What is retort processing?

Retorting is heating of low acid foods prone to microbial spoilage in hermetically sealed containers to extend their shelf life. The goal of retort processing is to obtain commercial sterilization by application of heat. 01. Rapid heat transfer and hence, reduction in processing time 02. Fewer nutrient losses 03.

What is retort food?

Retort food is sterilized food to be kept for long time storage. It is sealed up in heat resistance pouch or moulded cup/tray. Preserving the food in correct and safe manner can help to reduce food disposal We can offer the entire setup for retort food including pre-cooked, cooking, packaging, pressurised sterilization etc.

How is food sterilized in an immersion retort?

It commercially sterilizes food after it has been packed into its container and the container has been sealed airtight. The method of sterilization in the Retort is a thermal-based various process. Water Immersion Retorts: Typically it has the most flexibility when it comes to processing various container types.

Why retort pouches are used for food processing?

Traditionally, metal cans were used for used for retort processing because of its rigidity but it could not efficiently transfer the heat due to which food in the middle takes larger time to get sterilized. Therefore, to combat this problem of uneven heating, retort pouches were developed which provides efficient heat transfer.

What does a retort do?

retort, vessel used for distillation of substances that are placed inside and subjected to heat. The simple form of retort, used in some laboratories, is a glass or metal bulb having a long, curved spout through which the distillate may pass to enter a receiving vessel.

What is retort technique?

What is the Retorting process? Retort is a processing method that uses heat and pressure to sterilize food. It is one of the most commonly used methods of thermal food processing and is popular with food producers across the world.

What foods are retorted?

Many different types of food may be canned and retorted e.g. Canned fruit and vegetables, canned meals (e.g. Irish stew), canned soups, retort pouches of tuna, etc. A package is hermetically sealed if it is “airtight” e.g. Heat sealed plastic bag, sealed can or glass jar with screw cap.

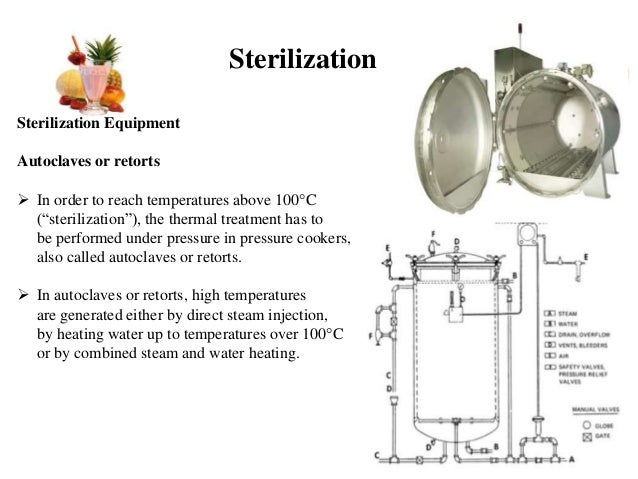

What is the difference between retort and autoclave?

An autoclave (also know as a retort) is a pressure chamber used to sterilize products, equipment and supplies by subjecting them to high pressure saturated steam at 121 °C for between 15–120 minutes depending on the size of the load and the contents.

Why is it called a retort?

The term retort comes by way of Middle French, but ultimately from Latin retortus, twisted back, for the shape of the neck.

What does retort mean in packaging?

3 Retort packaging. The term 'retort pouch' is used to describe a flexible or semi-rigid package made from heat-resistant laminated plastic, into which food products are placed, sealed and sterilized at temperatures up to 121°C. The resulting product is then sterile and shelf-stable.

How long is the retort process?

"If you look at the thermal processes available for microbial stability and they range from 240 to 280°F, the 240°F process would be about 50 minutes long.

How do you do retort packaging?

The food is first prepared, either raw or cooked, and then sealed into the retort pouch. The pouch is then heated to 240-250 °F (116-121 °C) for several minutes under high pressure inside a retort or autoclave machine. The food inside is cooked in a similar way to pressure cooking.

How do you retort rice?

In the method for manufacturing retort rice of the present invention, by subjecting the sealed container to immersion and flipping/absorption for 20 to 40 minutes, uniform absorption and permeation of the rice-cooking liquid into the grains can be brought about, in an amount appropriate for the type of rice.

Is a retort used for pasteurization?

Retorting can be applied for pasteurization (elimination of vegetative pathogenic microorganisms) requiring refrigeration and limited shelf life (such as two months) or sterilization (reduction of heat-resistant spores to acceptable levels, resulting in long shelf-life, such as two years at room temperature).

What is the pressure in retort?

Globally, most modern retort technologies are based on steam as the primary source of heating but steam alone cannot provide for an adequate process for flexible and some semi-rigid containers. At saturation temperature, steam provides overpressure at approximately 1 bar or 15psi at sea level.

Is retort used in canning?

Retort canning is safe and is widely used in commercial canning of foods for retail sale. Home use of pouches specifically designed for retort canning is easy and fun. However, you must use safe food handling practices and keep all food products cold until placed in canner for processing.

How long is the retort process?

"If you look at the thermal processes available for microbial stability and they range from 240 to 280°F, the 240°F process would be about 50 minutes long.

How is retorting done in bottling?

The retort sterilization process involves first filling the pouch and then exposing the sealed package to ultra-high heat. The thin packaging quickly transmits heat, permitting content sterilization to occur up to 40% faster than with jars and cans.

What is retort furnace?

In a chemistry laboratory, a retort furnace, or retort oven, creates a controlled atmosphere to apply extreme heat treatments to solidify products. A separate chamber within high-temperature retort furnace ovens creates a controlled atmosphere to heat the product indirectly.

Is retort canning safe?

Retort canning is safe and is widely used in commercial canning of foods for retail sale. Home use of pouches specifically designed for retort canning is easy and fun. However, you must use safe food handling practices and keep all food products cold until placed in canner for processing.

What is retort processing?

Retort processing is a new advance in making packages that have begun to transform the marketing and goods of food and beverage products. Retort technology is the solution to meet consumer’s demands that will help consumers save time and energy.

What is a retort system?

Retort technology systems use steam or superheated water for cooking in their package

What are retort operating principles?

The retort processing techniques also differ from the normal production process.

How does steam retort work?

The atomized environment gives a perfect heat transfer on rigid containers during the come-up or heating phase, as the water transfers its heat very quickly. A fan is not utilized to mix the atmosphere. Atomizing nozz les placed around the circum ference of the retort take water from a pump, re-circulating the condensate, and mix it with steam directly injected into the chamber. Whilst rapid heating can be achieved, the atomizing nozzles, by their design, tend to restrict the water during cooling, leading to longer processing times than conventional cascading water, immersion or water spray types. To get around this restriction, other manufacturers of this type of retort have considered and implemented separate heating and cooling circuits to maximize the efficiency of the process.

Why are retort pouches used?

Traditionally, metal cans were for retort processing because of their rigidity. Still, they could not efficiently transfer the heat because the product in the middle takes more time to get sterilized. Therefore, retort pouches were developed to combat this problem of uneven heating, which provides efficient heat transfer.

What are the three retort processes?

There are three basic retort processes: steam, falling water and total water immersion. There are also subdivisions within each category, including steam/ air, steam spray, water spray and half immersion. All the processes, bar simple steam, will work on all of the current container formats, so there is not necessarily a ‘wrong’ process for novel applications. However, some principles of transferring heat to sealed containers have advantages over others when specifying particular packaging media. This is particularly so when choosing between rigid, semi-rigid and flexible formats. While the tin can is processed in all three heating mediums, plastic pouches and CPET (crystalline polyethylene terephthalate) trays used for ready-meal production have different requirements

What is retort technology?

Retort technology systems use steam or superheated water for cooking in their package, thus extending shelflife and ensuring safety. Manufacturers of food and beverage products who face a challenge in making their packaging products attractive should design packages with an innovative look. The revolution in packaging technology has to boost suppliers’ minds to be creative in providing convenient products to the consumer.

What Is Retort Used For?

Retort is used to oxidize or purify a liquid. It’s also every so often known as the vacuum distillation process. The gas stream that is being purified flows via tubes with water at one end, which boils the water and generates vaporized steam. This condensed steam is then cooled before flowing into any other vessel wherein it mixes with the gas stream to be purified. Today, retorts are specifically utilized by industry as a way to remove oxygen from gases so they can be stored more effortlessly or shipped without worry of combustion because of exposure to air.

What is forced steam retort?

Forced Steam/Air: This retort is the last type of over pressure retort in which sterilization is accomplished by utilizing a steam and air mixture which is circulated within the retort through a turbine-type fan. A similar mixture of air and steam is drawn to the rear of the retort by the fan and then back to the front in a channel within the retort baskets and shell.

What is a full water immersion retort?

Full Water Immersion: Full water immersion retort is the most widely utilized over pressure retort in the industry. They are available in both rotary and non-rotary models wherein pouches can be run in this full water immersion retorts.

What is a water spray retort?

Water Spray: The water spray retort is an over pressure type of retort and similar to a full water immersion retort. It uses only a small quantity of water which is pumped at a high flow rate. In this retort, water is stored at the bottom of the retort vessel. And same water is utilized for both heating and cooling, where cooling water sanitizers are eliminated.

Retorts, Common Questions and Answers

By Chris Barbier, Technical Sales, Allpax Here we will be continuing a quarterly discussion about retort processing considerations. Our next topic will cover the “why” about retorts; “commercial sterilization”.

Shaka Retorts Shake Up the Shelf-Stable Food Paradigm

In the standard model of low-acid shelf-stable food processing, Ultra High Temperature (UHT)/aseptic packaging and retort sterilization are clearly differentiated in terms of the types of food processed, packaging used, and business models for which each is best suited.

Understanding the Retort Sterilization Process – Steam Retorts

The Saturated Steam Process is the oldest method of in-container sterilization, but are you familiar with the steps in the steam retort process?

Understanding the Retort Sterilization Process – Water Spray Retorts

The Water Spray process is an overpressure process, like water immersion, except that the product is exposed to the influence of the overpressure air. Do you know all there is to know about the water spray retort process?

Pouch Processing

There are many advantages to packaging food products in the retort pouch – processing times can be reduced by as much as 50%, shipping costs and storage costs are lower, and shelf appeal and consumer acceptance continues to grow. But are you familiar with the processing challenges in using the retortable pouch as compared to a metal can?

What is retorting in food?

Retorting is one of the major technique used for the thermal processing of food products which are packed either in semi-rigid flexible laminates or in metal or alloy cans. Retort Technology provides the advantage of processing the food and packaging together which makes the filled product more commercial stable.

What is retort processing?

Retort processing has evolved one of the major sterilization technique significantly since its incorporation into Department of Defence and NASA food system. While the technology still relies on aggressive application and penetration of heat throughout foods, recent advancement in process engineering coupled with evolution of packaging technology have allowed for overall improvement of the technology. Retort processing presents the advantage of increased shelf life with less loss of nutrients due to which it can be applied to process ready to meal, marinades, vegetable curry, soups and rice.

What is a retort?

Retort is the main processing chamber for where the packed food is sterilized, pasteurized or cooked properly to achieve safety and quality. The major objective of this thermal processing is to destroy microorganisms and to deactivate the enzymatic activity which are responsible for shortage of shelf life and changing of physical and chemical properties of food. Retort consists of basket in which packaged food is kept. Then these food products are exposed to the sterilizing temperature (121 Deg. C) mainly by the application of steam and high pressure (15 psi). Compressed air and water are used for sterilizing and cooling for the food products respectively. Principally, it involves seven steps

What temperature does a retort need to be?

Processing: When there is no automatic control, it should be seen that the retort temperature does not fluctuate more than 0.50C, throughout the process.

What is a bleeder in a retort?

Bleeder: It is a small opening used to remove air entering the retort with the steam and to provide circulation of steam in the retort and shall be open during the entire process, including the come-up time. Bleeder should be positioned at sufficient distances and also near the thermometer and pressure gauges.

What is retort food?

Retort food is sterilized food to be kept for long time storage. It is sealed up in heat resistance pouch or moulded cup/tray.

What is SGC type retort?

“SGC type” retort machine enables you to cook and sterilize a wide variety of foods. As you can do cooking and sterilize process at the same time, total production time will be intensively shortened. High temperature water 100-125degC will be sprayed evenly in huge pressure tank according to HACCP sterilization standard and each time more than a thousand packs of retort food can be prepared. The machine also has precise pressure and temperature management to prevent retort bag leaks/bursts due to internal pressure issue. We also offer bench top retort machine for small business and R&D purpose.