What is ASME Section IX: ASME Section IX Code is set of rules, guidelines, and requirements for Welding, Brazing, and Fusing Qualifications. It is a reference code that helps for BPVC

ASME Boiler and Pressure Vessel Code

The ASME Boiler & Pressure Vessel Code is an American Society of Mechanical Engineers standard that regulates the design and construction of boilers and pressure vessels. The document is written and maintained by volunteers chosen for their technical expertise. The American Society of Mechanical Engineers works as an Accreditation Body and entitles independent third parties such as verification, testi…

See more

What does ASME Section IX cover?

Section IX specifies the requirements for the qualification of welders and the welding procedure specifications employed when welding in accordance with the ASME Boiler and Pressure Code, and the ASME B31 Code for Pressure Piping.

What is ASME IX?

ASME section IX is a part of the ASME boiler pressure vessel code that contains the rules for qualifying welding procedures and welders. It is also used to qualify welders and procedures for welding to ASME B31.

What is the difference between ASME and AWS?

The difference between ASME and AWS is that ASME is for welding procedure and welder qualification. AWS is for both welder and welding procedure qualification including inspection, erection and fabrication. Contracts may specify one or the other code.

What is the meaning of ASME in welding?

The American Society of Mechanical EngineersThe American Society of Mechanical Engineers (ASME) offers certifications and stamps to companies that produce boiler and pressure vessels. Whether you plan to work for a welding company or one day own your own, you'll learn about the process of obtaining ASME certification as a company in this article.

What is meant by ASME standards?

ASME is the leading international developer of codes and standards, hereafter referred to as standards, associated with the art, science, and practice of mechanical engineering. ASME is the globally recognized, trusted source of consensus standards since 1884.

How many ASME standards are there?

The 28 books are either standards that provide the rules for fabricating a component or they are support documents, such as Materials, Nondestructive Examination, and Welding and Brazing Qualifications.

What is a Class 1 weld?

A Class 1 weld is defined as a structural weld requiring the most stringent level of inspection. The determination of a Class 1 weld is the responsibility of the designer and shall be noted on the manufacturing drawings.

What does AWS mean in welding?

The American Welding SocietyThe American Welding Society (AWS) was founded in 1919, as a nonprofit organization with a global mission: “Advancing the science, technology, and application of welding and allied joining and cutting processes worldwide, including brazing, soldering and thermal spraying.” That is our mission and it's why we exist.

What is the meaning of WPS in welding?

Welding Procedure SpecificationWhat is a WPS? A Welding Procedure Specification, or WPS, is a document that serves as a guide for the effective creation of a weld that meets all applicable code requirements and production standards.

What is ASME welding test?

The ASME is a mechanical engineering association that certifies products that meet its standards. ASME offers several different types of certification: Boiler and Pressure Vessels. Nuclear Components. Reinforced Thermoset Plastic.

What is a Class 2 weld?

Class 2 material is a designation of the Resistance Welding Manufacturers Alliance (RWMA). This is a group of copper alloys with high strength and electrical conductivity. Class 2 is the most used material in the resistance welding industry. As electrodes it is used for welding bare and coated steels.

What is difference between API 1104 and ASME IX?

The one difference that stands out the most is API 1104 Table 3 which requires Nick-Break tests. ASME IX does not require nick-break tests. However, API 1104 6.6. 1 states that RT may be substituted for the required destructive tests.

What does ASME Section 1 cover?

Division 1 provides requirements applicable to the design, fabrication, inspection, testing, and certification of pressure vessels operating at either internal or external pressures exceeding 15 psig. Such vessels may be fired or unfired.

What is difference between WPS and PQR?

A WPS and PQR are required documents in the fabrication process when a weld must comply with a certain standard. In simple terms, a WPS is a set of welding instructions and the PQR is a checklist to ensure those instructions were satisfactorily met. The PQR document is created first and is needed to create the WPS.

What is ASME VIII?

ASME Section VIII is the section of the ASME Boiler & Pressure Vessel Code (BPVC) that covers pressure vessels. It specifically refers to the pressure vessels that operate at pressures, either internal or external, that exceed 15 psig.

What is ASME Section IV?

Although the rules of the ASME B&PV Code, Section IV constitute the minimum requirements for the safe design, construction, installation, and inspection of low-pressure-steam boilers and hotwater boilers (which are directly fired with oil, gas, electricity, or other solid or liquid fuels), they do not cover the ...

What is ASME Section IX in General?

So therefore, ASME BPVC Sec IX dictates rules and procedures on Qualification of:

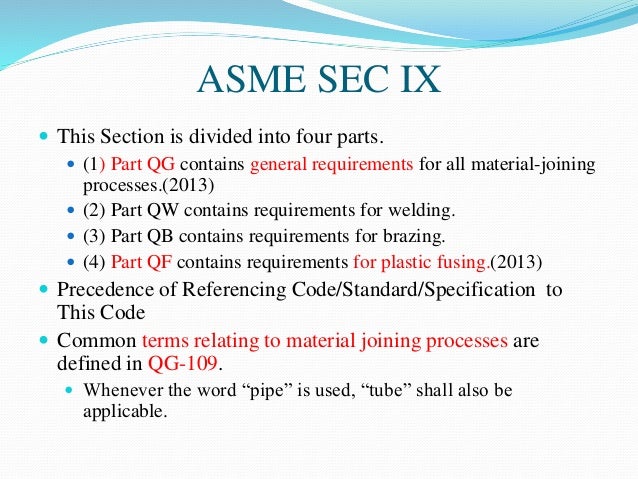

What is Part QG in ASME Section IX?

The QG part of the ASME Section IX gives general guidelines on all three section of code, the WPS, BPS and FPS (Welding, Brazing and Fusion Procedure Specifications), and their Qualifications.

What is the difference in AWS and ASME Section IX?

Whereas AWS in addition, includes, the inspection, erection, and fabrication requirements. The ASME Section IX covers all aspects of welding procedures and welder qualification. AWS codes also include the inspection, erection, and fabrication of welded fabrications used in buildings and other structures.

What is ASME section IX code?

ASME Section IX Code : It is reference code of Welding, Brazing and Fusing Qualification.

What are the Supplementary Variables?

Supplementary Variables : This Variables are related to Toughness Properties of Weld Properties of Weld Joints. Any Changes in this variables affect Toughness properties of Weld Joints so if you want to change any variables it needs to re-qualify Welding Procedure Specification (WPS). But this variables are applicable only if material required toughness properties.

Changes in Article II: Welding Procedure Qualifications

The following are the major changes that have been introduced in the 2021 edition, regarding procedure qualifications.

Changes in Article III: Welding Performance Qualifications

The following are the major changes that have been introduced in the 2021 edition, regarding performance qualifications.

Non-mandatory Appendix D Deleted

The Appendix D had contained a listing of materials, sorted P-number wise. All materials with one P-Number were bunched together. This was basically a regurgitation of QW 422, which is structured ‘SA’ specification wise. Same data was repeated at two places, and probably was only meant for easy reference of data.

How To Qualify A Welder In Accordance With Section IX?

A welder can be qualified in accordance with Section IX by welding on a test coupon, and subjecting it to the requisite testing. This article later covers the type of tests required for qualification of welders.

Why Should A Welder Be Qualified In Accordance With Section IX?

They are qualified in accordance with a national statutory standard. These welders do extensive welding on all kinds of challenging jobs, which makes me believe that they are fairly capable and qualified. Why do I need to qualify my welders as per ASME Section IX then?