A Reciprocating Pump can be categorized into three Types:

- According to Mechanism: Single-acting Double-acting Reciprocating Pump

- According to air vessel: Pump with air vessel and Pump without air vessel.

- According to Number of cylinders:

What is reciprocating pump and its principle?

Working principle of reciprocating pump

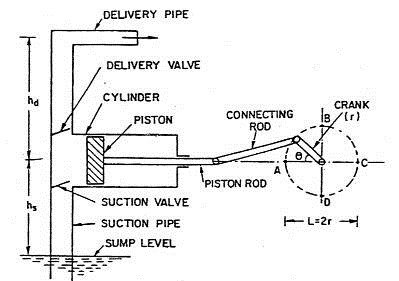

- A cylinder with a piston, piston rod, connecting rod, crank and crank shaft

- Suction pipe

- Delivery pipe

- Suction valve

- Delivery Valve

What is the normal efficiency of a reciprocating pump?

What is the normal efficiency of a reciprocating pump? Reciprocating pumps have an overall efficiency that is generally over 85%, sometimes as high as 90%. The most significant efficiency losses are from mechanical and volumetric considerations which often amount to just a few percent.

How to calculate the power of a reciprocating pump?

reciprocating pump capacity, normally denoted as Q. If Q is not known, you can calculate it by multiplying the pump's displacement, the amount of fluid displaced per unit time, and the pump's volumetric efficiency, the percentage of the total volume of the pump cylinder that is displaced during each stroke.

What are the advantages of reciprocating pumps?

Advantages of reciprocating pump. The reciprocating pump requires no priming. It can be used to deliver liquid at higher pressure. It has higher efficiency as compared to a centrifugal pump. Starting torque is less. It can work in a wide pressure range.

What are the types of pumps?

There are three basic types of pumps: positive-displacement, centrifugal and axial-flow pumps. In centrifugal pumps the direction of flow of the fluid changes by ninety degrees as it flows over an impeller, while in axial flow pumps the direction of flow is unchanged.

What are the 3 types of centrifugal pumps?

Single-stage, Two-stage, or Multi-stage.

What is reciprocating pump in simple words?

A reciprocating pump is a pump which uses a backward and forward movement to move a fluid. In a reciprocating pump, a piston, plunger, or diaphragm moves backward and forward. A reciprocating pump is one in which the liquid follows the movement of a piston during suction and delivery strokes.

How do reciprocating pumps work?

1:024:00How do Reciprocating Pumps work? | Skill-Lync - YouTubeYouTubeStart of suggested clipEnd of suggested clipAnd moves the water up to the outlet. While this is happening the bottom one way valve opens. AndMoreAnd moves the water up to the outlet. While this is happening the bottom one way valve opens. And water fills the reservoir. This is due to the low pressure created at the reservoir due to the upwards

What are the 2 types of pumps?

Main Types of Pumps: Centrifugal and Positive Displacement.

Where is reciprocating pump used?

2.2. Reciprocating pumps are used where a precise amount of fluid is required to be delivered, also where the delivery pressure required is higher than can be achieved with other types. The fluid is moved by the means of a piston that travels in a cylinder.

Which of the following is an example of reciprocating pump?

Explanation: A reciprocating pump consists of a piston pump, plunger and diaphragm pump. It is a class of positive displacement. Reciprocating pumps will last for years and decades. Explanation: Bicycle is the pump is the simplest application of the reciprocating pump.

Is a piston pump a reciprocating?

A piston pump is a type of positive displacement pump in which fluid is moved by the repeated back-and-forth movement (strokes) of a piston. These cycles are called reciprocation. The strokes of a conventional piston pump are shown in Figure 1.

Where is centrifugal pump used?

Centrifugal pumps are commonly used for pumping water, solvents, organics, oils, acids, bases and any 'thin' liquids in both industrial, agricultural and domestic applications. In fact, there is a design of centrifugal pump suitable for virtually any application involving low viscosity fluids.

What is main component of reciprocating pump?

A hollow cylinder made of steel alloy or cast iron. Arrangement of piston and piston rod is inside this cylinder. Suction and release of liquid is takes place in this so, both suction and delivery pipes along with valves are connected to this cylinder.

What is the use of pump?

Liquid can only move on its own power, and then only from top to bottom or from a high pressure to a lower pressure system. This means that energy to the liquid must be added, to moving the liquid from a low to a higher level. To add the required energy to liquids, pumps are used.

What is the efficiency of reciprocating pump?

Reciprocating pumps generally operate at higher efficiencies than other pumps, generally reaching levels of 90% or more efficiency.

What are two types of centrifugal pumps?

There are two main families of pumps: centrifugal and positive displacement pumps.

What are the two main classes of centrifugal pumps?

Pumps are divided into 2 major categories: Dynamic and Positive Displacement (aka Displacement).

How many types of centrifugal are there?

Accordingly, radial, Axial, and Mixed flow are three types of centrifugal pumps.

What type of pump is a centrifugal pump?

non-positive displacement pumpA centrifugal pump is categorised as a non-positive displacement pump. Traps a certain amount of liquid and forces it from the suction to the discharge port. Flow rate remains constant as change in pressure.

What is a reciprocating pump?

Reciprocating pump is also known a called a positive displacement pump. Because it discharges a definite quantity of liquid. It is often used where a small quantity of liquid is to handled and where delivery pressure is quite large.

What is a single acting reciprocating pump?

1. Single Acting Reciprocating Pump. In this pump, A cylinder, in which a piston moves forward and backward. The piston is reciprocating by means of the connecting rod. The connecting rod connects the piston and the rotating crank. The crank is rotating by means of an electric motor.

How does a crank work?

The crank is rotating by means of an electric motor. The suction and delivery pipes with suction and delivery valve are arranged to the cylinder. The suction valve allows the water to the cylinder and. The delivery valve leaves the water from the cylinder.

What is the next stroke of a water pump?

In the next stroke called delivery stroke, the water leaves the cylinder. In the delivery stroke, the crank is rotating from C to A (from 180° to 360°) the piston is moving to the left side of the cylinder. Due to this, the pressure of the liquid increases inside the cylinder. This pressure causes the suction valve to close and delivery valve to open. Then the water is forced into the delivery pipe and raised to a required height.

How many suction pipes are needed for a double acting pump?

Thus two suction pipes and two delivery pipes are required for a double-acting pump. When there is a suction stroke on one side of the piston, at the same time there is a delivery stroke on the other side of the piston.

Is a centrifugal pump a reciprocating pump?

Centrifugal Pump is simple in construction, less weight, less wear and tear, less maintenance cost, low efficiency and can run at a higher speed. Reciprocating Pump is complicated in construction, more weight, more wear and tear, high maintenance costs, high efficiency and cannot run at a higher speed. Centrifugal pumps are suitable ...

Can a centrifugal pump handle dirty water?

Centrifugal pumps are suitable for large discharge with small heads, it requires less floor space and it can handle dirty water Reciprocating pumps are suitable for less discharge with high heads, it requires more floor space and it cannot handle dirty water. Centrifugal pump needs priming, it cannot require air vessels and operations is quite.

What is Reciprocating Pump? Definition

Do you want to learn all about the Reciprocating pump? We have already got the basic idea about the positive displacement pump. Reciprocating Pumps are one kind of Positive Displacement type pump. It works based on the movement of the piston/plunger etc. in,

Parts of Reciprocating Pump and Functions

Reciprocating pumps are used in many industries as well as our few home applications too. Now, whatever the application, a reciprocating pump or pumping system consists of several parts.

How Does Reciprocating Pump Work? Diagram

The reciprocating pump consists of a piston in an enclosed cylinder, crank, piston, connecting rod.

Reciprocating Pump Discharge, Work Done, Power Requirement & Slip Explanations

Let’s calculate the discharge from the reciprocating pump. Discharge means the fluid flow rate from the pump per second.

Derivation for Acceleration Head in Reciprocating Pump

Piston continuously makes forward stroke and backward stroke and these strokes happen between two extreme positions of the cylinder,

Reciprocating Pump Calculation Examples

A single-acting reciprocating pump with 200mm piston diameter, stroke length 400 mm, rotational speed 60 RPM. Now, the water is to be pumped at 20 m height. Find out, theoretical discharge. If the actual discharge is 20.2 liters/sec, then what will be volumetric efficiency, slip & power requirement. Mechanical efficiency 80%.

What is the Difference between Reciprocating Pump and Centrifugal Pump?

Let’s see the differences of reciprocating pump vs centrifugal pump, in the below table,

What is reciprocating pump?

Reciprocating Pumps are positive displacement machines typically used for low-flow, high-pressure operations. ANSI and the Hydraulic Institute categorize reciprocating pumps by four types. Both pistons and diaphragms are used to provide pumping action while valves regulate flow into and out of the pump body.

What is a single action pump?

Single-acting pumps pressurize only on one direction of the stroke while double-ac ting pumps pressurize in both directions. Piston power pumps are used on a much larger scale as well. Common in petrochemical industries, piston power pumps are used for hydraulic fracking, salt-water disposal, etc.

How do steam power pumps work?

Steam power pumps eliminate the need to convert rotary motion to linear motion by directly coupling a steam driven piston to the piston of the power pump. These pumps are generally double acting on both the steam end and the fluid end.

What is an AODD pump?

Air Operated, Double Diaphragm (AODD) pumps have extensive application in pharmaceutical and semiconductor processing as they can be manufactured of high-purity materials. Stainless steel units are made for solvent delivery, etc. These pumps are also able to deliver powders.

What is a chemical dosing pump?

Chemical dosing pumps employ electrical/mechanical/hydraulic arrangements to drive their diaphragms. These will generally employ a mechanical stroke adjustment to control the amount of fluid delivered with each diaphragm flexure.

What is the power end of a pump?

Some pumps are run with pulsation dampeners. The crankshaft and its housing are referred to as the power end of the pump; the piston, cylinders, and valves make up the fluid or wet end. Valves are typically flat faced disc valves on ground seats but for higher pressure pumps, conical or ball valves are often used.

Do radial pumps have pistons?

Radial pumps sometimes employ pistons as well, especially hydraulic pumps used for powering hydraulic systems. These are not covered here. For information on other pumps, please see our Pumps Buyers Guide.

What is reciprocating pump?

The reciprocating pump is a positive displacement pump, i.e., initially, a small amount of liquid is transported into a chamber and physically displaced or forced with pressure by moving mechanical elements, reciprocating pumps are used to raise the energy level of the water. It does not require any kind of priming for their functioning.

What is a piston pump?

1. Piston Pump: A piston pump is a positive displacement pump, in which the high-pressure seal rotates with the piston. These types of pumps are used to move liquids or compressed gases. The two piston pumps are lift and force pumps operated by hand or by the engine. 2.

What is a diaphragm pump?

A diaphragm pump is an optimistic displacement pump that uses a rubber, thermoplastic or teflon diaphragm with appropriate valve interactions on both sides of the diaphragm to pump a fluid.

How many suction pipes are needed for a double acting pump?

Thus the double-acting reciprocating pumps require two suction pipes and two delivery pipes. When there is a suction stroke on one side of the piston, other side has supply stroke.

What is the end of a suction pipe?

3. Suction pipe: One end of the suction pipe is liquid in the inlet of the cylinder and dips in the other end.

What happens when a pump starts with an outlet valve open?

This pump always begins with the outlet valve open, otherwise, the pressure will proceed to rise and will break the pipeline or pump.

How much gas can a pump handle?

Pumps maintain high efficiency when pumping is carried at extremely high liquidity and can easily handle 50% volumes of gas.

What is reciprocating pump?

A reciprocating pump is a hydraulic machine which converts the mechanical energy into hydraulic energy.

What are the disadvantages of a reciprocating pump?

The major disadvantages of Reciprocating Pumps are: It requires high maintenance, because of more wear and tear of the parts. Low flow rate (it discharges a low amount of water). They are heavy and bulky in size. The initial cost is High.

How does a piston pump work?

The movement of the piston is obtained by connecting the piston rod to crank by means of a connecting rod . The crank is rotated by means of an electric motor.

How does a crank rotate?

The crank is rotated by means of an electric motor. Suction and Delivery Pipes with a suction valve and a delivery valve are connected to the cylinder. The suction and delivery valves are non return valves, which allow the water to flow in one direction only.

What is the name of the pump after centrifugal?

Written by Amrit Kumar in Fluid Mechanics and Hydraulic Machines. After Centrifugal Pump the Reciprocating pump is another Important type of Pump.

What is double cylinder pump?

Double cylinder: There is a two-cylinder attached to a single shaft. The main difference from the single-cylinder pump is here there is separate suction and the delivery valve is provided to each cylinder.

Why is a strainer provided at the end of the suction pipe?

A strainer is provided at the end of the suction pipe to prevent the entrance of the solids particle from a water source into the cylinder. Otherwise, solid particle choked the delivery.

What is a Reciprocating Pump?

A reciprocating pump is a mechanical device that changes the mechanical energy of the fluid into hydraulic energy (pressure energy). It uses a piston or plunger for pumping the fluid from one location to another. Because a reciprocating pump uses a piston or plunger for pumping purposes, therefore, it is also known as a piston pump.

How does a reciprocating piston pump work?

The reciprocating piston pump consists of a piston that moves back and forth in a cylinder. The piston is connected with a crankshaft with the help of a connecting rod. This piston moves as the connecting rod move due to the motion of the crankshaft. The crankshaft connects with a motor that rotates it.

What is the use of cast iron in a pump cylinder?

cast-iron or Alloy steel uses for the manufacturing of the pump cylinder. The piston rod and piston arrange in the pump cylinder. The fluid from the suction valve sucks inside the cylinder. The piston moves forward ad backward inside the cylinder for increasing its pressure.

How many cylinders does a water pump have?

As the name of this pump represents that it uses two cylinders for pressurizing the water. First of all, it sucks water or other fluid in the 1st cylinder where the piston increases its pressure after that it sents into the 2nd cylinder. In the 2nd cylinder, another piston increases the pressure of the fluid.

What is a delivery pipe?

Delivery pipe uses to deliver fluids from the pump cylinder to the desired height or position. It directly connects with the delivery valve of the cylinder of the piston pump.

How does a pump suction work?

The fluid opens the inlet valve of the pump and starts entering into the cylinder. As the suction process completes, the crankshaft rotates from C to A (θ = 180° to θ = 360°), and the piston also moves from the right position of the cylinder to the left position.

What is a piston pump?

Because a reciprocating pump uses a piston or plunger for pumping purposes , therefore, it is also known as a piston pump. In this pump, the piston reciprocates in an upward and downward position inside the pump cylinder. As the piston moves toward BDC, it sucks fluid while it pressurizes the fluid when it moves toward TDC.

According to The Source of Work

- They are the simplest and cheapest types of reciprocating pumps. Simple hand-operated pumps can give a continuous supply of water that is sucked from the ground through a strainer, which removes sand, clay, and other impurities up to a reasonable limit. They are usually used when t…

According to The Mechanism Or Use of Piston Sides

- In these pumps, only one side of the piston engages to displace the fluid. In single-acting pumps, a piston moves inside a cylinder with the help of a piston rod operated by a wheel through the connecting rod. They have one suction valve and one delivery valve. When the piston is moved backward in the cylinder, a vacuum is created that carries the opening of the suction valve, and …

According to The Numbers of Cylinders

- For pressurizing the water, these types of reciprocating pumps use only one cylinder which is connected to a shaft. They may be either a single-acting or a double-acting pump. These pumps have less efficiency than double-cylinder pumps, but have low prices and require less maintenance. Also known as two throw pumps, they have two single-acting cylinders connected …

According to The Air Vessel

- Some reciprocating pumps are provided with a separate air vessel attached to the suction and delivery valve. The purpose of using the air vessel is to build up an excessive quantity of water by compressing the air in the vessel and to obtain a continuous discharge of the fluid at a uniform rate from the reciprocating pump. Also, they are used to save the power required to drive the rec…

Conclusion

- Reciprocating pumps come in a variety of styles, shapes, and sizes. The specific type of these pumps chosen for an application takes into account the pressures encountered, the flow rates needed, measurement and control systems, fluid viscosity and corrosivity, pipe material, etc. Careful attention should be given to the application before selecting a reciprocating pump. Selec…