What are the different types of lintels?

The main types of lintels are: Brick lintel, timber lintel, steel lintel and concrete lintel.

What's a concrete lintel?

Modern day lintels are made using prestressed concrete and are also referred to as beams in beam and block slabs or ribs in rib and block slabs. These prestressed concrete lintels and blocks are components that are packed together and propped to form a suspended floor concrete slab.

What is precast concrete in simple words?

Precast concrete is a construction product produced by casting concrete in a reusable mold or "form" which is then cured in a controlled environment, transported to the construction site and maneuvered into place; examples include precast beams, and wall panels for tilt up construction.

What is a cast lintel?

Cast-in-situ lintels can be constructed to span around the entire length of walls in the building, and are often referred to chained lintels. On the other hand, they can be constructed to span across the opening concerned without extending far beyond the opening.

What is the purpose of lintel?

A lintel is one type of beam which used to support the above wall when openings like doors, windows etc. are necessary to provide a building structure. The main function of the lintel is to take loads coming from above wall and transfer its load to the side walls.

Are concrete lintels load-bearing?

The lintel is designed to carry the full load of wet masonry as soon as it is installed but must have a minimum end bearing of 150mm each side of the opening and be bedded on mortar with all perpendicular joints filled with mortar.

What are the disadvantages of precast concrete?

Disadvantages of Precast ConcreteHigh Initial Investment: For installing a precast concrete plant, heavy and sophisticated machines are necessary which requires a high initial investment. ... Transportation Issue: The construction site can be at a distant location from the precast concrete plant.More items...

What are the advantages of precast concrete?

Benefits of Precast ConcreteSaving time. Because the parts being used come already created, no time is wasted forming, framing, pouring, or curing. ... Uniformity. ... High-Quality Products. ... Saving Money. ... Transportation. ... Installation. ... Modification.

Is precast concrete stronger?

Precast concrete is often stronger than cast-in-place concrete. Not only are precast concrete products already reinforced with steel rebar, but the controlled curing process also ensures that the concrete will set correctly under ideal conditions for maximized strength.

How are lintels installed?

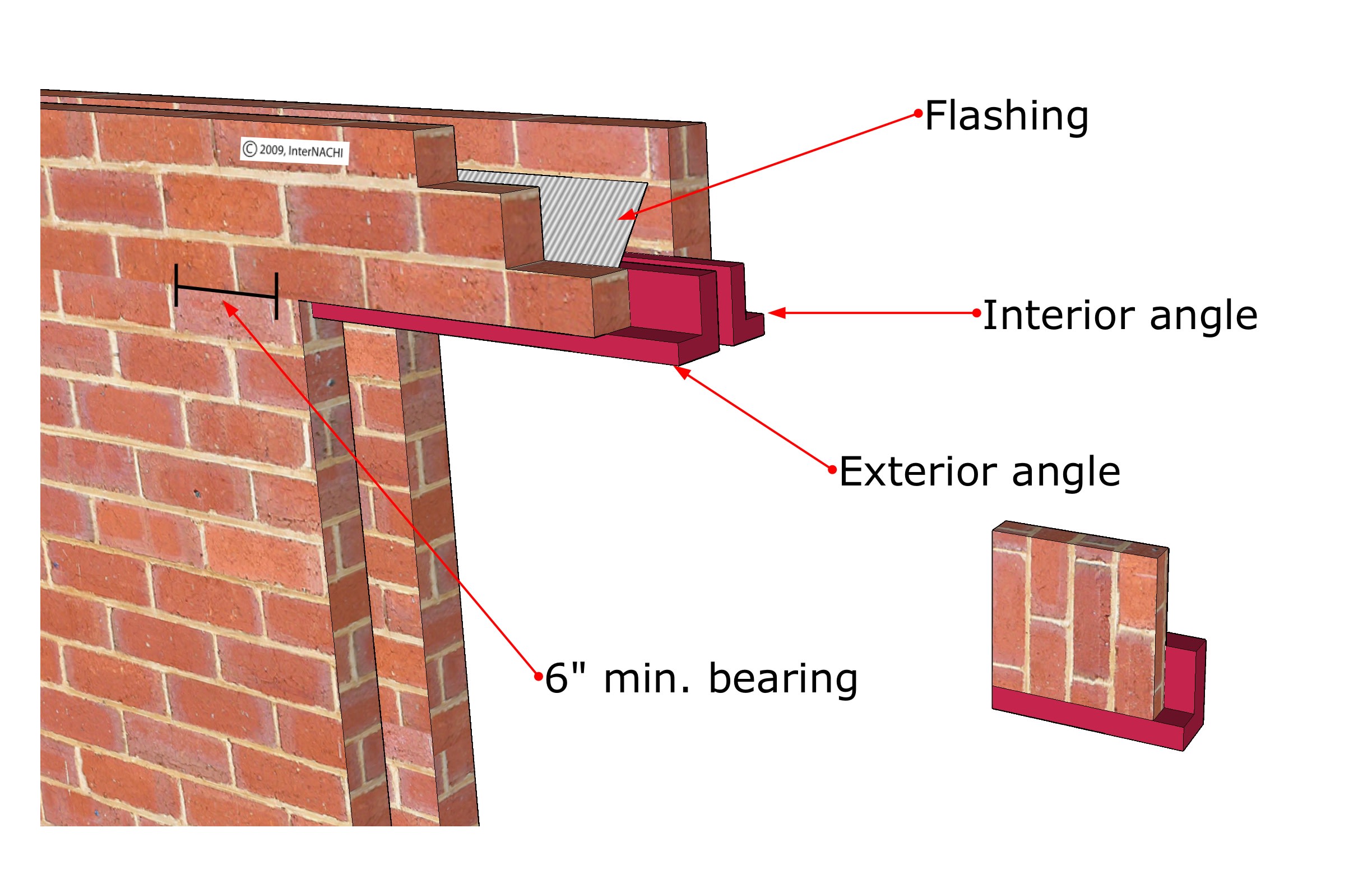

Steps to installing a LintelMinimum End Bearing. ... Bedded on Mortar. ... Make Sure the Lintel is Level. ... Allow Mortar to Cure Before Applying Loads. ... Lay Bricks on Both Sides. ... Install a Damp Proof Course if Necessary. ... Propping Lintels.

Can I drill into a lintel?

When drilling into a concrete lintel, you should start with the smallest drill bit for masonry you have in your set. A drill bit of 3mm is a good place to start, and you can then work up from there to get the size of hole you need. When it comes to concrete, the smaller the drill bit, the easier it will penetrate.

What type of lintel should I use?

if you are just making a standard opening say 60" or so wide then a concrete lintel should be fine. If it is a single skin internal wall i would use a 6" x 4" concrete lintel on end (so it is 6" high). If the opening is on an external wall you will require two linmtels one for each skin.

How can you tell if a lintel is concrete or steel?

The easiest way to tell if a lintel is concrete or steel is by appearance. Concrete lintels are often gray in color and look similar to a concrete block. Concrete lintels have an “unfinished” style and would often look great with brick walls due to concrete's contrasting gray shade to the brick's classic red color.

Can you still use concrete lintels?

Concrete, steel and reinforced brickwork are acceptable materials for use as lintels. Timber lintels should not be used, unless: protected from weather. they do not support masonry or other rigid or brittle materials.

Should I use a steel or concrete lintel?

One of the biggest advantages that steel lintels have over prestressed concrete lintels is their strength to weight ratio. Steel offers much better load bearing capabilities over concrete when looking at the comparative weight. This generally makes using steel a lot easier on site.

What is difference between lintel and beam?

The beam carries the load from slab and transfers it to the column from, column it is transferred to the footing and from footing finally to the soil. Whereas lintel carries the load of the wall above the openings and transfers it to walls only.

INTRODUCTION

Lintels function as beams to support the wall weight and other loads over an opening, and to transfer these loads to the adjacent masonry.

LINTEL DIMENSIONS

Precast lintel dimensions are illustrated in Figure 1. Precast concrete lintels are manufactured to modular sizes, having specified dimensions corresponding to the concrete masonry units being used in the construction.

LINTEL DESIGN

Precast concrete lintels are designed using the strength design provisions of Building Code Requirements for Structural Concrete, ACI 318-99 (ref. 2). In strength design, service loads are increased to account for variations in anticipated loads, becoming factored loads. The lintel is then sized to provide sufficient design strength.

DESIGN EXAMPLE

The residential basement wall shown in Figure 3 needs a lintel over the window opening. The floor live load is 400 lb (1.8 kN) per joist and the floor dead load is 100 lb (0.44 kN) per joist. Consider the floor joist loads, spaced at 16 in. (406 mm) on center, as uniformly distributed.

NOTATIONS

a = depth of equivalent rectangular stress block, in. (mm) As = area of tension reinforcement, in.² (mm²) b = actual width of lintel, in. (mm) c = distance from extreme compression fiber to neutral axis, in.

What is the Lintel Level

Lintel can be defined as the structural members of the superstructure that lies in between the uppermost portion of the window or door and top slab.

Window Lintels

Window lintels are a key component to making any window’s frame stable. It is the part of the wall that is immediately above a window.

Types of Lintels

Brick lintels are used in applications where the majority of the building is done in brickwork. Steel bars placed on the tension side of the bricklayer and rich cement are used to fill in the building joints where the steel bars were placed.

What is the Maximum Span for a Concrete Lintel?

A concrete lintel has a maximum span that is determined by its width and height. For example, a lintel that is 24 inches by 12 inches is limited to having a maximum span of 3 feet. It is recommended to use a lintel as long as 8 feet or less for spans of 3-4 feet.

What is Lintel? 6 Types of Lintel

A lintel is a pervasive part of buildings. Whenever we want to create an opening like doors & windows in the building, we use lintel above the opening as a simple solution.

What is Lintel?

A lintel is one type of beam which is utilized to support the above wall or partition material when openings like doors, windows, and so forth are necessary to provide a building structure. The primary function of the lintel is to take loads originating from the high wall and transfer its heap to the side walls.

Types of Lintel

While timber is as yet utilized in the development of homes, heavier materials, for example, block, concrete, and stone, can likewise be used, particularly in the event of business structures and private condo squares. Thus, the utilization of stirred steel lintels has developed increasingly well known.

1. Timber Lintel

In olden days of construction, Timber lintels were mostly used. But now a days they are replaced by several modern techniques, however in hilly areas these are using. The main disadvantages with timber are more cost and less durable and vulnerable to fire.

2. Stone Lintel

These are the most common type, especially where stone is abundantly available. The thickness of these are most important factor of its design. These are also provided over the openings in brick walls. Stone lintel is provided in the form of either one single piece or more than one piece.

3. Brick Lintel

These are used when the opening is less than 1m and lesser loads are acting. Its depth varies from 10 cm to 20 cm, depending up on the span. Bricks with frogs are more suitable than normal bricks because frogs when filled with mortar gives more shear resistance of end joints which is known as joggled brick lintel.

4. Reinforced Brick Lintel

These are used when loads are heavy and span is greater than 1m. The depth of reinforced brick lintel should be equal to 10 cm or 15 cm or multiple of 10 cm. the bricks are so arranged that 2 to 3 cm wide space is left length wise between adjacent bricks for the insertion of mild steel bars as reinforcement.

5. Steel Lintel

These are used when the superimposed loads are heavy and openings are large. These consist of channel sections or rolled steel joists. We can use one single section or in combinations depending up on the requirement.

6. Reinforced Cement Concrete Lintel

At present, the lintel made of reinforced concrete are widely used to span the openings for doors, windows, etc. in a structure because of their strength, rigidity, fire resistance, economy and ease in construction. These are suitable for all the loads and for any span.