Why choose elcometer for your test needs?

With a range of products specifically developed to meet the needs of the protective coatings industry, industrial finishing industry, non-destructive test (NDT) industry, Elcometer is well positioned to provide you with the solution to your inspection and physcial test requirements, whatever and wherever they might be.

What's new at elcometer?

In 2018, Elcometer expanded its product range to include blast equipment. Developed alongside Elcometer’s sister company, Blast Equipment Limited (BEL), the range is the culmination of over 35 years of design, manufacture, sales, and service of portable abrasive blast machines (ABMs) globally. In 2021 Elcometer acquired Sagola.

What is elcometer 101?

In 1947, Elcometer launched one of the world’s first non-destructive coating thickness gauges, the Elcometer 101. For more than 6 decades, the design and production qualities of this rugged and reliable instrument have been the watchwords for all our products and these philosophies are still held today.

Does elcometer comply with national and international standards?

All Elcometer products are designed to comply with National and International Standards. We have a team of experts working with Standards bodies around the world, ensuring we have products fit for purpose, exceeding the demands of our customers. We continuously review our products against current and new Standards.

How does paint meter work?

They use a constant-pressure magnetic probe and eddy currents to provide consistent readings shown on a liquid crystal display. Accuracy is typically plus or minus 1 to 3 per cent. Electronic paint gauges sell for $350 to $1,000.

What is used to measure paint thickness?

Ultrasonic paint thickness gauges can measure the thickness of coatings on nonmetallic substrates. The probe of the paint meter contains an ultrasonic transducer that sends a pulse through the coating.

How do I use my elcometer 456?

3:595:19Using the Auto Calibration feature of the Elcometer 456 Coating ...YouTubeStart of suggested clipEnd of suggested clipSimply press the escape soft key and start again after 3 readings the gauge automatically adjustsMoreSimply press the escape soft key and start again after 3 readings the gauge automatically adjusts the average to the predefined high you value you entered.

How do you use a DFT meter?

0:040:35How to Use A Dry Film Paint Thickness Gauge For Paint - YouTubeYouTubeStart of suggested clipEnd of suggested clipVery quickly and accurately simply turn the gauge on place the probe on the surface of the coating.MoreVery quickly and accurately simply turn the gauge on place the probe on the surface of the coating. You would like to measure and the screen will show you the thickness of the coatings.

What does DFT mean in paint?

Dry film thicknessDry film thickness (DFT) or coating thickness is arguably the single most important measurement made during the application and inspection of protective coatings. Coatings are designed to perform their intended function when applied within the DFT range as specified by the manufacturer.

What is DFT and WFT in painting?

Dry film thickness, or DFT is a measurement of the dry and cured material after all liquid has evaporated. DFT = WFT x % volume solids. For a 67% volume solids material with a WFT of 18 mils, DFT = 18 x 0.67 = 12 DFT. By simply reversing the equation DFT can also be measured to determine what the applied WFT was.

How do you calibrate coating thickness gauge?

2:325:25How to Calibrate the Elcometer 500 Coating Thickness Gauge - YouTubeYouTubeStart of suggested clipEnd of suggested clipSelect the one point calibration method from the I'll comments 500's calibration menu take aMoreSelect the one point calibration method from the I'll comments 500's calibration menu take a measurement of the coating at the same central point as the coating thickness gauge.

What is span calibration?

A span calibration involves delivering certified calibration gas of a known concentration to the monitor and monitoring the response to that concentration. An example might be delivering 10 ppm of carbon monoxide to the carbon monoxide sensor.

How do you check concrete DFT?

0:322:16How to take accurate DFT measurements on concrete with the ...YouTubeStart of suggested clipEnd of suggested clipTypically they use an ultrasonic. Sound pulse to determine the thickness of the coating. SometimesMoreTypically they use an ultrasonic. Sound pulse to determine the thickness of the coating. Sometimes the ultrasonic signal can be deflected or weakened by the substrate material or coating.

What is DFT measurement?

Dry film thickness (DFT) is the thickness of a coating as measured above the substrate. This can consist of a single layer or multiple layers. DFT is measured for cured coatings (after the coating dries). The thickness of a coating depends on the application and type of process employed.

How do you read a wet film thickness gauge?

0:231:54Wet Film Thickness Gauge Usage - YouTubeYouTubeStart of suggested clipEnd of suggested clipA thickness measured in mils to measure the wet film of a liquid is easy simply dip the wet filmMoreA thickness measured in mils to measure the wet film of a liquid is easy simply dip the wet film gauge into the liquid in several locations to determine the average.

How do you measure the thickness of paint on a wall?

1 AnswerV=area×height=25 m2⋅x m.1 gal=3.78×10−3 m3.V=25 m2⋅x m=3.78×10−3 m3 , dividing both sides by 25 gives the "height" (or thickness), x ,x=1.512×10−4 m=0.1512 mm.

What is paint measured in?

milsIn the U.S. the thickness of paint is expressed in mils (one mil equals 1/1000 of inch). The rest of the world expresses coating thickness in microns (1 micron = 1 millionth of a meter and 25.4 microns = . 001” inch or 1 mil).

How do you measure the thickness of wood paint?

2:475:35How to Measure Paint/Coating Thickness on Wood ... - YouTubeYouTubeStart of suggested clipEnd of suggested clipSimply clean the probe tip. Hold it in the air and select zero from the calibration menu unlikeMoreSimply clean the probe tip. Hold it in the air and select zero from the calibration menu unlike magnetic or eddy current gauges. There is no need to measure on the uncoated substrate.

What is a paint gauge?

Prerequisite: A paint thickness gauge (aka paint depth gauge) is used to measure the thickness of a vehicle's paint job to determine whether or not a car has received paintwork after it left the factory (either due to a prior accident, paint damage, etc).

What is Kolbe electrometer?

When charged the vane is repelled by the plate and hangs at an angle. An electrometer is an electrical instrument for measuring electric charge or electrical potential difference.

How does an electrometer measure current?

They measure voltage by means of "voltage balancing", in which the input voltage is compared with an internal reference voltage source using an electronic circuit with a very high input impedance (of the order of 10 14 ohms). A similar circuit modified to act as a current-to-voltage converter enables the instrument to measure currents as small as a few femtoamperes. Combined with an internal voltage source, the current measuring mode can be adapted to measure very high resistances, of the order of 10 17 ohms. Finally, by calculation from the known capacitance of the electrometer's input terminal, the instrument can measure very small electric charges, down to a small fraction of a picocoulomb.

What is the input resistance of an electrometer?

A modern electrometer is a highly sensitive electronic voltmeter whose input impedance is so high that the current flowing into it can be considered, for most practical purposes, to be zero. The actual value of input resistance for modern electronic electrometers is around 10 14 Ω, compared to around 10 10 Ω for nanovoltmeters. Owing to the extremely high input impedance, special design considerations must be applied to avoid leakage current such as driven shields and special insulation materials.

How does a vibrating reed electrometer work?

Vibrating reed electrometers use a variable capacitor formed between a moving electrode (in the form of a vibrating reed) and a fixed input electrode. As the distance between the two electrodes varies, the capacitance also varies and electric charge is forced in and out of the capacitor. The alternating current signal produced by the flow of this charge is amplified and used as an analogue for the DC voltage applied to the capacitor. The DC input resistance of the electrometer is determined solely by the leakage resistance of the capacitor, and is typically extremely high, (although its AC input impedance is lower).

What is the name of the device that records electricity?

Electricity readings may be recorded continuously with a device known as an electrograph. Francis Ronalds created an early electrograph around 1814 in which the changing electricity made a pattern in a rotating resin -coated plate. It was employed at Kew Observatory and the Royal Observatory, Greenwich in the 1840s to create records of variations in atmospheric electricity. In 1845, Ronalds invented photographic means of registering the atmospheric electricity. The photosensitive surface was pulled slowly past of the aperture diaphragm of the camera box, which also housed an electrometer, and captured ongoing movements of the electrometer indices as a trace. Kelvin used similar photographic means for his quadrant electrometer (see above) in the 1860s.

What is an early quadrant electrometer?

While the term "quadrant electrometer" eventually referred to Kelvin's version, this term was first used to describe a simpler device. It consists of an upright stem of wood, to which is affixed to a semicircle of ivory.

Who invented the Bohnenberger electrometer?

Bohnenberger electrometer. The Bohnenberger electrometer, developed by J. G. F. von Bohnenberger from an invention by T. G. B. Behrens, consists of a single gold leaf suspended vertically between the anode and cathode of a dry pile.

Where is Elcometer located?

In addition we operate local offices in France, The Netherlands, Germany, Singapore, Japan, the USA and the UAE. Elcometer also provides customers with a broad distributor network so there is bound to be a source of Elcometer products close by, wherever you are in the world.

When was the first elocometer gauge made?

Ever since the first Elcometer gauge was manufactures in 1947 , our philosophy has been to provide industry leading, innovative, high quality products; supported by a best-in-class customer experience at a competitive price. By concentrating on these core values, Elcometer has grown into a global network with representation in over 170 countries.

Is elocometer mercury free?

Elcometer is committed to reducing its impact on the environment, including product manufacture, packaging, catalogue production and our waste management. All our products are lead and mercury free and, where required, CE and RoHS compliant.

What is an elocometer?from elcometerusa.com

Elcometer is a leader in coating and concrete inspection equipment, rebar, and metal detection. With a range of products specifically developed to meet the needs of the coatings industry, Elcometer is well positioned to provide you with the solution to your inspection requirements - whatever and wherever they might be.

What is Elcomaster software?from elcometerusa.com

Our free software package, ElcoMaster® is the most flexible data management software on the market. Elcomaster® is designed to meet the demanding needs of the quality inspector while offering the ultimate flexibility for managing data into ‘projects’ for ease of use.

When was the first elocometer gauge made?from elcometerusa.com

Ever since the first Elcometer gauge was manufactured in 1947 , our philosophy has been to provide ‘best in class’ design, quality, and service at a competitive price.

What is ultrasonic gauge used for?from elcometer.com

Ultrasonic thickness gauges are used to accurately determine the thickness of a variety of materials.

What is an elocometer?

Elcometer is a leader in coating and concrete inspection equipment, rebar, and metal detection. With a range of products specifically developed to meet the needs of the coatings industry, Elcometer is well positioned to provide you with the solution to your inspection requirements - whatever and wherever they might be.

What is elocometer research?

Elcometer commits major resources to Research and Development. With departments in both the UK and US facilities, Elcometer is able to discover and explore new and exciting areas of product development. This culminates in the capability to offer products which exceed customer expectations.

What is Elcomaster software?

Our free software package, ElcoMaster® is the most flexible data management software on the market. Elcomaster® is designed to meet the demanding needs of the quality inspector while offering the ultimate flexibility for managing data into ‘projects’ for ease of use.

When was the first elocometer gauge made?

Ever since the first Elcometer gauge was manufactured in 1947 , our philosophy has been to provide ‘best in class’ design, quality, and service at a competitive price.

What is an elocometer?

The Elcometer range of mechanical coating thickness gauges provides cost-effective dry film thickness measurement. Mechanical Coating Thickness Gauges are suitable for working in high risk areas such as high temperature or flammable atmospheres, underwater or where the risk of explosion is high and could be triggered by the use of an electronic instrument.

What is the Elcometer 121/4?

The Elcometer range of destructive coating thickness gauges includes the Elcometer 121/4 Paint Inspection Gauge. The paint inspection gauge, commonly known as the P.I.G, is a popular method for determining dry film thicknesses on non-metallic substrates.

What is calibration of coating gauge?

Calibration is the process whereby manufacturers of a coating thickness gauge sets-up, during manufacture, to ensure that the gauge meets the required accuracy specification. The procedure normally requires the coating thickness gauge to be set to known values of thickness and checked on intermediate thickness values. In modern electronic instruments the values at key points across the coating thickness range are stored as reference points in the memory of the gauge.

How to test the accuracy of a coating gauge?

With the gauge adjusted to zero on an uncoated smooth substrate and set to a known thickness standard at or near to the maximum thickness, intermediate thickness standards are measured and the readings compared to the actual thickness of the standard. The errors are the differences between the values of the reading and the value of the standard. These are most conveniently expressed as a percentage of the reading.

How does coating gauge affect linearity?

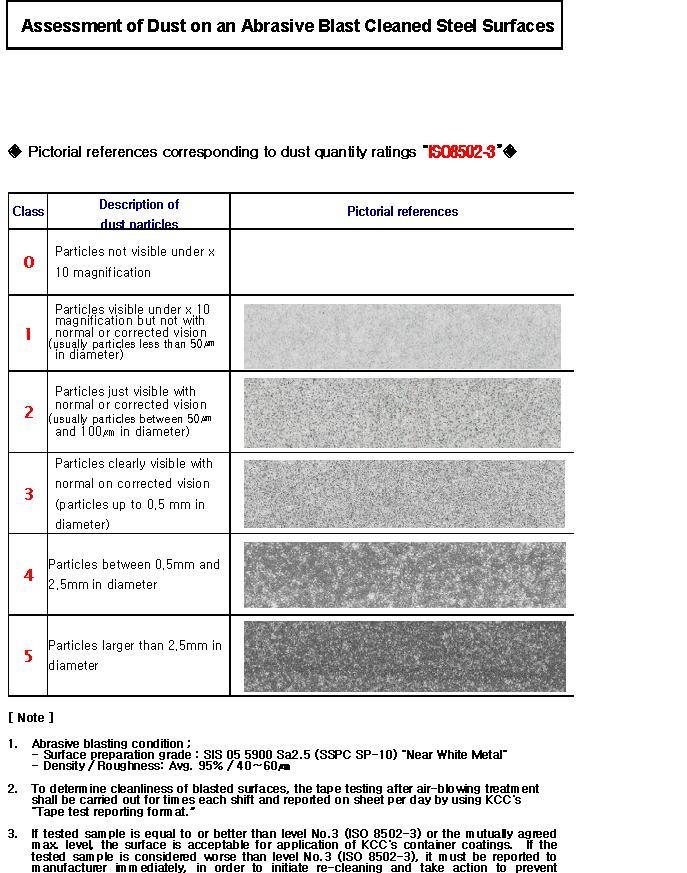

Calibration of coating thickness gauges will be affected by the type of material, the shape and the surface finish of the metal substrate to be tested. For example the magnetic properties of steel alloys vary and the conductivity of different aluminium alloys and different non-ferrous metals, copper, brass, stainless steel etc. also vary. These variations can affect the linearity of a coating thickness gauge. This means that a gauge set-up on mild steel for example will read a different value for the same thickness coating on high carbon steel. Similar linearity effects are seen on thin or curved substrates and particularly on profiled substrates such as blast cleaned steel used for structural steelworks.

How does a permanent magnet work?

A permanent magnet is mounted on a balanced arm and the force required to pull this magnet from the surface of the coating is a measure of the thickness of the coating . Force is applied through a helical spring attached to the balanced arm at one end and to a scale wheel at the other. As the scale wheel is turned the force is progressively increased until the magnet lifts from the surface. The scale is drawn in thickness units rather than force and the thickness of the coating can be read against a pointer on the case of the instrument.

What is an elcometer?

The Elcometer range of digital coating thickness gauges has been specifically designed to provide highly accurate, reliable and repeatable coating thickness measurements on almost any substrate , whether ferrous or non-ferrous.

How many readings per minute on Elcometer 500?

Taking over 60 readings per minute in standard mode and 140+ readings per minute in scan mode; the Elcometer 500 Coating Thickness Gauge allows users to inspect more coatings in less time. With a choice of intelligent, ergonomic probes, designed for continuous use and field replaceable probe tips you can inspect all day, everyday.

What is a ferrous paint meter?

The Ferrous paint meter is ideal for measuring coatings on steel body panels. The FNF paint meter enables the user to measure on both steel and aluminium panels using one gauge with automatic switching.

What is the signal strength indicator on a concrete gauge?

The built in signal strength indicator on the Elcometer 500 Coatings on Concrete Gauge prevents false or incorrect readings, as the gauge only displays the coating thickness measurement if the signal strength indicator goes green.

What is the thickness of Elcometer 415?

The New Elcometer 415 Industrial Paint and Powder Coating Thickness Gauge for Ferrous and Non-Ferrous Metal Substrates, 0-40 mils.

What model is the elocometer 456?

Beginning with Model E and ending with Model T , the Elcometer 456 is available in four different models. Learn more about the range of Elcometer 456 models by reading our Elcometer 456 model specifications page.

Is the Elcometer 456 interchangeable?

All Elcometer 456 probes are fully interchangeable and are available in a number of designs and scale ranges to meet your specific application.

Overview

An electrometer is an electrical instrument for measuring electric charge or electrical potential difference. There are many different types, ranging from historical handmade mechanical instruments to high-precision electronic devices. Modern electrometers based on vacuum tube or solid-state technology can be used to make voltage and charge measurements with very low leakag…

Historical electrometers

The gold-leaf electroscope was one of the instruments used to indicate electric charge. It is still used for science demonstrations but has been superseded in most applications by electronic measuring instruments. The instrument consists of two thin leaves of gold foil suspended from an electrode. When the electrode is charged by induction or by contact, the leaves acquire similar electr…

Modern electrometers

A modern electrometer is a highly sensitive electronic voltmeter whose input impedance is so high that the current flowing into it can be considered, for most practical purposes, to be zero. The actual value of input resistance for modern electronic electrometers is around 10 Ω, compared to around 10 Ω for nanovoltmeters. Owing to the extremely high input impedance, special design considerations (such as driven shields and special insulation materials) must be applied to avoid …

See also

• Electrical measurements

• Electron

• Electroscope

• Radiation

• Faraday cup electrometer

External links

• Build this FET electrometer - A very simple circuit - 2 components

• Simple FET electrometer - A simple bridged circuit

• An op-amp electrometer

• Early electrometers