What’s Welding Liner? The welder liner is one of the best and most crucial components of a gun that is helping welding wires with no troubles from the feeding wire. Wires can move from one section of the device to the next smoothly.

Where is a liner installed and what is its function welding?

A MIG gun liner spans from the front of the gun through to the power pin and is the conduit through which the welding wire feeds. Proper installation of the liner is critical to its ability to guide the wire through the welding cable and up to the contact tip.

What is the purpose of the conduit liner?

Conduit Liner Description For use where a lightweight conduit is required to contain the wire bundle and give mechanical protection, fluid resistance and sealing.

How often should you change a MIG liner?

While the rest of the components inside the cable will return to shape, a coiled steel liner that has become kinked must be replaced immediately. If you take care to keep contaminants out of your liner and not abuse your MIG gun, you can expect an average of 6-12 months of service life.

How do you put a liner on a MIG gun?

1:293:27Replacing your MIG gun liner - YouTubeYouTubeStart of suggested clipEnd of suggested clipIt's time to install the new liner feed the new liner inside the gun leaving the excess feed rightMoreIt's time to install the new liner feed the new liner inside the gun leaving the excess feed right at the end of the gun. New liners need to be cut to the exact length for each individual gun.

Are welding liners universal?

Each conduit liner wire has a crimped wire guide that is universal common to all brands of MIG guns. Attached to the wire guide is an adapter; use different adapter for different MIG gun brands.

Why does my MIG welder sound like a machine gun?

Listen To Your Welder “A loud, raspy sound could indicate the voltage is too low. A crackling sound like a machine gun going off indicates too high an amperage setting,” he adds.

How do I know if my MIG liner is bad?

Troubleshooting Your MIG Gun Liners Poor or erratic wire feeding, a loss of amperage or frequent contact tip burnback are all signs of liner problems. Unfortunately, because of the time it takes to replace the liner, this is often one of the last components checked during a troubleshooting effort.

Do you push or drag with MIG?

Key Factors in Weld Strength For instance, welding instructors will tell you that MIG welding with flux core on aluminum will always require a push angle. However, once you switch to another material, such as steel, you may need to consider pulling your weld bead instead.

What is the brown stuff on a MIG weld?

The brown powdery stuff as you say is generally a sign of not enough shielding gas, up the pressure a bit to try.

Do you Mig Weld Vertical Up or down?

The upside down V is one of the most effective techniques for vertical mig welding of lap and tee fillet welds. Sure there are other ways of making a good looking vertical uphill weld, but for ensuring penetration as well as making a good looking uniform weld, the upside down V is a very good way to go.

Should you whip when MIG welding?

The general guidelines for MIG welding are whip when welding thin metal or making the first pass in a joint, circles for a both thicker materials and wider welds.

How far should MIG liner stick out?

Note that the liner will spring back and stick out of the neck by approximately 1-3/4 inch, which is normal, as installing the consumables will compress the liner into its proper position.

Can you clean a MIG welder liner?

The most common way to clean the welding torch liner is by taking a can of compressed air and blowing it in bursts through the dirty liner. This process will push any metal powders that may be building up on your liner through it and keep it in a good condition.

How long does MIG shielding gas last?

Your 20 cf Argon tank could last you as long as an hour and 20 minutes while your MIG welding your Aluminum.

How far should MIG liner stick out?

Note that the liner will spring back and stick out of the neck by approximately 1-3/4 inch, which is normal, as installing the consumables will compress the liner into its proper position.

Do MIG welders wear out?

A modern MIG welder can do so much – but that doesn't mean that it can escape the ravages of wear and tear. With all that heat and power come the inevitable aging forces that wear out MIG welders.

How does a MIG gun liner affect weld quality?

The quality and maintenance of the MIG gun liner make a huge impact on weld quality. The proper installation and regular maintenance of these gun liners can help reduce downtime and unwanted expensive work. Follow these guidelines, to maintain a good-quality liner performance:

Why do MIG gun liner liners tear?

It leads to premature wear and tears due to the continuous rubbing of their surfaces and other serious feeding problems too. This causes ‘birdnesting’, which is the tangling of the welding wire between the drive roll and end of the torch and wastes some wire feed.

What is a MIG gun liner?

The MIG gun liner is one of the simplest components used in the MIG welding setup but has the most prominent effects on the fabrication down time which we had mentioned at the very beginning.

Why is welding downtime so bad?

There are several reasons that cause downtime in the welding industry like grounding problems, gas leaks, contaminated material malfunction in the machine, and sometimes even broken-down internal components . Wire feed problems and MIG gun liner issues make the situation even worse.

Why do welders use larger diameter wire liners?

Even if some do not like it, there are many welders who prefer using liners of larger diameters in a hope that the wire feed does not get damaged because of the accumulation of a large about of debris.

What causes wire feed problems?

Generally, when we talk about wire feed problems, there is a lot of issues that are comprised of erratic wire feed, wire burning, and even bird-nesting. Incorrect drive rolls, incorrect tip size, improper installation of wire liner, and clogged liners are some of the causes of wire feed problems.

What is a large diameter wire feed?

Hence, a large-diameter wire feed has a larger column feed strength and it should be accompanied by a limited liner’s outer diameter that must be used. If you use a compressed airliner, it can help you blow out the debris from the liner and increase its lifetime.

When should you change a MIG Gun Liner?

Truth be told, they don’t need a lot of attention, but a little bit of love goes a long way. The single most important measure a welder can take to prolong the service life of their liner is to keep contaminants out of it. This can be accomplished by keeping your wire feeder closed or off the floor and blowing out your liner with compressed air. It is generally recommended that the latter be done every time a new roll of wire is installed in the feeder. Simply remove all wire from the MIG gun, remove the contact tip, remove the MIG gun, and shoot a few blasts of clean compressed air from the power pin end. You should be able to feel the air pressure at the front end of the MIG gun. When the liner inevitably does reach the end of its life, you will likely encounter feeding issues. If a MIG gun cable is bent too sharply, the liner may become kinked. While the rest of the components inside the cable will return to shape, a coiled steel liner that has become kinked must be replaced immediately. If you take care to keep contaminants out of your liner and not abuse your MIG gun, you can expect an average of 6-12 months of service life.

How to remove liner from MIG gun?

Grip the liner from the rear with a pair of pliers and remove it from the MIG gun.

How to tell if you have wire feeding issues?

Consequently, you should carefully choose liners to fit the application.

What is a liners wire?

Most liners are manufactured from carbon steel wire (also called music wir e or piano wire), which is tightly wound in a coil to allow for a balance of rigidity and flexibility. The profile of the wire can be round, oval-shaped, or flat, with each shape lending itself to the optimum function of its design.

What is the purpose of a lining on a gun?

Tightly fitted insulation wrapped around the base of the liner prevents shielding gas from seeping through where the gun cable exits the feeder. Additionally, the insulation is often bent at a more substantial angle as gravity pulls it downward.

What is the function of a liner?

The basic function of a liner is to act as a guide for the wire electrode from the drive rolls to the contact tip. Sounds simple, right? Well, yes and no.

Do MIG gun liners help?

Have you ever encountered feeding problems in MIG Welding? MIG Gun Liners can help.

What consumables are used for welding liner?

There are also consumables — contact tip, nozzle, gas diffuser and liner — available in the marketplace that allow for error-proof liner installation. The diffuser locks the liner in place and concentrically aligns it with both the power pin and contact tip with no gaps or misalignments (and without the use of fasteners). There is no liner measuring required during installation or replacement. The welding operator or maintenance personnel simply feeds the welding liner through the neck of the gun, locks it in place and cuts the liner flush with the back of the power pin.

How to tell if a liner is a weld?

The liner is not designed to carry welding current, so a dramatic loss of current at the arc will result if loose cable connections or a degraded cable make it the path of least electrical resistance. One common sign that this has occurred is a discolored liner and excessive heat build up along the power cable. The discoloration is caused by heat and indicates weld current is being carried through the liner instead of the gun’s power cable. A degraded cable will require repair or replacement.

What is a MIG gun liner made of?

Most MIG gun liners are made from coiled steel wire, known as music or piano wire, which gives the liner a good balance of rigidity and flexibility and allows it to guide the welding wire through a tightly bent cable without kinking. Nevertheless, bending the cable too much can cause poor wire feeding, premature liner wear and birdnesting ...

Why is it important to clear out the liner with compressed air?

Tight bends in the cable increase friction between the liner and the welding wire . This friction makes it more difficult to push the wire through the liner, causing wear and metal fragments to accumulate inside the liner. Eventually these tiny particles can build up and cause serious wire feed blockages. This occurs to a lesser degree even with cables that are not bent tightly, so it’s a good idea to periodically clear out the liner with compressed air.

What is the purpose of a MIG liner?

Its sole purpose is to guide the welding wire from the wire feeder, through the gun cable and up to the contact tip. If it is not performing this task properly, the gun is virtually worthless. A number of problems can interfere with the liner’s ability ...

Why is the liner on a MIG gun important?

The liner is both one of the simplest and most important components of a MIG gun. Its sole purpose is to guide the welding wire from ...

How does a welding liner work?

The welding operator or maintenance personnel simply feeds the welding liner through the neck of the gun, locks it in place and cuts the liner flush with the back of the power pin.

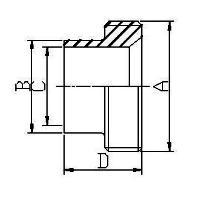

MIG Gun Liner Diameter Size

There is some debate within the industry as to how to match the MIG gun liner size to the wire size. Some welders prefer using larger diameter liners because they believe the extra space can collect more debris without impeding wire feeding. They also believe that larger diameter MIG gun liners offer less resistance.

Steel MIG Gun Liners

The traditional steel wound MIG gun liner has widespread use. These liners have a good balance of rigidity and flexibility and performance and cost effectiveness. Most standard mild steel welding wire (ER70S-3, ER70S-6, etc.) works well with these liners. Problems can arise when these liners are used for other types of wires.

Plastic MIG Gun Liners

Beyond steel MIG gun liners, which are very cost effective and popular among welders and welding shops, there are a variety of plastic liners you can use as well. Most plastic liners look very similar but have different properties to them that make them more durable or better fits for certain types of filler metal and MIG weld processes:

Neck Liners (Jump Liners)

Beyond the wire liner itself, neck liners are great tools to help extend the life of your wire liner. Neck liners, also called Jump Liners, are short liners with a small collet that sit in the welding torch swanneck and are far easier to replace should the liner fail.

Which MIG Gun Liner is Right For Me?

The best wire liner for your operation is going to depend on three main things: the parameters you're welding with, the filler metal you're using to weld, and your MIG gun liner size.

More MIG Gun Liner Tips

Affixing all plastic liners with a brass wound jumper or neck liner will always increase the working temperature of a MIG gun liner.

What is a Welding Liner?

The purpose of a MIG welder’s liner is to help the welding wire glide easily from the wire feeder through the gun cable and up into the contact tip for your gun.

Why is it so hard to get wire through a liner?

These tight bends along the cable will result in the friction between the liner and welding wire is increased. This will make it far more difficult to get your wire pushed through your liner.

What kind of liners do I need for steel wire?

With steel wire, you will need a Teflon coated steel liner instead. This wire is much more rigid and firm. These liners also have a ferrule on the end that will lock in with a supplied nut. Now there are more than this but these are the main two types of liners that I use in my welding shop.

What to check when welding a welder?

If the tip is good then the next thing I check is the welding liner itself.

Why do welding liners get dirty?

One of the ways welding liners get dirty is when they are not cleaned regularly. Bending the line and cable on your gun can also cause problems with your wire liner. Liners are designed to have a balance between flexibility and rigidity.

How to get a gun liner back in place?

It can’t be stressed enough that you should complete this process very slowly. Finally, you will get your nut and spanner and put it back in place.

What happens if you bend a gun cable too much?

Still, if you continuously bend the cable too much, it can lead to poor wire feeds, bird nests, and dirty liners that will wear out well before their lifespan.

What does the word MIG mean ?

Actually, MIG is a British English word that means ‘Metal Inert Gas ‘. It’s actually a welder which is very comfortable and easy to use.

What can you weld with a MIG welder ?

When it has become a very easy thing for you that you know all the process of cleaning a MIG welder then you can weld different metals with this welder such as stainless steel, carbon steel, aluminum, copper, nickel, bronze etc.

What is the contact tip of a MIG welding wire?

The contact tip is liable for disposing the welding current to the wire in the MIG welding method. The wire should feed through with little defense still at that time when it maintains the electrical contact.

What is the best liner for a MIG welder?

Teflon MIG welder gun liners supplies enough heat for welding that is used for water- cooler torches. Teflon has really good features and it is used in various types of wire. So, it’s one of the best liner.

What is a MIG liner?

A MIG welder gun liner is a pipe or helically sore wire and it acts as a cistern to set the welding wire with the help of the MIG gun to the connecting point. The most significant part is to match the size and type of the liner and the welding wire.

How to protect MIG wire from rusting?

You should always clean the nozzle after every use. And to protect MIG wire from rusting you never took them with dirt. Clean them properly and keep your wire-free from rust.

What is the most important part of a MIG gun?

The most important and significant part of a MIG gun is liner. Its main motive is to direct the welding wire from the wire observer via the gun cable. Various types of complications can arise with the welder liner ’s capacity to clearly take the wire through the cable of a welding machine. A very exclusive part of a MIG welder is that the liner should be clear.