Aeration is an in-line point-of-entry process that reduces the concentration of volatile organic compounds. Aeration also removes dissolved gases such as hydrogen sulfide

Sulfide

Sulfide is an inorganic anion of sulfur with the chemical formula S²⁻ or a compound containing one or more S²⁻ ions. Solutions of sulfide salts are corrosive. Sulfide also refers to chemical compounds large families of inorganic and organic compounds, e.g. lead sulfide and dimethyl sulfid…

Full Answer

What to do after aerating your lawn?

What To Do After Aerating Lawn?

- Leave Soil Plugs To Degrade. Soil plugs will disperse throughout your yard using a core aerator. ...

- Time to Seed New Grass. A core aerator creates holes 5-7 cm wide and uniformly distributed. ...

- Use Weed Killer. The crabgrass preventers destroy plants as they grow. ...

- Fertilizer. ...

- Provide Enough Water. ...

What is the principle of aeration?

Principles And Functions Of Aeration. Aeration is a unit process in which air and water are brought into intimate contact. Turbulence increases the aeration of flowing streams. ADVANCED WATER TREATMENT. The effluent from a typical secondary treatment plant still contains 20-40 mg/L BOD which may be objectionable in some streams.

Why and when you should aerate your lawn?

Why Aerate Your Lawn?

- If you use your lawn as a playfield for children and pets, there is a considerable possibility of the soil becoming compacted and solid materials pressed into the ground during ...

- Does your lawn dry out and absolves water easily. ...

- Aeration is crucial if imported sod soil of finer texture lays over existing coarse soil. ...

What can aeration do in baking process?

Aerate. The process of allowing air to be combined into ingredients to make them lighter and/or create more volume, which may also be referred to as aeration. For example, sifting flour removes lumps and adds air making the resulting flour and typically the food dish using the flour, lighter in texture and consistency.

What is the purpose of aeration?

In industrial water conditioning, one of the major objectives of aeration is to remove carbon dioxide. Aeration is also used to oxidize soluble iron and manganese (found in many well waters) to insoluble precipitates. Aeration is often used to reduce the carbon dioxide liberated by a treatment process.

What are the method of aeration?

METHODS OF AERATION Passing water through air Passing air through water Water can be exposed to air by spraying or by distributing it in such a way that small particles or thin sheets of water come in contact with the air. Water can also aerated by pumping large volumes of air through the water.

What is aeration and its types?

Aeration The process of absorbing oxygen from air is known as aeration. (or) The process of bringing water and air into close contact in order to remove dissolved gases, such as carbon dioxide, and to oxidize dissolved metals such as iron. It can also be used to remove volatile organic chemicals (VOC) in the water.

What is aeration chemical process?

Aeration is a physical treatment process used for taste and odour control and for removal of dissolved iron and manganese. It consists of spraying water into the air or cascading it downward through stacks of perforated trays.

What are the three types of aeration?

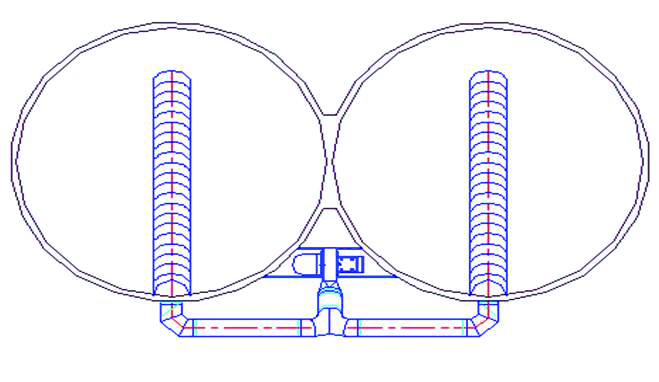

The three types of aeration devices in home usage are packed tower aerators, multi-stage diffused bubble aerators, and spray aerators.Packed tower aerator.Diffused-bubble aerator.Spray aerator.

Which is most common method used in aeration process?

Cascade aerators can be used to oxidize iron and to partially reduce dissolved gases. They are the oldest and most common type of aerators. Cone aerators are used primarily to oxidize iron and manganese from the ferrous state to the ferric state prior to filtration.

What are the 5 types of aeration?

Most common aeration typesFigure 1. Positive pressure aeration system.Figure 2. Negative pressure aeration system.Figure 3. Pull-up aeration system.Figure 4. Push-Pull aeration system.Figure 5. Manifold aeration system on two bins.Figure 6. Cross flow aeration system.Figure 7.

What is the unit of aeration?

The Aeration Unit, "PEAI", allows the study of the oxygen transfer characteristics of diffused air systems and the physical and chemical parameters which influence oxygenation capacity and demonstrates the water aeration process which, mainly, eliminates smell and taste from water.

What is the best type of aeration?

We did a deep dive into the specifications, features, and customer reviews for each of the products below.BEST OVERALL: Brinly PA-40BH Tow Behind Plug Aerator.RUNNER UP: Agri-Fab 45-0544 40-Inch Spike Aerator.BEST BANG FOR THE BUCK: Gardzen Plug Aeration, Hand Hollow Tine Lawn Aerator.More items...•

What is removed by aeration?

Aeration brings water and air in close contact in order to remove dissolved gases (such as carbon dioxide) and oxidizes dissolved metals such as iron, hydrogen sulfide, and volatile organic chemicals (VOCs). Aeration is often the first major process at the treatment plant.

Why does aeration tank increase pH?

Vigorous sulfate reduction at or before the aeration tank may have contributed to the high pH above 7.7, because one of the products from sulfate reduction is HCO3-, and it may buffer pH to higher values of 7.5~8.0. Stripping CO2 can also be a cause of increasing pH if CO2 is supersaturated in the water.

Which of the following are methods of aeration Mcq?

Explanation: There are four types of aerators. They are gravity aerators, spray aerators, diffused air aeration systems and mechanical aerators.

Which follwing method is aeration?

Methods. Aeration of liquids (usually water) is achieved by: passing air through the liquid by means of the Venturi tube, aeration turbines or compressed air which can be combined with diffuser(s) air stone(s), as well as fine bubble diffusers, coarse bubble diffusers or linear aeration tubing.

What is aeration in agriculture?

What Is Soil Aeration? The process of soil aeration provides air supply underground by moving O2 and CO2 between the earth pores and the atmosphere. It helps avoid oxygen starvation in crops and reduce harmful carbon dioxide levels in the subsurface air if they rise too high.

What is the process of aeration?

Aeration: This water aeration process is used for water bodies that suffer from anoxic conditions, usually caused by adjacent human activities such as sewage discharges, agricultural runoff, or overbaiting a fishing lake. Aeration can be achieved through the infusion of air into the bottom of the lake, lagoon, or pond or by surface agitation from a fountain or spray-like device to allow for oxygen exchange at the surface and the release of noxious gasses such as carbon dioxide, methane, or hydrogen sulfide.

How does aeration work?

Aeration can be achieved through the infusion of air into the bottom of the lake, lagoon, or pond or by surface agitation from a fountain or spray-like device to allow for oxygen exchange at the surface and the release of noxious gasses such as carbon dioxide, methane, or hydrogen sulfide.

How much energy does aeration consume?

The aeration process may be considered a major part of total energy demand and operational costs. The energy consumption of aeration in MBRs in a normal wastewater treatment plant is about 0.4 kWh/m3 effluent whereas in CASPs it is in the range of 0.25–0.40 kWh/m 3 ( Krause, 2005 ). Fouling control is another main part of energy consumption. The cost of chemical cleaning, regardless of the energy demand, is about 0.2–1.0 €/m 2 membrane surface area per year ( Li et al., 2008 ). Based on a biological activated sludge model study of the Schilde MBR, the energy consumption of the entire MBR is 0.63 kWh/m 3 with a yearly average permeate production of 220 m 3 /h. Therefore, the energy cost can be determined as 220 m 3 /h × 24 h/d × 365 d/yr × 0.63 kWh/m 3 × 0.08 €/kW = 97,130 €/yr. In this evaluation, the energy consumption for coarse bubble aeration, compressors, warming of the permeate for cleaning, mixing energy, and pretreatment are 35.2%, 3.1%, 6.6%, 7.0%, and 2.6%, respectively, for a total of 54.0% of the total energy when the system is operated at 220 m 3 /h ( Greenlee, Lawler, Freeman, Marrot, & Moulin, 2009 ). Blastakova et al. (2009) reported that with the Nordkanal wastewater treatment plant at full capacity, specific energy consumption ranges between 0.4 and 0.8 kWh/m 3 wastewater. On average, the energy demands of membrane air scouring, process aeration, bioreactor mixing, permeate suction, and biomass circulation are 49%, 12.1%, 11.5%, 2.7%, and 1.3%, respectively. The remaining 23.2% is consumed by pumping stations, pretreatment, dewatering units, and miscellaneous process units ( Blastakova et al., 2009; Judd, 2011 ).

How are extended aeration plants used?

The effluent may be comminuted (i.e. passed through a device which consists of a rotating knife-edge drum which acts both as a filter and a cutter) or simply passed through a bar screen from where it passes into the first chamber. Air is supplied to this chamber via a diffuser which breaks the air up into fine bubbles. The air is forced through the diffuser by a compressor. After a while a biological sludge is formed and this is dispersed throughout the tank by the agitation caused by the rising air bubbles.

How does aeration affect PMRs?

In PMRs with PMs, concentration polarization and fouling could be swept away by unstable flows and bubbles that are produced by aeration. Mass transfer enhancement and light attenuation by bubble clouds due to increasing aeration rate are two competing factors that limit the aeration process and must be adjusted and optimized to yield the greatest photocatalytic efficiency (Chin et al., 2007 ). Although aeration significantly mitigates membrane fouling and avoid serious flux reduction in PMRs, the complicated influence of bubbles and high-energy consumptions are its development bottlenecks and drawbacks ( Zhang et al., 2016 ). Therefore more investigation is necessary for industrial aeration processes in PMRs in the future.

How long does it take for a marine aeration tank to desludge?

Most marine biological waste treatment plants are designed to be desludged at intervals of about three months. The desludging operation entails pumping out about three quarters of the aeration tank contents and refilling with clean water.

How does a sewage plant work?

Basically this consists of oxygenating by bubbling air through or by agitating the surface. By so doing a family of bacteria is propagated which thrives on the oxygen content and digests the sewage to produce an innocuous sludge. In order to exist, the bacteria need a continuing supply of oxygen from the air and sewage wastes. If plant is shut down or bypassed or if the air supply fails, the bacteria die and the plant cannot function correctly until a new bacteria colony is generated. Change of flushing liquid—as when a ship moves from a sea-water environment to fresh water—drastic change of temperature or excess use of lavatory cleaning agents can also affect the bacteria colony. The process of regeneration can take several days depending on the level of harm caused.

Why is aeration important?

It is also important to ensure that nutrients can reach the soil beneath your grass. Aeration can be an extremely vital element to a healthy lawn because it allows air and water to penetrate built-up grass or lawn thatch. Get rid of thatch and make way for a beautiful lawn with this quick guide to aeration.

How does aeration help grass?

Aeration involves perforating the soil with small holes to allow air, water and nutrients to penetrate the grass roots. This helps the roots grow deeply and produce a stronger, more vigorous lawn.

What is the best way to aerate a lawn?

Two main aerating tools exist — a spike aerator and a plug aerator. With a spike aerator, you simply use the tool to poke holes into the ground with a solid tine, or fork. Plug aerators remove a core or plug of grass and soil from the lawn. For the best results, use an aerating tool or machine that actually removes plugs of soil. Poking holes is less effective and can actually cause additional compaction in the areas around the holes.

What is soil layering?

Soil layering means that soil of finer texture, which comes with imported sod, is layered over the existing coarser soil. This layering disrupts drainage, as water is held in the finer-textured soil. This leads to compacted conditions and poor root development.

Does aeration kill crabgrass?

This is not true — research shows that aeration will not affect crabgrass control or weed prevention. After aerating, it's important to continue basic lawn care practices such as proper fertilizing, ...

Do aeration machines cover a small percentage of the surface of the soil?

Most aeration machines cover only a small percentage of soil surface per pass, so make multiple passes over the most compacted areas. Save resources (and your energy) by leaving unaffected areas alone. The excavated soil plugs should be allowed to dry and then broken up to give your lawn a uniform, clean appearance.

Is aeration good for lawns?

Aeration is a beneficial practice toward achieving a beautiful lawn, but most people don't realize it or understand the process. If your lawn is a candidate, make it an integral part of your lawn care regime. Your lawn will thank you for letting it breathe again.

What is the purpose of aeration?

Its purpose is to keep stored grain cool to ensure minimise the risk of insect infestation and/or mould. This process is managed via silo aeration systems.

Why is aeration important?

The benefits of aeration? Protecting the quality and ensuring the longevity of your stored grain is critical to your bottom-line. Grain maintains its optimal condition if it is stored in an environment that is cool, low in moisture, low in insect activity and also low in mould activity.

What is the purpose of mechanical aeration?

In this method the surface of sewage is agitated violently with the help of some mechanical equipment to encourage absorption of oxygen from atmosphere. There are two well known forms of mechanical aerator. Vertical surface aerator and Horizontal surface aerator.

How many methods of aeration are there in the activated sludge process?

There are three methods for aeration in activated sludge process.

What is the process of absorbing oxygen from air called?

The process of absorbing oxygen from air is known as aeration. High amount of O 2 is provided in the aeration tank because of high BOD in sewage. This cannot be provided naturally therefore aerators are used to provide O 2 artificially.

Where is the aeration plate located in a sewage tank?

The aeration of sewage is done by air diffusers as well as mechanical aerators. Air diffuser plates are located at the bottom of tank and the submerged paddles rotate in the direction opposite to that in which the compressed air rises up from the air diffusers.

How does a perforated tube work?

It consists of a perforated tube suspended in the waste water near the bottom and can be taken out while cleaning. The compressed air is dent through the tube. The air comes out through the holes with great force and agitates the sewage.

What Is Lawn Aeration?

Providing much-needed lawn aeration for your grass entails dealing with thatch—which, along with compacted soil (see below), lies at the heart of the matter. 1

What is the basic idea behind lawn aeration?

The basic idea behind lawn aeration is that, like you, your lawn and the soil under it need to breathe. But how do you accomplish this? And when should you aerate your grass? These are issues I address in this article.

When is the best time to aerate lawns?

But for lawns planted with cool-season grasses (such as Kentucky bluegrass), early spring or fall is the best time for core aeration. You can easily rent a lawn core aerator from a big box store or rental center.

How deep should a lawn aerator be?

This lawn aeration equipment will pull plugs, or "cores" (thus the name) of soil out of the ground, letting air in. 1 These plugs should be two to three inches in depth. Such a plug should be pulled out of the lawn at about every three inches.