What is a shackle and how is it used?

A shackle is a u-shaped, load-bearing connecting device designed to be used with a removable pin. Shackles can be used in a number of different rigging and load securement applications to connect different types of lifting slings, chain, or rope to an object or to each other. Shackles can be used in a variety of different applications, including:

What are the best shackles for lifting?

Safety shackles are well suited for almost any lifting application; however, they are not as easy to remove as screw pin or round pin shackles. Bolt type shackles are available in DNV Type Certified versions which are perfect for offshore, saltwater and more broad marine applications.

Can a D shackle be side loaded?

This bow design gives D shackles the ability to carry extremely heavy loads in an in-line position. Unlike anchor and bow shackles, chain and D shackles should never be side loaded, as they are designed and rated for in-line tension only.

What are heavy duty rigging shackles used for?

Heavy duty rigging shackles are used every day in the material handling industry to connect lifting slings, wire rope, chain, and fiber rope either to a load or to each other. Shackles are extremely versatile and come in a variety of designs and constructions, as well as a variety of different materials.

What are D shackles used for?

D shackles are used every day – across a variety of different industries – for lifting, rigging, and connecting ropes and chains. They're a common piece of industrial equipment.

What are the 2 types of shackles?

“D” (chain) shackles are generally used to join two pieces rated for in-line tension, while bow (anchor) shackles are typically employed where more than one attachment has to be made to the body, for side and racking loads may twist or bend the chain shackle.

What type of shackle is used for overhead lifting?

For overhead lifting use shackles with pins made from alloy and the shackle body from forged carbon steel that has been heat-treated. For industrial lifting applications, along with tie-down and towing, these forged shackles are superior.

Is shackle a lifting gear?

Shackles can be used in lifting and static systems as a removable link to connect wire rope, chain and slings. The differing types of shackles are best used for different applications.

How do I select D shackle?

0:542:00Choosing the right shackle - YouTubeYouTubeStart of suggested clipEnd of suggested clipThen you need to make sure that the shackle that you use is going to fit either. One or both sidesMoreThen you need to make sure that the shackle that you use is going to fit either. One or both sides of the sling. Onto the shackle. A bow shackle is usually best for using in this application.

How many types of lifting shackles are there?

twoThere are two main shapes / styles of lifting shackle and they are “D” Shackles (or Dee Shackle) and bow shackles otherwise known as Omega shackles.

What are the 3 types of shackles?

What Are the Different Types of Shackles?Bow – the curved portion of the shackle body opposite the pin—often referred to as the bail, body, dee, or bowl.Ears – portion of the shackle body that support the shackle pin.Pin – a steel bolt made to span the two shackle ears.More items...•

How do you calculate D shackle capacity?

The rated capacity should be imprinted on the shackle and be visible. Shackles are sized according to the diameter of the bow section rather than the pin size. Never use a shackle if the distance between the eyes is greater than listed in the manufacturer's tables.

What is Dee shackle?

The Green Pin® Dee Shackle SC is a dee shackle with a screw collar pin. The screw pin enables quick (dis)assembly which makes the shackle perfect for rigging activities in which assembly and disassembly occur relatively frequently. Due to the galvanization of the shackle its long-term durability is assured.

What is a shackle look like?

A shackle, also known as a gyve, is a U-shaped piece of metal secured with a clevis pin or bolt across the opening, or a hinged metal loop secured with a quick-release locking pin mechanism.

What is a shackle rigging?

0:144:15Beginner's Guide to Rigging Shackles - Types, Coatings, and MaterialsYouTubeStart of suggested clipEnd of suggested clipAnd then you have to be able to connect that turnbuckle to the eye bolt a shackle is going to beMoreAnd then you have to be able to connect that turnbuckle to the eye bolt a shackle is going to be that component in between the two that's going to connect them together.

Do D shackles need to be tagged?

Shackle pins in all general use situations should be hand tightened to ensure the shackle pin is securely seated to the shackle eye. Shackles do not require tagging and are not required to be on a lifting equipment register. It is good practice to record the date of purchase, make of shackle, and batch number.

What are the different types of shackles?

The terms anchor shackles and bow shackles are both used interchangeably and refer to a type of shackle with a larger, round “O” shaped bow. A larger bow shape allows these types of shackles to be side loaded or used in multiple sling-leg connections.

What does 3 shackles in the water mean?

Anchor dragging: The anchor is said to be dragging when it is not held seabed. Brought up to three in water / four on deck: When the anchor is dropped and third joining shackle is in water and fourth joining shackle is on windlass (deck).

What is a 4 part shackle?

A shackle is made up of 4 general components The Bow | Shoulder | Pin | Ear. There are several body types available when choosing a shackle, today we will discuss Anchor shackles and Wide Body Sling Shackles as well as the two most popular pin styles, Screw Pin and Bolt Type.

What is a shackle?

Definition of shackle (Entry 1 of 2) 1 : something (such as a manacle or fetter) that confines the legs or arms. 2 : something that checks or prevents free action as if by fetters —usually used in plural. 3 : a usually U-shaped fastening device secured by a bolt or pin through holes in the end of the two arms.

What are shackles used for?

1. Overview Shackles have been widely used in the lifting industry for decades. However, despite (or perhaps because of) the apparent simplicity and extensive use of these components, incorrect and poor specification remains a problem. Indeed it is one of the ironies of the lifting industry that it is not uncommon to see the safety of an operation involving thousands of pounds-worth of crane being compromised by an inappropriate shackle costing next to nothing in comparison. Although there has been development of high performance shackles such as ROV for underwater off-shore use and Polar shackles for extreme temperatures. Our aim with this guide is to provide information on standard shackles for general lifting applications

What are the different types of shackles?

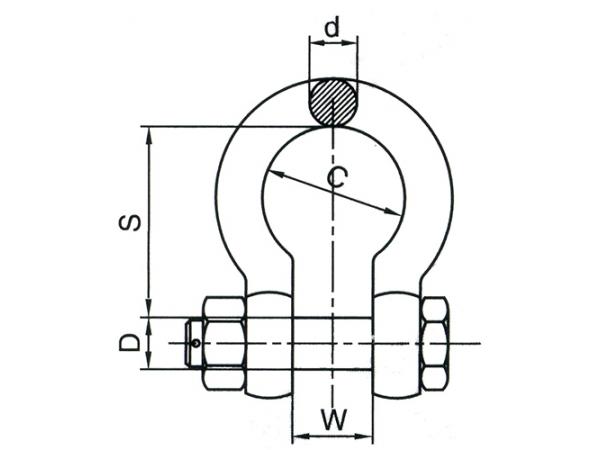

As far as shackles are concerned, there are three main types for the buyer to choose from: Bow (or anchor) shackles, Dee (or chain) shackles and Grab shackles with countersunk pin All comprise a ‘U’ shaped body and a pin and they are sized by the diameter of the material in the body, not the pin which has a larger diameter (Not to be confused with ‘Commercial’ mild steel shackles, where the body and pin have the same diameter and are not certified for lifting purposes). Back to Contents page

What are the three main decisions to be made when determining the correct specification of a shackle?

In terms of correct specification of shackles, there are three main decisions to be made: the SWL, the shape, and the pin type. The working load limit must be at least equal to the total load imposed upon the shackle. If the load on the pin is distributed over its length, or part of its length, the load bearing capacity of the pin is effectively increased but that of the body is not. It should be stressed that distributing the load right across the pin does not increase the strength of the shackle .

What is a grab shackle?

The grab shackle is effectively a Dee shackle with a screwed countersunk pin. As the name suggests, it is designed for use with grabs, where the shackle must pass through a circular aperture of minimum diameter.

What is the right body shape for a shackle?

Selection of the right body shape depends on the intended use. It is desirable to use a shackle with as small a jaw opening as is consistent with adequate articulation of the connection.

When did 6994 steel shackles come out?

In theory, the metric British Standard BS 6994 (steel shackles for lifting and general engineering purposes – Grade M (4)) should have been available since 1988 . In practice very few shackles have ever been made to this standard and its imperial predecessor, BS 3032 (higher tensile steel shackles) is still much more widely specified in the UK. Both standards have now been withdrawn by BSI although shackles to BS 3032 are still manufactured and the only current British Standard is BS 3551 (alloy steel shackles).

What is the standard for Crosby shackles?

US Federal Specifications, in the shape of RR-C-271, are increasingly popular and there is also a harmonised European Standard for grade 6 shackles, prEN 13889, Crosby shackles meet this standard.

What is a shackle?

A shackle is a u-shaped, load-bearing connecting device designed to be used with a removable pin. Shackles can be used in a number of different rigging and load securement applications to connect different types of lifting slings, chain, or rope to an object or to each other.

What Are the Different Types of Shackles?

Before we begin, let’s identify the different parts of a shackle so when we use terms like “bow,” “ears,” “pin,” or “shoulder,” you’re familiar with what we’re referring to:

What is a bolt type shackle?

Bolt type shackles can be used in any application that uses a round pin or a screw pin. These types of shackles remain secure even when the shackle is subjected to rotation or torque. Bolt type shackles are practical in many rigging applications where the anchor bolt is expected to experience some rotation. The tightening nut and the cotter pin ...

What is a screw pin shackle?

Screw pin shackles are quick and easy to connect and disconnect so they’re convenient for rigging that is used for “pick and place” applications or when slings and other hardware are often changed out. Screw pin shackles are not recommended for permanent or long-term installations.

Why is the bow of the shackle widened?

On a synthetic sling shackle, the bow of the shackle is widened to increase synthetic web sling or synthetic roundsling efficiency. This design allows for 100% of the sling’s WLL to be achieved by preventing the slings from pinching or bunching, which can damage the slings or reduce their rated capacity.

What is the part of the shackle that supports the shackle pin?

Ears – portion of the shackle body that support the shackle pin. Pin – a steel bolt made to span the two shackle ears. Shoulder – the part of the pin that makes contact against the ear when the pin is fully threaded or engaged.

What is an anchor shackle?

The terms anchor shackles and bow shackles are both used interchangeably and refer to a type of shackle with a larger, round “O” shaped bow. A larger bow shape allows these types of shackles to be side loaded or used in multiple sling-leg connections.

What is a chain shackle?

Chain Shackles. Chain shackles are best-suited for straight line, single connection pulls because of their U-shape. Anchor or bow shackles have a more generous loop. This allows them to be side loaded or used for multiple connections.

Which type of shackle is the most secure?

Of all shackle types, bolt, nut, and cotter shackles provide the most secure pin arrangement, resisting axial and torsional loading. This type of shackle should be used in semi-permanent applications where the pin is removed infrequently. Bolt, nut, and cotter shackles are suitable for overhead lifting.

How many types of pins are there for a chain shackle?

Whether you use chain or anchor shackles, there are three types of pins that are used to secure a shackle, each with their own benefits and limitations.

Can round pin shackles be used for overhead lifting?

They are not recommended for use where the pin is subject to an axial load. Round pin shackles are not suitable for overhead lifting.

What is the proper application of shackles?

The proper application of shackles requires that the correct type and size of shackle be used. The shackle’s working load limit, its size, a traceability code and the manufacturer’s name should be clearly and boldly marked in the bow. Traceability of the material chemistry and properties is essential for total confidence in the product. Material chemistry should be independently verified prior to manufacturing. G-209G-2130

What is round pin shackle?

Round Pin Shackles can be used in tie down, towing, suspension or lifting applications where the load is strictly applied in-line. Round pin shackles should never be used in rigging applications to gather multiple sling legs, or where side loading conditions may occur.

What is a G-215 chain shackle?

G-215 Round pin chain shackles meet the performance requirements of Federal Specification RR-C-271G Type IVB, Grade A, Class 1, except for those provisions required of the contractor. For additional information, see page 476.

What is a G-213 round pin anchor?

G-213 Round pin anchor shackles meet the performance requirements of Federal Specification RR-C-271G, Type IVA, Grade A, Class 1 , except for those provisions required of the contractor. For additional information, see page 452.

What is the theoretical reserve capability of carbon shackles?

The theoretical reserve capability of carbon shackles should be as a minimum 5 to 1 , and alloy shackles a minimum of 5 to 1*. Known as the DESIGN FACTOR, it is usually computed by dividing the catalog ultimate load by the working load limit. The ultimate load is the average load or force at which the product fails or no longer supports the load. The working load limit is the maximum mass or force which the product is authorized to support in general service. The design factor is generally expressed as a ratio such as 5 to 1. Also important to the design of shackles is the selection of proper steel to support fatigue, ductility and impact properties.

Do you need a cotter pin for Crosby shackles?

No cotter pin or tools required Both shackle and pin Wide opening ergonomic are RFID equipped grip provides easy access for all hand sizes 316 stainless steel design resists corrosion The new Easy-Loc V2TMcan be retrofited on all original Crosby Easy-Loc® Shackles

Can Crosby shackles be point to point?

It has been determined that all Crosby® shackles can be point-to-point loaded to the Working Load Limit without bending of the pin/bolt. This loading can be bow-to-bow, bow-to-pin, or pin-to-pin (if there is not interference between the diameter of the shackle ears). However, caution should be given to maintain the load at the center of the span by spacers so the load will not slide over to one side, and overload that ear. See “Off Center Loading Of Crosby® Screw Pin & Bolt Type Shackles – 3/16” to 3” Sizes”

How can the strength of a shackle be affected?

The strength of a shackle can be affected by exposure to caustic or acidic environments. If your shackles have been exposed to or will be used in a chemically-active environment, you should consult the manufacturer or a Qualified Person.

What happens if a shackle is side loaded?

If the shackle is side loaded, the rated load shall be reduced according to the manufacturer or a Qualified Person

How Often Do You Need to Inspect Your Shackles?

Similar to the inspection of slings, or to the inspection of hooks, all shackles need to be inspected on a regular basis. Below, we will address the three types of ASME shackle inspections that will occur throughout the service life of a shackle:

What is rigging training?

Professional rigging training provides your team with the knowledge needed to inspect their rigging equipment before each shift / each lift and to identify damage and irregularities that may require an item to come out of service.

What temperature should shackles be used?

Extreme Temperatures. Avoid using shackles in temperatures in excess of 400°F (204°C) and below –40°F (–40°C). If shackles are to be used in temperatures above or below these ranges, the manufacturer and/or a Qualified Person should be consulted.

When using a shackle with multiple sling legs, should the sling legs rest against the?

When using a shackle with multiple sling legs, the sling legs should rest against the body of the shackle, not the pin. If multiple sling legs are present in the body, they should not exceed 120° in angle. The angle of loading affects the stress in the shackle, so as the horizontal angle decreases, the stress increases in the shackle—see below:

Who inspects a shackle?

A complete inspection of the shackle shall be performed by a Designated Person. During an ASME shackle inspection, the shackle shall be examined for conditions listed under Removal Criteria and a determination made as to whether they constitute a hazard.

What is a bow shackle?

The terms anchor shackles and bow shackles are both used interchangeably, feature a large rounded shape that increased area on the inside of the shackle body and allows them to take loads from many directions without developing significant side load. That makes them ideal for use with multiple-leg slings, connecting slings to load rings, and accommodating a wider strap.

What is a shackle in rope?

A shackle is a jaw or u shaped connecting link, which is designed to connect the lifting slings, wire rope, chain, and rope for a variety of rigging, lifting, pulling, and hoisting applications. The removable pin design is perfect for temporary lifting jobs or quick connect and disconnect.