TYPES OF AGGREGATE

- [1] GRAVEL. Gravel or Graded stone, is another coarse aggregate suitable for concrete mixes. ...

- [2] SAND. Sand is the finest aggregate. ...

- [3] GRANITE. Granite is a types of felsic intrusive igneous rock that is granular and phaneritic in texture. ...

- [4] CRUSHED STONE. ...

- [5] RECYCLE CONCRETE. ...

- [6] VERMICULITE AGGREGATE. ...

- [7] GLASS AGGREGATE. ...

- [8] SLAG AGGREGATE. ...

How does coarse aggregate affect mix design of concrete?

Surface moisture of aggregates affects the following concrete properties:

- Mix-design of concrete.

- soundness of concrete.

- strength/abrasion resistance.

What does aggregate mean in concrete?

- 3/4 of the clear spacing between rebar or between rebar and forms (cover distance)

- 1/3 the depth of the slab

- 1/5 the narrowest dimension of a member

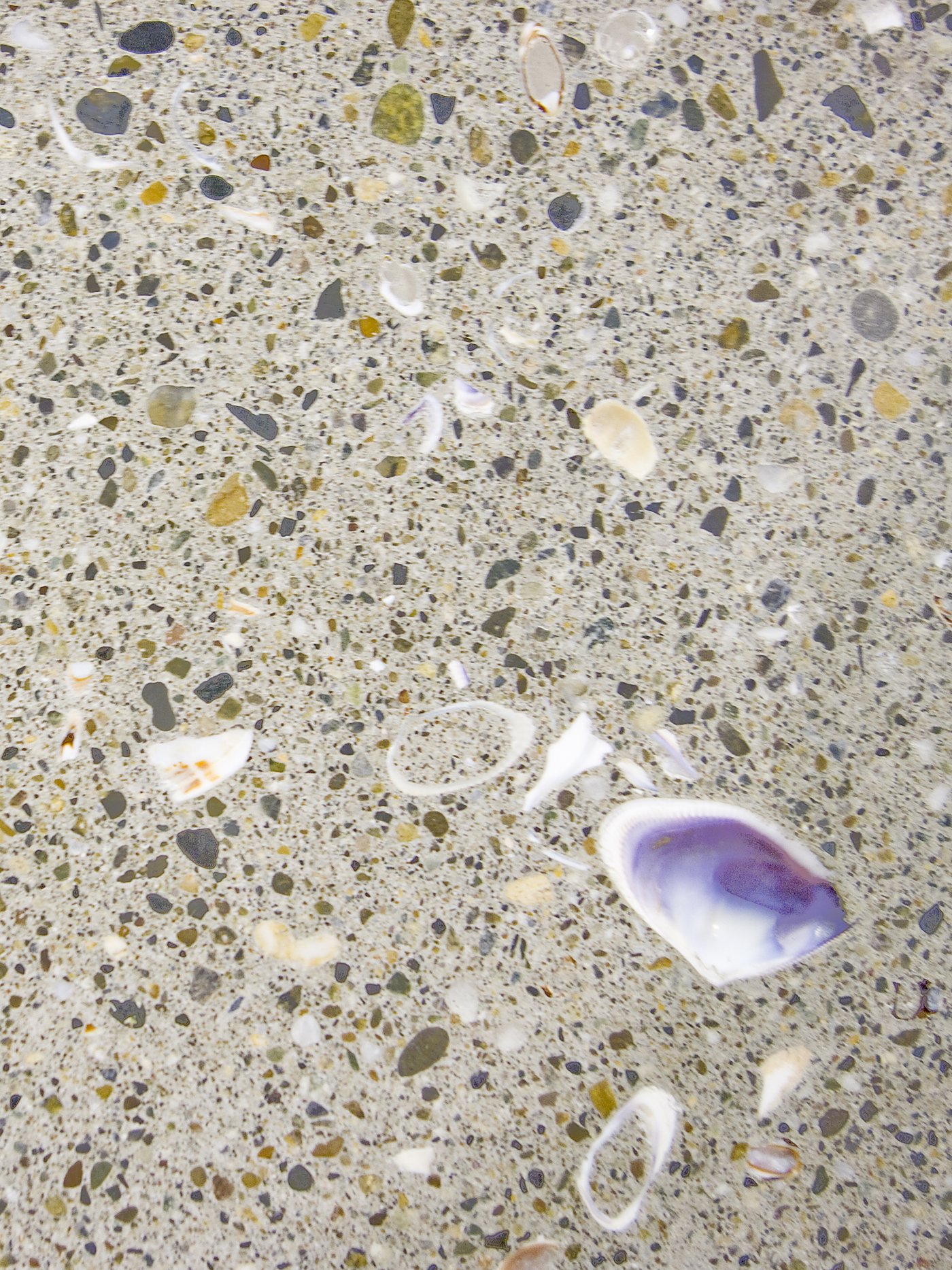

What are the different types of exposed aggregate concrete?

What are the different types of concrete finishes?

- Troweled Finish. Trowel finish is the most common and popular finish of concrete used for major types of applications.

- Broom Finish.

- Stamped Concrete Finish.

- Salt Finish.

- Exposed Aggregate Finish.

- Swirl Finish.

- Polished Finish.

- Colored Finish.

What is lightweight aggregate concrete and its uses?

Uses of Lightweight Aggregate Concrete

- Screeds and thickening for general purposes especially when such screeds or thickening and weight to floors roofs and other structural members.

- Screeds and walls where timber has to be attached by nailing.

- Casting structural steel to protect its against fire and corrosion or as a covering for architectural purposes.

- Heat insulation on roofs.

What is mix aggregate?

'Aggregate' is a term for any particulate material. It includes gravel, crushed stone, sand, slag, recycled concrete and geosynthetic aggregates. Aggregate may be natural, manufactured or recycled. Aggregates make up some 60 -80% of the concrete mix.

What are the 4 main types of aggregates?

The most common types of aggregate that are used in landscaping include: crushed stone, gravel, sand, and fill. Varying in material and stone size, each type can have its own purpose when it comes to landscaping projects.

Do I need aggregate in cement?

Aggregate is also very important for strength, thermal and elastic properties of concrete, dimensional stability and volume stability. Cement is more likely to be affected by shrinkage. Including aggregate in the mix can control the shrinkage level and prevent cracking.

Is aggregate the same as cement?

Although the terms cement and concrete are often used interchangeably, cement is actually an ingredient of concrete. Concrete is basically a mixture of aggregates and paste. The aggregates are sand and gravel or crushed stone; the paste is water and portland cement. Concrete gets stronger as it gets older.

Why is aggregate used in concrete?

Aggregate materials help to make concrete mixes more compact. They also decrease the consumption of cement and water and contribute to the mechanical strength of the concrete, making them an indispensable ingredient in the construction and maintenance of rigid structures.

What is the best aggregate for concrete?

GravelGravel or broken stone aggregates with rough and non-glassy texture are the best aggregates because they create a good bond with the cement paste. Aggregates need to be hard, strong, chemically inert, and non-porous. Organic substances and dirt coating compromise the strength and durability of concrete.

Does aggregate make concrete stronger?

Aggregates make up 60-80% of the volume of concrete and 70-85% of the mass of concrete. Aggregate is also very important for strength, thermal and elastic properties of concrete, dimensional stability and volume stability. Cement is more likely to be affected by shrinkage.

What is aggregate used for?

Aggregates are the most basic material used in construction. They provide the foundation for roads, bridges, and buildings, while also making up over 90% of an asphalt pavement and up to 80% of a concrete mix. On average, 38,000 tons of aggregates are necessary to construct one lane mile of interstate highway.

Does adding more cement make concrete stronger?

Concrete is rated on a system that indicates the strength of the mix after it's cured for approximately a month. To make the concrete stronger, add more cement or less sand. The closer you bring the ratio to an even one-to-one of sand to cement, the stronger the rating becomes.

How do you make an aggregate?

Add together all the numbers in the group. In the example, 45 plus 30 plus 10 equals an aggregate score of 95.

Which size of aggregate is used in concrete?

Generally the 9.5-37.5 mm diameter range aggregate are used in RCC concrete work. But Maximum size of aggregate generally on site used are 40 mm.

Is aggregate expensive?

Comparing the two, aggregate is more affordable as it is usually at the lower end of the pricing range. Stamping is not expensive, but using aggregate concrete is more economical, especially if you have a larger project. Typically, stamped concrete starts at $120 while an exposed aggregate finish is around $100.

What are the different types of aggregates?

According to American Concrete Institute, there are five categories of shape that describe concrete aggregates: angular, rounded, flaky, elongated and flaky/elongated. Aggregates with a round shape, such as sand and gravel from beaches or rivers, typically have a low percentage of void spacing and a low surface-to-volume ratio. Rounded aggregates demand less cement paste to produce a workable mix due to a reduction in frictional resistance. However, rounded aggregates are not typically considered suitable for high-strength concrete designs because of their poor interlocking behavior and weaker bond strengths.

What are the physical properties of aggregate?

Physical properties of aggregate such as size, shape and texture have a large impact on the strength, durability and workability of concrete . Pictured is Frank Bowen, director of quality assurance at Piedmont Precast in Atlanta, Ga. Photo courtesy of Frank Bowen

What is flaky aggregate?

The types of aggregates considered unsuitable for concrete mixing are flaky, elongated or a combination of both. Flaky aggregates tend to be aligned in one plane, thereby causing issues with concrete durability. Aggregates are considered flaky when the smallest dimension of the aggregate is less than the 60% of its mean dimension. That is, when the thickness of the aggregate is compared with its length and width. Slate is an example of a flaky aggregate. When the length of aggregate is greater than 180% of its mean dimension (thickness and width combined), then it is considered elongated. Aggregate is deemed flaky and elongated when it satisfies both the previously mentioned conditions. Elongated or flaky particles exceeding 15% should be considered unsuitable for concrete use.

Why are angular aggregates preferred?

Angular aggregates are preferred for manufacturing high-strength concrete because of an improved bond between the aggregate and paste.

Why are rounded aggregates not suitable for high strength concrete?

However, rounded aggregates are not typically considered suitable for high-strength concrete designs because of their poor interlocking behavior and weaker bond strengths.

Why is it important to grade coarse aggregate?

Proper grading of coarse aggregates is important to achieve dense and interconnected packing. The voids left by larger particles are filled by smaller particles, thereby reducing the possibility of segregation and improving the ability to compact the concrete.

Can crushed stone be used to segregate?

Crushed stone is less likely to segregate during handling and placing, but may require an increased use of admixture dosages to achieve the desired slump or spread. When using angular aggregates, it is also important to know that more air may be entrapped in the fresh concrete during mixing and placing.

What is the purpose of aggregate in concrete?

Aggregate provides much of the strength, thermal and elastic properties of concrete, as well as dimension and volume stability. Including aggregate in the mix can also control shrinkage and prevent cracking.

What is aggregate?

Aggregate is a collection of inert granular material that comprises as much as 60% to 80% of a typical concrete mix. There are many different types of aggregate commonly found in concrete. These include:

What is concrete made of?

In its simplest form, concrete is the combination of cement and aggregate. The cement is added to the aggregate in its fluid form. As the cement hardens, it binds with the aggregates to produce an extremely tough and resilient material we know as concrete. But what is aggregate exactly?

What is aggregate gradation?

Aggregate gradation is a method of utilising all available space within the concrete. Aggregate grades determine how dense or sparse the aggregate is. There are three typical gradings given to aggregates. These are:

Can you mix concrete on site?

Order and we’ll deliver your ready-mix concrete straight to your door. Alternatively, take advantage of our on-site-mixed concrete service. We’ll travel to you and mix your concrete on site. This ensures you get a fresh batch mixed to the exact proportions you need.

Is concrete graded well or poorly?

The more closely packed the particles of the aggregate are, the greater its strength and therefore the greater the strength of the concrete. Poorly-graded concretes require excessive amounts of cement paste to fill the voids. Well-graded aggregate is best, however, aggregates graded to maximum density can give the concrete a harsh texture.

What percentage of concrete is aggregate?

Aggregates, which account for 60 to 75 percent of the total volume of concrete, are divided into two distinct categories--fine and coarse. Fine aggregates generally consist of natural sand or crushed stone with most particles passing through a 3/8-inch sieve.

What is the most common type of aggregate used in concrete?

Gravels constitute the majority of coarse aggregate used in concrete with crushed stone making up most of the remainder. Natural gravel and sand are usually dug or dredged from a pit, river, lake, or seabed. Crushed aggregate is produced by crushing quarry rock, boulders, cobbles, or large-size gravel. Recycled concrete is a viable source of ...

What are the properties of freshly mixed concrete?

Particle shape and surface texture influence the properties of freshly mixed concrete more than the properties of hardened concrete. Rough-textured, angular, and elongated particles require more water to produce workable concrete than smooth, rounded compact aggregate. Consequently, the cement content must also be increased to maintain the water-cement ratio. Generally, flat and elongated particles are avoided or are limited to about 15 percent by weight of the total aggregate. Unit-weight measures the volume that graded aggregate and the voids between them will occupy in concrete.

What are the properties of concrete?

Aggregates strongly influence concrete's freshly mixed and hardened properties, mixture proportions, and economy. Consequently, selection of aggregates is an important process. Although some variation in aggregate properties is expected, characteristics that are considered include: 1 grading 2 durability 3 particle shape and surface texture 4 abrasion and skid resistance 5 unit weights and voids 6 absorption and surface moisture

What is the best material to mix with concrete?

Aggregates. Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and portland cement, are an essential ingredient in concrete. For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials ...

Why is moisture measured when selecting aggregate?

Absorption and surface moisture of aggregate are measured when selecting aggregate because the internal structure of aggregate is made up of solid material and voids that may or may not contain water. The amount of water in the concrete mixture must be adjusted to include the moisture conditions of the aggregate.

How do aggregates affect concrete?

Aggregates strongly influence concrete's freshly mixed and hardened properties, mixture proportions, and economy. Consequently, selection of aggregates is an important process. Although some variation in aggregate properties is expected, characteristics that are considered include:

Aggregate Proportions in Concrete

Aggregate comprises a majority of all concrete mixes. While the percentage can differ among products and concrete providers, aggregate in concrete usually comprises 60% and 75% of the mix. The rest of the mix will contain about 10% cement, 15% water and about 5% entrained air.

Concrete Aggregate Types and Qualities

To achieve a good concrete mix, the chosen aggregate must be hard, clean particles free of clay coatings and absorbed chemicals. If these variables are accounted for, then you can trust that you’ll achieve a good concrete mix based on the properties of your chosen aggregate.

Aggregate Shape and Size

The shape and size of aggregate will impact the characteristics of the concrete consisting of it. It’s important to note the effect of aggregate size on concrete strength. For instance, when comparing 10mm vs. 20mm aggregate in concrete, the smaller size will yield the strongest concrete.

Get Aggregate From Union Quarries

Union Quarries is your destination for aggregate. Since 1961, we have been providing Central Pennsylvania and surrounding counties with high-quality aggregate. Whatever your project, we have the aggregate materials to help you get the job done.

Is exposed aggregate resurfacing?

Going for the natural look never gets out of style. For a long time now, the exposed aggregate finish has been resurfacing among many properties. Outdoor surfacing is where one often finds this look.

Can you use stamped concrete on outdoor surfaces?

Of course, if you want an alternative, stamped concrete is also a popular option for outdoor surfaces.

Can you seed gravel over concrete?

An expert installer can use a shovel to seed in the gravel mix. Or, they can opt to use their hands. What is vital in this step is to avoid clumping of the aggregates.

What is coarse aggregate?

Coarse aggregate is one of the essential components of concrete and occupies the largest volume in the mix. That is why it greatly affects the concrete mix design. Its properties such as strength, maximum size, shape, and water absorption influence water demand, the quantity of cement and fine aggregate in concrete mixture.

What is aggregate absorption?

Aggregate absorption is used for applying a correction factor for aggregates in dry condition and determining water demand for concrete in saturated surface dry condition. Aggregate can absorb water up to 2 % by weight when in bone dry state. However, in some cases, the aggregate absorption can be as high as 5%.

What happens to the surface area of coarse aggregate?

As the maximum size of coarse aggregate reduces, surface area of coarse aggregate increases. Higher the surface area, greater is the water demand to coat the particles and generate workability.

Why is grading of coarse aggregate important?

The grading of coarse aggregate is important to get cohesive and dense concrete. The voids left by larger coarse aggregate particles are filled by smaller coarse aggregate particles. Proper grading of coarse aggregate can minimize ...

Why is 40mm down aggregate better than 20mm down?

So, for the same workability, 40mm down aggregate would have lower water/cement ratio, thus higher strength when compared to 20mm down aggregate. Because of its lower water demand, advantage of higher maximum size of coarse aggregate can be taken to lower the cement consumption.

Does higher aggregate strength increase concrete strength?

As far as strength is concerned, higher aggregate strength would produce higher concrete strength provided that other controlling factors have been dealt with properly.

Is coarse aggregate good for concrete?

However, angular coarse aggregate is desired in the case of high strength concrete. This possibility of segregation is minimized if coarser aggregate is properly graded. This explains how important is good grading for concrete mix design.

What mix to use for concrete?

For very small projects, such as setting a mailbox post or doing repairs, you may want to purchase a packaged concrete mix. Such a mix combines cement, sand, and gravel in the correct mixing ratios and requires only the addition of water to create fresh concrete.

What is the best mix for concrete?

When making your own concrete it's important to use the correct concrete mixing ratios to produce a strong, durable concrete mix. To make concrete there are four basic materials you need: Portland cement, sand, aggregate (stone), and water. The ratio of aggregate to sand to cement is an important factor in determining the compressive strength ...

How much cement is needed to make 4000 PSI?

To produce a cubic yard of 4000 psi concrete, you have to adjust the concrete mixing ratio to: 611 pounds of cement or (277kg) 1450 pounds of sand or (657kg) 1600 pounds of stone or (725kg) 33- 35 gallons of water or (133L) As you can see a little more cement and a little less sand is required to produce this stronger concrete mix ...

How much cement is needed for 1 cubic meter of concrete?

Or... 1 cubic meter of concrete will require approximately 7.15 bags of Portland cement, .48 cubic meters of sand, and .51 cubic meters of gravel.

How to make smaller batches of concrete?

To make smaller batches of concrete, use the same proportions, but with smaller quantities, substituting buckets for cubic feet. (For the mix proportions given previously, you'd use 1 bucket of cement, 3 buckets of sand, 3 buckets of stone, and 1/2 bucket of water.) For any batch size, the most important thing is to keep the proportions ...

What is concrete edging?

Concrete edging for your lawn or garden. For very small projects, such as setting a mailbox post or doing repairs, you may want to purchase a packaged concrete mix. Such a mix combines cement, sand, and gravel in the correct mixing ratios and requires only the addition of water to create fresh concrete.

How much cement is in 1:3:3?

A 1:3:3 mixing ratio calculates to 115 lbs of cement to 343 lbs of sand and 343 lbs of stone. (Rounded off)