Cell of a cross-flow type cooling tower with fill material, and circulating water visible An HVAC (heating, ventilating, and air conditioning) cooling tower is used to dispose of ("reject") unwanted heat from a chiller

Chiller

A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. This liquid can then be circulated through a heat exchanger to cool air or equipment as required. As a necessary byproduct, refrigeration creates waste heat that must be ex…

What are the principles of cooling tower?

Some important factors which is essential for cooling tower to cool the water:-

- Size and height of the cooling tower.

- Temperature of the air.

- Humidity of the air.

- Arrangements of plate in the cooling tower.

- Velocity of air entry of the cooling tower.

- Accessibility of air to all parts of the cooling tower.

What chemicals are in cooling tower?

Cooling Tower Chemicals

- Mud

- Dirt

- Corrosion

- Oily Matter

What is the difference between cooling tower and condenser?

Cooling Tower & Chiller Types

- Cooling Tower & Chiller Major Components. Cooling towers major components include the pumps and basin. ...

- Uses & Applications. Chillers are used in areas which will not be affected by the additional heat discharged by it. ...

- Efficient Power Consumption. Chillers use compressors and heat exchangers to cool and are not as energy efficient as cooling towers.

How to increase cooling tower efficiency?

How to increase cooling tower efficiency

- Cooling tower water treatment. Critical parameters and properties of circulating water that affect the cooling water systems are hardness, chloride, alkalinity, pH and temperature, as well as scaling indices.

- Scaling indexes for cooling tower water. ...

- Biological treatment for cooling towers. ...

- Reuse from wastewater streams. ...

- Summary. ...

What is cooling tower for?

Cooling towers are primarily used for heating, ventilation, and air conditioning (HVAC) and industrial purposes. Cooling towers provide a cost-effective and energy efficient operation of systems in need of cooling. More than 1,500 industrial facilities use large quantities of water to cool their plants 2.

What is cooling tower and how it works?

Cooling towers are essentially large boxes designed to maximize evaporation of water. To do this, they contain material, typically PVC plastic sheets, that create large surface areas for water evaporation to occur. This material is what fills the inside of the cooling tower and is called "Cooling Tower Fill".

What is cooling tower and types?

There are three main types of cooling towers that are defined by how water or air pass through them. These types include crossflow, counterflow, and hyperbolic. There are also two varieties classified solely on airflow, known as induced draft and passive draft cooling towers.

What are cooling towers called?

Heat transfer methods closed circuit cooling towers (also called fluid coolers) pass the working coolant through a large heat exchanger, usually a radiator, upon which clean water is sprayed and a fan-induced draft applied.

What is cooling tower in HVAC?

Cooling towers are heat exchangers that use water and air to transfer heat from air-conditioning systems to the outdoor environment. Most commonly, they are used to remove heat from the condenser water leaving a chiller.

What is chiller unit?

A chiller (cooling water circulation device) is a general term for a device that controls the temperature by circulating a liquid such as water or heat medium as a cooling liquid whose temperature was adjusted by the refrigerant cycle.

What is the pH of cooling tower water?

between 6.5 and 7.5If you have doubts about the proper pH levels for your tower water, ask your water treatment company for recommendations. A pH between 6.5 and 7.5 is generally considered the ideal range for reducing scale formation, though some non-acid treatments for scale prevention can increase the cooling tower pH range up to 8.5.

What are the components of the cooling tower?

Cooling tower componentsCooling tower packing. Cooling tower packing is one of the most important parts of a cooling tower. ... Drift separators. ... Gear and fans. ... Water distribution system. ... Air intake louvers.

Do cooling towers use refrigerant?

Cooling Tower water is circulated through a heat exchanger where refrigerant vapor is condensed and heat is transferred to the water. The purpose of the cooling towers is to cool the warm water returning from the heat exchanger so it can be reused.

What is the temperature of cooling tower?

A nominal cooling tower ton is defined as the capability to cool 3 GPM (0.19 lps) of water from a 95ºF (35.0ºC) entering water temperature to an 85ºF (29.4ºC) leaving water temperature at a 78ºF (25.6ºC) entering wet-bulb temperature.

How cooling towers are built?

They are often constructed as hyperboloid, doubly-curved concrete shell structures supported on a series of concrete struts. The foundations typically consist of an inclined pond wall forming a circular 'tee' beam with a wide concrete strip. The beam acts to resist the lateral load of the tower's shell structure.

What is condenser water?

A water-cooled condenser is a heat exchanger that removes heat from refrigerant vapor and transfers it to the water running through it. Having the refrigerant vapor condensed on the outside of a tube does this. In doing so, the vapor condenses and gives up heat to the water running inside the tube.

What is the purpose of a Cooling Tower?

A water cooling tower is used to cool water and is a huge heat exchanger, expelling building heat into the atmosphere and returning colder water to...

How does a Cooling Tower work?

Air conditioning equipment and industrial processes can generate heat in the form of tons of hot water that needs to be cooled down. That’s where a...

Why is an Industrial Cooling Tower Needed?

An industrial cooling tower is a key component of many refrigeration systems and can be found in industries such as power plants, chemical processi...

What is the best material for a Cooling Tower?

Water-cooled systems are primarily made from three materials: Metal, fiberglass, and plastic. As you know, metal can rust and corrode, and whatever...

What are the advantages of using engineered plastic?

Engineered plastic cooling towers are designed to stand up to wear and tear. It doesn’t rust or chip—and it can weather harsh environmental conditi...

What is the connection between Cooling Tower systems and Legionnaires' Disease?

According to the Centers for Disease Control and Prevention (CDC), cooling towers can be a breeding ground for Legionella bacteria, the microbes th...

Is a cooling tower environmentally friendly?

With the increasing concerns about meeting green standards and improving ROI on capital equipment expenditures, there are some standards to conside...

How can Cooling Tower systems help businesses save money?

Think of it this way: Cooling tower systems are essential to many businesses, which means looking for efficiencies in operations and products can h...

Cooling Tower Basics: What are common cooling system terms?

The approach is the difference between the temperature of the cold water leaving the tower and the wet-bulb temperature of the air. The establishme...

What is a cooling tower?

Cooling towers systems are often vital to industrial processes. These tall, open-topped, cylindrical structures are responsible for cooling water generated from industrial or HVAC comfort cooling airflow. They are classified by the type of draft (natural or mechanical) and by the direction of airflow (counter or cross).

How does a cooling tower work?

A cooling tower is used to cool water and is a huge heat exchanger, expelling building heat into the atmosphere and returning colder water to the chiller. A cooling tower receives warm water from a chiller. This warm water is known as condenser water because it gets heat in the condenser of the chiller. The chiller is typically at ...

Why is water called condenser water?

This warm water is known as condenser water because it gets heat in the condenser of the chiller. The chiller is typically at a lower level, like in a basement. The cooling tower’s role is to cool down the water, so it can return to the chiller to pick up more heat.

What is an industrial cooling tower?

Industrial cooling towers can be larger than HVAC systems and are used to remove heat absorbed in the circulating cooling water systems used in power plants, petroleum refineries, petrochemical plants, natural gas processing plants, food processing plants, and other industrial facilities.

What is the purpose of a fan on top of a cooling tower?

The purpose of the fan on top of the cooling tower is to bring in air from the bottom of the tower and move it up and out in the opposite direction of the warm condenser water of the top of the unit. The air will carry the heat through evaporating water of the cooling tower into the atmosphere.

Why do cooling towers have fans?

When the warm condenser goes into the cooling tower, the water is passed through some nozzles which is sprayed into small droplets across the fill, which increases the surface area of water and allows for better heat loss thru greater evaporation. The purpose of the fan on top of the cooling tower is to bring in air from the bottom ...

How does heat leave a cooling tower?

Heat leaves the recirculating cool ing tower water through evaporation. The colder water then reenters the air conditioning equipment or process to cool that equipment down, and the cooling cycle repeats over and over again. When the warm condenser goes into the cooling tower, the water is passed through some nozzles which is sprayed ...

Why do cooling towers work?

A cooling tower is a specialized heat exchanger in which air and water are brought into direct contact with each other in order to reduce the water’s temperature. As this occurs, a small volume of water is evaporated, reducing the temperature of the water being circulated through the tower.

How does water get into a cooling tower?

Water, which has been heated by an industrial process or in an air-conditioning condenser, is pumped to the cooling tower through pipes. The water sprays through nozzles onto banks of material called “fill,” which slows the flow of water through the cooling tower, and exposes as much water surface area as possible for maximum air-water contact. ...

What is a FAP tower?

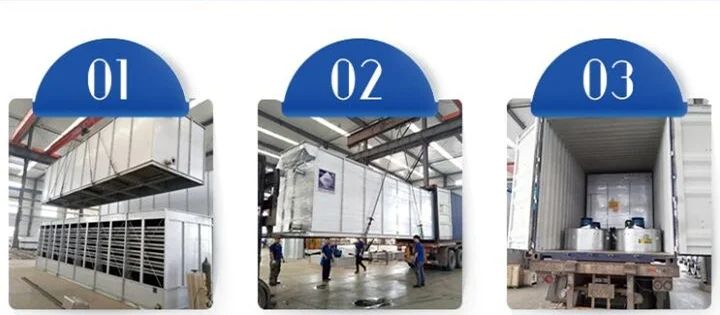

Factory-assembled towers (FAP) are built and shipped in as few sections as the mode of transportation will permit. A relatively small tower will ship essentially intact. A larger, multi-cell cooling tower is manufactured as modules at the factory, and shipped ready for final assembly. Factory-assembled towers are also known as “packaged” or “FAP” (factory-assembled product). Factory-assembled cooling towers can be crossflow or counterflow, induced draft or forced draft, depending on the application. While all applications are different, the factory-assembled Marley NC crossflow, induced draft tower is widely used for HVAC and light industrial applications.

What is variable flow in cooling towers?

Variable Flow – There may be significant energy savings opportunities if the cooling tower can be operated under variable flow in off-peak conditions. Variable flow is a way to maximize the effectiveness of the installed tower capacity for whatever flow the process has. Learn more about SPX Variable Flow.

What is free cooling?

HVAC Free Cooling – A free cooling system allows the tower to directly satisfy a building’s cooling needs without the need of operating the chiller in cold weather. The goal of a free cooling system is to save energy. There are specific types of free cooling systems and certain elements that must be in place for a free cooling system to be considered. Click here to learn more about SPX Free Cooling.

What is a counterflow tower?

Counterflow towers are designed so that air flows vertically upward, counter to the flow of falling water in the fill.

How does water flow in a crossflow tower?

In crossflow towers the water flows vertically through the fill while the air flows horizontally, across the flow of the falling water.

How does a cooling tower work?

Industrial cooling towers can be used to remove heat from various sources such as machinery or heated process material. The primary use of large, industrial cooling towers is to remove the heat absorbed in the circulating cooling water systems used in power plants, petroleum refineries, petrochemical plants, natural gas processing plants, food processing plants, semi-conductor plants, and for other industrial facilities such as in condensers of distillation columns, for cooling liquid in crystallization, etc. The circulation rate of cooling water in a typical 700 MW coal-fired power plant with a cooling tower amounts to about 71,600 cubic metres an hour (315,000 US gallons per minute) and the circulating water requires a supply water make-up rate of perhaps 5 percent (i.e., 3,600 cubic metres an hour, equivalent to one cubic metre every second).

How tall is a wet cooling tower?

Forced draft wet cooling towers (height: 34 meters) and natural draft wet cooling tower (height: 122 meters) in Westfalen, Germany. A cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a coolant stream, usually a water stream to a lower temperature.

Why use biocides in cooling towers?

Another very important reason for using biocides in cooling towers is to prevent the growth of Legionella, including species that cause legionellosis or Legionnaires' disease, most notably L. pneumophila, or Mycobacterium avium. The various Legionella species are the cause of Legionnaires' disease in humans and transmission is via exposure to aerosols —the inhalation of mist droplets containing the bacteria. Common sources of Legionella include cooling towers used in open recirculating evaporative cooling water systems, domestic hot water systems, fountains, and similar disseminators that tap into a public water supply. Natural sources include freshwater ponds and creeks.

What is a 1902 engraving of a self cooling tower?

A 1902 engraving of "Barnard's fanless self-cooling tower", an early large evaporative cooling tower that relied on natural draft and open sides rather than a fan; water to be cooled was sprayed from the top onto the radial pattern of vertical wire-mesh mats.

What is crossflow in cooling towers?

Crossflow is a design in which the airflow is directed perpendicular to the water flow (see diagram at left). Airflow enters one or more vertical faces of the cooling tower to meet the fill material. Water flows (perpendicular to the air) through the fill by gravity. The air continues through the fill and thus past the water flow into an open plenum volume. Lastly, a fan forces the air out into the atmosphere.

How does a counterflow work?

In a counterflow design, the air flow is directly opposite to the water flow (see diagram at left). Air flow first enters an open area beneath the fill media, and is then drawn up vertically. The water is sprayed through pressurized nozzles near the top of the tower, and then flows downward through the fill, opposite to the air flow.

Why are liquid cooled chillers more efficient than air cooled chillers?

Liquid-cooled chillers are normally more energy efficient than air-cooled chillers due to heat rejection to tower water at or near wet-bulb temperatures. Air-cooled chillers must reject heat at the higher dry-bulb temperature, and thus have a lower average reverse- Carnot cycle effectiveness.

How to measure cooling tower height?

Height - On cooling towers erected over a concrete basin, height is measured from the elevation of the basin curb. "Nominal" heights are usually measured to the fan deck elevation, not including the height of the fan cylinder. Heights for towers on which a wood, steel, or plastic basin is included within the manufacturer's scope of supply, are generally measured from the lowermost point of the basin, and are usually the overall height of the tower.

What is interference in cooling towers?

Interference - The thermal contamination of a tower's inlet air by an external heat source. (i.e. the discharge plume of another cooling tower.)

What is a fan deck?

Fan Deck - Surface enclosing the MIDDLE structure of an induced-draft cooling tower, exclusive of the distribution basins on a crossflow tower.

What is double flow cooling?

Double-Flow - A crossflow cooling tower where two opposed fill banks are served by a common air plenum.

What is a flume in a cooling tower?

Flumes are sometimes used in cooling towers for primary supply of water to various sections of the distribution system. Fogging - A reference to the visibility and path of the effluent air stream after having exited the cooling tower. If visible and close to the ground it is referred to as "fog".

What is evaluation in cooling?

Evaluation - A determination of the total cost of owning a cooling tower for a specific period of time. Includes first cost of tower and attendant devices, cost of operation, cost of maintenance and/or repair, cost of land use, cost of financing, etc., all normalized to a specific point in time.

What is casing in construction?

Casing - Exterior enclosing wall of a tower exclusive of the louvers.

What is a cooling tower?

Cooling towers might be one of the most crucial parts of any industrial or HVAC process. These tall open-topped, water cooling structures are responsible for cooling equipment vital for industrial or HVAC comfort cooling processes. And, you may be surprised to learn that there is much more to these cooling towers than you ever knew.

How does a dry cooling tower work?

Dry cooling towers. These work by using an electric motor that transfers heat that separates the fluid from the air. These towers use no water in their operations.

What are the different types of cooling towers?

Cooling towers can differ by build as well as heat transfer and air generation methods. When it comes to cooling tower build, there is the: 1 Package type. These are small, compact, and pre-fabricated cooling towers used for smaller industries, such as hospitals or schools. These are factory fabricated and ship on trucks 2 Field erection type. These are large, specified units used for power plants and other larger industrial factories. These are fabricated on-site and are larger than a typical house.

How to calculate cooling tower efficiency?

The cooling tower efficiency formula reads as: μ = (ti - to) 100 / (ti - twb), which may be tough to understand by just looking at it. Fundamentally, a cooling tower’s efficiency is measured in terms of approach and range. When the topic of efficiency is discussed, it usually has to do with the type of airflow used within the unit, not its heat transfer method or size.

How long is Delta cooling tower warranty?

Delta, the technology-leading cooling tower supplier and cooling tower manufacturer in USA, rises above the standards of other manufacturers to provide a 20-year warranty, so you do not have to worry about periodic replacements.

What is an open circuit cooling tower?

Wet cooling towers (open circuit). These tend to be one of the most popular styles because they are cost-effective and will achieve the most possible cooling. Heat transfer is measured via a decrease within the process temperature and the wet bulb temperature and how cold water temperature becomes.

How many types of mechanical draft cooling towers are there?

There are two types of mechanical draft cooling towers. Read on to learn more:

Overview

Maintenance

Clean visible dirt & debris from the cold water basin and surfaces with any visible biofilm (i.e., slime).

Disinfectant and other chemical levels in cooling towers and hot tubs should be continuously maintained and regularly monitored.

Regular checks of water quality (specifically the aerobic bacteria levels) using

History

Cooling towers originated in the 19th century through the development of condensers for use with the steam engine. Condensers use relatively cool water, via various means, to condense the steam coming out of the cylinders or turbines. This reduces the back pressure, which in turn reduces the steam consumption, and thus the fuel consumption, while at the same time increasin…

Classification by use

An HVAC (heating, ventilating, and air conditioning) cooling tower is used to dispose of ("reject") unwanted heat from a chiller. Liquid-cooled chillers are normally more energy efficient than air-cooled chillers due to heat rejection to tower water at or near wet-bulb temperatures. Air-cooled chillers must reject heat at the higher dry-bulb temperature, and thus have a lower average reverse-Carnot …

Classification by build

These types of cooling towers are factory preassembled, and can be simply transported on trucks, as they are compact machines. The capacity of package type towers is limited and, for that reason, they are usually preferred by facilities with low heat rejection requirements such as food processing plants, textile plants, some chemical processing plants, or buildings like hospitals, hotels, m…

Heat transfer methods

With respect to the heat transfer mechanism employed, the main types are:

• wet cooling towers or evaporative cooling towers operate on the principle of evaporative cooling. The working coolant (usually water) is the evaporated fluid, and is exposed to the elements.

• closed circuit cooling towers (also called fluid coolers) pass the working coolant through a large heat exchanger, usually a radiator, upon which clean water is sprayed and a fan-induced draft applied…

Air flow generation methods

With respect to drawing air through the tower, there are three types of cooling towers:

• Natural draft — Utilizes buoyancy via a tall chimney. Warm, moist air naturally rises due to the density differential compared to the dry, cooler outside air. Warm moist air is less dense than drier air at the same pressure. This moist a…

Categorization by air-to-water flow

Typically lower initial and long-term cost, mostly due to pump requirements.

Crossflow is a design in which the airflow is directed perpendicular to the water flow (see diagram at left). Airflow enters one or more vertical faces of the cooling tower to meet the fill material. Water flows (perpendicular to the air) through the fill by gravity. The air continues through the fill and thus past the water flow into an open plenum volume. Lastly, a fan forces the air out into th…