Fabtech’s Uniball Upper Control Arms provide increased strength to the front suspension by replacing the stock ball joint upper arms that can become worn and eventually fail under aggressive offroad use. These heavy duty upper arms are designed for longevity in rugged offroad conditions. They also feature additional caster compared to stock upper arms for superior on road use with oversized tires.

How do you remove a uni-ball control arm?

Because with a Uni-Ball, you must remove the control arms, press out the Uni-Ball to remove it from the control arms, wash it out and re-lube by hand, then press it back into the control arms, then reinstall them onto the vehicle. But the JBA Ball Joint comes with a grease fitting to expedite maintenance.

What is a Uniball joint?

The big uniball joints provide unparalleled strength over factory ball joints. Heavy duty 1 inch chromoly tubular construction and reinforced pivot bushing mounts are used to eliminate flex and handle the added load from extreme suspension cycling.

What are the parts of a control arm attached to?

In most control arms, the two lower parts of the “A” are attached to the frame via control arm bushings, which are rubber pivot-points. The top of the “A” is attached to the steering knuckle by way of a ball joint. In older vehicles, this ball joint is serviceable on its own, without the need to remove or replace the control arm.

Do I need to replace the ball joint on my control arm?

On most newer vehicles, the ball joint is incorporated into the design of the control arm, hence, the entire arm must be replaced. Vehicles can have a different numbers of control arms. Some have as few as just one lower control arm, many vehicles an upper and a lower, and some even have more elaborate, multi-link arm set-ups.

Are uniball upper control arms better?

One will get more flexibility out of a uniball UCA, plus a 1” lift +/-. The uniball is much stronger and requires less maintenance.

What is a uniball joint?

Uni-Balls, also known as spherical bearings, have an open design which differs from the JBA Ball Joint's semi-sealed construction. Both are primarily used in off-roading vehicles, but there are many differences between these two rival parts — let's take a closer look.

How do you replace a uniball?

4:2724:39How To Replace Uniballs Using a TOTAL CHAOS Uniball Press ToolYouTubeStart of suggested clipEnd of suggested clipPut it inside of the uniball cup. We do this so that when you press the new ball in it kind ofMorePut it inside of the uniball cup. We do this so that when you press the new ball in it kind of spreads all up inside of there. And that way when you go to do the next uniball.

How do you maintain uniball UCA?

1:114:02HOW TO: Maintain Your ICON Uniball Upper Control Arms - YouTubeYouTubeStart of suggested clipEnd of suggested clipStarted you're first going to watch the lift vehicle off the ground. Support. It so there's noMoreStarted you're first going to watch the lift vehicle off the ground. Support. It so there's no weight on suspension. And then remove the wheels and tires.

How do you assemble a uniball?

0:322:31How to replace your Uni-Balls fast and with zero struggle - YouTubeYouTubeStart of suggested clipEnd of suggested clipJust place the tool on the backside of the uniball cup. Taking the piston and uniball into the frontMoreJust place the tool on the backside of the uniball cup. Taking the piston and uniball into the front side install the coupling nut and as you thread down make sure that the uniball is going in square.

How are uniball made?

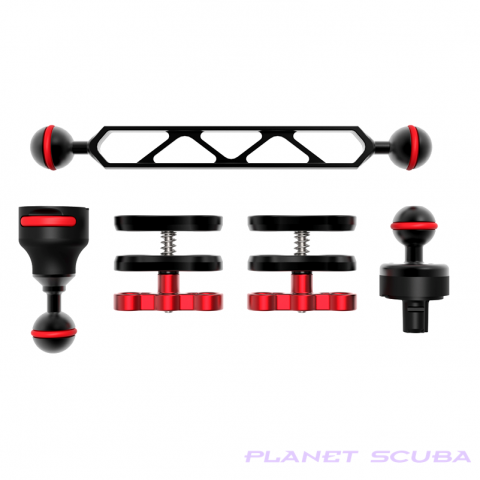

Uniball assembles consist of a cup that is typically welded into a component, such as an A-arm, plus the spherical bearing assembly that presses into the cup. Servicing worn components is done by pressing the bearing out of the cup and installing a replacement.

Can you grease a uniball?

With heims and uniballs you want to make sure you use the right lube and not a grease or oil that attracts dirt. Tri-flow is a teflon (PTFE) based lube that goes on wet and drys to a film to coat and seal the surfaces. This minimizes stiction and corrosion in extreme conditions.

How often should I grease my UCA?

every 5,000 to 10,000 milesWe recommend using a grease gun and adding 3-4 pumps of grease in the ball joint and 1 pump in greaseable bushings, every 5,000 to 10,000 miles. If you drive through creaks and in mud pits, we would recommend greasing the ball joint after you are done playing in the mud and water.

How often do you grease UCA?

The application will greatly determine how often customers grease their bushings. Most customers grease their arms every oil change although we have some customers that go closer to 10-15k and even 20k miles.

How do you grease UCA bushings?

0:232:55How to grease your CAMBURG upper control arm bushings on ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipTake the nut off we're then going to put the grease gun onto the zert fitting. Here we're going toMoreTake the nut off we're then going to put the grease gun onto the zert fitting. Here we're going to pump grease into the bushings. And you'll see when you start pumping the grease.

How do you lube UCA?

0:002:32TOTAL CHAOS Upper Control Arm (UCA) Bushing MaintenanceYouTubeStart of suggested clipEnd of suggested clipThe first step is to loosen the 19 millimeter through bolt. Your next step will be to connect theMoreThe first step is to loosen the 19 millimeter through bolt. Your next step will be to connect the grease gun to the zerk fitting. Next pump grease into the bushing.

How do you grease a lift kit?

0:323:04How To Grease Your Suspension - YouTubeYouTubeStart of suggested clipEnd of suggested clipI like to take a little brake cleaner and wipe down the fittings. This will prevent any dirt fromMoreI like to take a little brake cleaner and wipe down the fittings. This will prevent any dirt from passing through and either stopping up the fittings or ruining the parts you're working on.

What is the part number for the Uniball upper A arms?

A: Thanks for the inquiry Jorge, the Pro Comp Suspension Uniball Upper A-Arms With Billet Dust Cap part # EXP57001B these are sold in pairs.

What are the new Pro Comp control arms?

The new Pro Comp Pro Runner Control Arms deliver amazing performance and increased durability for lifted, leveled or stock trucks. The factory upper control arms have weak ball joints and stamped steel construction that is not designed to handle off road use. Pro Comp has engineered the new Pro RunnerTM Control Arms utilizing oversized stainless steel FK uniball joints. The big uniball joints provide unparalleled strength over factory ball joints. Heavy duty 1 inch chromoly tubular construction and reinforced pivot bushing mounts are used to eliminate flex and handle the added load from extreme suspension cycling. Large PTMEG pivot bushings are equipped with zerk fittings for easy maintenance and quiet operation. Each arm is finished in a durable black powder coat finish for years of lasting performance, and includes a billet machined dust cap to keep dirt and debris out of the uniball.

What is the part number for the Pro Comp suspension?

A: Thanks for the inquiry Big D, the Pro Comp Suspension UNIBALL UPPER A ARM W/BILLET DUST CAP part # EXP52001B are a factory replacement arm and can normally work with any after market lift.

What is the upper control arm for a 2014 F150?

A: The 57003B is for the Toyota 4Runner / FJ cruiser. The Upper control arm for the 2014 F150 needed is 52001B.

Does Jimbo Pro Comp have an arm?

A: Thanks for the question Jimbo Pro Comp Suspension Uniball Upper A-Arms With Billet Dust Cap EXP57001B Procomp does not make an arm for your application. These are the arms that will fit the your vehicle application. CAM310006 Thank you Answer box sales

Does the Uniball upper work with factory knuckles?

A: Yes the Pro Comp Suspension Uniball Upper A Arm with Billet Dust Cap will work with the factory knuckles. Hope this helps!

Can you use a Pro Comp 6" coil over lift?

A: Hello there, the Pro Comp Suspension UNIBALL UPPER A ARM W/BILLET DUST CAP will work fine with a Pro Comp 6" stage 2 coil over lift. Shop with us anytime, on your schedule. Browse 4WheelParts.com, call our customer service center, or come visit us in one of our stores. You can even save on shipping costs by shopping online and picking your order up in a store. No matter which method you prefer, we’re ready to help with excellent parts, advice, and service

What is a Uni ball?

Uni-Balls, also known as spherical bearings, have an open design which differs from the JBA Ball Joint’s semi-sealed construction. Both are primarily used in off-roading vehicles, but there are many differences between these two rival parts — let’s take a closer look.

What is the difference between a JBA ball joint and a Uni ball joint?

The JBA Ball Joint, on the other hand, has a semi-sealed construction that keeps debris and the elements out, extending the life of the joint and allowing you to use it in your daily driven vehicle.

How many degrees of range of motion does a Uni ball have?

The Uni-Ball has 66 degrees total range of motion. The JBA Ball Joint, on the other hand, gives you 90 degrees range of motion. That is the widest range of motion that you will find on the market today!

What is a ball joint?

Ball joints are a crucial component of the steering and front suspension in virtually all vehicles in existence, and they have been around since the conception of the automobile. The ball joints used in an OffRoad racing vehicle will differ from the ball joints used in your daily driver / weekend warrior style vehicle.

Can you use a JBA ball joint on an off road vehicle?

When performing maintenance on your off-road vehicle, you will have a much easier time working with a J BA Ball Joint. Why? Because with a Uni-Ball, you must remove the control arms, press out the Uni-Ball to remove it from the control arms, wash it out and re-lube by hand, then press it back into the control arms, then reinstall them onto the vehicle. But the JBA Ball Joint comes with a grease fitting to expedite maintenance.

What Does A Control Arm Do?

To keep it simple, the control arm is a link that connects the frame of the car to the wheel hub assembly or steering knuckle. Control arms can come in many different shapes in sizes, upper Control arms are often call “A” arms as they have a shape vaguely like a capital letter A. The control arm (s) move up and down with the spring when a car hits a bump or other road irregularity. This allows the tires to maintain contact with the road and, thus, control. The control arm is part of the suspension system that helps your car remain in full contact with the road at all times, that’s giving you necessary control.

What happens when a control arm fails?

When a control arm fails, multiple things can happen. Most failures occur from the ball joint failing. Complete ball joint failure can cause a steering knuckle disconnection and loss of control of the vehicle. Control arm bushings can also wear and fail, creating clunking, wandering steering, and loss of control.

How to tell if your control arm is failing?

One of the earliest signs of a failing control arm is hearing a popping noise when you drive over road irregularities. You may also hear a popping noise when you speed up or reduce the speed of your vehicle, but normally going over bumps at slower speeds, like speed bumps is an indicator of a ball joint that is popping, or possible worn bushings.

What is the top of the steering knuckle?

The top of the “A” is attached to the steering knuckle by way of a ball joint. In older vehicles, this ball joint is serviceable on its own, without the need to remove or replace the control arm. On most newer vehicles, the ball joint is incorporated into the design of the control arm, hence, the entire arm must be replaced.