you use pop rivets on plastic?

Pop rivets can fasten wood, metals, and even plastic in a blind setting on a range of projects. At home, for example, gutter construction often uses nails, which aren’t always an effective fastener because of the weight of water and other materials that can get stuck in the gutter. Pop rivets offer a better, longer-lasting alternative by attaching metal sheets together effectively.

An Overview of Rivets

In a nutshell, a rivet is a mechanical fastener or connector with a head and tail at opposite sides. It has a head, a smooth cylindrical body, and a tail that looks more like a metallic pin.

Materials Used for Rivets

There are several metal materials for manufacturing rivets. They include steel, copper, brass, aluminum, copper, and stainless steel. Designers and manufacturers choose these different materials to satisfy their needs.

Different Types of Rivets Available for Manufacturing

There are several different types of rivets available. However, they are broadly divided into the following categories.

What are Rivets Used For?

Rivet’s primary purpose is to ensure a firm and reliable tightening of two or more metallic or wooden materials. When you do this, you have a joint stronger than that of a screw with the same diameter.

Conclusion

Rivets are a better substitute for screws, bolts, and nuts. They prove more efficient and reliable than all other connectors. Today, different types of rivets have various purposes. This is a result of the dynamic nature of machines and structures. However, you have to choose suitable metal rivets for your applications to get the best results.