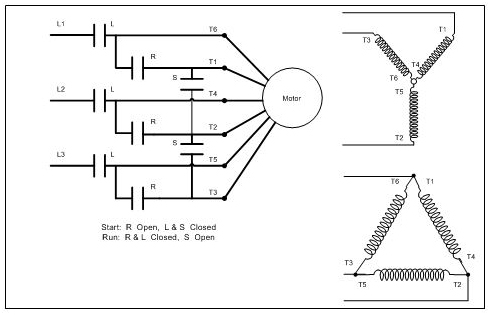

Per NEMA MG1 1998-1.76, a Wye Start, Delta Run motor is one arranged for starting by connecting to the supply with the primary wind-ing initially connected in Wye, then reconnected in Delta for continuous run operation. This is accomplished by a special Wye-Delta starter con-figuration using six leads from the motor and is intended to limit the

What is a wye start-Delta run motor?

Wye start - delta run motors are specifically design and manufactured to run delta connected at the full final line to line voltage. A motor with twelve leads can be operated wye start delta run providing the exact voltage line to line for the pretended final delta connection.

What is the difference between a wye and a delta starter?

Little has changed over time with this method. Simply put, a traditional wye-delta starter starts in the wye configuration and transitions to a delta run, thus allowing reduced voltage and current when starting. The starting voltage, current and torque are reduced in traditional wye-delta starting.

What is the starting torque of a wye delta motor?

The percent voltage applied during the start in the wye is 58% of full voltage, resulting in a percent of full load starting torque of 33%. This is a great way to start a delta motor designed for a wye-delta start.

How do you start a delta run on a power supply?

Wye Start Delta Run. This method is actually reduced voltage but is accomplished by changing the motor phase connections such that a winding that is designed to run with phase voltage equal to line voltage on delta connection is wye connected for starting to put less than line voltage on each phase.

What is the difference between Y start in Delta run?

5:1712:48Y Start-Delta Run Reduced Voltage Starters (Part 1 of 2) - YouTubeYouTubeStart of suggested clipEnd of suggested clipThe Y start Delta run reduced voltage starting method takes advantage of this by starting a motorMoreThe Y start Delta run reduced voltage starting method takes advantage of this by starting a motor and a Y configuration. And then once the motor is accelerated.

What is the difference between a wye and delta motor?

For a wye wound motor as compared to a delta wound motor, presuming each phase resistance is the same, between any two phases, a delta wound motor has 1/3 the resistance as compared to the wye. The wye-wound has higher resistance and higher inductance, better for drives with lower switching frequencies.

Where are wye-delta starter typically used?

three phase induction motorDefinition: A Wye-Delta starter (also known as Start Delta) is one of the most commonly used methods for the starting of a three phase induction motor. In this configuration of starting an induction motor, the motor is started in the Wye configuration (ref fig 1.)

How does a motor switch from Wye to Delta?

Switching the motor from wye to delta by the open transition method allows it to be completely disconnected from the power source for a brief time period before being reconnected delta. Closed transition switching maintains connection of the motor to its source during the reconnection cycle.

How do I know if I have Delta or Wye?

The Delta configuration has the three phases connected like a triangle. Delta systems have four wires total: three hot wires and one ground wire. Wye systems utilize a star configuration, with all three hot wires connected at a single neutral point.

Which is better Wye or Delta?

The Wye connection joins together one end of each of the coils and applies the individual phases to the open ends. These two connections produce very different results when power is applied. An advantage of the Delta connection is higher reliability.

What is the advantage of Wye Delta starting?

Advantages and disadvantages of star-delta starters The cheapest method to start a motor. The starting current is reduced to 33% of direct online starting current. Better torque per ampere of line current than other starters. Star-delta starters do not require any voltage reduction equipment.

How do you know if a motor is Star or Delta?

0:092:01How To Identify Star And Delta Motor Terminal Connections? In 2 minsYouTubeStart of suggested clipEnd of suggested clipOn your screen you can see actual motor picture connected in star for delta winding connection theMoreOn your screen you can see actual motor picture connected in star for delta winding connection the plates in the terminal. Box are connected. Across u1 to w2 v1 to u2. And w1 to v2.

What happens if you connect a Delta motor in Star?

when you connect the delta connection motor into a star connection mode, the effective per phase voltage is reduced to (1/1.732) times hence to maintain the torque/speed it will draw 1.732 times higher current.

Can you start a motor in Delta?

In star delta starting an induction motor is connected in through a star connection throughout the starting period. Then once the motor reaches the required speed, the motor is connected in through a delta connection. A star delta starter will start a motor with a star connected stator winding.

What is wye connection in motor?

– The wye connection is a three-phase four-wire circuit used in a three-phase electrical system which is formed by connecting stating or terminal ends of all the three windings together. This common point is called neutral point which is represented by “N”.

How many leads does a wye-delta motor have?

In both the Wye and Delta configurations, three of these leads are connected internally, and so only nine leads are brought out of the motor for connection.

Should I wire motor as a Wye or Delta?

If leads are numbered 1-6, the winding can usually be connected wye or delta. On machines rated for two voltages, the wye connection is for the high voltage; the delta connection is for the low voltage. For a single voltage rating, most 6-lead machines are capable of wye-delta starting (and will run in delta).

Is 480 volts Delta or Wye?

Classification of Electrical ServicesWye Line-to-Neutral VoltageWye or Delta Line-to-Line Voltage2304002404152774803476002 more rows

How can you tell if a motor is delta or star?

0:092:01How To Identify Star And Delta Motor Terminal Connections? In 2 minsYouTubeStart of suggested clipEnd of suggested clipConfiguration. On your screen you can see actual motor picture connected in star for delta windingMoreConfiguration. On your screen you can see actual motor picture connected in star for delta winding connection the plates in the terminal. Box are connected.

Why delta connection is used in motor?

Star/Delta starters are probably the most common reduced voltage starters. They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply.

What is a delta starter?

After a period of time the winding are reconfigured as delta and the motor runs normally. Star/Delta starters are probably the most common reduced voltage starters. They are used in an attempt to reduce the start current applied to the motor during start as a means of reducing the disturbances and interference on the electrical supply.

What is the star state of a motor?

The motor is connected in star and will produce one third of DOL torque at one third of DOL current.

What happens when a star contactor opens?

Once the star contactor opens, current is able to flow round through the motor windings to the supply via the resistors. These resistors are then shorted by the delta contactor. If the resistance of the resistors is too high, they will not swamp the voltage generated by the motor and will serve no purpose.

How does star delta reduce voltage?

During starting the motor windings are connected in star configuration and this reduces the voltage across each winding 3. This also reduces the torque by a factor of three.

How to limit surge in induction motor?

To limit the starting current surge, large induction motors are started at reduced voltage and then have full supply voltage reconnected when they run up to near rotated speed.

What is the control circuit for an AC induction motor?

Controlling the interchanging star connection and delta connection of an AC induction motor is achieved by means of a star delta or wye delta control circuit. The control circuit consists of push button switches, auxiliary contacts and a timer.

Where to place overload protection on Star Delta starter?

For a star-delta starter there is a possibility to place the overload protection in two positions, in the line or in the windings. Overload Relay in Line: In the line is the same as just putting the overload before the motor as with a DOL starter.

What is a wiring diagram for a delta motor?

wye start delta run motor wiring diagram – What is a Wiring Diagram? A wiring diagram is a straightforward visual representation from the physical connections and physical layout associated with an electrical system or circuit. It shows how the electrical wires are interconnected and may also show where fixtures and components could possibly be attached to the system.

Why do we need wiring diagrams?

When and How to Use a Wiring Diagram. Use wiring diagrams to help in building or manufacturing the circuit or computer. They are also helpful for making repairs.

What is the NEC for electrical wiring?

The National Electrical Code (NEC) requires that all wiring connections be made in a appropriate enclosure. In most cases, this means a power box. Enclosures not just protect the connections—and protect people from accidental experience of those connections—they in addition provide means for securing conductors (like electrical cables) and devices.

Does a Wye Start Delta start over 5HP?

Name: wye start delta run motor wiring diagram – STAR DELTA Starter Will always work over with your 5HP above rated motors

How to use a wye delta motor?

An easier way to utilize a wye-delta designed motor, or for that matter, a delta motor with six accessible leads, is to use a soft starter enabling zero transition to start the motor. A soft starter can produce the same amount of torque as an electro-mechanical starter. Torque is needed to start the motor. This can be done in two ways, one is connecting the motor in line configuration, the second is inside-the-delta.

How many leads does a Wye Delta have?

Wye, Delta, Wye-Delta, three, six, nine or 12 lead motors. There are many different ways a motor can be connected and to match, and there is a myriad of starting methods. Some motors are more versatile than others for starting options depending upon access to the motor leads themselves.

What is inside the delta?

Inside the delta is a configuration where the SCRs of the soft start are “inside the delta.”. Not only can the soft starter provide similar amount of torque as an electro-mechanical, it can provide higher or lower torque if needed just by adjusting the starting current limit or initial torque for soft starting.

What is a soft starter?

A soft starter can produce the same amount of torque as an electro-mechanical starter. Torque is needed to start the motor. This can be done in two ways, one is connecting the motor in line configuration, the second is inside-the-delta.

What is used to reduce the current spike of the transition?

In addition to the components utilized with the open transition, an additional contactor and power resistors are used to reduce the current spike of the transition.

What are the two starting methods for the transition wye-delta?

Going further, there are two starting methods with the electro-mechanical, open and closed transition wye-delta.

Can you start a wye delta starter?

The short answer is yes! Electro-mechanical starters have successfully started wye-delta starters for decades. Little has changed over time with this method. Simply put, a traditional wye-delta starter starts in the wye configuration and transitions to a delta run, thus allowing reduced voltage and current when starting.

What is a Wye-Delta starter?

Star-delta starter (Wye-Delta Starters) – Circuit, working. Induction motors are robust and reliable and are used in all industries across the globe. Various methods are followed to start induction motors, out of which star-delta starters are the most commonly used ones to reduce the starting current. Star-delta starters are cheaper ...

How much current does a star delta starter draw?

When an induction motor is started directly online, it tends to draw a starting current ranging between 6 to 10 times its normal full load current. It can result in voltage sags. A star-delta starter can help to reduce this starting current by 33%.

What is a K3 contactor?

Star contactor (K2) and Delta contactor (K3) are electrically interlocked using NC contacts, such that both contactors are never closed at a time. Additionally, they are also mechanically interlocked. This makes sure that the coil of K2 is energized only when K3 is open and the coil of K3 is energized only when K2 is open.

What happens to the K2 coil on a Star Delta timer?

After the time duration set on the star delta timer, the K2 coil is de-energized and K3 is energized and the motor runs in the delta configuration. When S0 is pressed or during overload trips or F1 fuse blown outs, the coils of the contactor K1 and K3 de-energizes and the motor stops.

How many contactors are in a star delta starter?

As mentioned earlier, apart from protection fuses (F1), overload relay (F2), the circuit consists of three contactors – a line or main contactor (K1), a delta connection contactor (K2), and a star connection contactor (K3). The terminals (U1, V1, W1) are connected to K1 through F2 & (U2, V2, W2) K2 and K3.

What happens when K1 is closed?

When connected K2 is closed, the phase voltage is applied across the motor terminals.

Is delta contactor transition more efficient than closed transition?

It is easier, cost-effective, and widely used than the closed transition starting.

How many volts does a wye motor have?

You are correct that in a wye motor each internal coil (or set of two coils in series for a dual volatage motor) will only have 277 volts across it, however that is what it is designed to run on. Each coil or set of coils in a delta wound motor is designed for 480 volts.

What is the reduction factor of a Wye start?

But when you bring all of the motor leads out to the connection box and connect them in Wye, you get the 1.73 reduction factor (58%) on effective voltage across the windings.

What is a 9 lead motor?

A 9-lead motor is actually a 12-lead motor with one connection point inaccessible. To switch a motor between wye and delta, you need all of the winding ends individually accessible, which means it will be a 6-lead, single-voltage motor, or a 12-lead, dual-voltage motor. C.

Is Delta vs Wye winding irrelevant?

Assuming you are in North America, don't get hung up on the "Delta vs Wye" winding issue, it is almost completely irrelevant. A NEMA designed motor is what it is, you usually have no way of knowing, short of dissection, whether it is wound in Delta or Wye internally, nor should you care. .

Is a NEMA motor a Wye?

A NEMA designed motor is what it is, you usually have no way of knowing, short of dissection, whether it is wound in Delta or Wye internally, nor should you care. Don't confuse this with Delta or Wye power systems, the issues are completely separate and not related as far as functionality goes.

Can windings be in series?

Looking at one side of the large triangle, say T1 to T4 and T7 to T2, each pair of windings can be in series or in parallel; in series for high volts, or in parallel for low volts. Either way, each winding receives its design voltage, thus current, thus power, thus its contribution to output horsepower.

Does Delta make a 9 lead motor?

Carl, they do make a nine lead, dual voltage, delta motor. Give me a few minutes and I'll draw the diagram amd post it.

Is 480 VAC a normal motor?

Normal for the U.S. (me anyway) 480 VAC 3ph, 9 lead motor. Internally lead #10, #11, & #12 are connected together, making it a Y motor. If this is normal, and it is in Y for run, why do we Start in Y and run in Delta?

Will Eng tips check this out?

The Eng-Tips staff will check this out and take appropriate action.